As you may know, a cooling tower is a heat rejection device that rejects waste heat to the atmosphere through the cooling of a water stream to a lower temperature. Most cooling towers use an electrical fan motor to create an air draft or airflow through the cooling tower. In this article, Linquip is providing valuable information on induced draft cooling tower which is a type of mechanical draft cooling tower.

Our goal is to make this website as informative as possible – to provide you with all the data you may need about induced draft cooling towers so that you can make an educated decision. Linquip is your best choice of the solution when it comes to cooling tower questions. You can contact Linquip as soon as you have a question regarding Cooling Towers. We invite you to spend some time reading Linquip’s article titled, “What Is An Induced Draft Cooling Tower?“.

Several components of the Linquip platform require a Linquip Expert registration in order to fully utilize all the features and capabilities. How about sharing your insights on Linquip as a guest post? Would you be interested in doing so? It is possible for you to post your content in the Guest Posting section of the Linquip platform.

What is an Induced Draft Cooling Tower?

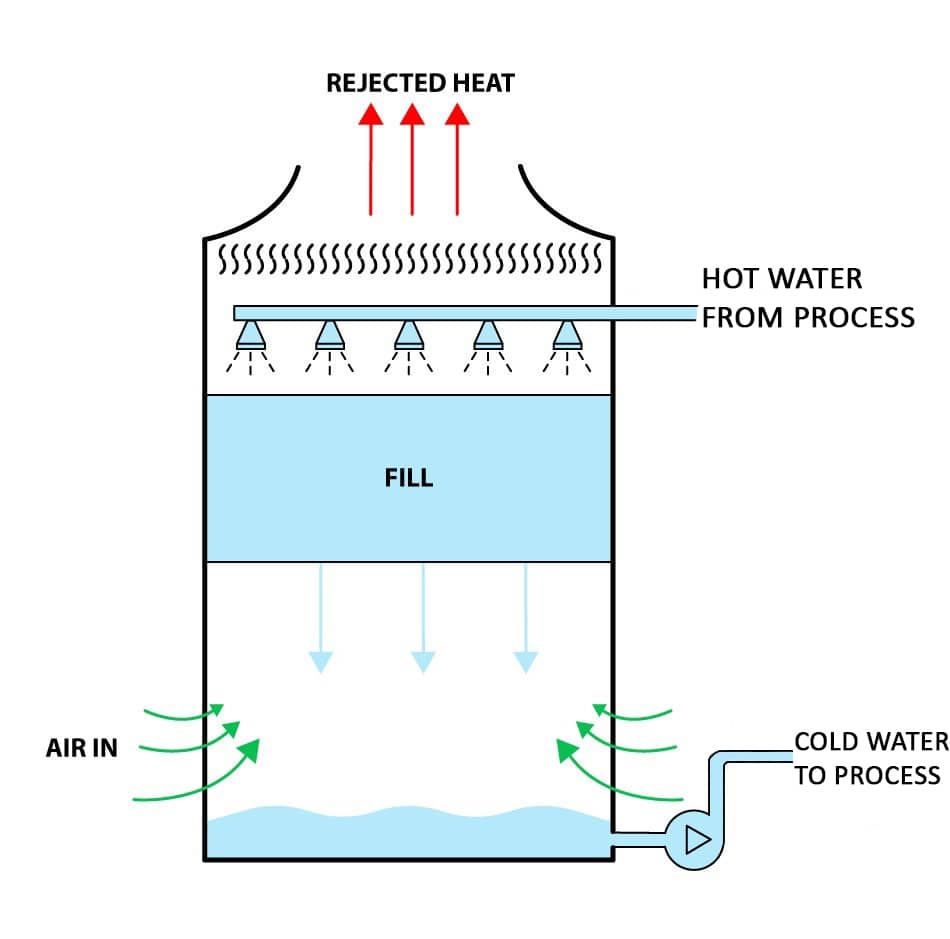

An induced draft tower is a type of mechanical draft tower which has one or more fans, located at the top of the tower, that draw air upwards against the downward flow of water passing around the wooden decking or packing. Since the airflow is counter to the water flow, the coolest water at the bottom is in contact with the driest air while the warmest water at the top is in contact with the moist air, resulting in increased heat transfer efficiency. Induced draft tower comes in square or round shape and the distribution of water may be done either by static branch system or by the sprinkler.

Induced Draft Cooling Tower Working Principle

At induced draft cooling towers, the incoming cooling water is injected throughout the cooling tower with a spray distribution header. The spray is directed downwards to baffles for maximizing the time of contact of water with air. Maximizing heat exchange surface area is accomplished through the ‘cooling water fill’, made of PVC, wood, metal or other material. Air enters the interior of cooling tower through properly designed ‘louvers’. Air is drawn through the baffled area by big fans and causes the cooling of water. In order to avoid the entrapment of water droplets in the leaving air stream, special device called ‘drift eliminators’ are used.

