Each control valve has its own advantage and so does the globe valve. But when you want to choose the right one, you need to know everything about different globe valve parts and their function to make an informed decision and also make sure that this control valve type is the right fit for your system and also avoid different problems and issues that are caused by a failing valve. In this article, Linquip will tell you all about different globe valve parts and also explain their use and application.

⇒ View a List of Globe Valves for Sale and Their Suppliers ⇐

What is a globe valve?

Globe valves are types of valves that regulate the flow of different gasses or liquids. They can also start or stop the flow. Globe valves have different parts such as disc, plug, ring seat, etc. and there are also different Globe valve types in the market such as y type globe valve, Z globe valves and angle types that are designed for specific purposes to serve diverse flow control needs and provide different globe valve functions.

Globe valve symbol is so easy to use and to remember: It’s a colored circle that contains 2 triangles on either side.

This linear-motion valve enables different industries such as pharmaceuticals, aerospace, petrochemicals, etc. to have better control over their systems.

What are different globe valve parts?

Now that you know what a globe valve is, let’s dive into a detailed explanation about different globe valve parts and learn their function in a globe valve, one by one.

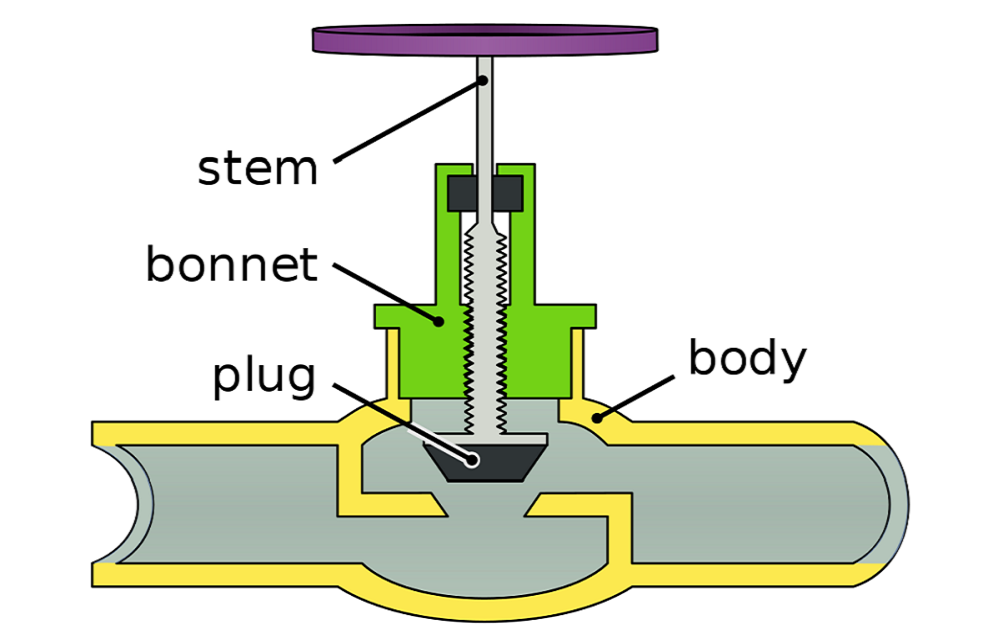

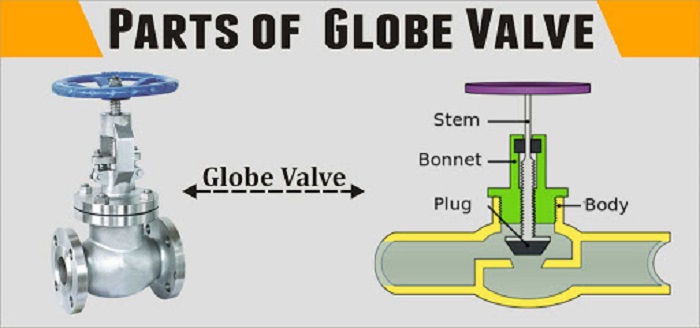

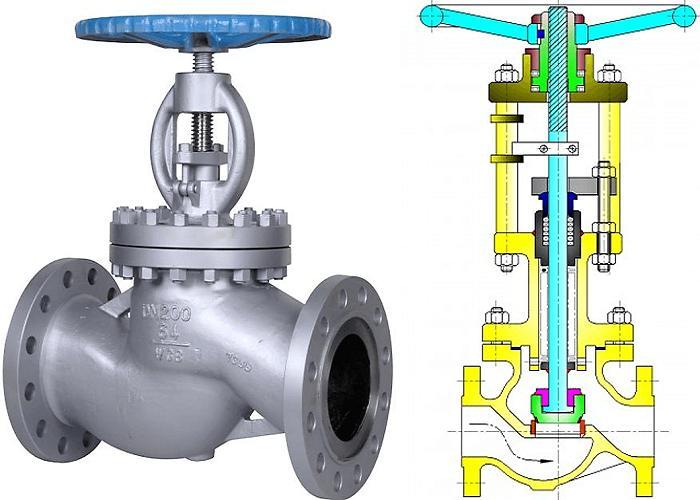

No matter what type of globe valve you have, there are several key parts that all globe valves contain: body, seat ring, cage, bonnet, stem, plug (disk), yoke, yoke nut, back seat, packing, and valve Actuator.

-

Body

The body is the main structure of the valve that keeps everything together. This part contains all internal parts of the globe valve to allow the control of the substance that needs regulation. The opening of the body contains ports (usually two or three ports) to enable the movement of the fluid to the inside or outside of the globe valve.

-

Seat Ring

The seat is among other globe valve parts that seal the space between the disk/stem and bonnet. The seat ring can be screwed into the valve or torqued. The seat is also known as a seat ring and provides a shutoff surface that’s stable and also replaceable. Seat rings can hold the cage firmly to the body of the valve.

-

Cage

The cage is also a globe valve part which we already mentioned its name while we explained the function of the seat ring! This cage has been designed to surround the stem and the plug within the globe valve. The cage is among the parts that determine the flow within the globe valve. With the movement of the plug, the flow can increase or decrease. Based on the layout and the design of the openings, the flow of the material inside the valve differs.

