Hydrokinetic Turbines include clean sources of renewable energy that significantly reduce the carbon emissions of off-grid sites, especially when relying on diesel fuel.

Many remote areas are not connected to the electrical power grid and have to use diesel generators for power production. Most types of diesel must be imported and stored for long time periods, especially in winter, which costs a lot. Using renewable energy devices leads to a reduction in the running time compared to diesel generators, saving money, decreasing CO2 emissions and environmental damage, makes additional capacity, and creates job opportunities.

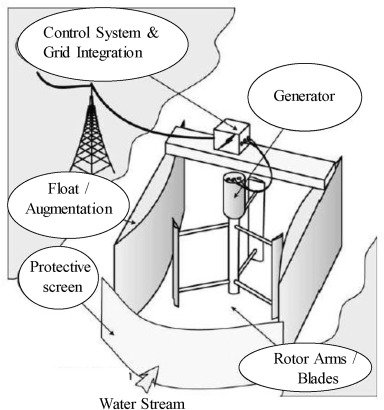

Hydrokinetic turbines produce a base load for the microgrid power systems. The portability of the system reduces the need for costly infrastructure. The turbines are designed to be installed underwater, in floating, fixed, anchored, or towed configurations, in any place where the effective water flow preferably has a minimum speed of about 0.25 m/s.

Hydrokinetic Turbines Basics

The hydrokinetic turbines, a class of renewable energy devices, offer methods to gain the energy of flowing water without the need for conventional hydroelectric facilities like dams and penstocks. Hydrokinetic technologies are developed to be installed in natural streams, such as rivers, ocean currents, tidal estuaries, and also in some human-made waterways and canals. In ocean-energy structures, hydrokinetic turbines can be arranged into multi-unit arrays, which like the wind farm, can extract energy from tidal and marine currents.

Efforts have been made to grow new renewable energy industries and markets with the ability to obtain potentially renewable energy resources, including low-head hydropower and hydrokinetic (HK for short) power in water flows and waves. However, relatively a small portion of this potential has been accurately harnessed or developed in the world.

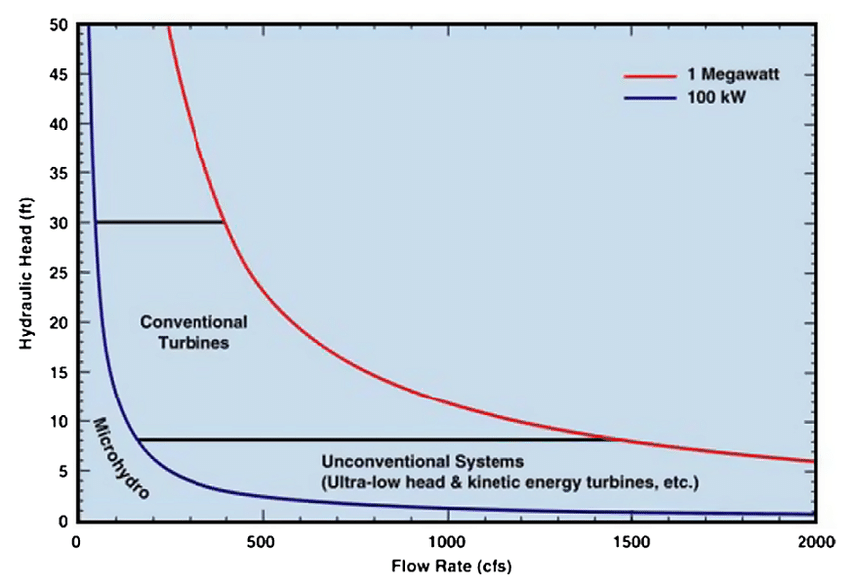

Low head hydropower is defined as electricity generation devices that transmit sustainable volumes of water at relatively low-pressure heads (up to 30 meters). More precisely, hydrokinetic turbines fall into the “zero-head” class whereby energy is transferred from the kinetic energy of water flow, like wind turbines, instead of the potential energy of falling water. Hydrokinetic systems can be utilized in rivers or free-flowing streams.

