Heat dissipation and transferring are key processes without which it would be impossible to establish an industrial and manufacturing process. Cooling tower systems are cost-efficient constructions that have the mission to remove heat from industrial objects and cool plants. It is one of the solid, flawless, and highly functional cooling devices available in the industry today. Industrial enterprises, nuclear power plants, and thermal power stations cannot operate properly without a specific type of cooling tower. Let’s take a closer look at some of the common types.

Where can a cooling tower be useful?

The range of applications of cooling systems is incredibly broad. Such structures are needed to be installed if industrial water is used in large quantities to ensure hassle-free implementation of technological processes and the necessary microclimate. At the same time, each type of cooling tower has its own specifications.

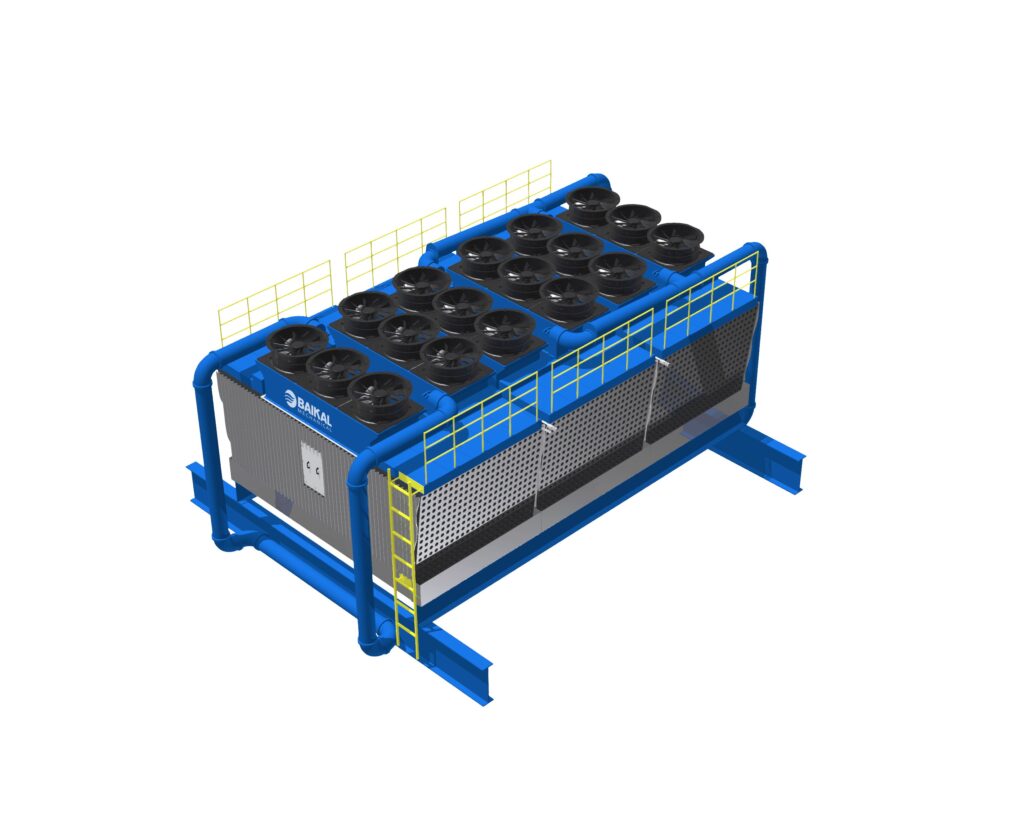

For example, fan cooling towers are designed for the needs of a stable functioning production, as they allow the removal of excess heat as quickly and efficiently as possible and create ideal working conditions for process equipment used in materials and chemical and processing. Hyperboloid towers are expensive, so most often only thermal power plants or nuclear power plants can afford them. To install tower structures, a large area is required, but they can also be constructed in the immediate vicinity of the object. Open structures are beneficial for industries using large refrigeration equipment and large volumes of cold water, as well as for compressor stations. At the same time, ejection units are most often used at facilities with variable climatic conditions, hydraulic and thermal loads.

General selection criteria of towers

In addition to the design features and principle of operation of the industrial cooling tower, when choosing the appropriate equipment for organizing your own production, you need to pay attention to a number of other factors:

- The total costs for the purchase of equipment, including the purchase of additional devices and installation services of the crew of specialists.

- The life expectancy of the cooling tower without the need for repair.

- The simplicity of service and maintenance.

- The materials from which the tower is made.

To learn more details, you can contact Baikal Mechanical. The crew is capable of introducing you to the latest modernization and upgrades. Each system, part, or equipment designed by Baikal Mechanical will last up to 20 years before it will be needed to be replaced. The reputable assistance is the guarantee of the expanded service life and tower structural stability. Moreover, professionals will consult you on other vitally important features. For example, they will advise the right size that is based on the needs of the object that require the tower. Assessing efficiency and taking into account the level of noise can also be useful to maximize your investment.

Installation and replacement

Whether it’s new construction or cooling tower fixing or replacements, it’s important to make sure that your system is competently built with efficiency and longevity in mind, as well as meeting all the industry standards and requirements. Baikal Mechanical experienced professionals will evaluate your needs and design the best solution for you. Creating a new project, the company will work to design and install the most energy-efficient system possible. You can trust the team of well-coordinated and highly skillful specialists when it comes to the supply and installation of equipment. The company is a trustable and reliable partner that is ready to provide professional, first-class customer service and satisfaction throughout the installation process. Rely on the well-respected team of professionals for getting the highest level of superiority at affordable prices.