After a brief description, we will discuss how to use a socket wrench in this post. A socket wrench is one of the handiest and most helpful tools every tool enthusiast should carry, whether they are mechanics or just curious about tools. Socket wrenches are much easier to use than standard wrenches and allow you to loosen or tighten the nuts very quickly.

With Linquip’s extensive knowledge of socket wrenches, you will gain a broader understanding of them. Linquip’s “Tools and Instruments” webpage can help you determine what Linquip can offer you based on your intended use. Getting to know socket wrenches now will enable you to improve your efficiency at work.

Are you having trouble deciding which socket wrench is right for your application? The wide selection of Tools and Instruments Products at Linquip makes it easy to find just what you’re looking for. The Linquip online form will help you receive quotes from a variety of Tools and Instruments Suppliers and Companies within a short timeframe.

Socket wrenches are a useful tool, but many people are not familiar with their proper use. If you experience something similar, don’t worry! The page you are on is the right one for everything about socket wrenches, including how to use them in the most convenient and easiest way to make your job easier. Make sure to read the whole post until the end.

Basics

Common fasteners, such as nuts and bolts, can be tightened and loosened easily with socket wrenches. These tools function similarly to standard spanners and wrenches, only their ratcheting mechanism allows them to be used with greater efficiency.

DIY enthusiasts and professionals usually purchase socket wrench sets rather than individually fitting nuts and bolts of various sizes. A variety of adaptors and head fittings will be included to address a range of imperial and metric drive sizes.

The socket wrench is one of the most versatile and useful tools in your toolbox. Consequently, many mechanics, carpenters, electricians, and other tradespeople carry them in their tool bags.

Sockets & Socket Sets: What Are They?

Whether sold as individual kits, sets of sockets and wrenches, or in combo kits, socket wrenches are used for similar tasks as regular spanner sets. As a result, they assist in fastening and unfastening bolts and nuts of different sizes.

There is one major difference between socket wrenches and standard spanners: they have ratchet mechanisms built in. When pushed in one direction, a ratcheting wrench head locks into place, providing torque, but when pulled in the other direction, it can be rotated freely.

Using a ratchet tool means the user does not have to lift and reposition the wrench after each rotation to keep applying more torque to a nut or bolt. By doing so, fasteners can be completely tightened or loosened much more quickly, and the user’s wrists and hands are greatly relieved of strain. Additionally, it can make working in tight spaces much easier, including under cabinets or behind radiators.

Socket wrenches are simple handled tools with built-in ratchet mechanisms, generally with a head design that can accommodate various socket shapes and sizes. Basically, the sockets are the various-sized drives that go on the handle, allowing nuts and bolts to be driven. Multiple pieces in the best socket sets are made to fit over any standard nut and bolt type (both imperial and metric). So acquiring a good set of wrenches and sockets will ensure that you will rarely have difficulty adjusting rotary fasteners.

Working Principle of Socket Wrench

This tool enables the user to exert torque in one direction while rotating freely in the reverse direction. This type of system is called a ratchet system and involves gears that operate by locking when they are turned in one direction but releasing when they are turned in the opposite direction.

There are other ratchet tools available besides socket wrenches. Hand tools such as ratchet screwdrivers and T-handle ratchets can also be found there. The basic geared mechanism will be utilized in some form in all of them.

With a ratchet drive wrench, you can perform multiple rotations without constantly removing and replacing the tool. Working this way is easier and faster, and it is also less strenuous on the wrists and hands. Additionally, it makes it easier to work with fasteners located in cramped, confined, or otherwise challenging places.

Using a Socket Wrench Effectively

Here are the steps you need to follow if you want to use a socket wrench set, including how to choose the right wrench. The information in this section is intended for beginners and should guide you toward the successful and safe use of this tool.

Step 1: Pick the Right Socket

With socket wrenches, you can attach sockets of different sizes to the handle. It is possible to use the same tool for a variety of applications and fastener sizes. For your task to be completed quickly and efficiently, it’s imperative to pick the right socket size. The size won’t have to be measured or estimated by sight, so the process is probably easier than it appears.

A socket’s size marks are usually on the socket itself. If you’re not sure if it’s going to fit, try fitting the socket to the fastener first. Trying another size might work if the socket seems too small or too big on the fastener. Preventing damage to your hardware begins with this step. Start with a larger fastener size and decrease the size to avoid getting trapped.

Step 2: Connect the Socket

You will need a wrench that has several removable sockets to attach the socket to the handle. If you’re using an adjustable socket wrench set, make sure the appropriate size is locked in place.