Some conditions provide the scenario for installing hydrokinetic turbines like hydraulic structures in rivers, irrigation canals, low height dams, gauging weirs, etc. These turbines can be installed along the canals, where there are suitable conditions for flow volumes, velocities, and flow reliability. Hydrokinetic turbines allow new applications and new potential in previously unexplored areas such as a long flat river or canal sections in which conventional hydro turbines in the form of available potential energy do not exist.

By extracting this form of energy, hydrokinetic energy production avoids many challenges existing in the traditional hydropower units, including high civil works costs and the need for a potential energy head. Hydrokinetic turbines are of the oldest hydropower systems; however, the evolution of these systems may be divided into periods, from the waterwheel concept to the recent modernized pilot plants and experimentation. Today, technological development is growing with several hydrokinetic designs through river, tidal, and wave energy systems.

Types of Turbines: Classifications and Types

Hydrokinetic Turbines Working

HK turbines have relatively simple designs without the need for a reservoir or spillway. Initial testing indicates the adverse environmental effects are minimal, and the simplicity of these designs results in low-cost installation and maintenance. Therefore, this simplicity makes these systems valuable in rural or remote areas. In the following figure, you can see the flow conditions of hydrokinetic turbines.

Two main schemes where hydrokinetic turbines can be used in power generation systems are tidal current and river stream. Ocean current represents another potential ocean energy source in which the flow is unidirectional, contrary to bidirectional tidal variations. Moreover, other resources include irrigation canals, man-made canals, and industrial outflows. While all hydrokinetic devices work on the same principles of energy conversion regardless of their application areas, some differences exist in their designs and operational features.

Design

The design includes the following items:

Size

To achieve economic efficiency, tidal current turbines can be designed for greater capacities (several megawatts). On the other hand, river turbines are considered in the range of several kilowatts to several hundred kilowatts.

Directionality

The flow of a river is unidirectional, and this removes the need for rotor yawing. But in tidal streams, if a yaw/pitch mechanism exists, a turbine may work during both flood and ebb tides.

Placement

Depending on the cross-section of the canal, a tidal or river current turbine can only be installed at the seafloor/riverbed or in other configurations such as floating structures. This is due to technical (instrumentation and power generation capacity) and nontechnical (fishing, shipping, and recreational boating) constraints.

Operation

The operation can be evaluated as the following items:

Flow Nature

The river flow characteristic is significantly different from tidal streams. While the river flow has an extreme stochastic variation (seasonal to daily), the tidal currents are subject to fluctuations of their periodic nature (diurnal to semidiurnal).

Water Density

The seawater density is more than that of freshwater. This means that there is less power generation capacity in a tidal turbine unit when located in a river stream. Additionally, seawater in different sites and times may have varying energy content depending on the salinity and temperature.

Control

Tidal turbines are designed to operate under particular tide conditions. River turbines may require more dynamic control systems to be synthesized.

Resource Prediction

Tidal conditions are almost entirely predictable, and available charts can be applied to determine a tidal power unit operation. But, for river stream turbines, forecasting the conditions is more complex, and many geographical areas may not have such adjustments. For a hydrokinetic turbine, the amount of output power is directly related to flow velocity. Even though the information about volumetric flow is available, water velocity may vary from one location to the other due to the cross-sectional area.

Users

While tidal turbines may be used in large-scale applications (analogous to large wind farms), river stream turbines can be installed to provide powers for remote areas or off-grid loads. It is anticipated that these technologies will lead to similar network integration challenges to wind turbines and benefit from more resource predictability.

Hydrokinetic turbines may potentially be used connected to existing large hydropower in the tailrace of a flowing stream to increase the capacity. Other areas are the use of hydrokinetic turbines in pumping for irrigation, seawater desalination, and heating the space.

Hydrokinetic Turbines Output Power

The output power of a hydrokinetic turbine is dependent on flow speed, similar to a wind turbine. The power density is given by the following equation:

P_{HK}=\frac{1}{2}E\rho V^{3}

and the output power is:

P=\frac{1}{2}C_{p}\rho AV^{3}

where E, Cp, ρ, A, and V are manufacturer-specified device efficiency, overall power coefficient, fluid density, turbine swept area, and fluid speed, respectively. The overall power coefficient determines the amount of kinetic energy extracted from fluid flow and converted into electricity. It considers losses due to Betz law and the losses in the internal sections. The Cp of a practical system is typically approximately 0.35.

