Stepping into the world of CNC machines is like stepping into a technological labyrinth, filled with metal, motors, and many moving parts. The acronym “CNC” refers to Computer Numerical Control, representing a world of machinery that thrives on precision, speed, and consistency. The CNC machines’ universe is particularly instrumental in the metalworking industry, where these machines are often tasked with shaping, cutting, and forming metal pieces into useful products.

Defining CNC Machines

As we unravel the complexities of CNC machines, it’s crucial first to understand what they represent. In essence, CNC machines are automated machining tools that utilize computerized controls to perform various tasks involving drilling, lathes, mills, grinders, routers, and 3D printers. Their automation enables superior accuracy and efficiency in metalworking, propelling the industry into a new era of precision manufacturing.

Main Types of CNC Machines Used in the Metalworking Industry

There are several different types of CNC machines utilized in the metalworking industry, each offering unique advantages and being suitable for specific applications.

CNC Milling Machines

CNC milling is a prominent entity in the CNC world and has advanced metalworking processes by leaps and bounds. These machines utilize rotary cutters to remove material from workpieces, following directions set by the computer controls. The milling machines are versatile, with capabilities ranging from drilling and boring to cutting and thread milling.

Key characteristics of CNC milling machines include:

High level of precision and accuracy

Flexibility in creating complex shapes

Multiple axes for added control and functionality

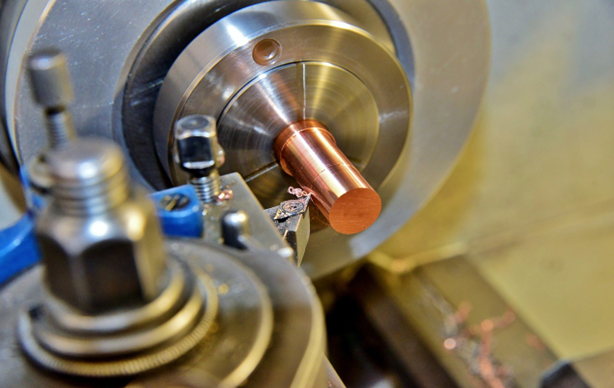

CNC Lathes

If we consider the broad spectrum of CNC machines, CNC lathes deserve a notable mention. These machines rotate a workpiece about an axis of rotation, performing various operations, such as cutting, sanding, drilling, and turning. Lathes are especially effective for producing parts that have symmetry around an axis, such as cones and cylinders.

Notable attributes of CNC lathes include:

High speed and efficiency

Capable of producing symmetrical parts

Exceptional precision for rounded products

CNC Plasma Cutters

CNC plasma cutters are the chosen ones when it comes to cutting 2D shapes from sheet metal. They employ a plasma torch controlled by a computer to cut through metal, offering fast and efficient cutting for large metal sheets.

The unique features of CNC plasma cutters comprise:

Ability to cut large sheets of metal

High cutting speeds

Efficient energy consumption

CNC Press Brake Machines

A CNC press brake machine, standing for Computer Numerical Control, is a sophisticated piece of machinery used in the metalworking industry. At its core, it’s a device designed to bend sheet metal to precise angles and shapes, guided by instructions fed into its computer system. But it’s more than a mere machine; it’s the embodiment of precision, efficiency, and automation, shaping the world one bend at a time.

The term ‘press brake’ refers to the machine’s core functionality – applying pressure to brake (or bend) metal. CNC, on the other hand, denotes the machine’s computer-guided operation, ensuring unprecedented precision and repeatability in the bending process.

CNC Waterjet Machines

CNC Waterjet is an industrial tool that uses a high-pressure stream of water, often mixed with an abrasive substance, to cut a wide range of materials. The ‘CNC’ stands for Computer Numerical Control, which means the waterjet cutting is managed by a computer.

The beauty of this tool lies in its versatility. It can be used to cut through materials such as metals, ceramics, glass, and even stone. Its precision and ability to handle complex cuts make it an essential tool in the metalworking industry.

Grappling with Grinders: CNC Grinding Machines

One cannot discuss the pantheon of CNC machinery without recognizing the indispensable role played by CNC grinding machines. They play a crucial role in the final stages of metalworking, creating finely-tuned, finished products that meet exact specifications. Grinding machines utilize an abrasive wheel to create a finish on metal surfaces, or to perform high-precision cuts on metal parts.

Surface Grinding Machines

Specifically tailored to deliver superior surface quality, CNC surface grinders ensure the smoothness and exact dimensions of metal pieces. They make use of a spinning wheel covered in rough particles to grind away minor irregularities and achieve a smooth finish. Surface grinding machines are an essential element in producing finished components that require precise flatness and tight tolerances.

Noteworthy aspects of surface grinders include:

Capability to provide superior surface finish

Ability to achieve high precision and accuracy

Offering a variety of shapes, including square, angular, or contoured surfaces

Cylindrical Grinding Machines

Cylindrical grinders are another subset of grinding machines that deserve a spotlight. As the name suggests, these are designed to shape the exterior of cylindrical objects. By securing and rotating the workpiece at one end, cylindrical grinders use a rotating grinding wheel to shape the surface.

Key attributes of cylindrical grinding machines:

High precision for cylindrical parts

Accommodate a range of shapes and sizes

Ideal for finishing and fine-tuning components

CNC Drilling Machines: The Powerhouse of Precision

The formidable drilling machine stands as a cornerstone in the edifice of the metalworking industry. CNC drilling machines, in particular, are used to bore precise holes into metal workpieces. They come in a variety of types, from upright drills for larger workpieces to bench drills for smaller, more detailed work.

Each CNC drilling machine possesses a sophisticated level of control that allows it to handle intricate tasks such as creating complex hole patterns and depths with incredible precision. This is accomplished by coordinating the machine’s movements and actions with the aid of advanced software, ultimately achieving the desired outcome with high-speed efficiency.

Features of CNC drilling machines that set them apart:

Ability to drill intricate hole patterns

High precision and consistency

Time-efficient and capable of high-volume production

Conclusion

As our exploration concludes, the role of CNC machines in shaping the metalworking industry’s present and future becomes crystal clear. Each machine—from milling machines and lathes to drilling machines—contributes uniquely to the industry’s dynamic landscape.

Their distinct attributes, functionalities, and applications combine to form an intricate network of automated processes, each one crucial in transforming raw metal into meticulously crafted, ready-to-use products. By combining precision, speed, and efficiency, CNC machines have undoubtedly revolutionized the metalworking industry.

As we continue to innovate and embrace emerging technologies, these machines’ roles will undoubtedly evolve, promising an exciting future for the world of metalworking.