Generally speaking, low head turbines produce hydroelectric power where the head of the water is less than 20 meters although the precise definition varies. A hydraulic head is a vertical distance between the intake water level and the discharge water level. Low head drops in rivers or tides could provide a renewable energy source with minimal environmental impact. As generated power is a function of the head (calculated similarly to the general hydropower system), these systems are typically classified as small-scale hydropower systems that do not exceed 5MW.

In a hydroelectric generation, conventionally, large hydraulic heads are used to drive turbines. Typically, hydraulic heads are either created naturally, such as waterfalls, or artificially such as dams built in rivers. Turbines are driven by the controlled release of water from a reservoir. Many countries find traditional hydroelectric projects unpopular as a result of the cost and environmental impact of dam building. The introduction of new eco-friendly technologies has evolved since 2010 and is now economically viable: low head turbines.

Most hydropower systems with the low head are installed close to areas that need energy. So large electrical transmission lines are not necessary.

It is important not to confuse low head hydro with “free flow” technology, which uses kinetic energy and the velocity of the water.

Types of Low Head Hydropower

There are several standard low head hydropower scenarios:

Run-of-River Hydropower (RoR)

It is possible to generate low head hydroelectric power from rivers, known as river-of-run or run-of-the-river projects. Weirs, rivers, streams, locks, and wastewater outfalls are suitable locations for this purpose. Weirs are common along rivers throughout Europe. They are also common along canalized rivers and rivers that have groynes.

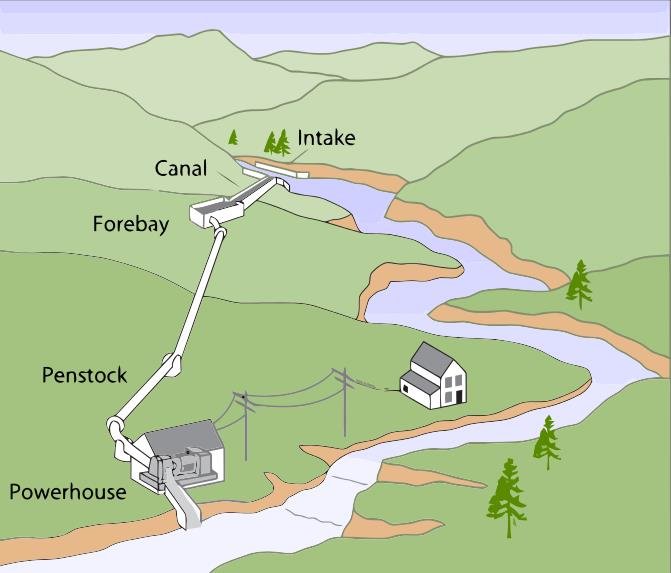

Conventional technologies typically require large volumes of water to generate significant power at low head locations. In order to drive generators efficiently, gearboxes must be used resulting in costly equipment and civil infrastructure. When run-of-the-river is used, the head is typically delivered by canals, pipes, or tunnels built upstream of the power houses. Because upstream construction is expensive, a steep drop such as falls or rapids is attractive.

Hydroelectric plants using run-of-river technology contain little or no water storage. Depending on the power plant, run-of-the-river operations may have no water storage or only have a limited amount of storage, whence storage reservoirs are called pondages. Those plants without ponds are subject to seasonal river flow patterns, so they operate as intermittent energy sources. Water is stored in conventional hydro reservoirs, which serve as flood control, an electric power source for dispatch, and fresh water provision for agriculture.

