Regulating and controlling fresh air in our home is an essential point of keeping good indoor air quality, which is applicable by Energy Recovery Ventilator systems. A desired ventilation system will keep people safe from harmful pollutants, such as radon, VOCs (Volatile Organic Compounds), and other toxins. It can also protect us from unpleasant odors. As a result, today, the need for an Energy Recovery Ventilator (ERV) system in our homes and offices is a very important and vital issue.

What is Energy Recovery Ventilator or What is ERV?

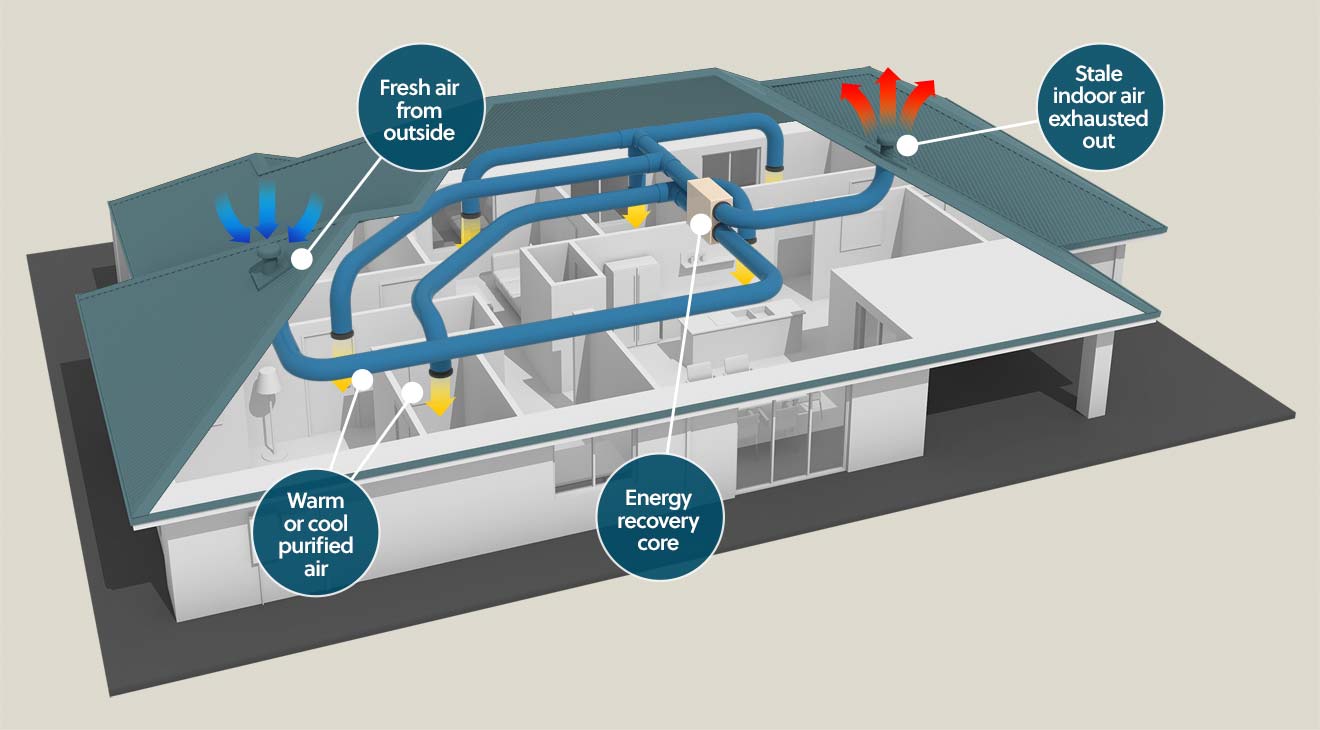

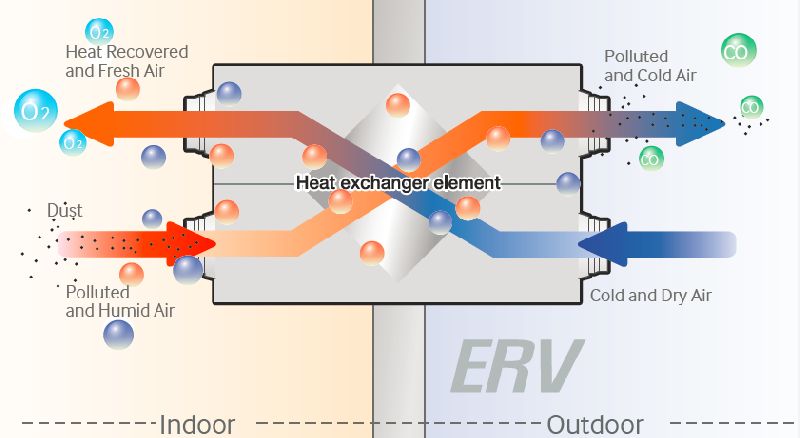

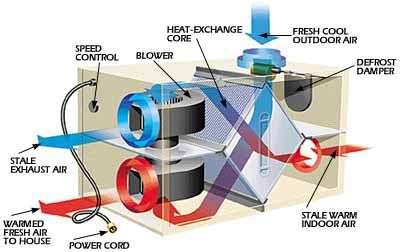

Homes and buildings are being made or restored to be closer than ever before to retain energy. Sealing slots and cracks in the building envelopment ceases the reciprocity of air with the outside, preserving energy and promoting solace. ERV stands for Energy Recovery Ventilator, with ordinary name variations containing ERV air exchangers and ERV ventilation systems. An ERV presents a method of transferring new, temperature-controlled air into the house while taking out musty, poisonous air. ERVs are systems designed to be joint to the channels that are sections of the HVAC (Heating, Ventilation, and Air Conditioning) system. Using two fans, ERVs pull neat and new air into a home or office and take stale air away. An ERV permits fresh air to a building while keeping preconditioned heating or cooling.

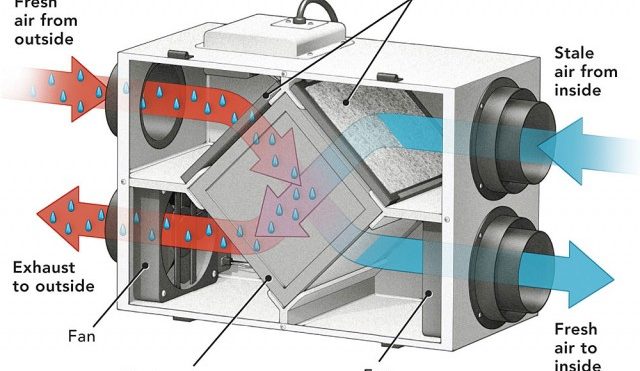

