Parts of CNC Machine + Function – Some significant components and elements that contribute to the machine’s efficacy are present in machine tools with CNC systems. Before utilizing any CNC machine, one must be familiar with the control code, according to a previous post. We have looked at two G-codes and two M-codes.

Basics of CNC Machining?

Understanding the CNC process and how it functions will help you better grasp the challenges associated with properly using your data for a CNC-controlled machining or cutting operation. This little introduction should be useful.

Some Basic Definitions

CNC: Computer Numerical Control – A computer and CAM software are used to automate, control, and observe the motions of a machine using digital data. The machine might be a robot, router, lathe, grinder, welder, sheet metal stamping machine, laser or waterjet cutter, or any number of other devices. The computer is often an on-board specialized controller for bigger industrial machinery. However, the computer can be an external PC for machines that are more suited to hobbies or with certain retrofits. In order to move and control the machine axes and carry out the preprogrammed movements, the CNC controller collaborates with a number of motors and drive components. The advanced feedback system that continuously analyzes and modifies the cutter’s speed and position is often present on industrial equipment.

Desktop CNC: There are a lot of smaller desktop CNC machines designed for model makers and hobbyists. These are often less costly, slower, less accurate, less stiff, lighter, and less rigid than their industrial equivalents, but they work well for milling things made of softer materials like plastic, foam, and wax. Some desktop computers may operate quite similarly to a printer. Others may even have specialized CAM software and their own closed command system. A few will also take input in the form of regular G-code. Certain desktop industrial standard machines have specific controllers for performing fine tiny operations.

CAM: Computer-Aided Machining or Manufacturing – This is the process of using different software programs to generate toolpaths and NC code for a CNC-operated machine based on data from 3D computer models (CAD). The combination of the two is frequently referred to as CAD/CAM.

It should be noted that CAM only generates code for the CNC machine to follow. Additionally, it does not import your CAD model and automatically generates the appropriate NC code. In order to execute the program, create machining strategies, and know which tools and operations to employ in each circumstance to produce the best results, CAM programming, like 3D modeling, requires knowledge and expertise. While there are certain straightforward programs that a novice user can pick up and use without too much trouble, more complex models require time and financial commitment to become skilled.

NC code: This is a unique, relatively basic computer language that can be understood and used by CNC machines. These languages were first created to enable direct part programming at the keyboard of the machine without needing a CAM application. Along with managing other machine operations like spindle and feed speeds and coolant, they instruct the machine on what actions to do one at a time. The most widely used language is G-code, often known as ISO code, a basic alphanumeric programming language created in the 1970s for the first CNC machines.

Postprocessor: Although G-code is regarded as the industry standard, individual manufacturers are free to change certain components, such as auxiliary functions, making it possible for G-code designed for one machine to malfunction on another. Many machine makers have also created their own programming languages, including Heidenhain and Mazak. Therefore, there is a bridge software component software called a postprocessor to convert the internally determined routes of the CAM software into precise NC code that the CNC machine can interpret. Once properly set, the post processor generates the appropriate code for the selected machine, allowing any CAM system to produce code for any machine theoretically. Postprocessors may come with the CAM system for free or at an additional fee.

How Do CNC Machines Work?

All-automatic CNC machines are available nowadays. All they need are digital files with details on the cutting instruments and trajectories.

A variety of tools are required for design or machining procedures to produce a particular product. Digital tool libraries that are connected to the actual machine can be made by machinists. Because they can switch tooling automatically based on digital instructions, these machines are production workhorses.

The initial stage of CNC production is the component design using CAD software. The 3D model is used to establish the necessary dimensions and features for the finished product.

Since several of these programs are part of CAD-CAM packages, the flow can continue in the same programs. Otherwise, CAD models are employed with CAM software. If the CAD and CAM systems are from the same product family, no file translation is necessary. Otherwise, the CAD files must be imported.

Thanks to CAM (computer-aided manufacturing) software, the model is prepared for the full production process. It starts by checking the model for errors. Then, CNC software is used to construct the real piece.

The program is simply a set of coordinates that directs the cutting head throughout the production process.

The final step is choosing the proper parameters. These include parameters like voltage, RPMs, and cutting speed. The configuration is influenced by the part’s shape as well as the equipment and tooling that are available.

Finally, the software chooses the nesting. The term “nesting” describes how parts are arranged and orientated in relation to raw resources. The objective is to make the most out of the resources.

