Like any machine, a DC generator consists of different parts. It is an electrical instrument that transforms mechanical energy into electricity. The working principle, different types as well as pros and cons will be discussed besides parts of DC generators in detail at Linquip.

A DC generator may be utilized as a DC motor without any changes in construction, and vice versa. A DC machine can therefore be defined as a DC generator or a DC motor. These fundamental building characteristics also apply to the design of a DC motor. As a result, instead of just referring to this point as the “building of a DC generator,” we’ll refer to it as the “construction of a DC machine.” Parts of DC generators are available from a variety of Suppliers and Companies, as well as manufacturers and distributors, with several DC Generators for Sale on Linquip.

There is a comprehensive list of DC generator services on the Linquip website that meets all of your needs. Linquip can connect you with several DC Generator Service Providers and experts who can help you. Linquip can provide you with a list of DC Generator Professionals and subject matter experts who can help you test your equipment.

⇒ View a List of Generator for Sale and Their Suppliers ⇐

Parts of the dc generator

A DC generator is often used as a DC generator motor without altering its construction. So, a dc generator motor may usually be called a DC machine. The key parts of DC generators are yoke, poles, pole shoes, armature core, armature winding, commutator, brushes, magnetic field system, commutator, end housings, bearings, and Shafts.

These are the parts of DC generators and will be discussed below in more detail.

12 Parts of DC Generators are:

- Stator

- Rotor or Armature Core

- End Housings

- Bearings

- Yoke

- Poles

- Pole Shoe

- Commutator

- Brushes

- Shaft

- Magnetic Field

- Armature Windings

Stator

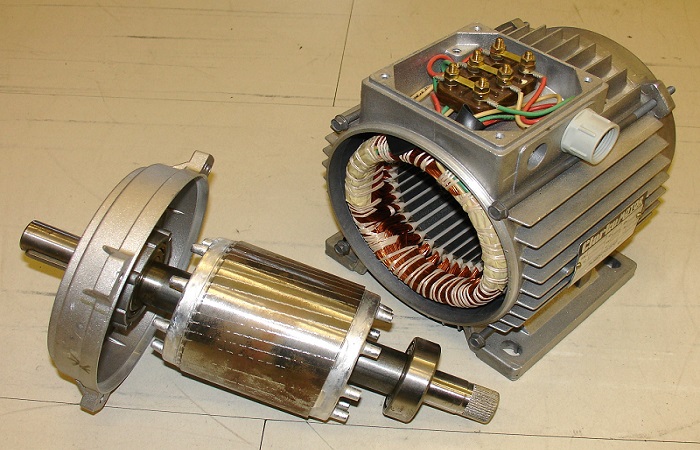

A direct-current (DC) generator consists of two main parts, a rotating section and a fixed one. Stator is the stationary part of this system that includes a core, stator winding, and the outer frame and houses the rotor (the rotating part) in its core.

Among parts of dc generators, the stator is a key component and its main function is to supply magnetic fields around which the coils spin. This contains stable magnets with opposite poles facing two of them. These magnets are mounted in the rotor field.

