Is gold renewable or non-renewable _ Mineral resources can be classified into Metallic and Non-metallic. Metallic resources are matters like Gold, Silver, Tin, Copper, Zinc, Lead, Iron, Nickel, Aluminum, and Chromium. Nonmetallic resources are matters like sand, gravel, halite, gypsum, Uranium, and dimension stone.

What is Mineral Source?

A mineral resource is a mass of rock enriched in one or several useful materials. In this sense, a mineral is a valuable material, a definition that may differ from source to source. Here the word mineral is any substance that comes from the earth.

Exploiting and finding mineral resources requires applying the principles of geology that need more discussion. Some minerals are sent to the facilities to be used as they are found in the ground, and they do not need any further processing or have just a little processing—for example – gravel, gemstones, sand, and salt (halite). The process of gold extraction will be discussed in the next sections.

Due to such things as labor costs, extraction costs, and energy expenses vary from country to country, and with time, what forms an economically viable deposit of minerals changes considerably in place and time. Generally, the higher the concentration of the mineral, the more cost-effective it is to mine. So we define an ore as a mass of material from which we can extract one or more valuable substances economically. An ore deposit will include ore minerals that hold the valuable substance. Gangue minerals are matters that occur in the deposit but do not contain the worthy substance.

As economics is the main reason for controlling the grade or concentration of the substance in a deposit that makes the deposit sufficient to mine, different substances need different concentrations to be beneficial. It should be cared for and kept in mind that the financial concentration for mining can change due to economic conditions, the same as the demand for the substances and the cost of extractions. A well-known example of this situation is gold.

Gold prices change daily. When gold prices are rising, old vacated mines re-open, and when the rate drops, gold mines close. The operation cost is currently so high in the US that made few gold mines are profitable, but in third-world countries, as the labor costs are lower, gold mines that include ore concentrations can operate with a good profit.

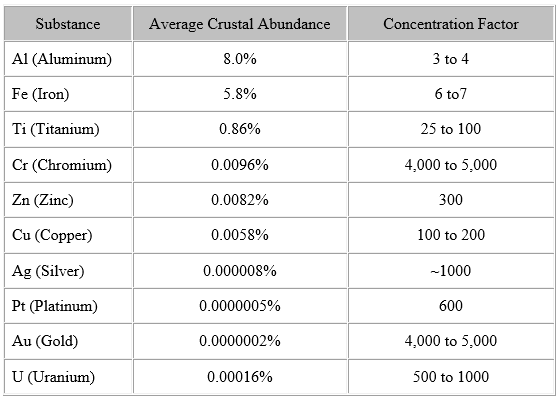

For each substance, we can define the concentration required in a mineral deposit for profitable extraction. By dividing this beneficial concentration by the medium crustal abundance for that substance, we can determine the concentration factor’s value. The table below shows average concentration factors and crustal abundances for some of the important substances that are regularly sought. For instance, aluminum (Al) has an average crustal abundance of 8%, which means that it has a concentration factor of 3 to 4. It indicates that aluminum’s economic deposit must be between 3 and 4 times the average crustal abundance, which is between 24 and 32%, to be economical.

It should be noted that we will not likely run out of these substances, as we can always discover deposits of any of them that have lower concentrations than are economical now. If the amount of currently used deposits is reduced, the price will grow, and the concentration factor will rise.

Origin of Mineral Resources

Mineral deposits can be listed based on the mechanism responsible for concentrating the valuable substance.

Magmatic Ore Deposits

Substances are accumulated within a body of volcanic rock by magmatic processes like crystal settling and crystal fractionation. Magmatic processes like partial melting, crystal settling, or crystal fractionation in a magma material can concentrate ore minerals with valuable substances by taking parts that were earlier widely dispersed in low concentrations and concentrating them in minerals apart from the magma.

Hydrothermal Ore Deposits

It can be by concentration in hot aqueous (i.e. water-rich) fluids flowing through cracks and pore spaces in rocks. Hydrothermal deposits happen when water flows to a depth and heats up either by reaching near a hot igneous body at that depth or by circulating to a great depth beside the geothermal gradient. This hot water dissolves valuable substances in a large volume of rock. As the hot water moves into the crust areas with less temperature, the dissolved minerals are precipitated from the hot water solution. Suppose there is a rapid cooling, such as cooling upon reaching a body of cool surface water or in open fractures. In that case, precipitation will happen over a specific area, resulting in a concentration of the substance succeeding at a higher value than was initially present in the rocks which the water passed through.

