In this article from Linquip, we will talk about one of the most important turbines that work with gas to do the demanded task smoothly: Gas Turbines! And we mainly focus on the gas turbine cycle for you to better understand the gas turbine working principle and the way it works. So, stay with us in this article and continue reading to know all about the gas turbine cycle and components.

What is the gas turbine?

Gas turbines are considered as a type of internal combustion engine that is also continuous. This turbine operates with rotary motion instead of reciprocating motion.

Gas turbine components

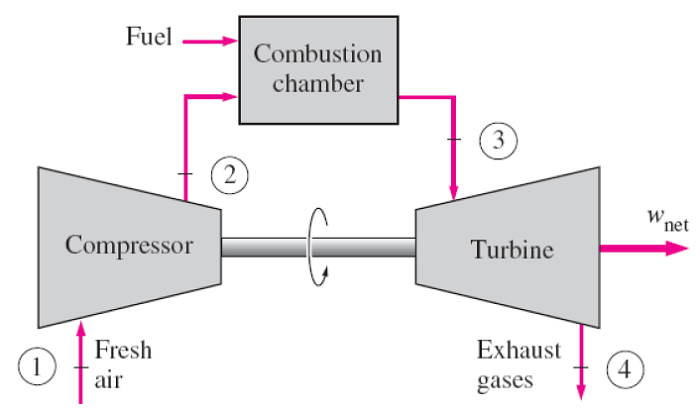

There are three main elements that are common in the design of all gas turbine engines. These elements are:

- Compressor (an upstream rotating one);

- Combustor;

- And power turbine (a downstream one)

The downstream power turbine is located on the same shaft as the compressor.

Some turbines also contain a fourth element to boost efficiency, increase thrust to weight ration, and also to convert power into other forms (mechanical or electric.)

Gas Turbine Working Principle and Gas Turbine Cycle

The basic operation of this turbine type has roots in the gas turbine cycle which is also known as the Brayton cycle. The gas turbine cycle works like this:

Though this cycle is not ideal for open circle gas turbines, it’s still used for them with a small change in the steps. They are perfect for the closed-cycle gas turbine. This cycle contains four steps:

- Isentropic compression in the compressor

- pressure heat-addition in the combustion chamber of the combustor

- Isentropic expansion in the power turbine

- pressure heat rejection

The compressor part of the gas turbine has been designed in a way that receives the flowing atmospheric air which increases the pressure. The air in this process is compressed up to 30 times more than the ambient pressure. When the air flows through this element, fuel will be sprayed into the air. Then, igniting this fuel with air will add energy and the combustion results in generating a high-temperature flow.

Combustors that are used in the gas turbine cycle are either silo, annular, or can-annular. The combustion chamber of the annular combustors is doughnut-shaped and the can-annular combustion chambers are can-shaped and unlike annular which only has one chamber, it has several combustion chambers. Silo combustors can have one or several combustion chambers and are larger in size compared to the other two. Silos are used for large scale operations while the other two are used for small scale applications.

The outcome of the combustion chamber, which is a high-temperature pressurized gas, will enter a turbine to produce a shaft work output which drives the compressor. The extra energy will be exhorted out in the exhaust gasses and will be used for external work or will be repurposed for other uses such as rotating a second power turbine.

In an open cycle gas turbine that has open systems, the fourth step of the gas turbine cycle (Brayton cycle) is omitted because these gas turbines do not reuse the same air for cooling of the working fluid (this cooling is the last step of the mentioned cycle.) closed-cycle ones have this fourth cycle as well.

These elements are all connected together with the help of one or several shafts and all of them together are called gas turbines or gas generators.

Watch Video About Gas turbine cycle

Gas Turbine Cycle Application

The gas turbine cycle enables these turbines to power different systems such as electrical generators, gas compressors, pumps, aircraft, ships, tanks, and trains.

The difference between an open-cycle gas turbine and a closed-cycle gas turbine

The main difference between these two gas turbines is that the open cycle one releases the exhaust gasses that leave the turbine into the atmosphere and these gasses are not recirculated. As we already mentioned in the steps of the gas turbine cycle, the fourth step only happens for the closed-cycle gas turbine that reuses the same air for cooling of the working fluid.

Advantages and disadvantages of gas turbine

One of the great advantages of gas-turbine engines is that they are smaller than many reciprocating engines that contain the same power rating. They also have few moving parts compared to reciprocating engines, resulting in lower maintenance needs and also lower maintenance costs.

Gas turbines have some disadvantages as well. A gas turbine’s core engine can be expensive since it uses exotic materials which can cost a lot. Another disadvantage of gas turbines is that compared to reciprocating engines, they are less responsive to changes that happen in the power demand. One of the most important things is that reciprocating engines at idle speed are far more efficient than gas turbines. But don’t forget that they can run on a wide variety of fuels and have lower peak combustion pressures than these engines.

Gas turbines are highly reliable where you need sustained high power output. Another good thing to remember about gas turbines is that compared to reciprocating engines, they have a very high power to weight ratio. Plus, waste heat that is produced in the gas turbine cycle almost entirely dissipates in the exhaust. Not to mention that the smooth rotation of the main shaft is the reason why the gas turbine has less vibration compared to the reciprocating engine.

All in all, it highly depends on your application and the place you want to install the turbine to know whether the fourth step of the gas turbine cycle is needed or not and which engine to choose when buying a turbine.

Now you know all there is to know about the gas turbine cycle, its components, and the working principle. What do you think about gas turbines and other turbine types? Comment below and share your thoughts and knowledge with us and our readers. Do you still have questions about their working principle? Then feel free to sign up on Linquip and our experts will help you get the answers to all your questions.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Marine Gas Turbines Equipment for Sale

- Mechanical Drive Gas Turbines Equipment for Sale

- Micro Turbines Equipment for Sale

- Mobile Generator Sets Equipment for Sale

- Aeroderivative Gas Turbines Equipment for Sale

- Taurus 60 PG Industrial Gas Turbine for Sale

- Taurus 60 PG Industrial Gas Turbine for Sale

- Gas Turbine Type: Overview of Types and Profitable Applications

- Gas Turbine Parts: Fast Basic Guide about Components

- Cross-Flow Turbine: Working Principle, Components, and Advantages

- What is Marine Gas Turbines?

- What is Mechanical Drive Gas Turbines?

- What is Micro Turbines?

- What is Mobile Generator Sets?

- What is Aeroderivative Gas Turbines?

- 7FA Nozzle Frame Gas Turbine for Sale

- Bucket Frame 9 Gas Turbine for Sale

- Spare Parts Gas Turbine for Sale

- Combined Cycle Gas Turbine

- Open Cycle Gas Turbine

- Closed Cycle Gas Turbine

- Top 15 Gas Turbine Manufacturers In India In 2022

- Top Gas Turbine Manufacturers In US (2022 Update)

- More Information about GE Frame 7 Gas Turbine

- See List of Gas Turbine Products

- See List of Siemens Gas Turbine Products

- See List of General Electric (GE Power) Gas Turbine Products