Step 3: Inspect Thoroughly and Quickly

Before using your socket wrench set, you should ensure that it is functioning correctly. Turn the ratchet repeatedly from left to right with one hand while holding the socket firmly in place.

Step 4: Connect the Socket to the Fastener

You should be able to adjust the ratchet whenever necessary by connecting the socket to the head of the fastener. This phase is crucial and requires precision, so don’t rush it.

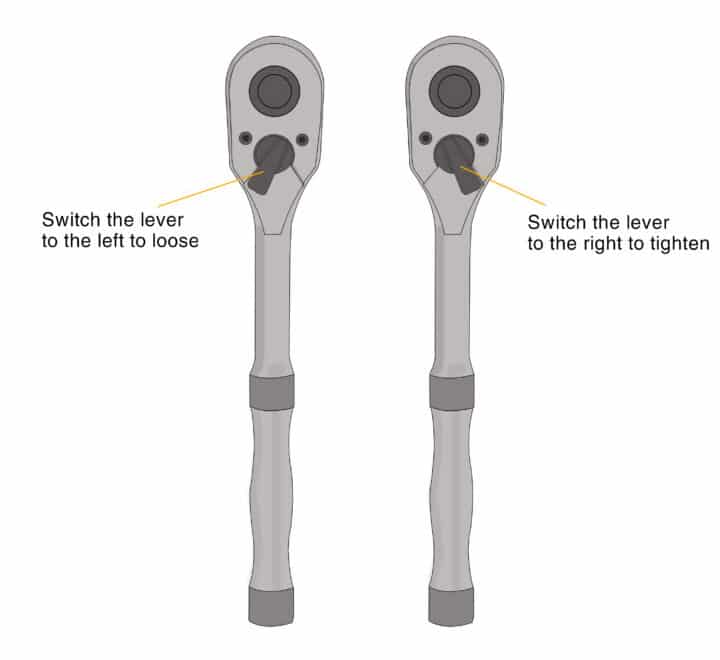

Step 5: Turn the Fastener

In order to tighten a fastener, the wrench handle must be twisted clockwise, and in order to loosen a fastener, the handle must be twisted counterclockwise. Turn the wrench handle into the position in which the bolt or nut should be placed. It is possible to create more turns if you are able to achieve a solid grip and move the handle again. Because the tool needs resistance, you may even have to grasp the socket in order to keep it from turning in the wrong direction.

Step 6: Keep Turning Until Tight

Continue rotating the handle until the fastener is completely tightened or loosened. In some socket wrench sets, a button facilitates the removal of the socket from the fastener. As soon as you’re finished using the tool, release it by pressing the button. The socket will need to be physically removed if your wrench does not have a quick-release feature, which can be challenging.

Tips and Techniques for Socket Wrench Maintenance

- Buy a high-quality socket set if you intend to use your wrench regularly or for a variety of projects. When you buy a high-quality set, you can expect it to be easy to use and include many socket sizes (for example, a good wrench should have a quick-release button).

- Ensure you don’t harm the wrench’s jaw if you have to apply a great deal of force to turn it.

- Don’t use a socket that is excessively large or loose and is not the right size for the fastener. A fastener can be stripped or destroyed by this precaution, and you might even slide, which is unsafe.

- Extensions for your socket wrench set can make your labor much more comfortable. It may be necessary to use a shorter or longer bar for different tasks. It is important to purchase a wrench that is able to accommodate extensions (or one that includes extensions), as well as multiple different extension sizes. If you need to work on automotive components in remote or hard-to-reach areas, you can use this tool.

- After use, put your sockets back where they belong by separating them by size. In the long run, this will save you time, energy, and money.

- Before using your wrench, consult a handy tool safety guide.

Different Types of Socket Wrenches

Various types are available, each with its own feature set depending on the cost and quality of the tool. It is common for torque wrenches to share similar basic components, such as solid handles and ratchet sockets.

There will typically be some mechanical switch as well, so you can reverse the ratchet direction and therefore torque can be applied in either direction.

A lot of buyers ask ‘what is a ratchet wrench? ‘, most people want to know what kinds of ratchets are available on the market, and what extra features they’ll need or not. Ratchet tools with higher quality features and benefits, such as adjustable socket wrenches and quick-release socket wrenches, will often be described in terms of these characteristics.

To enhance the functionality of the basic handled tool, various adapters are also widely available – either separately or as part of multi-part kits.

