Motors are used when there is a need to move something, and motor efficiency identifies how cost efficient that movement is. Motors usually produce some rotational motion that is transferred to the end compartment which uses that motion. Some of the power generated by motors gets lost on the way due to factors such as friction or heat loss; therefore, motor efficiency is the ratio of the energy actually used to the energy put into a mechanical system. It is clear that a more efficient motor could guarantee lower operational costs, which is what every motor user is looking for.

Since we are committed here at Linquip to provide our customers with the easiest ways of finding their desired equipment, not only we have established a platform for you to find the motor you need here, but also we have tried to explain in this post how you could make a more insightful decision about which motor might be a better choice for your application.

Some Terminology

Before continuing further with the motor efficiency and its estimation, let us first see some important terminology:

- Work

Work is the amount of energy that could be used to move a mass through a distance by applying some force.

- Power

Power is the amount of work done per unit time.

- Efficiency

A measure of how much of the input energy to the system can be turned into the output energy or work.

- Rated load

The maximum load a machine can deliver where its efficiency would still be high enough.

- Full load

The maximum load a machine can deliver.

- Power factor

The ratio of the real power to the apparent power in a circuit.

The real power is the amount of electrical power actually used, and the apparent power is the total electrical power delivered to the circuit.

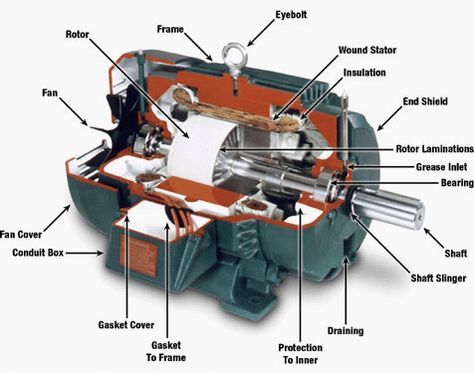

- Rotor

The moving part of the electric motor which rotates the shaft to produce mechanical energy.

- Stator

The stationary part of the motor that has some windings or a fixed magnet with a core made of different sheets of metals or lamination.

Calculating Motor Efficiency

The overall motor efficiency is simply the output power of a motor divided by the power supplied to it. The input power is most likely from the power grid and the output power is what that is used to do some mechanical work. Therefore, we have:

Motor\ efficiency=\eta\ =\frac{Motor\ output\ power}{Motor\ input\ power}\times100

Now, this overall motor efficiency which is also called the commercial efficiency can be decomposed into electrical and mechanical efficiencies:

Electrical\ efficiency=\eta_e=\frac{The\ developed\ mechanical\ power\ in\ the\ armature}{Motor\ input\ power}\times100

Mechanical\ efficiency=\eta_m=\frac{Motor\ output\ power\ }{The\ developed\ mechanical\ power\ in\ the\ armature}\times100

It is clear that the commercial motor efficiency would be the multiplication of its mechanical efficiency and electrical efficiency.

The electrical efficiency is due to losses which are known as copper (denoted by Cu on the periodic table) losses. What remains after the Cu losses is the ‘developed power’ in the armature. This developed power will also undergo some losses known as friction and iron losses. The final power is the output or mechanical power delivered at motor shaft, letting us now to calculate the mechanical efficiency of the motor.

Now, when you want to calculate motor efficiency, you will most likely know about your motor rated power output hp (horsepower), its load (the current output power as a percentage of its rated output power), and the input power in KW. Therefore, the formula for motor efficiency would be:

\eta=\frac{0.7457\ \times m o t o r\ horsepower\ \left(hp\right)\times l o a d}{Motor\ input\ power\ \left(KW\right)}

The number 0.7457 is a correction factor to convert hp to KW.

In addition to the above formula, there is another approach to calculating motor efficiency. Instead of load and its input power, you might have other measurements such as the current, voltage, motor torque and RPM. With these parameters you can calculate motor efficiency as follows:

P_{in}=current\ \times voltage=I\ \times V

P_{out}=torque\ \times rotational\ velocity=\tau\ \times\omega

\omega=\frac{2\pi}{60}\ \times RPM

\rightarrow\eta=\pi/30\ \ \times(\tau\ \times\ RPM)/(I\ \times V)

So, if you have a motor with 80% efficiency, you could only use that much of the input power, and 20% of your input energy would be lost through heat dissipation, which is evident in the temperature rise of the equipment.

Now, we always hear that we should look for more efficient systems. While that is true, we need to appreciate the fact that ‘energy efficiency’ does not necessarily correspond to ‘cost efficiency’. To elaborate on this regarding motors, you might use the motor in places where the operating time of the motor is low or the electricity is not expensive. Considering the fact that more efficient equipment are generally more expensive than their less efficient counterparts, you might not be able to tradeoff the higher initial cost with your operational cost savings any time soon, which might present your purchase as a mistake from a financial point of view.

Nonetheless, the power costs and operating time is high for most applications, making efficient motors the better choice both technically and financially. National Electrical Manufacturers Association (NEMA) has introduced a design and labeling protocol for three phase motors, which have considerably higher efficiencies than single phase motors, categorizing them in A, B, C, and D design types. Almost 90% of induction motors used in the market for general purposes are of the design B type. Now, let us see an example of how efficient a standard B design motor operates against an energy-efficient one in average.

| Rated hp | Standard Motor* | High-Efficiency Motor* |

| 1.0 | 75.5 | 82.6 |

| 1.5 | 78.1 | 83.3 |

| 2.0 | 80.5 | 83.8 |

| 3.0 | 81.2 | 87.7 |

| 5.0 | 82.8 | 88.6 |

| 7.5 | 83.8 | 89.8 |

| 10.0 | 85.2 | 90.1 |

| 15.0 | 86.8 | 91.3 |

| 20.0 | 87.8 | 91.9 |

| 25.0 | 88.3 | 92.8 |

| 30.0 | 89.1 | 92.7 |

| 40.0 | 89.6 | 93.3 |

| 50.0 | 90.5 | 93.8 |

| 60.0 | 90.6 | 94.1 |

| 75.0 | 91.2 | 94.4 |

| 100.0 | 91.8 | 94.7 |

| 125.0 | 92.4 | 95.3 |

| 150.0 | 92.9 | 95.5 |

| 200.0 | 94.0 | 95.4 |

Now, imagine you want to make up your mind about purchasing a motor. Take the example of 10 hp motor with an efficiency of 85%. The following table shows how fast more efficient motors despite being more expensive will eventually offset the initial cost of purchasing an energy-efficient motor.

| Standard Motor | High Efficiency Motor | |||

| A | B | C | ||

| Efficiency | 85.0 | 87.5 | 88.5 | 89.0 |

| Electricity Required (kW) | 8.78 | 8.52 | 8.43 | 8.38 |

| Initial Cost | $180 | $224 | $252 | $279 |

| Difference in Initial Cost | -0- | $44 | $72 | $99 |

| %Life Annual Cost | $22.50 | $28.00 | $31.50 | $34.88 |

| Difference in %Life Annual Cost | -0- | $5.50 | $9.00 | $12.38 |

| Annual Electric Cost | $2,107 | $2,045 | $2,023 | $2,011 |

| Difference in Electricity Costs | -0- | -$62.00 | -$84.00 | -$96.00 |

| Total Annual Cost | $2,130 | $2,073 | $2,055 | $2,046 |

| Initial Cost Return – Years | -0- | 0.71 | 0.86 | 1.03 |

These two tables were adopted from NEMA Publication MG-1.

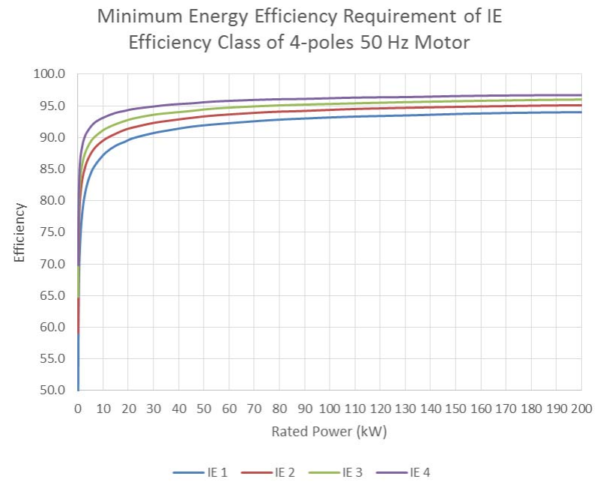

Motor Efficiency and Its Classes

There are two different ways of classifying motors based on their efficiencies. One of the methods of such classification is the EFF classification. EFF, which is comprised of three different classes of EFF1, EFF2, and EFF3 has been used in Europe and some other countries around the world. The other method of classification is the International Efficiency (IE) introduced by the International Electrotechnical Commission (IEC) which is adopted internationally.

