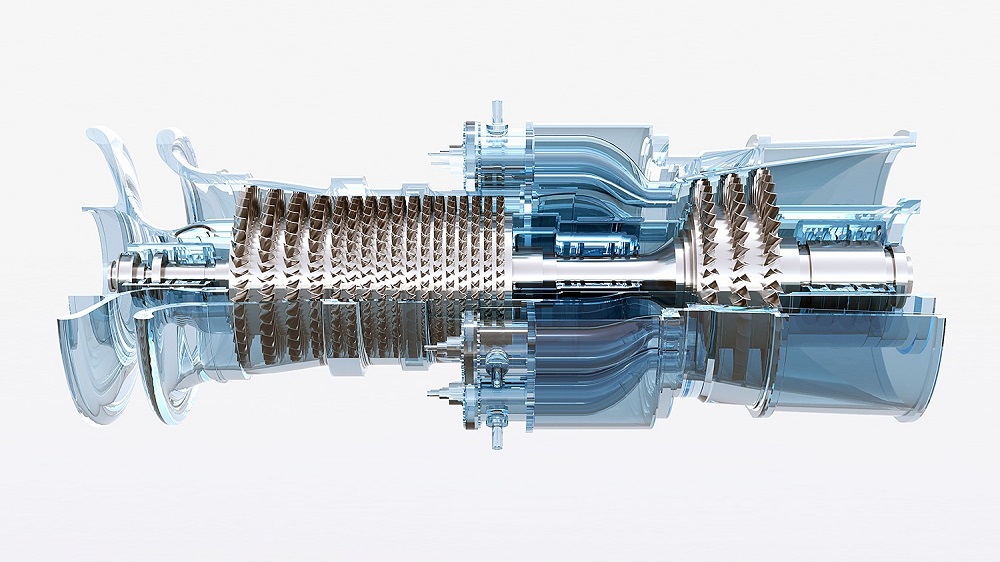

Gas turbine parts are essentially identical, but due to the difference in terminology for each manufacturer, the naming process of gas turbine parts varies slightly. Generally, there are mainly three items regarded as gas turbine parts: a compressor, a combustion engine, and a turbine plus other parts such as rotors, casings, and auxiliary components. Now, we are going to talk about what gas turbines are and where they are used.

A compressor, a combustion engine, and a turbine, as well as additional elements such as rotors, casings, and auxiliary components, are all considered Gas Turbine Parts. Gas Turbine Parts are essential for using this product. Gas Turbine Parts are available from a variety of Suppliers and Companies, as well as manufacturers and distributors, and there are many Gas Turbines for Sale on Linquip.

There is a comprehensive list of Gas Turbine services on the Linquip website that meets all of your needs. Linquip suppliers can assist you with this. Please Contact Gas Turbine Part Experts in Linquip to learn more about how to connect with a diverse group of service providers who consistently deliver high-quality products.

Later on, at Linquip, you will find more about gas turbine parts, Non-OEM gas turbine parts, gas turbines in aircraft as well as air compressor and combustor.

What is a gas turbine? Where is it used?

A gas turbine is a combustion engine capable of creating mechanical energy from converting natural gas or other liquid fuels. This energy then drives a generator to produce electrical power. In fact, a gas turbine has emerged as a reliable for power generation, transportation, and many other applications.

Regarding gas turbine applications, there are many types of gas turbines with a range of 1 to 10+ meters. Gas turbines come in a wide variety of forms, from moving tanks, jets, and helicopters to energy generation and industrial activities.

How do gas turbine parts go together?