This kind of device also catches some of the moisture in the air to retain it on the identical side of the thermal cover that it came from. If the house is excessively dry in winter, an ERV would be the most effective option as it helps keep humidity, removing the need and cost to produce it within other means (for more information, click here). Along with this transition of airflows, ERV ventilation systems catch pollutants, allergens, pollen, contaminants, and more, ensuring that the air that arrives and is kept inside the home or office is healthy and clean.

3 Types of Energy Recovery Ventilator

There are two classes of ERVs based on their installation: One is independent of, and totally intercept from, the home’s compelled-air system, whereas the other, is integrated straightly into it.

According to their application, there are four different media-component options for them: rotational heat exchanger (wheel), a heat-pipe heat exchanger (refrigerant); plate heat exchanger (fixed core); and runaround coils (water).

Energy Recovery Ventilator’s internal parts

- A wheel is a plastic or metal implement that spins between the exhaust and outdoor air flows. It raises heat from one airflow and transmits it to the other. Wheels are the most admired ERV because of their comparatively low primary cost, the facility of maintenance, sensible pressure drop, and smaller physical footprint.

- Heat pipes are somewhat restricted because they cannot revive hidden energy. They are practical-only energy- restoration systems. Heat pipes are tubes from copper with refrigerant inside them. These tubes operate between the two airflows (outside and exhaust air). One airflow heats the refrigerant inside the tube, making it to vaporize. That refrigerant vapor then transfers down the pipe to the other airflow. When the other airflow chills the pipe, the refrigerant condenses, warming the cooler air stream in the procedure.

