Electric motors play an essential role in almost every industry. As you may know, there are two types of electric motors, AC motors, and DC motors. While both AC and DC motors serve the same function of converting electrical energy into mechanical energy, they are powered, constructed, and controlled differently. In this article, we will discuss the difference between DC motor and AC motor. Read on this new blog in Linquip to find out more.

What Is a DC Motor?

A direct current (DC) motor is a type of electric machine that converts electrical energy into mechanical energy. DC motors take electrical power through direct current and convert this energy into the mechanical rotation.

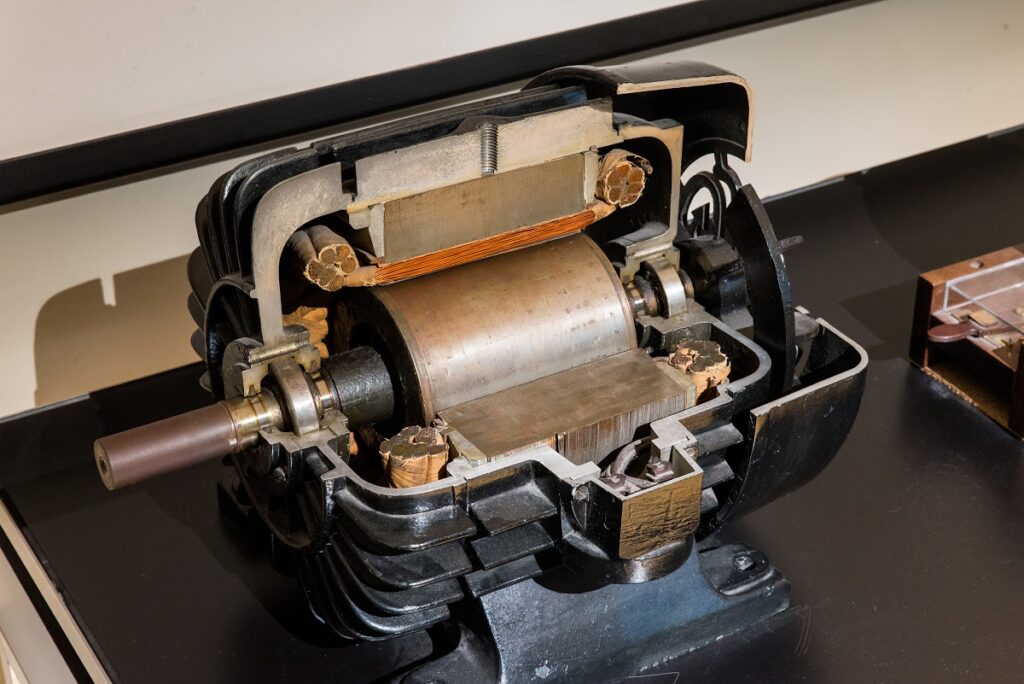

DC motors include two key components: a stator and a rotor. In a DC motor, the stator provides a rotating magnetic field that drives the rotor to rotate.

A simple DC motor uses a stationary set of magnets in the stator, and a coil of wire with a current running through it to generate an electromagnetic field aligned with the center of the coil. One or more windings of insulated wire are wrapped around the core of the motor to concentrate the magnetic field.

What Is an AC Motor?

The motor that converts the alternating current into mechanical power by using an electromagnetic induction phenomenon is called an AC motor. This motor is driven by an alternating current. Just like a DC motor, the AC motor also consists of two basic parts, an outside stator having coils supplied with alternating current to produce a rotating magnetic field, and an inside rotor attached to the output shaft producing a second rotating magnetic field.

The Difference Between DC Motor and AC Motor

The most basic difference between DC motor and AC motor is the power source. AC motors are powered from alternating current while DC motors are powered from direct currents. Several factors play a key role in choosing between these two types of motors. The following table indicates the main differences between these two.

| Differentiating factor | DC Motor | AC Motor |

| Types | Has two types: DC motors with brushes and DC motors without brushes. | Has two types: synchronous AC motors and induction motors. |

| Supply Sources | Energy is obtained from batteries, cells, etc. | Three-phase or single-phase power from the supply mains. |

| Current Input | DC motors will only run when DC supply is given. In the case of the DC series motor, the motor might run with an AC supply. But, for shunt motors, the motor never runs on AC supply. | AC motors only run when an alternating current is given as input. |

| Commutators and Brushes | Commutators and carbon brushes are present in the DC motors. | Commutators and brushes are absent in AC motors. |

| Input Supply Phases | Can run only on a single-phase supply. | Can run on both single-phase and three-phase supplies. |

| Startup Mechanism | Always self-starting in nature. | A three-phase type is self-starting but a single-phase type requires a starting mechanism. |

| Armature Characteristics | The armature rotates while the magnetic field remains stationary. | The armature is stationary while the magnetic field rotates. |

| Input Terminals | Has two input terminals (positive and negative) | Has three input terminals (RYB) |

| Speed Control | can be controlled by changing the armature winding’s current. | Can be changed by varying the frequency. |

| Rotational Speed | Higher depending on setting | Less |

| Load Change | Shows a quick response to the change in load. | Shows a slow response to the change in load. |

| Life Expectancy | The brushes and commutators in DC motors limit the speed and reduce the life expectancy of the motor. | Since AC motors do not have brushes and commutators, they are very rigged and have a high life expectancy. |

| Efficiency | High efficiency as there is no slip and induction current loss. | Less efficiency Due to induction current loss and motor slip |

| Maintenance Frequency | Requires excessive maintenance due to the presence of brushes and commutators. | Requires less maintenance as brushes and commutators are absent. |

| Maintenance Cost | DC Motor maintenance is more expensive. | Less expensive as compared to DC Motor. |

| Control Algorithm Applied | Normally closed loop | Normally open loop |

| Applications | DC motors are required where there is a need for variable speed and high torque. | AC motors are required where there is a need for high speed and variable torque. |

| Practical Uses | Mostly used in small domestic appliances. | Mainly used in large industries. |

That was everything you needed to know about the difference between DC motor and AC motor. Comment below and let us know what you think about these two and their differences. And if you have any questions about gas turbines or reciprocating engines, feel free to sign up on Linquip and we will help you right away!

Dear Sir/Madam.

this is samira from Aaran Steel Co, we are working on steel line supplying. we faced to a new change between chosing AC or DC motor for one of our application. we have 8 MW connected power ( 6X1000 KW and one 2.5 MW motor ). this line is Cold Rolling Mill . we need tourque at the start of line, so i guess we should select DC motor in this regard. another point is choosing Drive. we need a comparison between AC motor and Drive or DC motor and DC drive. which one has better price for this job?

i would appreciate to have your reply.

Regards,

Samira