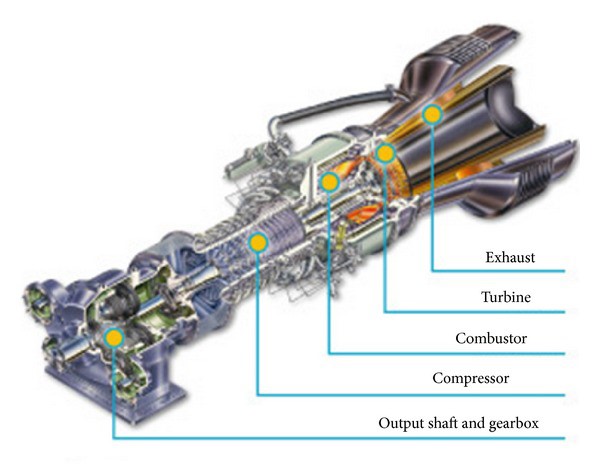

By looking at a gas turbine, you can see the combustion section, one of the very important gas turbine parts, which is between the compressor and the turbine flow direction. The fuel and the air are combined and burned in this way. Then, the hot exhaust passes the turbine and leaves the nozzle. We can consider two important roles performed by the nozzle. It is designed to make thrust by accelerating thrust generation via heat exhaust gas. Then the nozzle controls the engine’s mass flow.

Gas turbine parts in more detail: What is a Combustor?

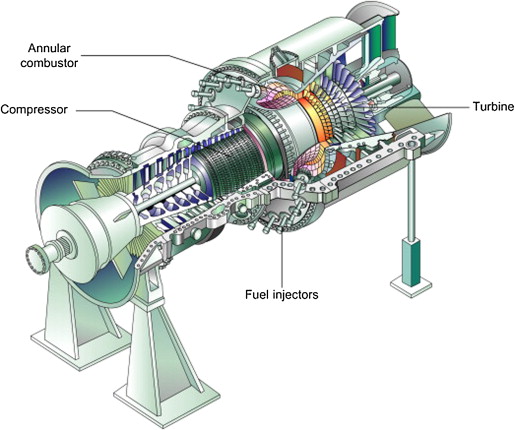

There are various types of gas turbine engine and all share several common parts. One of the gas turbine parts is called, combustor or burner in which the fuel is mixed with the high-pressure air and burned. To turn the power turbine and produce thrust when passed via a nozzle, the resulting high-temperature exhaust gas is used. combustors are also used in propulsion systems for ramjet and scramjet. Their configuration for ramjet and scramjet varies slightly from those used in gas turbine engines, but the basic thermodynamic concepts are similar.

In modern gas turbines, you can find three major types of combustion systems.

Watch Video About Gas turbine parts

What is an Air Compressor?

You certainly have seen where and how air compressors are used over the years but do you know the basics? Here is a quick recap:

Air compressor is in fact another gas turbine part that is used in a gas turbine power plant . The air filter is connected to the inlet on the compressor, the place the air is filtered from dust. The rotating blades attached to the shaft force the air between stationary blocks, which raises air pressure and at the compressor outlet, high-pressure air is available.

There are several sets of small airfoil blades consisting of the compressor and the turbine. Some lines have been linked and rotate in high speed with the inner shaft, while others remain stationary. The spins are referred to as rotors and the fixed rows are referred to as stators. Turbomachinery is the name of the combination of the shaft, compressor, and turbine.

What Drives an Air Compressor?

As parts of gas turbines, air compressor drives are typically devices driven directly or by the belt systems. Once the motor activates on a belt-driven system, the belt is turned around and the pump in the system is triggered. This is the cheaper option for all compressor types because the belts can be adapted to the air demands. Although these power units cannot be much adjusted, the efficiency is higher because the power transfer to the crankshaft is not lost much.

The Mechanics of an Air Compressor

A basic compressor includes an electric-powered engine, an inner air compression pump, an entry/outlet valve for air drawing and air release, and – more often than not – an air storage tank which depends on the type of air compressor. So, air is pulled into the compressor by reducing the volume of air through the creation of a vacuum, which increases air pressure when pushed into a holding tank. The service cycle is completed when the maximum pressure in the tank is reached and the compressor is shut down until pressure is under a specified threshold. This is done through the use of pistons, screws, and scrolls by positive displacement air compressors.

What Are the applications of an Air Compressor?

