Efficiency Of Electric Motor – An electric motor is a mechanical machine that converts electrical energy. Most electric motors work by generating force in the form of torque imparted to the motor’s shaft by interacting between the magnetic field of the motor and the electric current in a wire winding. Electric motors can be powered by either direct current (DC) or alternating current (AC) sources, such as batteries or rectifiers, or by alternating current sources, such as electrical generators, the power grid, or inverters. An electric generator is mechanically comparable to an electric motor, but it converts mechanical energy into electrical energy through a reversed flow of power.

Even though there were lots of opportunities for improvement, the first industrial electric motor was certainly regarded as a breakthrough in its day. Motor makers have improved their motors to consume less energy and cost less as technology has grown. While it’s only natural for manufacturers to use the most up-to-date technology when designing electric motors, the potential for future breakthroughs in manufacturing procedures has been critical in increasing the efficiency of these motors.

This article also includes an Efficiency of Electric Motor PDF about determining an electric motor efficiency and load. Furthermore, you can also visit the Linquip site for viewing top manufacturers and experts in the field of electric motors.

Basics and Classification of Electric Motors

Considerations such as internal construction, power source type, application, and type of motion output are used to classify electric motors. Aside from AC versus DC, motors can be brushed or brushless, have different phases (single-phase, two-phase, or three-phase), and be air-cooled or liquid-cooled. For industrial applications, general-purpose motors with conventional dimensions and features provide convenient mechanical power. The largest electric motors, with ratings of up to 100 megawatts, are utilized for ship propulsion, pipeline compression, and pumped-storage applications. Industrial fans, blowers, and pumps, as well as machine tools, household appliances, power tools, and disk drives, all use electric motors. In electric timepieces, little motors can be found. Electric motors can be utilized in reverse as generators in some applications, such as regenerative braking with traction motors, to recover energy that would otherwise be wasted as heat and friction.

Electric motors generate torque (linear or rotary force) that is used to push an external mechanism such as a fan or an elevator. Electric motors are often built for continuous rotation or linear movement over a large distance, given their size. Magnetic solenoids are likewise transducers that transfer electrical power to mechanical motion, but they have a restricted range of motion.

Electric motors are far more efficient than the internal combustion engine (ICE), which is utilized in industry and transportation. Electric motors are normally over 95% efficient, while ICEs are considerably below 50%. They are also lighter, physically smaller, mechanically simpler, and less expensive to construct, capable of providing instant and consistent torque at any speed, run on renewable energy, and do not emit carbon into the atmosphere. Electric motors are replacing internal combustion engines in transportation and industry for these reasons, while their usage in vehicles is currently limited due to the high cost and weight of batteries with an appropriate range between charges.

