Gate Valve vs Butterfly Valve – One of the most critical components employed in a plumbing system is the valves. Valves regulate liquid flow by allowing it to start and stop, and they must function properly to prevent leaks and unwanted flow. The gate valve and the butterfly valve are two of the most common types of industrial valves. There are numerous additional types of valves available. The structural designs, usage, and working principles of these two are vastly different. The gate valve is a category of cut-off valve that can only be used as fully open or fully closed, with no way to regulate the flow. A butterfly valve, also known as a flap valve, is made up of a fixed disc that revolves around the stem of the valve shaft to open and close.

What Is Gate Valve?

For water delivery systems, the gate valve is the most common valve. It’s a linear-motion isolation valve that can either stop or let flow through. These valves should not be used to control flow; instead, they should be utilized totally open or completely closed, as partial opening can cause damage. The name “gate valve” originates from the closing component of the valve sliding into the flowing fluid to induce shutoff and therefore functioning as a gate. Gate valves isolate specific areas of the water supply network for maintenance, repair, and new installation activities, as well as reroute water flow across the pipeline.

Because of its simple design and versatility to be employed in a range of low-pressure-drop applications, the gate valve is one of the most commonly used valves today. Gate valves are designed to be full-port valves. This means that the valve port is the same size as the inner diameter of the connecting pipe. A full-bore gate valve allows fluid to pass through the pipeline without being obstructed or producing a pressure drop. This also makes it possible to clean the pipe using a cleaning pig.

Since gate valves are less complex to design than other large-size valves, they are widely utilized with bigger pipe diameters, ranging from 2″ to the largest pipelines. Gate valves come in a variety of sizes, materials, temperature, and pressure ratings, as well as gate and bonnet styles. Electric and pneumatic actuator gate valves are available, however due to their occasional use, manual gate valves are more cost-effective.

The gate valve can be classified in three ways:

- Disk Designs

- Solid taper wedge,

- Flexible wedge, and

- Split wedge or Parallel disks valve.

- Body Bonnet Joint Designs

- Screwed Bonnet,

- Bolted-Bonnet,

- Welded-Bonnet, and

- Pressure-Seal Bonnet.

- Stem Movement Designs

- Rising Stem or OS & Y type (Outside Stem and Screw Type), and

- Non-rising Stem type.

For more information about Gate valves visit this link.

What Is Butterfly Valve?

Butterfly valves are a type of quarter-turn rotational motion valve that is used to shut off flow in pipelines. Butterfly valves are frequently mentioned as a way to control flow. However, this is not suggested because it can harm the valve disk and compromise the sealing characteristics. Butterfly valves are simple to use and open. The valve can be completely closed or opened by rotating the handle 90 degrees. Large Butterfly valves are commonly equipped with a gearbox, which connects the handwheel to the stem via gears. This makes the valve’s operation easier, but it comes at the expense of speed.

These valves are applied in a wide variety of process media and industries, including water supply, distribution, and collection, as well as pumping stations, and they have a wide range of uses, particularly in flow isolation. Easy fabrication and compactness are two of their primary advantages over other valve families, resulting in lighter weight and lower cost end products with smaller installation footprints and faster actuation rates.

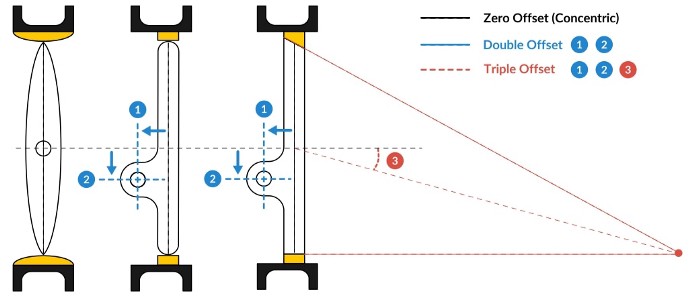

Butterfly valves come in a variety of shapes and sizes, each suited to particular pressures and purposes. There are three types of disk offset designs for the butterfly valves:

- Zero offsets (concentric) butterfly valve,

- Double offset (double eccentric) butterfly valve, and

- Triple offset (triple eccentric) butterfly valve.

The zero-offset butterfly valve, which relies on the flexibility of rubber, has the lowest pressure rating. The high-performance double offset butterfly valve, which is utilized in somewhat higher-pressure systems, is offset from the centerline of the body seal and the disc seat (offset one), as well as the centerline of the bore (offset two); this provides a cam motion during operation to elevate the seat out of the seal, leading to reduced friction and a lower wear tendency than the zero offset design. The triple offset butterfly valve is the optimum valve for high-pressure systems. The disc seat contact axis is offset in this valve, effectively eliminating sliding contact between the disc and the seat. The seat is a triple offset valve is made of metal so that it may be machined to create a bubble tight shut-off when it comes into contact with the disc.

Furthermore, butterfly valves have different body designs, as stated below:

- Lug type butterfly valve,

- Wafer type butterfly valve,

- Flanged butterfly valve, and

- Butt-welded butterfly valve.

For more information about butterfly valves visit this link.