Advantages of Induced Draft Cooling Tower

The induced draft tower generally offers the most effective and economical solution to most of cooling needs. Its numerous advantages are as follows:

- flexibility

- cost effectiveness

- easy installation and maintenance

- Low noise level

- constant airflow regardless of ambient air temperature

- adaptability to any water flow

- flexibility of operation by shutting some cells

- adaptability to high thermal performance

- compatibility with all types of structure – wood, FRP, concrete, steel

- compatibility with all types of heat exchange surfaces from splash grids to high performance film

- Ability to provide excellent protection against icing of the mechanical components.

Comparison Between Forced Draft And Induced Draft Cooling Tower

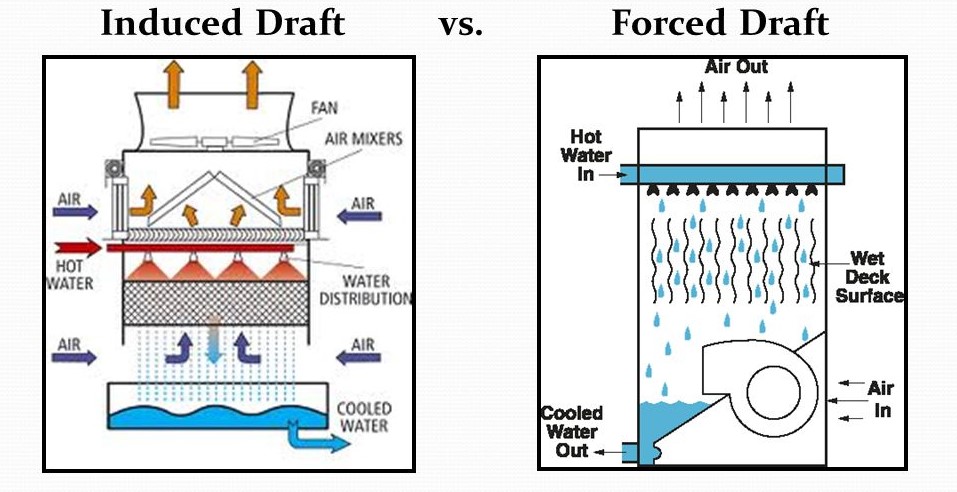

The difference between an induced draft cooling tower and a forced draft one is the placement of the fan in order to meet the requirement of atmospheric air suction. In Induced draft tower, the fan is placed at the top and above the eliminator such that atmospheric air is circulated from the top to the bottom. However in Forced draft tower, the fan is placed outside the tower and at the bottom such that atmospheric air is circulated from the bottom to the top.

Some benefits of using induced draft tower over forced draft cooling tower are listed as below:

- More efficient compared to forced draft cooling tower

- Employs 50% less energy while comparing to forced draft design

- Contains a fan located on the top, which drives the air via the fills

- Placement of an inlet fan on the top of the cooling tower, which creates low pressure

- Location of the fan in the warm air stream provides excellent protection against icing of the mechanical components

- Forced draft designs typically require more motor power than equivalent induced draft towers

Furthermore, induced draft towers work by use of axial fans while in forced draft towers, both axial and centrifugal fans can be used. The following table indicates advantages and disadvantages of each fan used in forced and induced draft cooling towers.

|

Advantages |

Disadvantages |

|

Induced draft – Axial fan |

|

|

|

|

Forced draft – Axial fan |

|

|

|

|

Forced draft – Centrifugal fan |

|

|

|

Download Induced Draft Cooling Tower PDF

For your convenience, the following link contains the entire contents of this article in a PDF format, which you can access whenever you want.

So, this is all you need to know about the induced draft cooling tower and its advantages. If you enjoyed your time on Linquip and want to share your experience with others, feel free to leave it in the comment section. We will be more than glad to have your viewpoint on the article. If you need any assistance with similar subjects, do not hesitate to sign up on our website where our experts are prepared to solve your issue.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

- Types of cooling towers: an ultimate guide to knowing different types

- Types of Heat Exchangers: An Introduction to All Essential about Specifications

- The Essential Guide to the 4 Types of Air Compressors

- Cooling Tower Water Treatment: A Guideline About the Basics of Water Treatment in Cooling Tower

- Cooling tower diagram: A go-to guide to learn about their function

- Wet vs dry cooling towers 101: An easy to understand guide

- What Is a Cooling Tower Used for?

- Dry cooling towers: Everything you need to know about them

- Closed circuit cooling towers : learn the basics, stay optimized!

- Chiller vs. Cooling Tower: Differences between a Cooling Tower and a Chiller

- Cooling Tower Maintenance: Essential tips

- Cooling Tower Fill Material: Gain a Deep Understanding

- Cooling Tower Approach : Basic Elements of Efficiency in Cooling Towers

- Crossflow vs Counterflow Cooling Towers: Which to Use Where

- The Counterflow Cooling Tower: A Quick Intro

- A Quick Guide to the Crossflow Cooling Tower

- Easy Guide to Cooling Tower Efficiency & How To Increase it

- A Constructive Intro to Increasing Cooling Tower Efficiency

- Cooling Tower Parts and Functions: A Concise 10,000-Foot yet Essential View