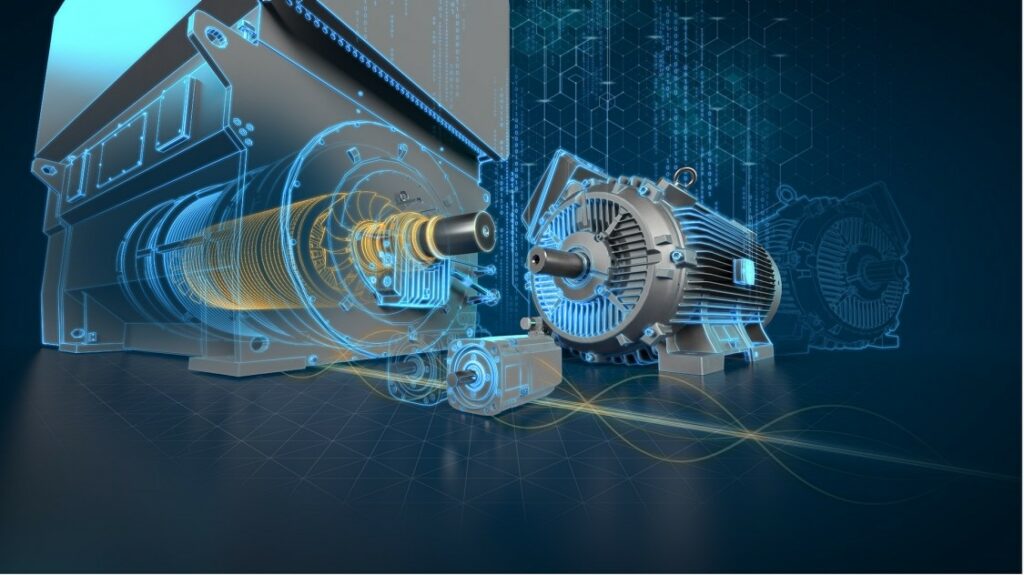

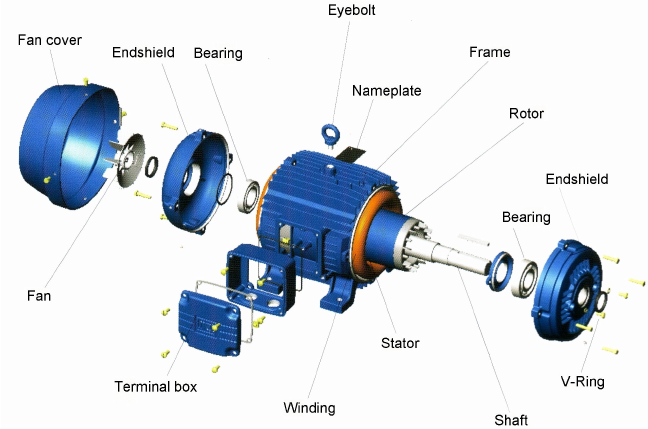

Components of Electric Motors

A motor is made up of two electrical components that move in relation to each other and generate a magnetic circuit when combined. One of these components is positioned on the stator, which is the motor’s stationary element attached to the frame, while the other is mounted on the rotor, which rotates. In most motors, the field magnet is on the stator, and the armature is on the rotor, however, this is not always the case.

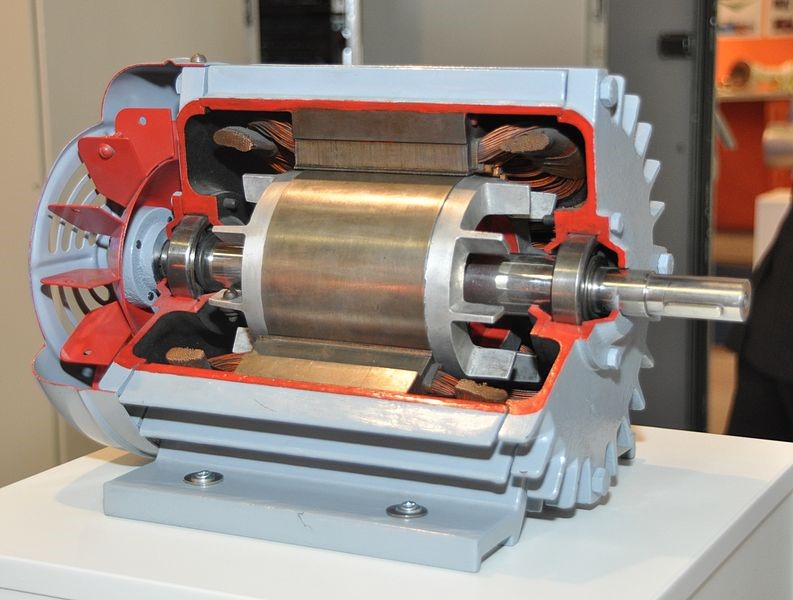

Rotor

The rotor, which turns the shaft to deliver mechanical power, is the moving part of an electric motor. The rotor normally has current-carrying conductors that the magnetic field of the stator puts force on in order to turn the shaft. Alternatively, some rotors contain permanent magnets, with the conductors held by the stator.