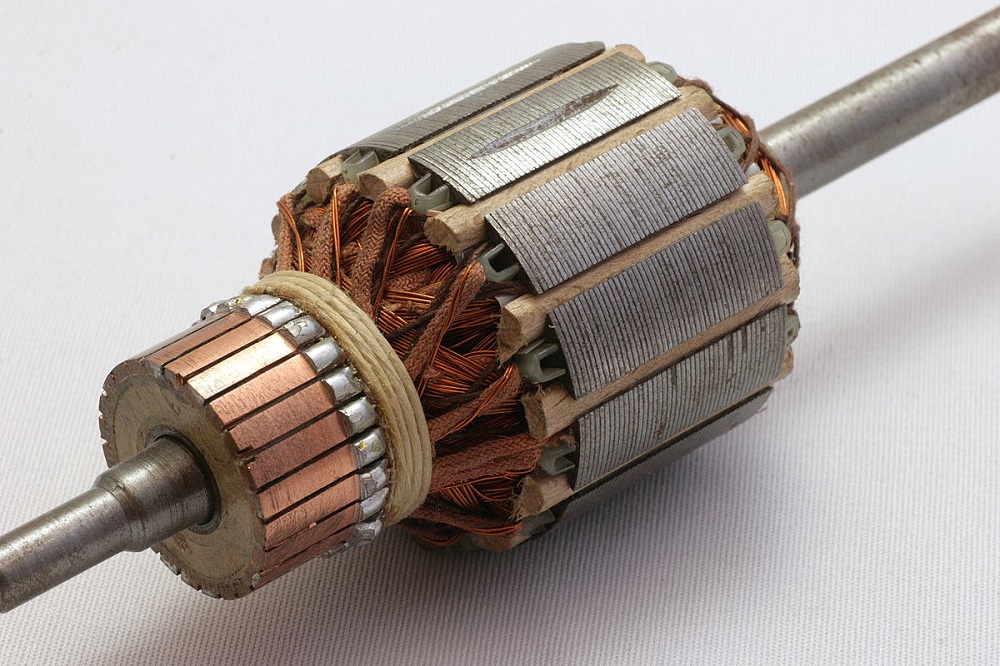

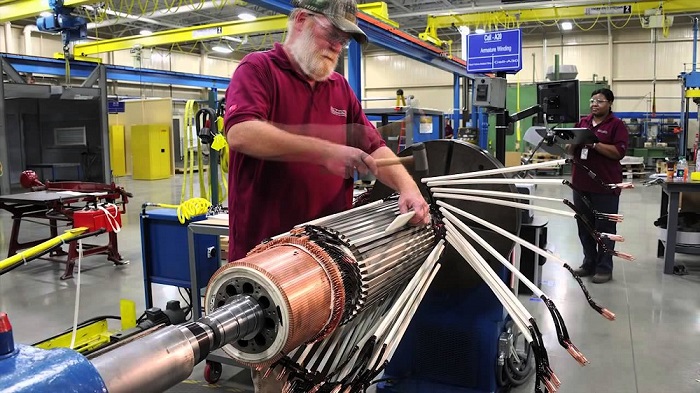

Rotor or Armature Core

The second important component of a DC generator is the rotor or armature core that is consisted of a fan, armature, commutator, and shaft. Unlike the stator, this part is moveable and rotates in the magnetic field created by the stator. In a DC generator, the armature’s rotation is the process that generates a voltage in the rotor coils. The armature core includes iron slot laminations with slots that have been stacked to form a cylindrical armature core. Generally, the losses are decreased due to the eddy current in these laminations.

During the whole process, the fan is responsible to supply the needed air for the armature core or rotor as it spins.

End Housings

End housings are the components attached to the ending parts of the mainframe with a function to protect the bearings. The bearings are the essential parts of the system that lessen the friction between the moving and the fixed parts of the generator they can gradually deteriorate over time.

While the front housings protect the bearing plus the brush collection, the end housings’ function is limited to supporting the bearings only.

Bearings

Bearings are used in a system to achieve smooth movement between the different components. The main function of bearings is to minimize the friction between the rotating and stationary parts of the machine. Thanks to these parts, there is no need for the continual lubrication of the system components and they would also last longer due to the reduction in friction.

Bearings are mainly made from high carbon steel as it is a very hard material and is designed in a way to be constantly greased and protected from dust intrusion.

Bearings come in two common forms: roller bearings and ball bearings. Ball bearings include spherical balls that transfer the load from the inside to the outside and create motion in circles. Ball bearings can be easily found in items around the house; they are more common because they are simple.

Roller bearings, unlike ball bearings, are consisted of different forms of cylinders. While ball bearings’ contact area with the load is limited to a point, in roller bearings this contact is extended to a line so they can be used to handle heavy loads and, thus, are mainly used in industrial equipment.

