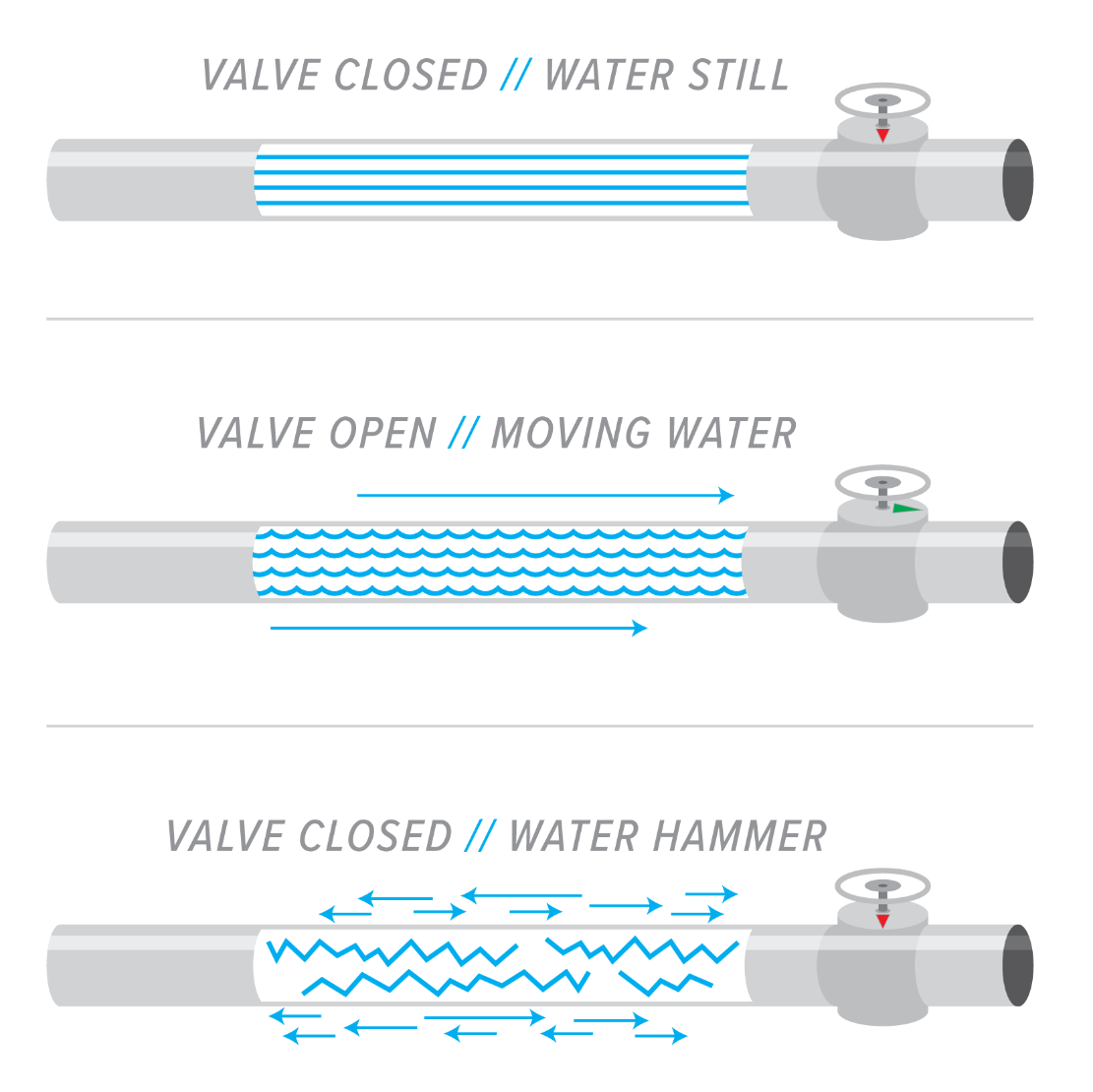

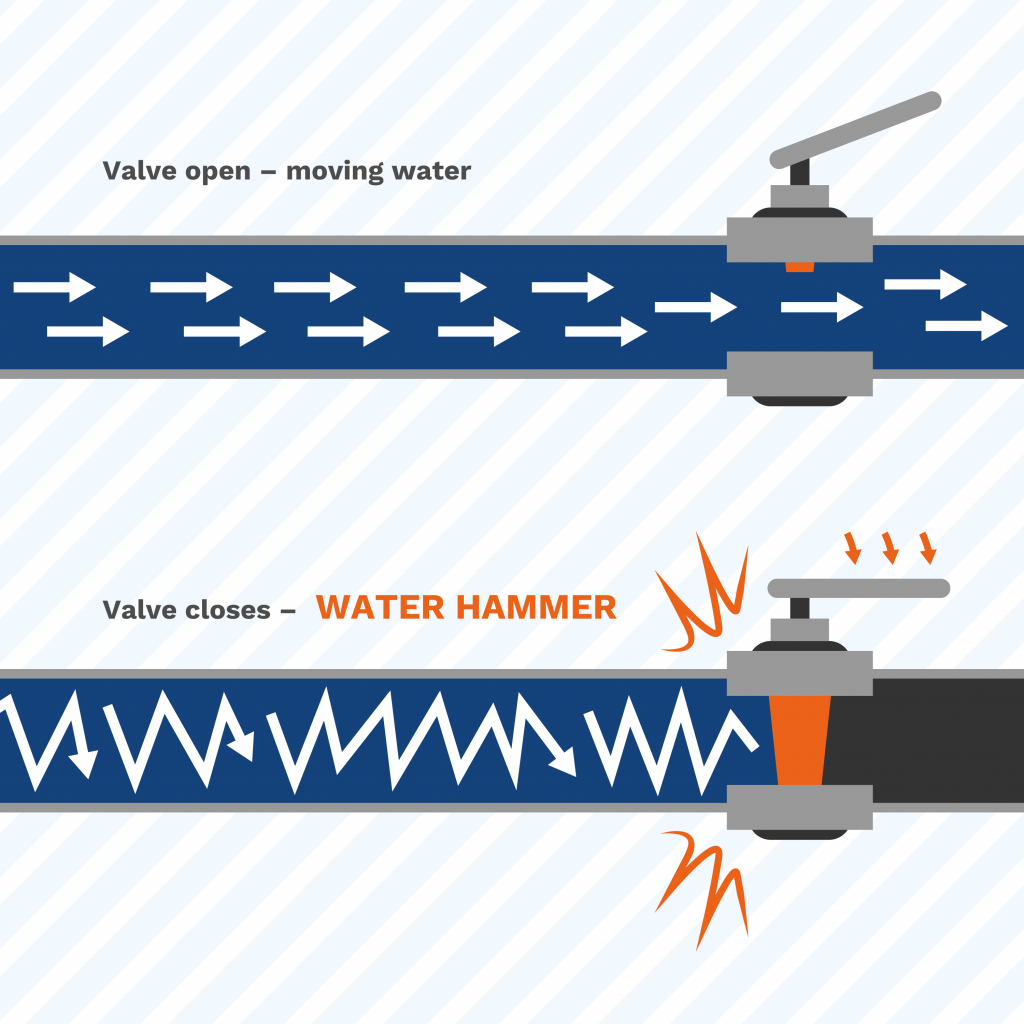

How to fix water hammer_ is a phenomenon that can happen in any piping system where valves control the flow of fluids. Water hammer results from a pressure surge, or high-pressure shockwave that travels through a piping system when a liquid in motion is forced to change direction or stop suddenly. This shockwave is also usually referred to as a hydraulic surge or hydraulic shock and may be defined by a marked banging or knocking noise on the pipes shortly after shutoff.

How Does Water Hammer Happen?

Abruptly stopping momentum of the fluid creates a pressure wave that travels through the liquid in the pipes, subjecting everything in the system to notable forces.

Water hammer generally occurs when a valve is shut suddenly at the head of a pipeline. The moving fluid slams into the closed valve, building a hydraulic shock wave resonating throughout the channel.

Certain types of check valves—including tilting disc check valves, swing check valves, and double door check valves—are intrinsically prone to closing fast because of their design. The use of these kinds of valves in a piping system can lead to difficulties with water hammer.

Water hammer may also occur by pump failure. If a pump pushing fluid in a pipeline system breaks suddenly, the velocity of the moving liquid also changes abruptly. The fluid downstream of the pump tries to continue flowing, making a vacuum in the line that may lead to a water hammer.

The Effects of Water Hammer

The shock force on the valve – provoked by the fluid’s momentum – may look and sound safe, but it can build pressure spikes that may exceed the system’s working pressure ten times. These sudden stoppages of flow and increased pressure from the shock waves can significantly damage the entire piping system either as a result of a singular event or cumulative damage happening over time.

Ignoring the water hammer can finally result in a catastrophic collapse in your flow system. The long-term consequences of water hammer are presented in continuation. As we will see, immediate action must be taken at the initial signs of water hammer. Neglecting to do so, will finally result in wide system damage and may expand beyond the flow system to other equipment or facility foundations.

Pump and Flow System Damage

Repeatedly happening water hammer may lead to significant damage to existing valves, pumps, and instruments. Finally, catastrophic failure of joints with gaskets and expansion joints would occur.