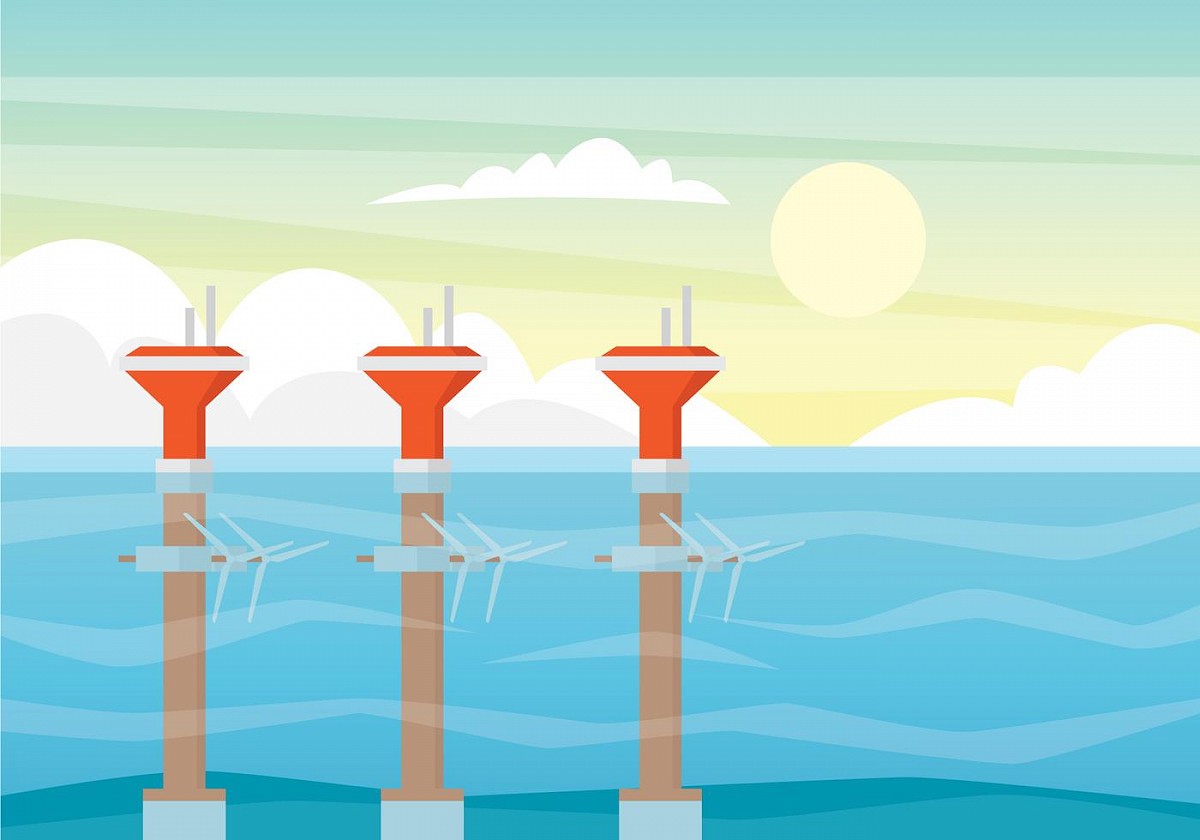

Tidal Hydropower

When combined with a barrage or lagoon, tides can create a head difference. Le Rance in France was the first place to open a tidal range.

In the future, tidal energy may be a significant source of electricity even though it is not currently widespread. There is more predictability in tides than in the wind or the sun. The main disadvantage of tidal energy among renewable sources has been that it is relatively expensive and difficult to find sites with strong tidal flow velocity or range.

In recent years, technological improvements have led to many technological developments that indicate tidal power could have a much higher capacity than previously assumed. Design improvements include dynamic tidal power and tidal lagoons with various configurations such as new axial turbines and cross-flow turbines. This can bring down economic and environmental costs to a competitive level.

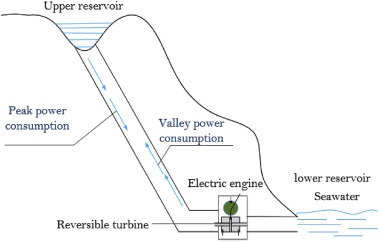

Low Head Pumped Seawater Storage

At the moment, these technologies are at very low TRL levels; however, they could become part of our energy system in the future. Load balancing is achieved via this form of hydroelectric energy storage. A turbine releases the stored water during times of high electricity demand to produce electric power.

Dynamic Tidal Power

Dynamic tidal power, a method for harnessing the power of tidal movement, presents another promising type of low head hydropower. Even though a dam-like structure is required, no area is enclosed, which allows most of the benefits of ‘dam-less hydro’ to remain while generating massive amounts of electricity.

