Ever wondered how metal parts and components are crafted with such precision and accuracy? Welcome to the realm of CNC machines, the game-changing technology that has revolutionized the metalworking industry. In this extensive guide, we’ll dive deep into the various types of CNC machines, their applications, and the benefits they bring to the table. So buckle up and get ready to explore the fascinating world of computer numerical control technology.

Defining CNC Machines

Numerical control (NC), commonly referred to as computer numerical control (CNC), is the automated control of machining tools, such as drills, lathes, mills, grinders, routers, and 3D printers, by means of a computer. CNC machines execute programmed commands with remarkable precision and consistency, enabling manufacturers to produce high-quality metal components quickly and efficiently.

Types of CNC Machines in the Metalworking Industry

In the metalworking industry, several types of CNC machines have been developed to cater to different needs and requirements. In this section, we’ll take a closer look at some of the most popular CNC machines used for various metalworking tasks.

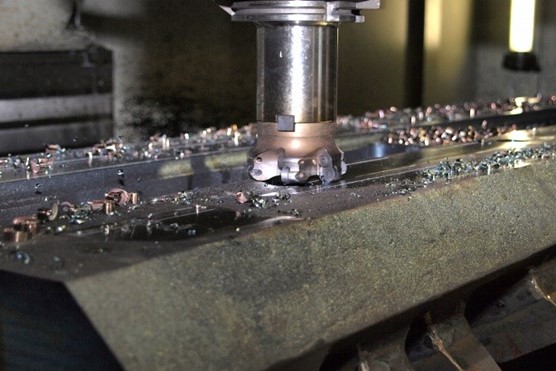

CNC Milling Machines

CNC milling machines are among the most versatile and widely used CNC machines in the metalworking industry. They utilize computer-controlled rotating cutting tools to remove material from a workpiece and shape it into the desired form. Key features of the CNC machines processinclude:

Multiple axes of movement, allowing for complex geometries and intricate designs

Wide range of cutting tools and materials, providing flexibility in manufacturing Can be used for both prototyping and mass production

CNC Lathes

CNC lathes, also known as turning centers, are designed for precision cutting and shaping of cylindrical workpieces. These machines spin the workpiece at high speeds while a stationary cutting tool removes material to create the desired shape. Some notable characteristics of CNC lathes are:

Highly accurate and efficient in creating symmetrical parts

Can accommodate a wide range of materials, including metal, plastic, and wood

Often used in conjunction with other CNC machines for complex part production

CNC Plasma Cutters

CNC plasma cutters are specifically designed for cutting through electrically conductive materials, such as metals, with high precision and speed. They employ a plasma torch that generates a high-temperature stream of ionized gas to cut through the workpiece. Benefits of CNC plasma cutters include:

Fast and efficient cutting process, suitable for large-scale production

Capable of cutting through thick metal plates with minimal distortion

Relatively low operating costs compared to other cutting methods

CNC waterjet machine

A CNC waterjet is a machine that consists of three main components for using a stream of water under high pressure to erode a narrow line into a piece of material.

Waterjet cutting is simply an accelerated erosion process within a selected material. Water under high pressure is shot through a ruby or diamond nozzle into a mixing chamber. This pressure creates a vacuum and pulls garnet sand into the stream, where it is then shot towards the object at a cutting location. The sand particles eat away at the material, causing the erosion effect to take place at such a high rate that it is considered cutting. This allowed water cutting to become an extremely powerful and versatile tool that is used in many industries around the world.

CNC Wire EDM (Electrical Discharge Machining)

CNC wire EDM machines use an electrically charged wire to cut intricate shapes and patterns in metal workpieces. The wire, which is typically made of brass or copper, is submerged in a dielectric fluid that helps control the spark discharge and remove debris. Some benefits of CNC wire EDM include:

Capable of producing complex and intricate shapes with high precision

Minimal force exerted on the workpiece, reducing the risk of distortion

Ideal for processing hard or heat-sensitive materials

Factors to Consider When Choosing a CNC Machine for Your Metalworking Project

Selecting the right CNC machine for your specific metalworking project can be a daunting task. To help you make an informed decision, consider the following factors:

Material and Size of Workpiece

Different CNC machines excel at processing various materials and sizes of workpieces. For example, CNC lathes are ideal for creating cylindrical parts, while CNC milling machines are more versatile and can handle a wide range of shapes and sizes. Consider the requirements of your project and choose a machine that can accommodate the material and dimensions of your workpiece.

Level of Precision and Complexity

The complexity and precision required for your project will significantly impact your choice of CNC machine. If your project demands intricate designs and tight tolerances, a CNC wire EDM or a multi-axis milling machine might be more suitable than a CNC lathe or plasma cutter.

Production Volume

The scale of production is another crucial factor to consider when selecting a CNC machine. For large-scale manufacturing, a machine with high-speed capabilities and automation features, such as CNC plasma cutters or milling machines, will be more efficient. On the other hand, if you’re working on a small-scale or prototype project, a CNC lathe or even a 3D printer may be sufficient.

Budget Constraints

CNC machines can vary significantly in terms of cost, with some being more affordable than others. When choosing a CNC machine, it’s essential to strike a balance between your budget and the required capabilities. Keep in mind that while more expensive machines may offer advanced features and higher precision, they might not always be necessary for your specific project.

Available Space and Infrastructure

CNC machines come in various sizes and configurations, and it’s crucial to ensure that you have adequate space and infrastructure to accommodate the chosen machine. Consider factors like power supply, ventilation, and safety requirements when selecting a CNC machine that fits your workshop or production facility.

Advantages of Using CNC Machines in the Metalworking Industry

The integration of CNC machines in the metalworking industry has brought numerous benefits, including:

Increased precision and accuracy, resulting in higher-quality products

Enhanced productivity and efficiency, leading to reduced production times and costs

Greater flexibility in manufacturing, as there are different types of control systems in CNC machines and they can be easily reprogrammed for different tasks

Improved safety, as operators can monitor and control machines remotely

Reduced material waste, as CNC machines optimize material usage and minimize errors

Conclusion

CNC machines have revolutionized the metalworking industry by offering unprecedented levels of precision, efficiency, and versatility in manufacturing. From CNC milling machines and lathes to plasma cutters and CNC waterjet, each type of CNC machine serves a unique purpose and caters to different project requirements. By understanding the capabilities of these machines and carefully considering factors such as workpiece material, size, project complexity, production volume, budget, and available space, you can select the ideal CNC machine to elevate your metalworking endeavors to new heights.