Leaks

Water hammer damage joints, fittings, and connections, resulting in leaks. These leaks often begin slowly and gradually expand their intensity over time. Minor leaks may go unseen for a long time, making surrounding equipment sensitive to any damage.

Ruptured Pipes

Ruptured pipelines because of the pressure spikes are costly to repair. The rupture results in regional pipeline collapse and can cause the whole system and other equipment to break. The ensuing damage can be massive, often causing major replacement operations.

External Property Damage

If you do not check periodically, water leaks can destroy electrical equipment or cause the corrosion of equipment or foundation.

Accidents

Pipeline rupture can also compromise the health and safety of employees and maintenance staff. Depending on the industry and particular facility, unmanaged leaks can also double the risk of falls, slips, and electrocution.

Downtime/Maintenance

Property damage leads to expensive repairs or accessories replacements. Extra financial losses may also be incurred because of downtime needed for additional repairs, maintenance, or installations.

How to Avoid Water Hammer

You should never ignore the water hammer. If you get away with it for days, weeks and years, finally, all that banging, clanging, and hammering will have predictable results.

Proper System Design

It’s essential to cooperate with a trusted partner who knows sanitary processing and is able to design an arrangement to meet the specific demands of your process. This partner should recognize the complexities of hygienic processing and the risks of water hammer to develop a design that reduces these dangers.

For available systems, it’s essential to consider the operating features of your pipeline system. The fluid velocity in the lines, for instance, should be lowered. Pipe sizing charts for some applications suggest no greater than 1.5 meter/second of fluid process flow. However, this can be a conflict with the design.

The following notes will help to lower the fluid velocity in the pipe, and therefore reduce the risks of hydraulic shock:

- Use shorter lengths of straight pipe.

- Use shorter branch pipe lengths.

- Add expansion loops and elbows to the process piping arrangement. Water hammer is related to the sound speed in the fluid, and elbows decrease the impact of pressure waves.

- Arrange the primary pipes in loops with smaller, shorter, run-out pipe branches.

Proper System Programming

Fluctuations in pressure, which can make water hammer, happen every time a liquid is accelerated or slowed by pump status changes or valve position switches. Usually, this pressure is slight, and the difference is so gradual that the water hammer is not practically detectable. However, in processing plants that move flow quickly down long piping runs, the pressure produced from turning a pump on or off can lead to a significant water hammer.

You can reduce these extreme pressure variations by proper system programming, the same as programming pumps to ramp up or down slowly. This process can increase the pressure change out over many seconds and also longer than a minute. Experts can estimate your process system to help minimize or dismiss the potential for water hammer for proper design or programming.

Proper System Training

Properly-trained processing plant employees go a long way towards decreasing or eliminating water hammer. Adequate training prepares operators on the importance of perfectly opening and closing actuated or manual valves — minimizing the impacts of water hammer.

Establishing good pipeline control practices, like startup and shutdown methods, also guarantees that your system operates correctly, efficiently, and reliably.

Air Pockets

Another problem that can cause a banging sound is air pockets in your pipelines. If the noise begins just as you open those taps, then air pockets are the reason. To fix the water hammer, turn all the taps on one by one and then turn them all off in reverse order. This can potentially release air pockets in your pipes.

Close Valves Halfway

It’s not a long term answer to water hammer problems, but it’s worth trying before it’s completely fixed. Washing machines and dishwashers typically cause water hammer because the shut-off valves close very quickly. So try turning these valves on only halfway.

Replace Intake Connections

It may be possible for these same problematic appliances to change the hoses for the intake components with wider ones.

Install Water Hammer Arresters

These nifty little gadgets, which can be bought from any hardware store, are mounted on the cold water outlet. They can solve water hammer if you have multiple appliances joined in the same taps.

Secure the Pipe

If you can discover the noisy water pipe that is the main water hammer culprit, check if you can reach it and try to secure it.

Install Pressure Limiting Valve

If the high water pressure is the cause of your problem, call a plumber to install a pressure limiting valve.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

Hi

We are interesting in a quote for Water hammer arrestor for this application

Item: 1

Qty: 1

Description: Industrial Water Hammer Damper or Suppressor

Application: Waste water

Material: Stainless steel

Pipe Diameter: 4 inch

Pipe Material: Stainless Steel

Process Connection: Flange ANSI 150

Type: L (90° elbow mount)

Fluid Temperature: Below 45°C

please specify the shipping cost to Cartagena de Indias and weight.

Thanks for visiting our website. You can visit our Industrial Equipment page, where you can find various Water hammer arrestor based on your application and demand. You can also visit our expert page and take advice from hundreds of professionals on your issue.