Another task that cages are responsible for is to help guide the plug to the seat to provide a good shutoff.

-

Bonnet

The bonnet is one of the outer globe valve parts that’s connected to the body to provide a leak-proof closure. There are different bonnet types such as bolted, screw-in, or union bonnet that are used in different globe valves. Each of these bonnet types has its own advantages. For example, the union bonnet not only adds strength to the body but is also great for applications that need regular cleaning or inspection. The screw-in bonnet with its simple design offers a pressure-tight seal. And the last bonnet type, the bolted bonnets that are attached with bolts are great for higher pressures.

-

Stem

The stem is part of the globe valve that connects the disk to the handwheel or the valve actuator to transmit the actuation force. Since it connects the actuator to the parts inside of the globe valve, it is considered as one of the critical globe valve parts. If the valves are controlled by actuators, the stem is smooth but for the manual valves, they are threaded.

The ends of smooth steam are threaded allowing the connection to the actuator and the plug. A wearable packing surrounds the smooth stem to prevent leaking material from the valve. So, the packing should be replaced regularly in the maintenance period. The stem can withstand a large amount of compression force in the closure state. And when the valve is opening, it has high tensile strength.

-

Plug (Disk)

The plug or the disk is among the essential globe valve parts. It moves perpendicular to the seat and its movement can block or free the flow since it works as a moveable physical barrier. When the valve is closed, the plug sits against the seat to block the flow and when it sits above the seats. it enables the flow of the material.

Different disk arrangements have been designed for globe valves such as composite type, ball type, and needle type. The composite disk can provide a better shut-off, while the ball type is used for low-temperature and low-pressure systems. The needle disk has the advantage of providing a better throttling compared to the other two.

Read More on Linquip

- globe valve vs ball valve; Which One Is the Best for You?

- Globe valve types: basic types plus bold pros and cons

Trim

The operating parts of a valve that are normally exposed to the process fluid are referred to as ‘valve trim’. Valve trim is the physical shape of the plug and seat arrangement. The shape of the valve plug determines the flow characteristics of the valve.

The primary trim components for globe valves include the stem, disc and seat, seating surfaces, and the backseat if an operable backseat is installed in the valve. The area where confusion exists in globe valves concerns the ancillary components such as nuts and washers that help to contain and align the disc. Some manufacturers consider these items trim, while others do not. Alignment cages or seat-guided disc connections are sometimes added to the trim designation list as well.