Gate Valve vs. Butterfly Valve

Working Mechanism

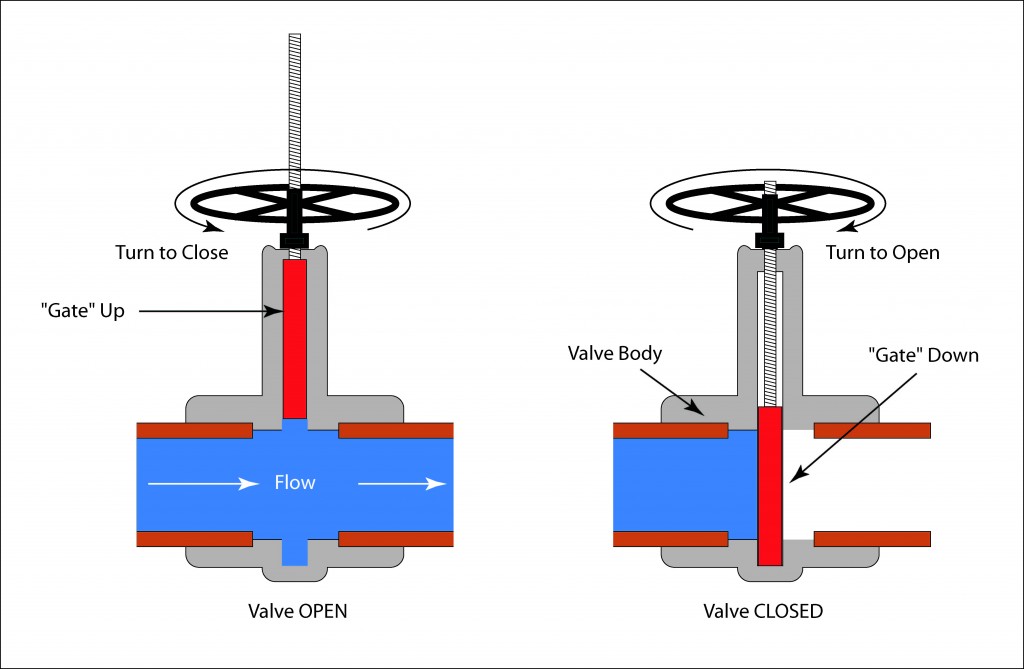

In a gate valve, the medium flow is controlled by a gate. A gate is a solid rectangular or circular disk that is attached to a stem and serves as a barrier. An actuator, such as a handwheel, is widely used to operate gate valves. A valve stem is attached to the actuator, which sends rotational energy to it. When the gate valve is opened, this energy converts the threads of the valve stem into the gate and vice versa when the gate valve is closed. As a result, this energy moves the gate upward or downward. This valve is referred to as a multi-turn valve since it requires more than a 360° turn to fully open or close. Stem and gate will move in a downward direction across the fluid flow line when the handle wheel is rotated clockwise, and the gate will be tightly placed between the two seats. As a consequence, once the valve is entirely closed, there will be no leakage of fluid. When the handle wheel is turned in an anti-clockwise manner, the stem and the gate move upward across the fluid flow line, and the valve opens from its closed state, allowing fluid to flow through the gate valve. When the gate valve is fully open, there will be no or very little resistance to the flow of fluid.

The relationship between the vertical movement of a gate valve and flow rate is nonlinear, with the largest changes occurring near shutoff. The gate valve can be utilized in a semi-open position as well, however there will be an issue with gate erosion if the valve is partially open since a relatively high velocity fluid will impact the gate. As a result, the gate valve should be employed in either a completely closed or completely open state. Gate valves are typically positioned in locations of a pipeline where they will longer remain open or closed, as they require time to move between these two states.

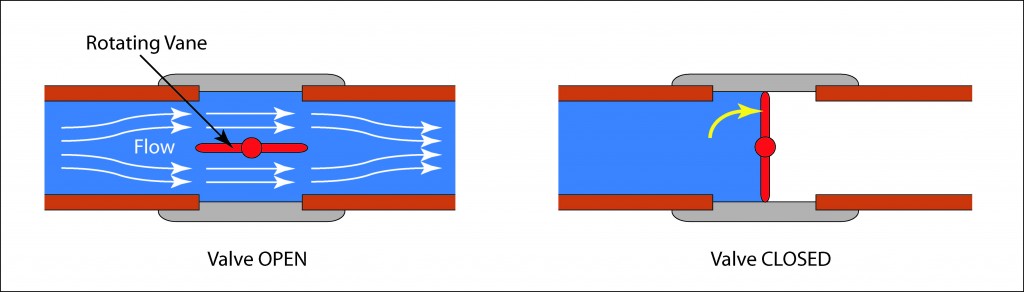

In a butterfly valve, the operation resembles that of a ball valve, allowing for rapid shutoff. Butterfly valves are popular because they are less expensive than other valve types and are smaller in weight, requiring less support. The disc is situated at the center of the pipe. A rod connects the actuator on the outside of the valve to the disc. The disc is turned perpendicular or parallel to the flow by rotating the actuator. The disc, unlike a ball valve, is constantly present within the flow, causing a pressure drop even while it is open. A butterfly valve belongs to the quarter-turn valve family of valves. When the disc is rotated a quarter turn, the valve is fully open or closed. A metal disc fixed on a rod serves as the butterfly. As the valve is closed, the disc is rotated until the pathway is entirely blocked. As the valve is fully open, the disc is spun a 1/4 turn, allowing nearly unrestricted fluid flow. The valve can also be opened gradually in order to throttle flow.