Yoke

If we divide the DC generator parts in two, Yoke is the outer cover that not only provides mechanical protection to the whole inner assembly and fixes them to the foundation of the machine, but also creates a path for the magnetic flow that the field winding produces.

Based on the size of the machines, yokes are of two kinds and materials; in large apparatuses, yokes are made up of cast or rolled steel while in smaller ones they are composed of cast iron.

Poles

Poles are used primarily to keep windings in the sector. Such windings are usually wound on the poles and are otherwise connected to the armature windings in order. Therefore, by using the screws, the poles join the welding technique to the yoke.

The pole core is mainly made of several thin annealed steel or wrought iron joined together by the use of hydraulic pressure. To reduce the Eddy Current loss, the poles of a DC machine are laminated.

These poles are one of the parts of the DC machine whose job is to support the field coils and ensure a more integrated magnetic flow over the armature.

Pole Shoe

The pole shoe is an iron or steel plate that is used primarily to disperse the magnetic flow and avoid the spinning field coil from falling.

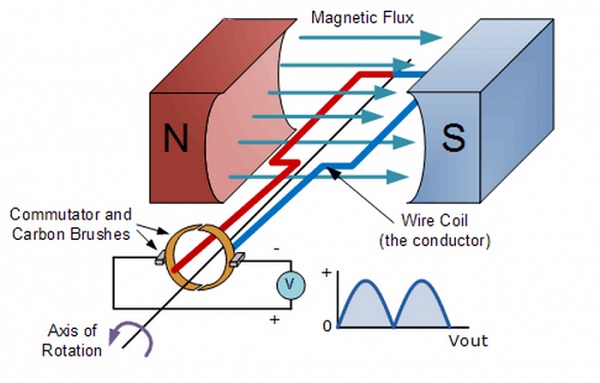

Commutator

The operation of the commutator is like a rectifier to convert AC voltage to DC voltage in the reinforcement of the armature winding. This conductive metal ring has a copper segment and each copper segment with the aid of mica sheets is shielded from each other.

This cylindrical electrical switch sits on the machine’s shaft and contributes to connecting the conductors of the rotating armchair to the external circuit that is fixed. In the process, the original induced current is converted to a unidirectional one in the output terminals.

Brushes

Brushes are one of the essential parts of the DM generator. With the aid of these carbon blocks, the electrical connection between the commutator and the external load circuit can be assured.

Due to the arc discharge and the ongoing contact with the commutator, however, these components deteriorate over time. But the good news is they can always be replaced with new brushes. All you need to do is check them from time to time and make sure they are in good condition and change them if needed.

Shaft

The shaft is a mechanical piece in a DC machine that produces the rotational force known as torque and brings about rotation. It is made from mild steel and has maximum breaking strength. For parts of a DC generator, the shaft helps the generator to transfer mechanical energy through the shaft. The spinning parts are keyed into the shaft like the armature center, a commutator, a cooling fan, etc.

Magnetic Field

This is a permanent magnet that generates a magnetic field that is used to rotate the coil.

Armature Windings

For holding the armature windings, the armature core slots are primarily used. They are connected in a closed-circuit winding form in series to increase the amount of produced current, and they are parallel. This special arrangement of conductors is called the armature winding which is known to be the heart of a DC generator. Depending on the kind of connections, armature windings are either lap winding or wave winding.

All the armature windings, whether lap or wave, are the centers of power conversion inside the machine. In the case of armature windings of a DC generator, this energy conversion occurs from mechanical power to electrical power.

E.M.F Equation of DC generator

After explaining the parts of the DC generator, it’s time to learn about the EMF equation. So, what is it? the EMF equation of the DC generator is according to Faraday’s Laws of Electromagnetic Induction, that is Eg= PØZN/60 A

In the DC generator formula:

- Z means the total number of armature conductor

- P means the number of poles in a generator

- A means the number of parallel lanes within the armature

- N means the rotation of the armature in rpm

- E means the induced emf in any parallel lane within the armature

- Eg means the generated emf in any one of the parallel lane

- N/60 means the number of turns per second

- Plus, time for one turn is dt=60/N sec

But, wait! It was not just parts of the DC generator and its equation. You can find more information about DC generators! DC generators are used almost everywhere. They are used in factories that manufacture aluminum, chlorine, and related raw materials in a large quantity of current. Dc generators are also used in diesel-electric-engine locomotives and vehicles. They can be found in remote control autos, electric car windows, and TVs with flat screens.