Bearings

Bearings support the rotor and enable it to rotate around its axis. The motor housing, in turn, supports the bearings. The motor shaft extends from the inside of the motor to the outside, where the load is applied, through the bearings. The load is said to be overhung when the load’s forces are exerted beyond the outermost bearing.

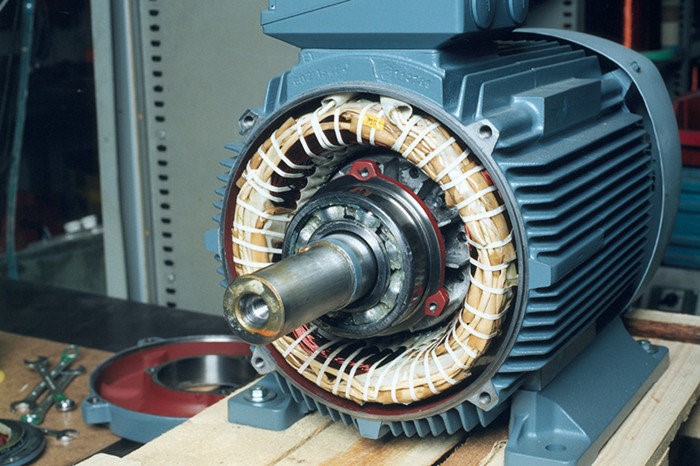

Windings

When powered with current, windings are wires that are laid in coils and wrapped around a laminated soft iron magnetic core to generate magnetic poles.

Salient- and nonsalient-pole configurations are the two most common magnetic pole configurations in electric devices. The ferromagnetic cores of the rotor and stator have projections called poles facing each other, with a wire looping around each pole below the pole face, which become the magnetic field’s north and south poles when current passes through the wire. The ferromagnetic core of a nonsalient-pole, distributed field, or round-rotor machine does not have protruding poles and is instead a smooth cylinder with the windings equally dispersed in slots around the circumference. A shaded-pole motor features a winding around a portion of the pole that delays the phase of the magnetic field for that pole. The alternating current in the windings forms poles in the core that cycle constantly.

Stator

The field magnets, which are either electromagnets made of wire windings around a ferromagnetic iron core or permanent magnets, make up the stator, which is the stationary element of the motor’s electromagnetic circuit enclosing the rotor. It generates a magnetic field that flows through the rotor armature and acts on the windings. The stator core is made up of laminations, which are thin metal sheets that are isolated from one another. Laminations are employed to mitigate energy losses that would occur with a solid core. The damping qualities of resin (plastic) are exploited in resin-packed motors, which are used in washing machines and air conditioners to reduce noise and vibration. The stator is fully encased in plastic in these motors.

Commutator

In some motors, a commutator is a rotary electrical switch that sends electricity to the rotor. The revolving armature of the machine consists of a cylinder made up of several metal contact segments. Two or more “brushes” consisting of a soft conductive substance like carbon press against the commutator, sliding contact with consecutive segments of the commutator as it rotates, giving current to the rotor. The commutator segments are connected to the rotor windings.

With each half turn (180°), the commutator changes the current direction in the rotor windings, ensuring that the magnetic field of the stator exerts the same torque on the rotor. The direction of torque on each rotor winding would reverse with each half turn if the current was not reversed, and the rotor would stop. Brushless direct current motors, permanent magnet motors, and induction motors have mostly replaced commutated motors due to their inefficiency.

The Good Guide to Types of Electric Motors

Efficiency of Electric Motor

The mechanical output power is divided by the electrical input power to determine a motor’s efficiency:

\eta=\frac{P_m}{P_e}

In which \eta is the efficiency of electric motor, P_m and P_e are mechanical output power and input electrical power, respectively, which can be determined by the following equations:

P_e=IV

P_m=T\omega

Where V and I are the input and output voltages, T is the output torque, and \omega is the angular velocity of the output.