Types of Low Head Turbines

Compared to those used in more conventional large hydro applications, turbines suitable for use with low heads may be different from Francis, propeller, Kaplan, and Pelton designs. Low head turbines come in a variety of types:

Archimedes Screw Turbines

In the small-scale hydro world, the Archimedean screw hydro turbine is relatively new, having only been introduced ten years ago. However, they have been present for many decades as pumps, with tens of thousands installed all over the world, particularly in wastewater treatment plants.

The Archimedean Screw Turbine functions in the same way as the Archimedean Screw Pump but is reversed. The weight of the water pushing on the screw blades causes the shaft to rotate when water enters the top of the shaft, allowing the water to fall to the lower level.

An electric generator can then be driven by the rotating shaft. Due to the low rotational speed, a gearbox is required. The screw is designed for low heads (1.5 to 5 meters) and medium to high flow rates (1 to 20 m3/s). In order to increase flow, multiple screws are employed. The construction and slow rotation of the turbine blades result in a large but friendly turbine for aquatic wildlife.

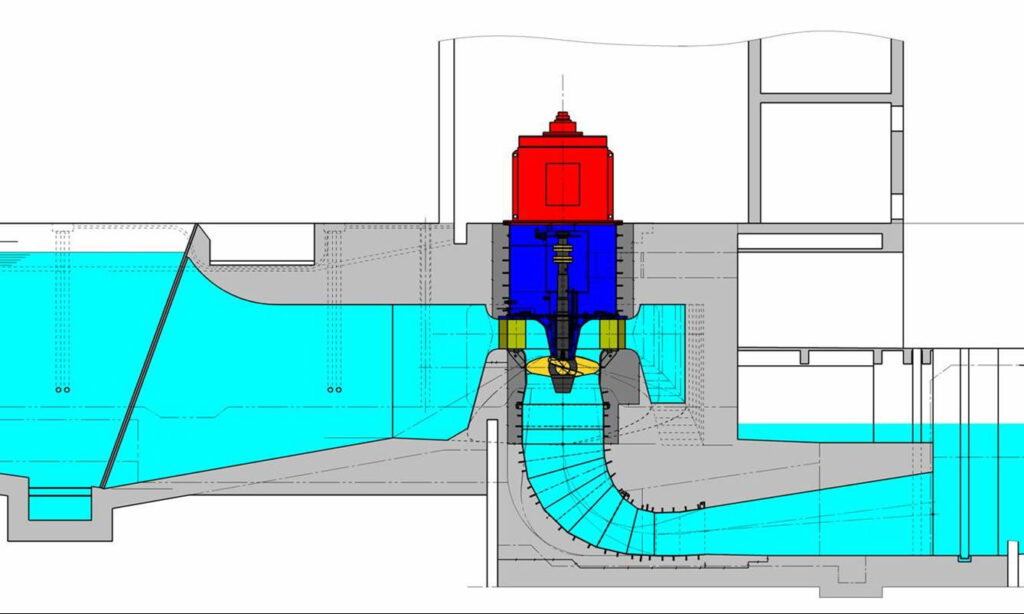

Kaplan Turbine

Kaplan turbines are propeller-type turbines that are capable of producing power at various heads and flow rates. Kaplan pumps can be operated at low to medium heads (1.5 to 20 meters) and a range of flows, from 3 m3/s to 30 m3/s. It is possible to use more than one turbine at high flow rates. These turbines can have an adverse effect on aquatic life. They usually require a complete screen out of the water.

VLH (Very Low Head) Turbine

The Very Low Head (VLH) turbine has been developed in Europe and works well for sites with low head in the range of 1.4 – 4.2 m. It includes an inclined Kaplan runner with eight blades. Installation of the VLH turbine is best suited to existing hydraulic structures due to its low environmental impact, low cost and high efficiency.

The machine has the advantage that it contains the turbine, the generator, the blades, and the trash rack cleaner all in one unit. All the turbines are packaged together and can be lowered into the waterway by a crane from the delivery truck. It is, therefore, possible to install a VLH in one week or less. It is not necessary for the owner of the waterway to have large machine halls or power units; a container-sized building will hold all the electronic equipment.