A hydrokinetic turbine with a fluid velocity of about 2–3 m/s may annually provide up to four times more energy per square meter of rotor swept area than a wind turbine with similarly rated power. Although harnessing tidal energy may be expensive, the utilization of this high energy source compensates more than the higher costs.

Power performance tests are performed to find the overall power coefficient in a range of tip speed ratios. The output power gained from angular velocity (ω in (rad/s)) and torque (τ in (N.m)) measurements is compared to the available power density of a hydrokinetic turbine to obtain the overall power coefficient as the following equation:

c_{p}=\frac{\tau\times \omega}{P_{HK}}

The turbine power coefficient depends on the Reynolds number in terms of chord length and the ratio of projected rotor area to flow section area (known as blockage ratio).

What is Kaplan Turbine? Diagram and Working Principles

Hydrokinetic Turbines Types

The major types of hydrokinetic turbines are described here. The classification is done by the rotational axis orientation according to the water flow direction.

Horizontal Axis Turbines

The rotational axis of the horizontal (axial) axis turbine is parallel to the direction of the flow. The rotor plane is perpendicular to the flow to achieve appropriate power conversion efficiency. Horizontal axis turbines are popular in tidal energy conversion and are very similar in concept and design to modern wind turbines.

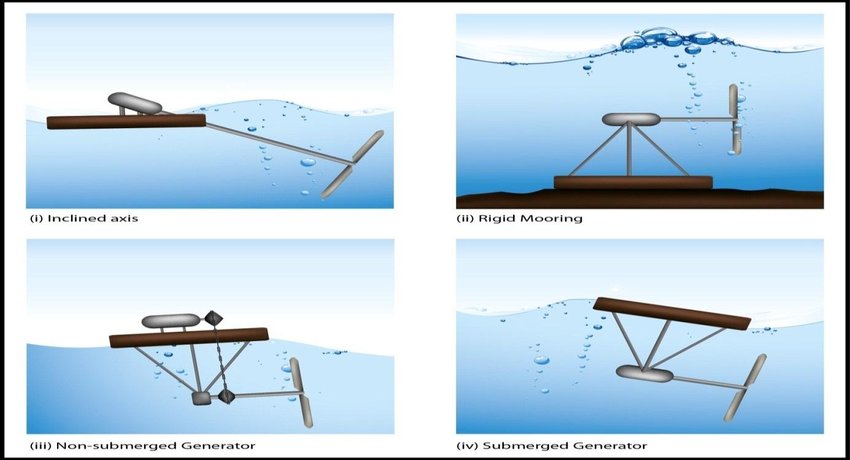

Straight axis turbines and inclined axis turbines are categorized as horizontal axis turbines.

Inclined axis turbines are often applied for small river energy conversion. An example of inclined axis hydrokinetic turbines is VLH (Very Low Head) turbine, an impeller-type turbine used in small heads (below 5 meters) and large flow rates.

Straight axis turbines are subdivided into solid (or rigid) mooring turbines and buoyant mooring turbines (including submerged and non-submerged generator turbines). In solid mooring turbines, the generator is installed near the riverbed or seafloor.

The following figure shows different types of horizontal axis hydrokinetic turbines:

Cross Flow Turbines

The cross-flow turbines have orthogonal rotor axes to the flow and parallel to the water surface. These turbines can also be called floating waterwheels. These are principally drag-based machines and have less efficiency than their counterparts working based on the lift. Another problem is the large quantity of material used in them. Maybe Darrieus turbines with cross-flow configurations fall into this class of turbines.

Vertical Turbines

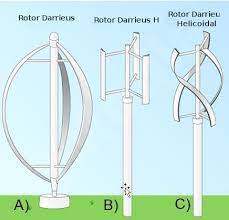

Various arrangements in the class of vertical axis turbine include Darrieus, SC- Darrieus, H- Darrieus, Gorlov, and Savonius.