Sedimentary Ore Deposits

Chemical precipitation concentrates substances from lakes or seawater. Although clastic sedimentary processes can make mineral deposits, the term sedimentary mineral deposit is limited to chemical sedimentation, where minerals with valuable substances are precipitated out of the water directly.

Placer Ore Deposits

Substances are concentrated by moving surface waters either in rivers or along coastlines. The velocity of streaming water determines whether minerals are carried in deposition or suspended. When the velocity of the water decreases, large minerals with a higher density are deposited. Some heavy minerals like diamond, gold, and magnetite of the same size as a low-density mineral, same as quartz, will be deposited at greater velocities than the quartz; thus, the flow concentrates the heavy minerals in areas where the velocity of water is low. Mineral deposits developed in this process are called placer deposits. They befall in any area where the flow speed is low, such as in point bar deposits, behind submerged bars, between ripple marks, or in holes in the bottom of a river. The California gold rush in 1849 occurred when someone found rich placer deposits of gold in waters draining the Sierra Nevada Mountains. The gold formed initially in hydrothermal veins, but it was a detachment out of the veins and carried in rivers to be deposited in placer deposits.

Residual Ore Deposits

Chemical weathering processes concentrate substances of this type. During chemical weathering, the original parts of rocks are greatly separated in volume by the leaching process. The most important ore of aluminum, bauxite, is formed in tropical climates. In this weather, high water throughput and high temperatures during chemical weathering make highly leached lateritic soils that are rich in iron and aluminum. Most bauxite deposits are young because they appear near the earth’s surface and can be easily removed by erosion acting over long periods.

A current mineral deposit may also be turned into a more highly concentrated mineral deposit by weathering in a process named secondary enrichment.

Mineral Exploration and Production

Ores are discovered by evidence of metal enrichment. Geologists are looking for hints in rocks exposed near the surface. For instance, the enrichment process often follows in the discoloration of the soils and rocks. By finding such hints, geophysical survey’s involving measuring magnetism, gravity, or radioactivity are conducted. Geochemical surveys analyze the composition of water, rocks, sediment, soil, and sometimes even plants and trees.

Once it is discovered that valuable material is present, the deposit is assessed by core drilling to obtain subsurface samples, followed by chemical analysis of the pieces to know the grade of the ore. If the samples show signs of being economical to mine, then plans are made to define how they will be mined.

Suppose the ore body is inside the ground and 100 meters from the surface, large excavations open to the air and open-pit mines are used to obtain the ore before processing. Open-pit mines are less costly and less risky than tunnel mines, although they leave large marks on the land surface. Suppose the ore body is placed deeper or narrowly dispersed within the non-ore bearing rock. In that case, tunneling is required to extract the ore from underground mines. An adit is called to mine tunnels that are linked to a vertical shaft. Ores are removed from the tunnels’ walls by drilling and blasting, with the shoveled ores being hauled to the surface from processing. Underground mines are much more expensive and dangerous compared to open-pit mines and still have scars on the landscape where non-ore rock is discarded as tailings.

Global Mineral Requirements

Because the processes forming ores happen on geologic time scales, the most economical mineral resources are truly nonrenewable. New deposits cannot be formed in human timescales. But, as mentioned earlier, if the reserves of materials become depleted, it is probable to find other sources that are more expensive to exploit. Moreover, mineral resources are not equally distributed.

Some countries have mineral-rich soils, while some are mineral-poor. This is a critical issue for strategic mineral resources. These strategic metals are economical sources that do not exist in one country and must be imported from other likely non-friendly nations but are required for particular applications such as national defense, security, or aerospace applications. These metals are Manganese, Platinum, Cobalt, and Chromium, all of which are stockpiled by the country the same as the US government in case supplies are cut off.