VLH turbines can be easily removed from the dam due to their compact size, for instance, in spring during high flow.

Among the most important considerations when developing the turbine was its environmental friendliness, and a special focus was placed on the fish-friendly design.

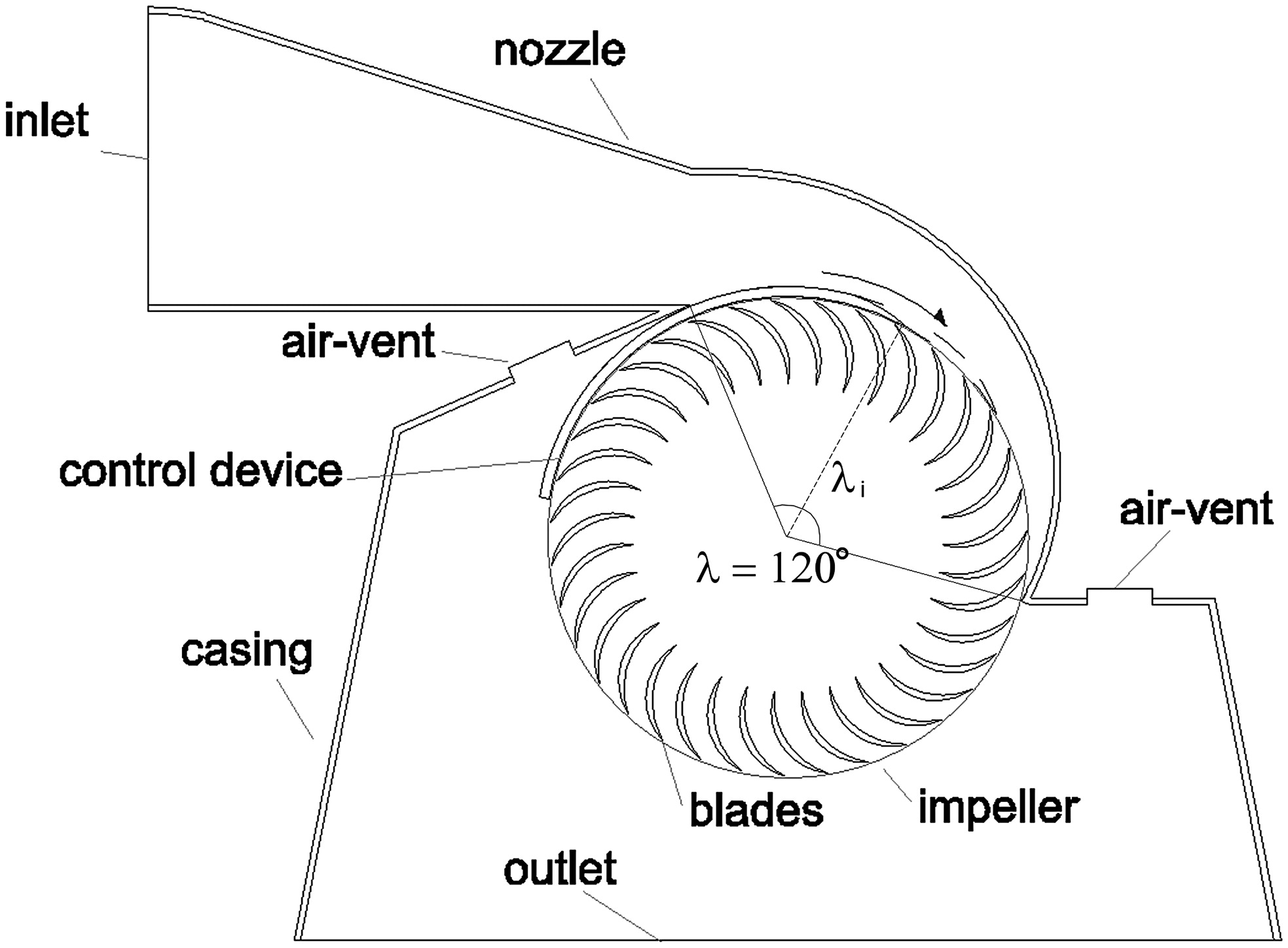

Cross Flow Turbine

These machines, also known as Banki-Mitchell turbines and Ossberger turbines, are used for hydraulic heads (between 2 and 100 meters) and flow rates (from 0.03 to 20 m3/s), although they are generally more efficient for low heads and low power outputs. Hence, they are referred to as “impulse” turbines since they rely on reducing water’s velocity for energy (all hydraulic energy is turned into kinetic energy). The risks to aquatic life are high, so they need to be thoroughly screened. To learn more about cross flow turbines, we suggest this link.

Venturi-Enhanced Turbine

A low head renewable energy opportunity of 1.5 to 5 meters can be economically exploited using Venturi-Enhanced Turbine Technology (“VETT”). Since it is a low-cost technology, its development began with small uses in onshore rivers.

Venturi turbines use pressure amplification to create smaller, faster, no-gearbox turbines that can be installed in low head hydro settings without requiring large infrastructure or large watercourses. When water passes through a venturi (a constriction), a low-pressure area is created. There is a higher differential pressure in this area of low pressure, meaning that a turbine discharging into this area will experience a higher head.

Fish and aquatic life can pass easily through the venturi (80% of the flow), preventing the need for large screens. However, only 20% of the flow passes through the propeller turbine. Various flow rates (1m3/s-20m3/s) can be handled with Venturi turbines. Parallel installation of multiple turbines is possible.

Water Wheel

When water flows or falls, water wheels convert the energy into usable power. They are used in watermills. In a water wheel, a wheel (often made from wood or metal), along with a set of blades or buckets, is used to create a driving machine. In addition to their low head requirements (1 to 5 meters) and medium flow requirement (0.3 to 1.5 m3/s), water wheels are considered safe for aquatic life.

Gravitation Water Vortex Power Plant

It is a type of micro vortex turbine system that uses a low hydraulic head of 0.7–3 meters to convert energy from a moving fluid into rotational energy. Hydropower plants of this type utilize gravitational water vortices, which only exist at low head. Basins with a central drain are used in the technology. A stable line vortex forms over the drain, driving a water turbine.