Different valve characterizations may be achieved by re-shaping the valve trim. For instance, the plug profiles of a stem-guided globe valve may be modified to achieve the common quick-opening, linear, and equal-percentage characteristics.

Yoke

A Yoke connects the valve body or bonnet with the actuating mechanism. The top of the Yoke holding a Yoke nut, stem nut, or Yoke bushing, and the valve stem passes through it. A Yoke usually has openings to allow access to the stuffing box, actuator links, etc. Structurally, a Yoke must be strong enough to withstand forces, moments, and torque developed by the actuator.

Yoke Nut

A Yoke nut is an internally threaded nut and is placed on the top of a Yoke by which the stem passes. In Globe valves, the nut is fixed and the stem is rotated through it.

Back Seat

A back seat is a seating arrangement inside the bonnet. It provides a seal between the stem and bonnet and prevents system pressure from building against the valve packing when the valve is fully open. Back seats are often applied in gate and globe valves.

Packing

Valve packing is a gasket that provides a sturdy seal between the valve’s stem and the bonnet. It is used to prevent liquid leaks in valve stems and stuffing boxes. In most valves, gland followers are tightened until the valve is leak-proof. Loose packing results in leakage; tight packing negatively affects the valve movement and may cause damage to the stem.

Packing is available in different materials, like PTFE, elastomers, fibrous material, etc. The valve packaging shall be properly designed and manufactured to minimize the possible damages to the stem and minimize the risk of leakages of fluids. On the other hand, it is necessary to observe that a too-tight packing may affect the stem.

Valve Actuator

The valve actuator operates the stem and disk to open and close the valve. There are several types of actuators depending on the needs of the system such as the torque necessary to operate the valve, speed, and the need for automatic actuation.

Manual/hand operated actuators use a handwheel or crank to open or close the valve. They are not automatic but offer the user the ability to position the valve as needed. The handwheel can be fixed to a stem or hammer which allows for the valve to be pounded open or closed if necessary. In manual globe valves, the stem screws the plug in to close or shut the valve. The threaded system is slower and not as smooth as an automated system, but it does offer easy operator control.

Automatic actuators offer smooth control for throttling. They typically use a smooth sliding stem instead of a threaded stem.

Electric motor actuators permit manual, semi-automatic, and automatic operation of the valve. The motor is usually reversible and used for open and close functions. The actuator is operated either by the position of the valve or by the torque of the motor. A limit switch can be included to automatically stop the motor at fully open and fully closed.

Advantages and disadvantages of globe valves

Each valve type has certain advantages as well as disadvantages. Among the advantages of the globe valve, we can mention the fast operation due to its short-stroke length as well as easy repair and maintenance since the disk and seat can be accessed from the globe valve top. Another advantage of using a globe valve is that it works well for frequent operation due to its materials. It also provides a better shut-off compared to other valves. Other advantages of globe valves are given below.

- Moderate to good throttling capability

- Available in tee, wye, and angle patterns, each offering unique capabilities

- Easy to machine or resurface the seats

- With disc not attached to the stem, the valve can be used as a stop-check valve

Every good device has disadvantages too! When globe valve parts are large, resulting in a larger globe, it requires considerable power or a larger actuator to seat the valve which also increases the noise when it’s activated. Another disadvantage of the globe valves is that they are heavier compared to other valves with the same purpose. Other disadvantages of globe valves include:

- Higher pressure drop (compared to a gate valve)

- Throttling flow under the seat and shutoff flow over the seat

That’s all there is to know about globe valve parts and their function! Do you know any details that can help our readers expand their knowledge on the subject? Then comment below and share your experience with us and our readers. And if you have any questions, feel free to sign up on Linquip and one of our experts will answer your questions right away.

Read More on Linquip

- Valve Parts Manufacturers

- Valves & Parts Manufacturers in United States

- Diaphragm Valve Manufacturers

- Plug Valve Manufacturers

- Downstream Valve Manufacturers

- Needle Valve Manufacturers

- Air release valve Manufacturers

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Explanation is clear about globe valves and their parts.

Dear Freind

Thanks for your Attention