Drive Shape

Standard drive sockets come in a variety of shapes, so they can handle many different types of nuts and bolts. In choosing a hex socket wrench, you may want to check for options like square and double socket sets.

Having a few of each socket shape will let you handle almost all standard fastener types on a regular basis. Hex and square drive sets are the most common drive shapes you’ll encounter.

There are some socket wrench models that come with extenders that make it easier to reach recessed fasteners. You may have to purchase these accessories separately if you own a more basic model of the tool, usually as part of an all-inclusive socket drive set.

Socket Wrench Sizes

In terms of the actual handled tool itself, there are many sizes, styles, and designs to choose from.

In order to choose the best wrench for your needs, you will need to take into account a number of factors. Consider the type of space you will work in, whether you’ll need to access difficult nuts and bolts, and what materials you’ll have to add to your tool kit. You can often find a socket wrench set with various different shapes cheaper if you need several assorted types.

People who purchase ratchet spanners online often search for small, mini, half-inch (1/2”) inch, deep, or long socket wrenches (this can be accomplished by adding accessories or extension pieces).

It is important to note that the sizes of socket spanners or ratchets are different from socket drive sizes. As for the latter, it refers to the size of the fasteners.

Socket Drive Sizes

Choosing the right socket drive size or ratchet drive size can seem a bit confusing from a distance since there are multiple options to choose from. Nevertheless, they are relatively straightforward in practice, since most nut and bolt sizes are standard imperial or metric.

Two measurements are often marked on socket drives. One describes the drive socket size (i.e. the part attached to the wrench head), while the other specifies the socket head size (i.e. the part that covers a fastener). Most socket drive sets cover the most common drive sizes.

Inches are the standard units of measurement for drive sockets (the parts that attach to the ratchet head). The most common variants are the 1/4″, 3/8″, 3/4″, and 1″

A socket set kit contains a variety of socket heads (the parts that fit over or into nuts and bolts).

- Fasteners ranging from 3mm to 22mm will typically be covered by small socket sets.

- Large socket sets usually come with drives for nuts and bolts with diameters of 19mm to 50mm.

- Half-inch socket sets typically cover fasteners 8mm to 32mm in diameter.

Match the markings on your socket drive set pieces to the size of the nut or bolt you are handling in advance. Alternatively, you can gauge socket drive size visually by trial and error. Choose the drive that provides the most torque with the least amount of play by fitting a couple of them over the fastener you will be working with.

FAQs

- How do you loosen a socket wrench?

The socket handle should be turned counterclockwise to loosen a nut or bolt. When tightening a bolt or nut, the socket should be turned clockwise.

- How many types of socket wrenches are there?

There are five types of socket wrenches

- Ratcheting.

- Flex Head.

- T-Handle

- Nut Driver

- Gearless.

Conclusion

In this post, we have discussed what a socket wrench is and how it is used. If you haven’t used a socket wrench yet, you should start using one right away as it is a very useful, easy-to-use tool that everyone needs in their homes. Our article will explain how to use a socket wrench in detail, so if you already own one but don’t know how to use it, you will be able to learn it easily. Any questions you may have about which socket wrench is right for you can be answered by Linquip’s Tools and Instrument Experts. Also, for any special service you need for your tool, you can find Tools and Instrument Service Providers on Linquip.

Watch Video for Socket Wrench Use

This video will help you visualize what this article says about how to use a socket wrench.

Download PDF for How to Use a Socket Wrench?

You can download the PDF format of this post from the link provided here.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- How to Use a Torque Wrench? (Working Principle & Types)

- Different Types of Socket Wrench: Clear Guide

- 6 Types of Pipe Wrenches + Images: Clear Guide

- The 10 Best Torque Wrenches + PDF & Buying Guide

- The 9 Best Cordless Impact Wrenches

- 17 Types of Ratcheting Wrenches + Their Characteristics & Usages

- 15 Types of Wrench Sets and Their Features

- 13 Types of Adjustable Wrench: Clear Guide

- 42 Types of Wrenches + Guide for Choosing a Wrench

- How to Use a Laser Level? (Clear Guide)

- 11 Types of Industrial Chains + Their Features and Applications

- 8 Types of Scissors + Table of Characteristics and Usage

- 11 Types of Hand Tools And Their Usage

- 13 Types of Socket Sets + Characteristic & Usage (Clear Guide)

- 8 Types of Abrasives + Benefits & Usage

- 8 Types of Impact Sockets + Their Characteristics