Electric tools are known to provide portability and convenience, but might not be as durable as their pneumatic counterparts. However, with high-quality internal components, these tools might just last as long. One of the key internal components is the wiring harness, which must be selected carefully to ensure maximum tool durability in small and portable packages. Here’s how to choose one based on the device’s requirements.

Factors to Consider When Choosing a Cable Harness for Electric Tools

Electrical Load

Each harness in the tool must have the capacity to handle the current passing through it without overheating. So you must calculate the voltage and current requirements to determine the most suitable wire gauge to use for each section.

Cable Type

There are three primary wiring harness types.

Point-to-Point Cable Bundles

These wire harnesses feature point-to-point cables packaged in a single bundle using tape, adhesive, mesh jackets, or sheathing. They are the simplest type of wiring harness and can link parts like the battery to the motor in a drilling tool with connectors on each end.

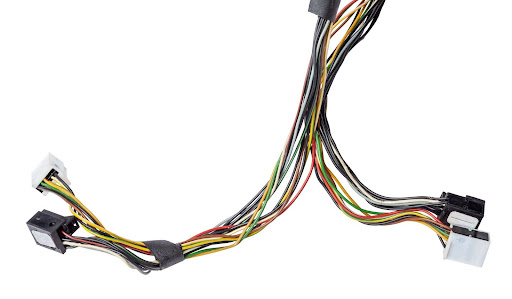

Wiring harnesses

Bifurcated Cables

A bifurcated cable assembly has a single connector on one end that hosts all the cables, but these split into at least two connectors on the other end. As such, they are suitable for linking power or signal lines that branch out to different destinations on the device or the PCB.

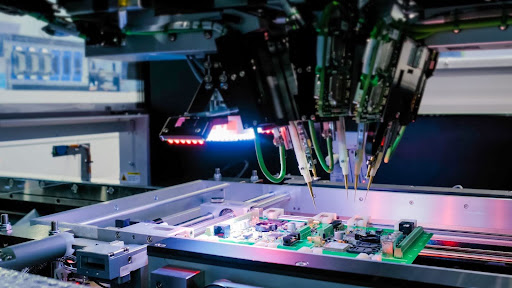

FPC (Flexible Printed Circuit) Cables

FPCs or ribbon cables have a flat design that makes them suitable for low-profile or compact electric tools. However, these cables are fragile and can easily snap if they exceed their bend cycle ratings.

Connector Properties

Instead of considering the connector types, the property of each connector is more important to check. For instance, in sections where signal clarity is important, the connector should minimize or not degrade the signal quality. The cable must also match the properties of the connector, such as using shielding for EMI protection. However, most tools don’t have sensitive signal transmission requirements.

Other factors to consider are waterproofing and ease of use to simplify maintenance.

Different wiring harness connectors

Strain Relief

To make harnesses as durable as possible, you must factor in their strain relief, especially if they are to be installed across moving sections.

Connector Compatibility

Each tool needs components sourced from third-party providers, such as sensors, which have unique connectors. The wire harnesses used in these devices must have compatible connectors for seamless fitting to provide optimal performance and enable quick installation.

Environmental Resistance

Most electrical tools have one thing in common; vibration. The harnesses inside must be able to withstand these, which means using stranded cables with flexible insulations. High humidity, extreme temperatures, and chemical exposure are other possible environmental conditions that these cables might encounter, so pick the most appropriate jacket material for the wires.

Safety and Compliance

The last factor is safety and compliance with national, regional, or international standards. When manufacturing tools to sell in different parts of the world, you can only be allowed to enter that market if the products meet the required standards, such as HAR, RoHS, and UL.

But more importantly, compliance ensures the harnesses are of high quality, resulting in tool durability.

The HAR wiring harness standard symbol for cables used in electrical and electronic equipment intended for the EU market

Final Thoughts

In conclusion, the wiring harness selection process should be left to the experts, unless you know what you are doing. For that, I recommend custom cable assembly from well-known wire harness manufacturers and assemblers, such as Cloom Tech and Wiringo. Their manufacturing process begins with a requirements analysis, where they analyze what your tool needs in its electrical system, to determine the best wires to use. If you get it right, your tools will stand the test of time (if the other parts are high-quality as well).