Issues to Consider When Using Low Head Turbines

The environmental impact of river currents and tidal turbines has raised several concerns. Here are a few of the most important:

Aquatic Life

Rotating blades pose a threat to aquatic life, such as fish. A screening system can be used within watercourses to eliminate the risk of moving parts contacting marine life. The technology is tested extensively by environmental regulators for safety and can be certified safe for smolts, mature fish, eels, seabirds, and marine ecosystems.

Bathymetry

It is undeniable that devices alter wave patterns and tidal streams, resulting in a change in how sediment is deposited. According to the research done to date, no significant effects have occurred or even experienced some benefits, i.e. slowing down coastal erosion. This is particularly relevant considering recent evidence that waves have grown steadily in size. In the lee of devices, the sea would probably be calmer than normal, but, it has been reported, this would create more space for activities like water sports and yachting.

Landscape

Considering sensitive environmental parameters can make obtaining a hydroelectric installation permit challenging in rivers and similar watercourses. There can be opposition to large infrastructure and other visible infrastructures above the water, such as Archimedes Screw systems and turbine houses.

Vibrations caused by gearboxes can also cause environmental objection due to feared impacts on nearby wildlife such as otters or birds. The main impact would probably be generated by the extensive transmission lines required to carry the energy from the shoreline to the final users. It might be necessary to use underground transmission lines to solve this problem.

Sediment Transportation

A weir and a groyne are historically used to manage water and to enable upstream transportation of riverine materials. The use of weirs and groynes may adversely affect water levels, as well as river bathymetry and fish migration. Low head hydropower turbines can provide increased sediment transport as well as fish migration pathways, either directly through the turbine or through the installation of fish ladders.

There is no harmful methane produced by low head dams and weirs. Weirs and groynes prevent silt (sediment) from moving downstream to fertilize fields and move sediment toward the oceans.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip