Most people are familiar with the First Industrial Revolution, which allowed production to leap forward due to the mechanization brought about by steam and waterpower. In the Second Industrial Revolution, production grew exponentially due to electric power. The Third Industrial Revolution was characterized by advances in information technology and electronics which allowed production to be automated. The world started moving into the Fourth Industrial Revolution in 2016. What is the Fourth Industrial Revolution and how does it impact manufacturing? We take a look at the answers.

What is the Fourth Industrial Revolution?

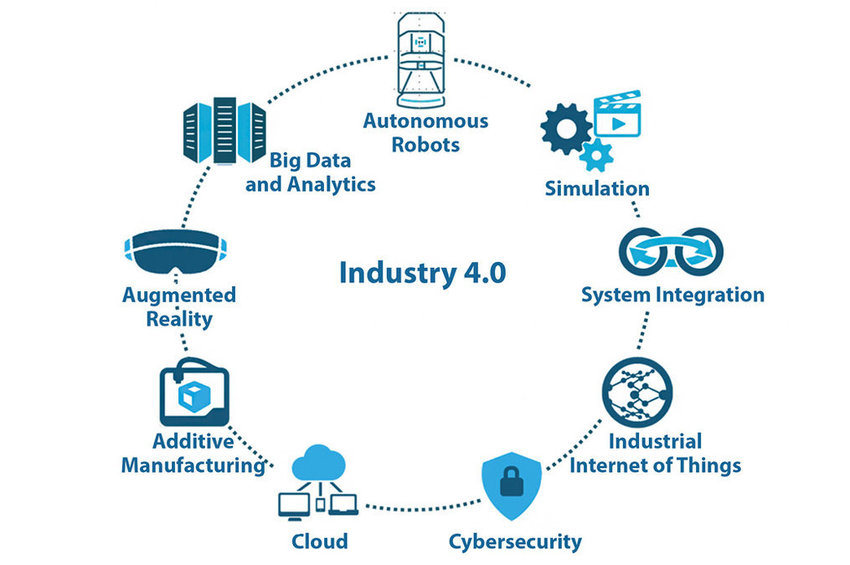

Well into the Fourth Industrial Revolution, many individuals have not even heard of it. An industrial revolution brings about a fundamental change in the way we produce goods, making us vastly more productive. The latest one has been ushered in by the practical uses of artificial intelligence and robotics, the Internet of Things, big data, and cloud computing. The global industry, known as 4.0 has an anticipated growth by 2026 of $165.5 billion.

The four key technologies driving this change include digital twin models, the Internet of Things, big data, and cloud computing. Digital twin models are based on the intersection of big data and the Internet of Things. The latter refers to the ability of modern technology to connect devices and equipment over the internet so that they can operate in concert. For example, a machine contains sensors to record speed, temperature, and other factors. This warns management of the need for maintenance before an actual break occurs, saving hundreds of thousands of dollars and keeping the business operational.

Unpacking These Technologies

Big data is made possible by the Internet of Things, which has provided the ability to gather large amounts of data for modeling and analytics. This information provides input into manufacturing processes, allowing them to be streamlined optimally. Together, big data and the Internet of Things lead to the simulation of designs and processes so that they can be tested in the virtual world before investing in the expenditure of the real item.

Cloud computing provides the infrastructure that makes all this possible. Nowadays, businesses can buy software applications or platforms from vendors. These internet bases are used to carry out the functionalities already mentioned. Clients only need to pay for the services they require instead of having to create their own gateways.

Essentially, the Fourth Industrial Revolution has caused an alignment between digital manufacturing and the biological and physical realms so that they work as one, seamlessly.

How Manufacturing Benefits from the Fourth Industrial Revolution

Predictive maintenance allows manufacturers to determine the best service and repair times for their machinery. It looks at trends in breakdowns and repair schedules to predict the optimal schedules so that managers of equipment are never caught off guard and decreases downtime for key manufacturing processes. Additionally, machines are used fully for as long as they will be productive.

Smart factories take advantage of the advancement of technology to monitor inventory levels. New materials or equipment parts can be automatically ordered in time, without human input. Thus, there are no delays in production. More processes can be automated, making employees available for more complex tasks.

One can only wonder what the Fifth Industrial Revolution will look like.