Butterfly valves have the ability to shut off and flow in both directions. Nevertheless, they are not full-bore, making them unsuitable for pigging or swabbing.

Read More on Linquip

- Parts of Gate Valve

- Gate Valve vs Ball Valve

- Difference between gate valve and globe valve

- Top Manufacturers and Suppliers of Butterfly Valves

Common Application

According to the above, the applications of gate valves can be determined as follows:

Gate valves have a good sealing property, so they are frequently utilized in pipelines that require tight sealing but don’t require frequent switching. They can only be employed in the completely open or fully closed states and cannot be used to regulate or throttle the medium flow rate since accurate control is impossible.

If the valve is kept partially or intermediately open, the valve’s seat and the gate will degrade rapidly. Noises and vibrations in the pipeline will be caused by the chattering wedge.

Furthermore, because the opening and shutting operations of the gate valve are slow, they are not suitable for pipelines that require emergency shutoffs. When comparing gate valves to butterfly valves, gate valves can sustain higher pressures along the pipe.

Finally, gate valves are frequently employed in large piping systems that require continuous bi-directional liquid and gas flows, as well as in time-based uni-directional media discharges.

On the other hand, the applications of butterfly valve also include the following:

Industrial butterfly valves are lighter than gate valves, making them easier to use and install in situations involving large pipe widths. They are perfect for small-space installations, where wafer butterfly valves are advised. In reality, as compared to gate valves, butterfly valves are employed more frequently in large sizes.

Butterfly valves are perfect for applications that demand quick opening and closing, notably emergency shutoffs because they open and close swiftly and can be operated often. They’re also utilized to alter or throttle flow rates, in addition to truncation. Butterfly valves are ideal for pipelines containing tiny contaminant particles.

Butterfly valves are also known as high-performance valves since they can be used in situations with moderate to high temperatures and pressure.

Advantage and Disadvantage

The below are the compiled advantages and disadvantages of each valve type:

- Advantages of gate valves

- The body of the gate valve is a straight-through design that can allow unrestricted flow in the completely open position, resulting in minimum pressure loss.

- Because the wedge operates slowly, it prevents water hammer.

- They are bidirectional and allow for consistent linear flow. They are not restricted to one-way flow and are not affected by the medium’s flow directions. Consequently, gate valves are desired for use in pipelines with varying flow directions.

- There are no residues in the pipes.

- When compared to butterfly valves, gate valves can withstand higher pressures.

- A wide range of applications; Gate valves are incredibly adaptable, and they can be utilized with a variety of media, including steam, oil, and other liquids. In addition, gate valves can be employed in media with granular materials and high viscosity. It can also be utilized as a low-vacuum system valve and a venting valve.

- Disadvantages of gate valves

- The medium flow can only be totally open or completely closed, with no adjustments allowed. When the valve is partially open, the seat and gate erode severely.

- Opening and closing slowly, the valve gate must be elevated to the upper portion of the valve chamber during the opening procedure and must fall into the valve seat during the closing one. Hence, the valve gate must move a considerable distance to open or close, resulting in a slow speed operation.

- Scratches prone; excessive friction between the gate and the two sealing surfaces of the valve seat might be formed during the opening and shutting cases, resulting in scratches on the sealing surface.

- These scratches may appear tiny at first, but they have an impact on sealing performance and service life over time.

- In comparison to butterfly valves, they require more room for installation and operation.

- When compared to butterfly valves, they are more expensive, particularly in large sizes.

- Advantages of butterfly valves

- Butterfly valves can be used to throttle fluid flows and conveniently control them.

- The quick operation time is perfect for emergency shut-offs.

- They are suitable for applications with temperatures and pressures ranging from moderate to high.

- In comparison to gate valves, they take up less area for Installation due to their lightweight and compact form.

- When compared to gate valves, they are more economical in larger sizes.

- Disadvantages of butterfly valves

- Butterfly valves obstruct the pipeline by leaving residue materials.

- Even when the valve is in a fully open state, the thickness of the valve body provides resistance, which obstructs the medium flow and causes the pressure to drop.

- Because the disc’s movement is unguided, it is influenced by flow turbulence.

- Since the disc is present in the flow channel evermore, thick liquids can prohibit it from moving.

- Water hammers are a possibility in these valves.

Read More o Linquip

- Butterfly Valve Manufacturers

- Gate Valve Manufacturers

- Angle Valve Manufacturers

- Solenoid Valve Manufacturers

- Plug Valve Manufacturers

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Dear sirs

I design a sprinkler and standpipe fire protection network. Which kind of valves and in what position of the network shall i specify, Gate or Butterfly valves?

Thank you

Sincerely yours

Kostas