- Fixed-core plates normally are greater in size and more expensive than wheels but have no rotating sections and can be utilized in specified usages (such as hospitals) where a wheel may not be allowed. As an alternative of a wheel rotating between air flows to shifts energy, the air streams move by each other within a series of ducts, cooling down or heating up the substance among the channels and conveying energy. Fixed-core plates can be plastic, metal, or even paper.

- Runaround coils assign some homogeneous with heat tubes but often are selected when the exhaust and outdoor air streams are detached by large spaces. This kind of system needs installing a water coil in the external airflow and a second one in the entering outdoor/ventilation airflow. Like heat pipes, these systems only are able to move practical energy, not latent energy.

Energy Recovery Ventilator Advantages

The advantages of installing an ERV into the home or office are diversified, with some of the key benefits, including:

- Filtering and elimination of formaldehydes, allergens, and other toxins from the inside spaces, and supplying fresh air in a room by identifying CO2 with selective CO2 sensor

- Improving the action of breathing for people with asthma

- Decreasing association on air conditioning by a method named EconoCool

- Raising the quality and energy efficiency of the home or office

- Maintaining the temperatures from one room to the next more stable

- Using a silent system, features easy maintenance and upkeep

- Finding moisture rate of the room and regulates its humidity level automatically

- Prolonging the life period of the HVAC system

Energy Recovery Ventilator Installation

Installing an energy recovery ventilator will permit the home to keep up air movement while reducing energy waste. An ERV continuously exchanges heat from the warmed air leaving, with the cooler and healthier air entering from outside. Multiple design regards should be considered when the ERV is installed:

- The fresh air entry should be placed where new air rotates and away from range hood external exhausts, driveways, furnace stack, and laundry gates.

- The remained air from home must come from a wall near the kitchen, 10 feet away from an oven, and within one foot of the roof. This is done because vaporized oil and grease can block the ERV system.

- The fan for the basic air control unity for the house must be on at all times to rotate new air around the whole of the house.

- The ventilated air from the ventilator must be attached to the reversal channel of the home’s compelled-air system. This is done so that the ventilated air can be rotated simpler with the home’s ductwork system.

- The homeowners should still install original external fans for exhaust in all bathrooms, even with these best workout strategies. For more details, see how an ERV installed.

Energy Recovery Ventilator Cost

Energy recovery ventilators save on energy costs by preserving energy and decreasing the amount of energy needed to cool or heat new air brought inside the home. ERVs, the developed type of an air exchanger, conserve energy by retrieving some of the energy before it goes out of the house. The national mean for an energy recovery ventilator in the United States with its installation is approximately $2,000. This number ranges by the area according to the cost of labor and the brand selected.

Adding an ERV is an ideal method to meliorate the performance of the HVAC system. It could be low-cost repair if the goal is to reduce the costs to operate the system. This system needs little maintenance and preservation. The ERVs’ filters should be replaced or cleaned quarterly, or every 90 to 120 days. A Minimum Efficiency Reporting Value (MERV), for the ERVs’ filters, generally costs between $7.00 – $20.00.

The ERV cost is much less when combined with the costs of the regular maintenance, repairs, and installation of the HVAC system or a new furnace. This is because installing a new channel for an ERV is much easier while the basic ducting for the furnace is previously taken apart, the technician is already working, their main equipment is already existing, and the worksite is organized. Finally, on the subject of ROI, the mediocre time to regain the finance through decreased energy costs is three months to three years according to energy consumption. These systems save the homeowner money on usefulness bills. Also, some regions propose considerable discounts and rebates for installing energy-efficient home instruments.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

Thank you for your comment.

who are the top manufacturer and brands for large erv roof deck installations? atleast 36,000 cfm?

Thanks for visiting our website. You can visit our Industrial Equipment page, where you can find various ERVs based on your application and demand. You can also visit our expert page and take advice from hundreds of professionals on your issue.