Then, using all of this data, M-code and G-code are generated, which the machinery can understand.

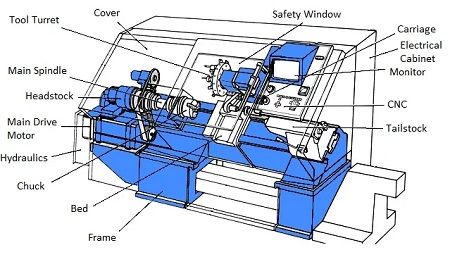

13 Parts of CNC Machine

13 Parts of CNC Machine are:

- The Input Device

- Machine Control Unit

- Machine Tools

- The Drive System

- Feedback Mechanism

- Display Unit

- Bed

- Headstock

- The Tailstock

- Tailstock Quill

- Pedal or a Footswitch

- Chuck

- The Control Panel

The primary components of a CNC machine are represented by the following:

The Input Device

These are the tools used to enter part-programming data into a CNC machine. Three types of input devices are often used: magnetic tape readers, punch tape readers, and computers connected via RS-232-C.

Machine Control Unit

The CNC machine’s brain is here. The MCU completes all of the CNC machine’s controlling operations. It completes and decodes the provided instructions and reads them among the many jobs. The coded instruction is decoded by it. This axis employs interpolation (linear, spherical, and helical) to create motion commands.

It supplies the amplifier circuit driving the spindle mechanism with the axis speed order. For each driving axis, it gets feedback signals indicating position and speed. It supports auxiliary control features like tool change, coolant, or spindle on/off.

Machine Tools

To manage position and speed, a CNC machine tool is always equipped with a sliding table and a spindle. The X, Y, and Z axes of the machine are used to operate the tables, while the Z-axis is used to control the spindle.

The Drive System

The ball drive motors, lead screws, and amplifier circuit make up the CNC machine’s driving system. The MCU provides the amplifier circuit with the signals (i.e., position and speed) from each axis.

The drive motors are then turned on by amplifying the control signals. And to position the machine table, actuated drive motors turn the ball lead screw.

Feedback Mechanism

Transducers, which serve as sensors in the system, are used. Another name for it is a measuring system. It is made up of position and motion transducers that constantly track the location and movement of the cutting tool.

The MCU receives signals from these transducers and creates control signals to rectify position and motion faults by comparing reference signals to response signals and comparing response signals to reference signals.

Display Unit

Programs, instructions, and other essential information about the CNC machine are shown on a monitor.

Bed

On CNC machines, these components carry the whole machine’s weight, necessitating mounting all other parts. Due to the fact that the tool turret in CNC lathe machines travels over them, the bed component is built of harder materials like cast iron.

Headstock

Due to the fact that the workpieces are secured to the headstock, it is one of the key parts of CNC lathe machines. The primary axle of the CNC lathe is driven by motors.

The Tailstock

When a CNC machine is used to conduct tasks like noodling, threading, and turning, this lathe gives the workpiece more grip. On the workpiece’s end surfaces, support is offered.

Tailstock Quill

Thanks to the tailstock quill, the workpieces are more evenly distributed between the headstock and the tailstock.

Pedal or a Footswitch

The tailstock quill is transferred to the forward and reversed positions, for example, as the pedal is utilized to open and shut the chuck while attempting to grip the component.

Chuck

Because the chuck is positioned on the main axle, the tool has room to fix.

The Control Panel

Control panels are one of the key components of CNC machines that are utilized to set or feed programs for the operation to be carried out on the workpieces. It is sometimes referred to as the CNC machine’s brain.

Advantages of CNC Machining

CNC machines assist manufacturers in enhancing productivity and accuracy and help lower the risk of human error by enabling them to automate various production operations that would otherwise need to be carried out manually.

Here are 5 significant ways they have changed engineering:

CNC Machining Is Excellent For Producing Lots Of Parts

If you need to produce more mechanical components in larger quantities (from the upper double digits to the 100s), CNC is likely to be the most cost-effective option since it is far less expensive to use CNC machining than 3D printing.

Various Materials May Be Worked On Using CNC Machines

While CNC machines are usually unconcerned with the materials they are cutting, 3D printing primarily focuses on plastics as long as the material is robust enough to avoid deforming or melting under the pressure of the cutting operation. At Geomiq, we take great care to use the appropriate material for each item and provide over 60 production quality materials for CNC machining. Aluminum, stainless steel, magnesium alloy, zinc alloy, titanium, and brass are the metals utilized most frequently.