| Class Type | IE | EFF |

| Below Standard Efficiency | – | EFF3 |

| Standard Efficiency | IE1 | EFF2 |

| High Efficiency | IE2 | EFF1 |

| Premium Efficiency | IE3 | |

| Super Premium Efficiency | IE4 | |

| Ultra-Premium Efficiency | IE5* | |

| * IE5 is currently under preparation for the next revision of IEC 60034-30-1, which intends to lower the losses by 20% compared to IE4. | ||

This classification is intended for single and three phase electric motors with 2, 4, 6, and 8 poles with rated output ranges of 0.12KW to 1MW, rated voltage of up to 1 kV, frequency of 50Hz to 60Hz.

Maintaining the Motor Performance and Improving Motor Efficiency

Every system has losses that lead them to deliver less output than their input. This is why we deal with system efficiency one of which being the motor efficiency. There are different reasons behind such losses in motors such as friction, dissipation of magnetic energy in electric motors, resistance losses, etc. It is clear that lowering motor losses will enhance the motor efficiency.

One thing to keep in mind is to continuously have your motor monitored. This means as well to keep a record of your motor(s)’s age, the output power provided as well as the rating of the motor(s), which can be used to calculate the motor efficiency over time. In addition, you need to keep an eye on the voltage unbalance, current unbalance, and power factor (PF). It is clear that you want a PF close to 100%.

Some of the methods that could be employed for improving motor efficiency include the following:

- Motor stators are the major reasons for motor losses. It is reported that they could account for approximately 30% or even higher percentages of the entire motor losses. In order to reduce their corresponding electrical resistance losses, you need to keep the mass of stator winding at larger values.

- Another very important cause of motor losses is the magnetic hysteresis that can be alleviated by using higher quality material such as silicon-containing steels that could remove the core magnetic losses. Increase of lamination length while decreasing its thickness could also lower magnetic flux density and hence core losses.

- There is a phenomenon called slip which is a measure of the difference between RPM of the magnetic field and the actual RPM of the rotor and shaft at a given load. One needs to lower slip, which means they need to increase the conductivity of the rotor. This can be done by using some highly conductive material such as die case copper for the rotor.

- You need to make sure the cooling system performance has not been compromised. In order to do that, you may periodically clean the motor surroundings and check for possible air obstruction flowing onto its frame and corresponding compartments. Speaking of the motor frame, it should be in good condition so that not only it would keep the motor at its place, but also guarantee a proper heat transfer from the inside to the outside surface where it is cooled by the air.

- Losses due to eddy currents will be reduced by using better insulation between the lamination or the sheets.

- Lubrication of the motor is another important factor for having an efficient performance of the motor. Make sure not to use different types of grease at the same time, and keep an eye on the lubrication intervals based on the installed rated speed of the motor, bearing size, type of grease and the temperature rise.

Q&A

What is motor efficiency?

A measure of the fraction of input energy to the motor that will actually be turned into the output work.

Why is motor efficiency so important?

To lower operational and maintenance costs of the system. To know more about this, watch here.

What is the acceptable range of motor speed?

Motors are usually designed to work at 50% to 100% of their rated RPM.

At what speed would the motor operate at its highest efficiency?

Motor efficiency is usually at its maximum value around 75% to 80% of the rated speed.

Is there a difference between power factor and efficiency?

Yes! Efficiency is simply the ratio of output power to the input power of the motor, while the power factor is the amount of electrical power used by it to the amount delivered to it. You can increase PF by fitting a power factor correction mechanism to the motor, while still having the same motor efficiency.

Do I need to calculate the motor efficiency myself?

No, there are efficiency calculator software packages out there, which might also be supplied by the motor vendor.