Many countries’ regulatory agencies have introduced and implemented regulations to encourage the development and use of higher-efficiency electric motors. Electric motor efficiencies range from at least 15% for shaded pole motors to as high as 98 percent for permanent magnet motors, depending on the load. Typically, peak efficiency occurs at 75% of the rated motor load. As an example, a 10-horsepower motor is most efficient while driving a 7.5 horsepower load. The efficiency of a motor is also affected by its size; larger motors are more efficient. Some motors can’t run continuously for longer than a certain amount of time (e.g. for more than an hour per run).

However, some losses adversely affect the efficiency of electric motors, which are stated in what follows.

Primary and Secondary Resistance Losses

Copper losses are the electrical power lost in the primary rotor and secondary stator winding resistance. Copper loss is proportional to the current squared and fluctuates with the load. It can be represented as,

P_{cl}=R I^2

Where P_{cl} , R , and I are copper loss, resistance, and current, respectively.

Iron Losses

When the motor’s magnetic field is supplied to the stator core, magnetic energy is dissipated, resulting in these losses.

Stray Losses

After primary copper and secondary losses, iron losses, and mechanical losses, stray losses are the losses that remain. Harmonic energies created when the motor is running at full speed account for the majority of stray losses. Currents in the copper winding, harmonic flux components in the iron sections, and leakage in the laminate core are all ways that these energies are dissipated.

Mechanical Losses

Friction in the motor bearings and the fan for air conditioning are examples of mechanical losses.

How Electric Motor Users Can Ensure Efficiency

As previously said, the efficiency of electric motors is determined by how they are used by manufacturers, industries, and homeowners. Users can take the following procedures to ensure motor efficiency and longevity:

Using Smart Motors in Combination with the Correct Motor Starter/Controller

While smart motors are extensively used and available, selecting the optimum match is critical for minimizing downtime, increasing efficiency, and lowering costs. Electrical consumption by motors can place a strain on a company’s operational budget, as industrial engineers are well aware. They commonly use motor control technologies to mitigate this, which use only the amount of energy required to start motors, expose diagnostic data, and save downtime. Motor starter technology is becoming more prominent as the motor starts to gain popularity.

Discontinue Using Motors When Not Needed

The most effective technique to save energy is to turn off the motor when it is not in use, which is as simple as it seems. Most people are hesitant to turn off a motor because they assume that starting it up repeatedly will cause significant wear and tear. Soft starts, which can lessen wear and tear, are one technique to mitigate this. A correctly installed and designed soft starter can help reduce mechanical and electrical system pressure.

Using High-efficiency Motors

The size of the motor and its efficiency quality are two elements that influence its efficiency. The size of a motor, especially for smaller motors, has a significant impact on its efficiency. The efficiency classifications are more important for larger motors.

Energy-efficient motors consume less energy, are less likely to overheat, and last longer. These motors are distinguished by their superior design, which leads to less heat loss and reduced noise. High-quality materials, better tolerances, and enhanced production procedures all contribute to lower losses and increased efficiency.

Reducing Wear and Tear

One of the main concerns of users is reducing motor wear and tear. When an electric motor is running, the high initial currents and stresses pressurize the mechanical and electrical systems, causing significant wear and tear. Although this can be harmful, the negative effects can be mitigated by using soft beginnings. VSDs can also be used, but they are more expensive and inefficient.

Buying the Right Motor Size

Between 60 and 100 percent of their full-rated load, motors are most efficient, while below 50 percent, they are inefficient. This means that simply purchasing the correct motor size can significantly improve efficiency.

Oversized motors typically operate at less than 50% of their rated load, which makes them not only inefficient but also more expensive than motors of the proper size. Furthermore, they may reduce the machine’s power supply, increasing the burden on the electrical system.

How Manufacturers Can Save Electricity with Electric Motors

The two determinants that can assist save electricity are how an electric motor is designed and how it is utilized. Let’s start with the design aspect.

