Drafts which are produced by the rising combustion gases in the stack, flue, or by mechanical means, play an important role in cooling towers. In fact, mechanical draft cooling towers are the all-rounders among the cooling towers. Now if you are interested in learning more about the mechanical draft, read the following article in Linquip to get acquainted with this type of draft and its benefits.

What is a mechanical draft?

It is a draft used in some gas burning appliances and cooling towers to remove flue or vent gases by mechanical means, such as a fan, which may include an induced draft portion under non−positive static pressure or a forced draft portion under positive static pressure.

Mechanical Draft Importance

For the proper and the optimized heat transfer from the flue gases to the boiler tubes draft is of high amount of significance. The combustion rate of the flue gases and the amount of heat transfer to the boiler are both dependent on the movement and motion of the flue gases. A boiler equipped with a combustion chamber which has a strong current of air (draft) through the fuel bed will increase the rate of combustion that is the efficient utilization of fuel with minimum waste of unused fuel. Furthermore, the stronger movement will also increase the heat transfer rate from the flue gases to the boiler which as a result, improves efficiency and circulation.

Mechanical Draft Cooling Towers

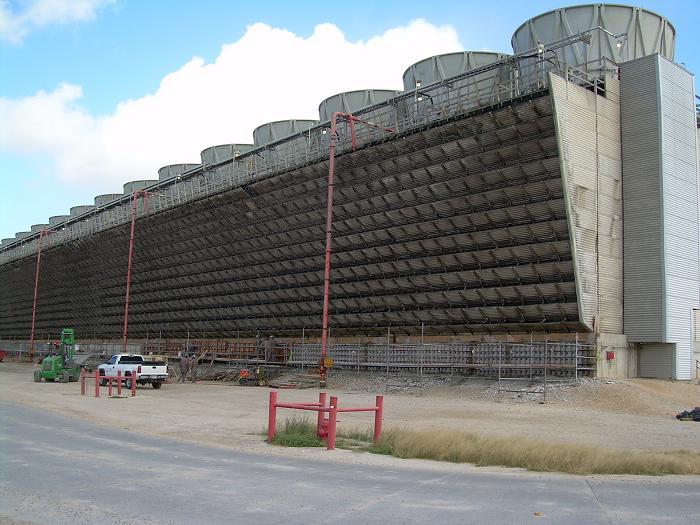

Mechanical draft cooling towers are the most widely used in buildings which rely on power-driven fans to draw or force the air through the tower. In other words, air is circulated inside the tower mechanically by use of propeller fans or centrifugal fans. They are normally located outside the building. Mechanical draft towers come with a compact design and are powerful and variably adaptable to the respective operating and climatic conditions. Furthermore, they are the ideal solution for industrial applications such as in power plants, chemical and petrochemical plants, steel plants, air separation plants, in the automotive industry, in timber and paper factories as well as in air conditioning/ refrigeration systems. The two most common types of mechanical draft towers are induced draft and forced draft.

- Forced Draft Cooling Towers: In this system, fan is located near the bottom and on the side. This fan forces the air from bottom to top. An eliminator is used to prevent loss of water droplets along with the forced air. Such a design has the disadvantages of air distribution problems, leakages and recirculation of the hot and moist air back to the tower.

- Induced Draft Cooling Towers: In this system, a centrally located fan at the top, takes suction from the tower and discharges it to the atmosphere. Air enters the sides of the tower at low velocity through large openings and passes through the fill, whereas the hot humid air is exhausted to the atmosphere through the ventilator. This maintains the tower at a negative pressure which reduces leakage.

The only difference between the induced draft cooling tower and forced draft cooling tower is that the fan is located at the top in the induced draft cooling tower.

Mechanical Draft Cooling Towers Advantages

Here are some advantages of mechanical draft cooling towers over natural draft cooling towers.

- For the same capacity used, the mechanical draft cooling towers are much smaller than the natural draft cooling towers. This is because of the increase in cooling capacity due to increase in volume of the air being forced out by fan.

- Capacity control is possible in mechanical draft cooling tower. By controlling the speed of the fan, the volume of air can be controlled, which in turn controls the capacity.

- The natural draft cooling towers can be located only in open space. As they do not depend up the atmospheric air, the mechanical draft cooling towers shall be located even inside the building.

Mechanical Draft Cooling Towers Disadvantages

- In Mechanical draft towers more power is required to run the system.

- In this type of towers, running cost is higher due to increase in maintenance of the fans, motors and its associated controls.

So this is all you need to know about mechanical draft and its use within a system. If you enjoy this article and want to share your experience with mechanical draft cooling towers in Linquip, let us know what you think by leaving your idea in the comment section. Is there any question we can help you with? Feel free to sign up on our website where our experts waiting to give you the professional advise you need.