Some mineral reserves will run out soon; for example, Pb, Zn, and Au’s global resources will be expected to run out in about 30 years. Continued usage of scarce minerals will need the discovery of new sources. Also, price rises will happen soon to make hard-to-obtain sources more practical, conservation, increased efficiency, recycling, substituting new materials, or doing without them. As a result, how long available mineral resources will last depends on reserve amounts and consumption rates.

Environmental Issues

Processing and extraction have large environmental impacts on surface water quality, groundwater quality, air quality, soils, vegetation, and aesthetics. Acid mine drainage is one example, Sulfide minerals newly exposed to Oxygen and water near the surface create sulfuric acid. Rainwater falling on the mine tailings becomes acidified and can create toxic conditions in the runoff. This can mobilize potentially dangerous heavy metals and kill organisms in the streams draining the tailings.

Gold Extraction Methods

In this section, some extraction methods will be discussed:

Concentration

Gravity concentration has been the most important way to extract native metal using pans or washing tables historically. Amalgamation with mercury was employed to enhance recovery by adding it directly to the riffle tables. Small diggings across the world still use mercury widely. However, froth flotation methods may also be applied to concentrate the gold. Froth flotation is regularly applied when the gold in an ore is closely combined with sulfide minerals such as pyrite, arsenopyrite, or chalcopyrite, and when there are such sulfides in large quantities in the ore.

In these cases, the concentration of the sulfides affects the concentration of gold values. Usually, recovery of the gold from the sulfide needs further processing, maybe by wet pressure oxidation or roasting. These hydrometallurgical or pyrometallurgical treatments are usually followed by carbon adsorption techniques or cyanidation in the final recovery of the gold.

Sometimes there is much gold as a minor constituent in base metal concentrates like copper and recovered as a by-product through base metal production. For example, they recover it in the anode slime through the electrorefining process.

Leaching

If we could not concentrate gold by smelting, then it should be leached by an aqueous solution:

- Thiosulfate leaching has been verified to be effective on ores with preg-robbing or ores with high soluble copper values: the absorption by carbonaceous ingredients that preferentially absorb gold and gold-cyanide complexes.

- An industry standard is the cyanide process.

Leaching through BLEG (Bulk Leach Extractable Gold) is a process to test a field for gold concentrations anywhere gold may not be visible immediately.

Refractory Gold Processes

“Refractory” gold ore is an ore with ultra-fine gold particles disseminated throughout minerals. Naturally, these ores are resistant to recovery by carbon adsorption and standard cyanidation processes. These refractory ores need pre-treatment for cyanidation to be efficient in the recovery of the gold.

There are organic carbon, sulfide minerals, or both in a refractory ore. Impermeable Sulfide minerals occlude gold particles, making it hard for the leach solution to form a compound with the gold. Organic carbon in gold ore adsorbs dissolved gold-cyanide complexes in the same way as activated carbon.

Pre-treatment alternatives for refractory ores include:

- Bio-oxidation, such as Bacterial oxidation

- Roasting

- Pressure oxidation

- Albion process

Gold Smelting

Before smelting, the following processes should be done.

Mercury Removal

Mercury is a health danger, especially in gas form. Gold precipitates from Merrill–Crowe processes or electrowinning are normally heated in a retort to recover any mercury and remove this hazard before smelting. Otherwise, it causes health and environmental issues due to its volatilization and release during smelting. The mercury’s presence is not regularly from the mercury amalgamation process used by formal gold mining companies in the past, but from mercury in the ore followed by the precipitation and leaching processes.

If there are high levels of copper available, leaching of the precipitate using sulfuric acids or nitric may be required.

Iron Removal

Forced air oven oxidation or Nitric acid can be employed on the electrowinning cathodes to dissolve iron before smelting. The gravity concentrate may have high grinding steel contents. Consequently, their removal using magnets or shaking tables is used before smelting. Iron can be oxidized using niter during smelting. Using extra niter will corrode the smelting pot, raising both the risk of catastrophic leaks and maintenance costs. The results of a corroding pot are known as run-aways or holes in the pot in which the molten charges are lost. Also, we can use magnetic separation, which is very effective for separating iron impurities.

Gold Refining and Parting

Gold parting is fundamentally the removal of silver from gold and enhancing the purity of gold. Since ancient times starting in the 6th century BC, the parting of gold from silver has been performed. Various techniques have been investigated same as salt cementation from ancient times and using distilled mineral acids from medieval times. We use chlorination, the Miller process, electrolysis, and the Wohlwill process in modern times.