What is the Working principle of a DC generator? How Does it Work?

The working principle of DC generators is based on Faraday’s laws of electromagnetic induction. Within the parts of the dc generator, when a conductor is in a dynamic magnetic field, an electromotive force is generated within the conductor. The magnitude caused by EMF can be measured using the electromotive power equation of a generator.

When the conductor has a closed path, the induced current flows in the path. The field coils produce an electromagnetic field and the armature conductors are converted to the field in the generator. Therefore, inside the armature conductors, an electromagnetically induced electromotive force (EMF) is produced. Fleming’s right-hand rule specifies the direction of the induced current.

What are the Types of DC generators?

DC generators can be classified into two main categories (separately excited and self-excited). There is also a third type of DC generator which is called, the “Permanent-magnet DC generator”. Each type has its unique features, frameworks, and advantages.

The function of parts of DC generators in separately-excited type is in a way that field coils are driven from an independent external DC source in a separately excited form generator. On the other hand, in self-excited DC generators, the field coils are energized from the produced current in the generator in a self- excited form. Such generators can also be identified as the series wound, shunt-wound, and compound wound.

DC generator has advantages

In many fields, we need a DC generator, especially for the following reasons:

- It’s built and designed plainly.

- It is suitable for operating large motors and large electrical devices that require direct control.

- It reduces the fluctuations described by smoothing the output voltage through a regular arrangement of coils around the armature for some stable state applications.

DC generators can generate some disadvantages as well

Like other machines, DC generators have some disadvantages, such as:

- DC generators can’t be applied to a transformer.

- DC generators have low efficiency because there are copper losses, eddy current losses, hysteresis losses, and mechanical losses.

- A voltage drop over long distances would occur.

This was all about DC generators. From what you read above, we can say that the main advantages of DC generators include simple design, simple parallel operation, and fewer problems of system stability. You also read about different types of DC generators and their working principle. However, you might need to know more about their design and some other information. So, you can leave your questions in the comment by signing up at Linquip (in the parts of the dc generator article) and get your answers.

Download Parts of DC Generator PDF

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Parts of Generator: a Simple, Yet Useful Guide

- The 5 Best Gasoline Generators of 2021

- Difference between AC and DC generators: An easy to understand guide

- Types of Generators: Learn the Basics, Get the Most Out f it!

- A Clear Classification of AC Generators

- Diesel Generator Parts: A Complete Description

- What are The Electric Generator Parts?

- What are the parts of AC Generators?

- The Best Diesel Generator of 2021

- Types of Alternator: Features, Advantages, and Vast Usage

- The 8 Best Standby Generators of 2021

- Alternator vs Generator: Your go-to guide to learning their difference

- A Clear Classification of DC Generators

- The 10 Best Solar Generator

- The Biogas Generator: A New Approach to the Future of Fuels and Energy

- What are The Electric Generator Parts?

- DC Generator Repair, Maintenance & Testing (Clear Guide)

- What is the Working Principle of a DC Generator?

- Electric Generator Maintenance, Repair, and Services

- Gasoline Generator Repair and Maintenance

- How Much Does It Cost to Install a 22kW Generac Generator?

- How Long Can A Standby Generator Run Continuously?

- What is the Difference Between a Whole House and Standby Generator?

- The Difference Between Prime & Standby Generators

- Can I install a Standby Generator Myself? (An All-In-One Guide)

- Portable vs. Standby Generator (Best Choose for Home)

- DC Generator Repair, Maintenance & Testing(Full Guide)

- Pros and Cons of Inverter Generators