An air compressor can be used for a wide range of tasks. It can provide air for items such as tires or provide power for instruments to function. It includes some of the devices that work well with compressed air power like:

- Drills

- Nail guns

- Grinders

- Spray guns

- Sanders

- Staplers

Non-OEM gas turbine parts

Non-OEM gas turbine parts are supplied by proprietary alloys from many turbine manufacturers supplied by the world’s largest ISO-certified suppliers of vacuum and air-melted master alloys used in high-tech castings and forging of stocks. The advanced complex ceramic cores that shape the cooling pathways used to create a reactive and non-reactive crystal, a directional solidification, and equivalent alloys in the investment-cast turbine airfoils.

Gas turbine in aircraft: What are the construction parts?

The intake, compression, combustion, and exhaust functions in a reciprocal engine take place in the same combustion chamber. As a result, during each part of the combustion cycle, each chamber shall be occupied exclusively. The gas turbine in aircrafts is distinguished by separate sections that are devoted to each task and are operated without interruption at the same time.

Aircraft turbine engines are specifically designed for light aircraft with a highly sophisticated mechanism. In the design, maximum capacity or thrust with minimum weight and maximum fuel efficiency are required. Gas turbine in aircraft has roller bearings that require exotic metallurgy and high firing temperatures. It can be used with a limited fuel variation. When an aircraft turbine engine is used in an industrial application, a shaft power generator must be combined with a separate power turbine.

Gas turbine engine in aircraft comes in a variety of types, with its maintenance and engine overhaul requirements.

Any gas turbine engine consists of:

- An air inlet,

- Compressor section

- Combustion section

- Turbine section

- Exhaust section

- Accessory section

Also, different systems are needed to start, lubricate, supply fuel for the system as well as other tasks such as ice protection, cooling, and pressurization.

Finally, we strive to provide complete quality information via a reliable source for all customers, manufacturers and service providers requirements. And we are proud of our reputation in this regard. Our fully trained staff are committed to answering any question you might likely have about gas turbine parts. So, by reading this latest guide to learn about gas turbine parts, you can sign up at Linquip to receive all your answers.

Download Gas Turbine Parts PDF

Read More on Linquip

- Micro Turbines Equipment for Sale

- Mobile Generator Sets Equipment for Sale

- Aeroderivative Gas Turbines Equipment for Sale

- Heavy Duty Gas Turbine GenSets Equipment for Sale

- Industrial Gas Turbine GenSets Equipment for Sale

- Steam Turbine Parts: A Comprehensive and understandable Introduction to All Components

- Gas Turbine Type : Overview of Types and Profitable Applications

- What is Micro Turbines?

- What is Mobile Generator Sets?

- What is Aeroderivative Gas Turbines?

- What is Heavy Duty Gas Turbine GenSets?

- What is Industrial Gas Turbine GenSets?

- Gas Turbine Cycle: Everything You Need to Know About Gas Turbine Working Principle

- Parts of Generator: a Simple, Yet Useful Guide

- Cooling Tower Parts and Functions: A Concise 10,000-Foot yet Essential View

- Heat Exchanger Parts: Description of Configuration

- 6B.03 Gas Turbine for Sale

- GE 7FA.03 Unit Rotor 7FA.03 for Sale

- 6B Shroud Set Frame Gas Turbine for Sale

- 6B Vane Frame Gas Turbine for Sale

- 9E Vane Frame Gas Turbine for Sale

- Top 15 Gas Turbine Manufacturers In India

- Top Gas Turbine Manufacturers In US

- Top Gas Turbine Manufacturers In UK

- More Information about GE Frame 7 Gas Turbine

- See List of Gas Turbine Products

- See List of Siemens Gas Turbine Products

- See List of General Electric (GE Power) Gas Turbine Products

Very useful help me a lot for more details,

Even better overhauling procedure and troubshooting methods if available.

Thanks

Thank you so much for taking the time to leave us this review. here are some useful tips for gas turbine troubleshooting:

• Determine when the problem began

• Provide a chronological list including date/time of all process and diagnostic alarms

• Don’t exclude process or diagnostic alarms you believe are irrelevant

For more tips on gas turbine troubleshooting please sign up on Linquip to receive professional advice from our experts.