How Much Gold is Left to Mine All Around the World?

While gold traders drove the price rise of many things, it begs the question about the precious metal supply and when it will eventually run out. Gold is in hot demand and popular matter as an investment, a status symbol, and a key ingredient in many electronic products. But it’s also a limited resource, and there will finally come a stage when there will be none left to be mined and explored.

Peak Gold

Specialists talk about the theory of peak gold – when we have mined the greatest we have ever been able in any one year. Some assume we may have already reached the point of peak gold.

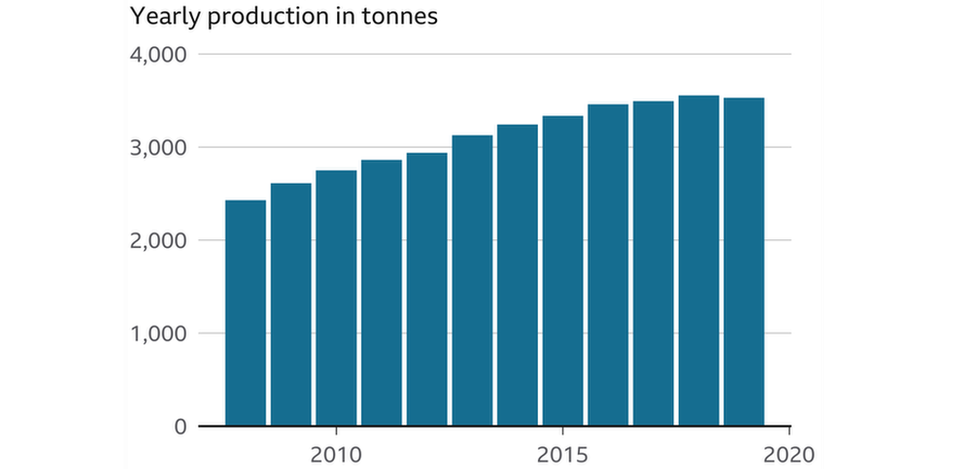

According to the World Gold Council, gold mine production totaled 3,531 tonnes in 2019, about 1% lower than in 2018, and this is the first annual drop in gold production since 2008.

“As the growth in mine output may slow or decrease slightly in the coming years, as current reserves are exhausted, and new major discoveries frequently become rare, suggesting that production has peaked might be a little precipitate yet,” states a spokesman for the World Gold Council, Hannah Brandstaetter.

Even when peak gold occurs, specialists say the years shortly after the peak is not expected to see a dramatic reduction in production. Instead, we will see a gradual consumption of output within a few decades.

“Mine production has flat-lined and is likely on a descending trajectory, but not dramatically so,” said Ross Norman of MetalsDaily.com.

IS Gold Renewable or Nonrenewable?

Mining companies expect the amount of gold that remains in the ground in two ways:

Reserves – gold that is economical to mine at the current gold value

Resources – gold that will probably become economic to mine after further investigation or at a costlier price level.

We can measure the number of gold reserves more accurately than resources, but this is still not a simple task.

The below-ground accumulation of gold reserves is currently expected to be around 50,000 tonnes, based on the US Geological Survey.

To put this amount in perspective, about 190,000 tonnes of gold have been mined in total. However, estimates vary from source to source.

Based on these rough numbers, there is about 20% of gold still to be mined. But that is a moving target.

Modern technologies may make it feasible to extract some explored reserves that aren’t currently practical to access.

The most recent innovations are using AI, big data, and smart data mining to optimize processes and bring down costs.

Robotics are already being employed at some sites and are expected to become standard technologies in mine exploration increasingly.

Biggest Sources Around the World

Witwatersrand Basin of South Africa has been the most significant single source of gold in history. Witwatersrand estimates to have roughly 30% of all the gold ever mined up to now.