Using Copper Windings in Stator Coils

When it comes to motor conductivity, copper coils are always preferable to outmoded aluminum coils. This is due to aluminum’s weaker conductivity than copper’s. Aluminum magnet wires may require larger cross-sections to keep up with copper coils and provide the same amount of conductivity. When compared to a copper wire motor of the same size, windings wound using aluminum wire may have more volume.

Using Copper Bars in the Rotor

Copper also has an efficiency advantage when it comes to rotors. Copper rotors are favored for energy-conscious companies in both industrialized and developing countries, where electricity is frequently scarce and expensive. In terms of motor quality, reliability, affordability, efficiency, and longevity, copper rotors are a better bet than aluminum rotors.

Using High-quality Steel for Rotors and Stators

High-tech electrical steel is required for the production of cost-effective stators and rotors for a variety of electric motor applications. For top-notch performance, this type of steel ensures strong magnetic permeability and minimum power losses. Power losses in electrical steel, on the other hand, are possible. When a magnetic field is alternated, eddy currents, also known as Foucault currents, emerge. Eddy currents are controlled, and current losses are reduced by rolling steel to a narrower gauge. This is especially true for frequencies higher than the normal 50 or 60 hertz.

Machining Moving Parts with Precision

Machining is the process of eliminating material from a compartmental unit and converting it to a more acceptable substance. To attain the maximum tolerance at the smallest measurable degree, precision machinery is required. Precision machinery can present the accuracy required to manufacture materials in the desired amounts, whether it’s for metal cutting or coal mining. For optimal productivity and efficiency, the moving machine parts will need to be maintained on a regular basis. Only experts should undertake maintenance, and all parts should be thoroughly inspected.

More Coils Make Motors More Efficient

The phase coils of modest power motors have smaller conductors. To improve the magnetomotive force or current density, the number of coil turns should be large. The phase winding resistance and power loss density are likewise higher in low-power motors than in high-power motors. As a result, high-speed, low-power motors will demand more magnetomotive force. This means that more coils will be required, as well as a greater number of turns on a thin wire with a higher current density.

You can also watch this nice video to know how to solve the efficiency of the motor.

FAQs of Efficiency of Electric Motor

What Is the Efficiency of Motor?

Efficiency is just the difference between output (useful) power and input power, with losses owing to design flaws and other inevitabilities accounting for the difference. For 1 to 4 hp motors, an efficiency of 0.80 is acceptable, while for 5-hp and higher motors, an efficiency of 0.90 is preferred.

What Electric Motor Has the Best Efficiency?

ABB recently set a new world record for the efficiency of electrical synchronous motors. On a 44 megawatt, 6-pole, synchronous motor, they achieved 99.05 percent full load efficiency during factory acceptance tests (FATs) with the client present.

What Does the Efficiency of a Motor Mean?

The ratio of mechanical power output to electrical power input is known as electric motor efficiency (electrical). Because energy is wasted in many forms during conversions (electrical to mechanical), such as heat and friction, mechanical power output is always lower than electrical power input.

What Is the Basic Principle of Electric Motor?

The electric motor operates on the principle of current magnetic effects. It works on the basis that when a rectangular coil is placed in a magnetic field and electricity is passed through it, the coil rotates due to the forces acting on it.

Can Electric Motors Be Made More Efficient?

Copper windings in the stator coils can make induction motors more energy efficient. In the rotor, copper bars are used. Precision machining of all moving parts is another method of increasing the efficiency of an electric motor.

Conclusion

With “energy efficiency” becoming a trendy buzzword, it’s critical that this notion be incorporated into an everyday household and industrial applications. Many advantages can be gained from using energy-efficient motors. They can operate cooler, give greater service standards, last longer, provide better insulation, and generate less noise and vibration with correct installation. Motor makers would be wise to guarantee that they are creating and deploying the most energy-efficient motors possible, given the numerous benefits.