CNC Equipment Produces Items Swiftly

You likely won’t be surprised to learn that machines operate more quickly than people do. You may receive the final goods in as little as 5 days when you purchase your CNC machined components from a perfect CNC machine.

CNC Equipment Is Very Precise

A typical CNC tolerance is +/- 0.127mm, and when you utilize the tolerance configurator, you can anticipate precise machining down to +/- 0.005mm, giving you an indication of how exactly they are.

There Are Several Post-Processing And Finishing Choices With CNC Machining

For instance, a CNC machine provides high-quality finishing procedures, including anodizing, polishing, heat treating, plating, powder coating, and more, for the majority of CNC-machined parts.

Limitations of CNC Controlled Machines

CNC machines’ capabilities may be constrained by the sophistication and age of their control and drive systems. The majority of CNC controllers only comprehend circular arcs and straight-line motions. The arcs are often only allowed on the main XYZ planes in many machines. Rotating an axis can be thought of as moving linearly, only in degrees rather than in space. Two or more axes must interpolate (move precisely and synchronously together) in order to produce arc motions or linear movements that are at an angle to the major axis. Also capable of simultaneous interpolation are rotary and linear axes. Five-axis machines require that all five be precisely synced, which is a difficult undertaking.

It is crucial that the machine controller can interpret incoming data quickly, send orders to the drive system, and keep track of the machine’s speed and location. In this regard, older and less costly devices are plainly less competent, much as how an older computer would perform demanding tasks less effectively and more slowly (if at all) than a modern one.

Conclusion

This post has produced a collection of data on CNC machining, its working principle, applications, limitations, and advantages. You are also encouraged to visit the Linquip website to learn more about these machines, as well as to find providers of additional industrial and commercial items. You can also visit our CNC Milling Machines Suppliers and Companies to find out a complete list of CNC machine products and suppliers.

FAQs about CNC Machining

1. How Does A CNC Machine Work Step By Step?

In order to move and control the machine axes and carry out the preprogrammed movements, the CNC controller collaborates with a number of motors and drive components. The advanced feedback system that continuously analyzes and modifies the cutter’s speed and position is often present on industrial equipment.

2. What Is G-Code and M Code?

The machine control language, often known as M code or G code, governs the whole program. M code governs the machine’s activities, whereas G instructions define locations. Although M stands for many codes, some people refer to it as machine code since it manages specific equipment functions.

3. How Many Types Of CNC Machines Are There?

CNC machines come in eight different varieties: mills, routers, lathes, plasma cutters, laser cutters, water jet cutters, electrical discharge machines (EDM), grinders, and water jet cutters.

4. Is CNC Easy To Learn?

If you have a basic understanding of technical design, computer and arithmetic skills, and manual machining expertise, you may become proficient at writing G-code and 2d-CAM programs in just one week.

5. Can You Teach Yourself CNC?

Given a rudimentary understanding of math and an understanding of how milling functions, learning very basic CNC programming is simple. Usually, you can master this within a few days. While learning advanced CNC programming might take many years, learning intermediate programming abilities can be taught in a year.

6. What Are The Main Components of a CNC Machine?

Three fundamental parts make up a computer numerical control (CNC) system: processing apparatus, often known as a machine tool, a machine control unit, and CNC software, which is a set of instructions.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What Is CNC Machining & How Does It Work? (A Comprehensive Guide)

- 10 Types of CNC Machine + Applications & Pdf

- 10 Best CNC Machines & Routers for WoodWorking 2022 (Clear Guide)

- 8 Different DC Motor Parts, Structure, Design and Advantages + PDF

- Types of Synchronous Motors: A Full Description

- Types of Induction Motor: A Concise and Useful Guild

I was looking for types of CNC machining and components of CNC machinings and I found your article its very informative the information you provide in this article is very informative.

Thanks for visiting our website, Elizabeth! Your comment made our day! You are also encouraged to visit Linquip website, where you can find thousands of industrial equipment, companies, and experts based on your need.

I GAIN SOME KNOWLEDGE TO READ THESE…. ?

Thanks for visiting our website and leaving your comment, Koneti! You are encouraged to visit Linquip Tech News, where you can find similar posts.