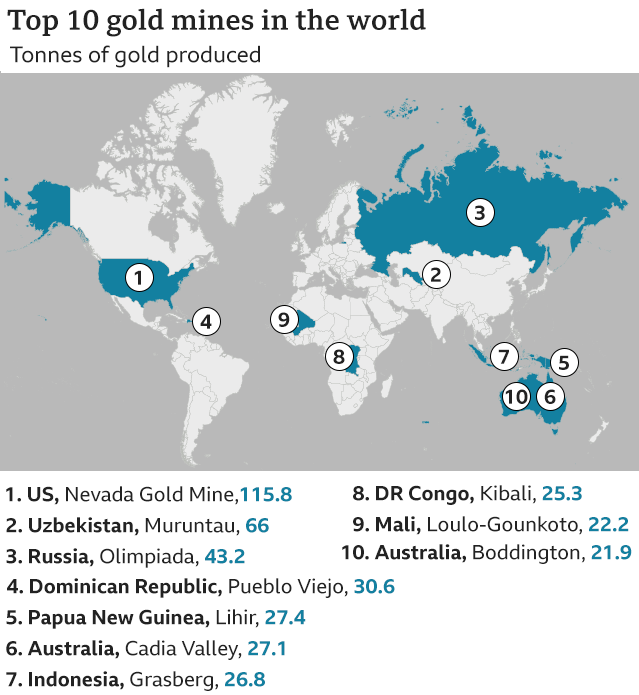

Other main sources of gold are the very deep Mponeng mine in South Africa, the Newmont Boddington and Super Pit mines in Australia, Grasberg Mine in Indonesia, and mines in Nevada, US.

Currently, the world’s biggest miner of gold is China, while Canada, Peru, and Russia are also major gold producers.

To compare the companies, Nevada Gold Mines is owned by Barrick Gold’s majority and is the single largest gold-mining complex globally. They produce around 3.5 million ounces per year.

Experts say, though new gold mines are still being discovered, finding large deposits is becoming increasingly rare.

Therefore, today’s gold production comes from earlier mines that have been mined for decades.

Is it Gets Harder to Mine?

Large-scale minings are incredibly capital-intensive, employing lots of expertise and machinery to mine vast fields below and on the surface.

Now, around 60% of the world’s mining developments are surface mines, while the remains are underground operations. “Mining is getting harder in the sense that many of the large, low-cost mines, and older ones such as in South Africa, are nearing exhaustion,” said Ross Norman.

On the other hand, gold mines in China are much smaller and consequently have higher costs. There are almost a few unexplored areas left for gold mining. However, perhaps the most hopeful mines would be in some of the world’s more unstable parts, such as West Africa.

Record Highs

Although gold prices hit records high in different periods, this doesn’t automatically explain a rise in gold mining activity.

“Changes in gold mine production often lag changes in the gold price much significantly,” Ms. Brandstaetter said: Given the scale of actions involved, it takes much time to alter mine plans in answer to changes in external circumstance factors, such as the price of gold.

Furthermore, the record costs have happened over Covid-19 restrictions, getting it harder to mine, as sites of mining were closed or partially shut down to control the spread of the virus. The pandemic has driven price rises as investors view gold as a safer investment in times of economic darkness.

Strange Places for Gold Discovery

As gold on the earth may be hard to reach, it should not think to be the only source. Gold also exists on the moon. However, the costs of mining gold and bringing it back here are significantly higher than the price of the gold.

Space expert Sinead O’Sullivan says, “Whilst it exists, it would never be economically meaningful to mine it,” and also adds, “You would lose an infinitely larger amount of money mining it than you would gain by selling it.”

Similarly, Antarctica has some known gold deposits that may never be economical to mine because of the continent’s extreme weather conditions. Also, gold is scattered along the ocean floor but is also regarded as uneconomic to mine.

An important factor gold has on its side, though, is that it can be recycled, unlike other nonrenewable resources like oil. So, never we will run out of gold, even while we can no longer mine it.

We use a large amount of gold in electronic products widely viewed as disposable, the same as mobile phones and laptops. The amount of gold in the average phone is worth just a few pounds. Attempts to recycle gold extracted from electronic waste are already well underway.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Is Wind Energy Renewable or Nonrenewable?

- Is Oil Renewable Or Nonrenewable: A Complete Research

- is biomass renewable or nonrenewable: Alarming information on this energy source

- Is Solar Energy Renewable or Nonrenewable: A Clear Answer