Among the vertical axis turbines, Darrieus turbines are the most noticeable ones. Although the use of H-Darrieus (straight-bladed) turbine is common, there are no examples of Darrieus (curved or parabolic blades) turbine used in hydro applications.

The Gorlov turbine is another type of vertical axis turbine, in which the blades have helical shapes.

Savonious turbines are drag-type hydrokinetic turbines consisting of straight or skewed blades.

Other classification methods for hydrokinetic turbines are based on the lift and drag characteristics, orientation to up or down flow, and fixed or variable (active or passive) blade pitching mechanisms.

Comparison of Horizontal and Vertical Axis Hydrokinetic Turbines

There are some opportunities and challenges associated with different hydrokinetic turbines. Horizontal and vertical axis configurations according to their technical advantages and disadvantages are discussed in this section.

Design

The simplicity of design and system cost are significant items in the success of hydrokinetic turbines. As opposed to the blade design of the horizontal axis turbines that involves careful machining and manufacturing, the use of straight blades of vertical axis turbines makes the design much simpler and less expensive.

Generator Placement

For hydrokinetic turbines, coupling the generator with the turbine rotor is a challenge. In the horizontal axis turbines, this can be performed by a right-angled gear coupling, long diagonal shaft, or underwater installation of the generator. However, in the vertical axis turbines, the generator can be located at one end of the shaft, enabling the generator to be above the water surface. This decreases the subsequent cost of arranging water-sealed electric devices.

Noises

Vertical axis turbines usually emit less noise than horizontal axis turbines. It is maybe because of diminished blade tip losses. This feature can make vertical axis turbines a better choice for aquatic life.

Working in Shallow Channels

The water velocity variation in a vertical direction of a channel has a notable influence on turbine performance. In a shallow channel, the upper sections of a turbine face higher water velocities. In these cases, vertical axis turbines, such as those with helical blades, are more efficient.

Turbine Placement

Axial turbines are often designed to be placed at the channel bottom, while vertical turbines are considered to be installed in floating or near-surface arrangements.

Overall Efficiency

In general, the starting torque for vertical axis turbines is weaker than for horizontal axis turbines, which means that electromechanical equipment is needed to solve this problem. The efficiency of horizontal axis turbines is higher than vertical axis turbines.

Cavitation

Due to the physics and unsteady nature of the flow in a vertical axis turbine, the risk of cavitation is higher than in horizontal axis turbines.

Hydrodynamic Features

One essential advantage of horizontal axis turbines is evenly exerted lift forces along the blades due to the blades design. Therefore, these turbines are self-starting. Besides, they operate optimally at higher rotational speeds.

Challenges of Hydrokinetic Turbines Projects

There are three phases of design, installation, and operation for every hydraulic turbine project.

In the design phase, the flow characteristics, turbine features, dimensions, components, location, and how the turbine components are connected must be carefully evaluated.

During the installation phase, the location must be carefully located. The necessary civil modifications must be made. The turbine must be assembled and placed in the selected position, and the necessary arrangements must be made to connect the turbine to the end-user.

During the operation phase, necessary maintenances, such as repair and cleaning are performed.

Hydrokinetic Turbines Advantages and Disadvantages

Hydrokinetic turbines are highly regarded for their benefits. However, some of the weaknesses can be seen that engineers constantly evaluate and try to overcome these drawbacks. Some of these strengths and weaknesses are described here.

Advantages

- Existing infrastructure is sufficient for installing hydrokinetic turbines without the need for new civil works such as dam construction. So, construction costs decrease significantly.

- Due to innovative technologies, very low- or zero-head hydrokinetic turbines are developed to generate power efficiently.

- The need for a potential hydraulic head, existing in the conventional counterparts, is eliminated here.

- Smaller hydrokinetic projects can be suitable investments where electricity costs in conventional power systems such as diesel systems are high.

- For users near flowing water, micro hydrokinetic turbines may be the most economical and reliable choice.

Disadvantages

- Since these turbines depend on the flow of water in pre-existing canals or rivers, it may not be possible to operate at certain times of the year or even during certain hours of the day due to flow conditions or the volume of water available.

- Due to the rotational structure and being located on the natural path of aquatic migrations and the noise they produce, these turbines can be harmful to the lives of these species.