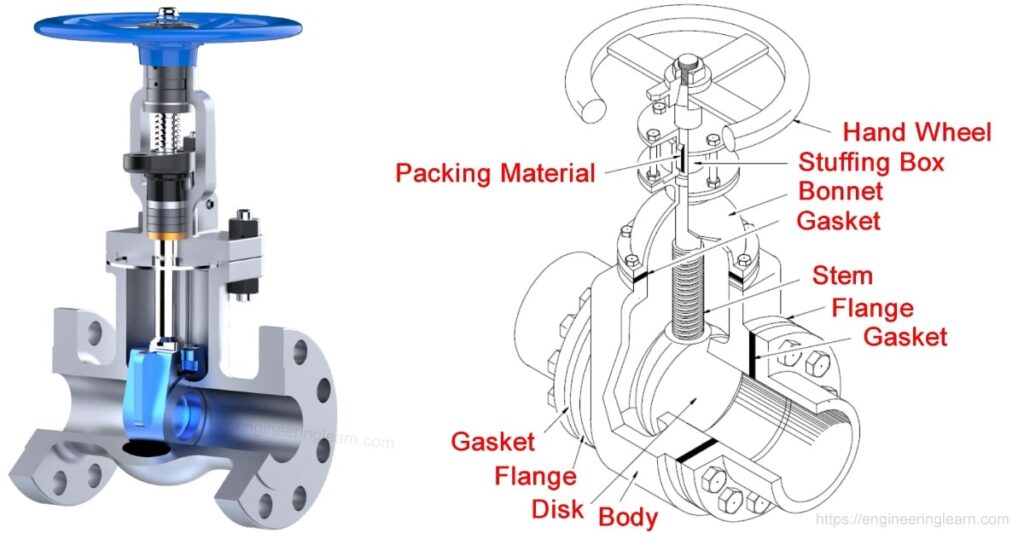

Parts of Gate Valve – In a pipeline, a gate valve is typically used to totally shut off fluid flow or to provide full flow in the fully open position. As a consequence, it can be used in either the fully closed or fully open state. Gate valves can be found in a variety of industries, including oil and gas, pharmaceuticals, manufacturing, automotive, and maritime. A gate valve consists of a valve body, seat and gate, a stem, a bonnet, and an actuator to operate it. Generally, the gate valves are activated by a threaded stem that connects the actuator, e.g., motor or handwheel, to the gate. The stem is rotated by the actuator, which can cause the gate to raise and lower.

Gate valve

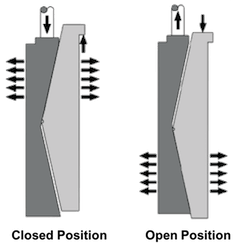

A gate valve, also called a sluice valve, is a type of industrial valve that opens by raising a barrier (gate or disk) out of the fluid’s path, allowing the fluid to flow in a pipeline; and closes by lowering a barrier (gate) that results in preventing the fluid from flowing. All the movements applied for the gate to be lifted or lowered are in the direction perpendicular to the fluid flow. Gate valves take up very little space along the pipe axis and barely hinder fluid flow when wholly opened. These valves should not be used to regulate flow; they should be utilized completely open or fully closed. In other words, this type of valve is in the category of on-off valves and will be damaged in the partial opening state.

The gate sides can be generally divided to parallel or wedge-shaped, but they are most typically wedge-shaped in order to be able to exert pressure on the sealing surface. The straight-through, unobstructed path of a gate valve is its distinguishing feature, resulting in minimal pressure loss across the valve. Unlike butterfly valves, the unobstructed bore of a gate valve allows for pig passage during cleaning.

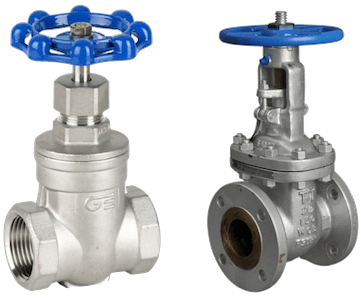

Gate valves are typically utilized with bigger pipe diameters, ranging from 2″ to the largest pipelines, since they are less complex to build in comparison to other types of large-size valves. Gate valves come in several sizes, materials, temperature, and pressure ratings, as well as gate and bonnet designs. Gate valves with an electric or pneumatic actuator are available although manual gate valves are more cost-effective due to their occasional use.

Functioning Principle

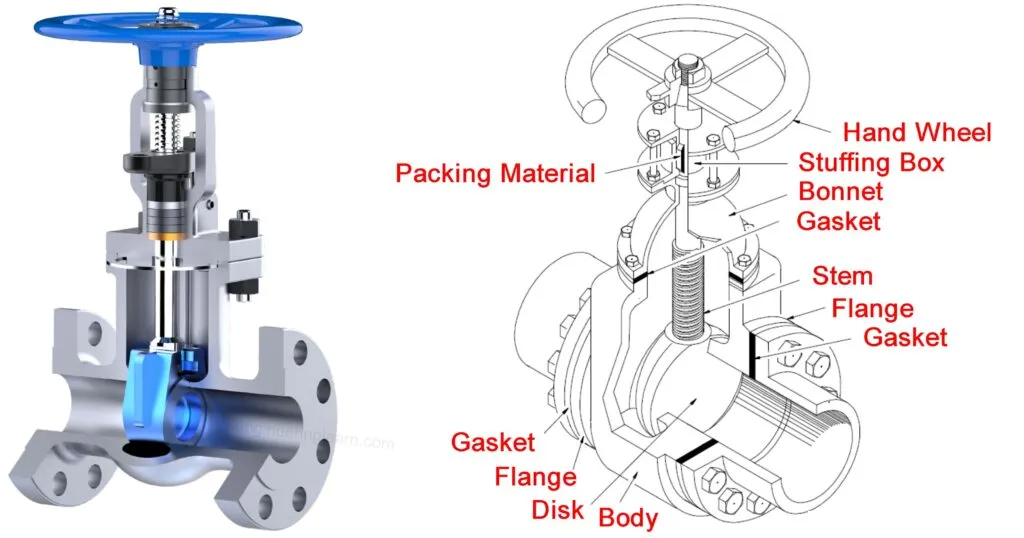

The body, seat, gate, stem, bonnet, and actuator are the essential components of a gate valve. The primary mechanism of operation is straightforward. Common gate valves are activated by a threaded stem that connects the actuator, e.g., handwheel or motor, to the gate. The stem is rotated by turning an actuator, which moves the gate up or down via the threads. To fully open or close the valve, it takes more than one 360° rotation. The valve opens by lifting the gate out of the flow path. As the gate is lowered to its closed position, the bore is sealed, and the valve is fully closed.

The relationship between the vertical movement of a gate valve and the flow rate is nonlinear, with the greatest variations happening near shutdown. When employed to control flow, the comparatively high velocity of the flow during partial opening causes gate and seat wear, as well as possible gate vibrations, reducing the valve’s service life.

Parts of Gate Valve

A gate valve’s vital components are the body, gate, seat, stem, bonnet, and actuator. Gate valves may have flanged ends drilled in accordance with pipeline-compatible flange dimensions requirements. Cast iron, cast carbon steel, ductile iron, gunmetal, stainless steel, alloy steels, and forged steels are common materials for gate valves. In the following, each part of the gate valve that is mentioned above is fully described.

Gate

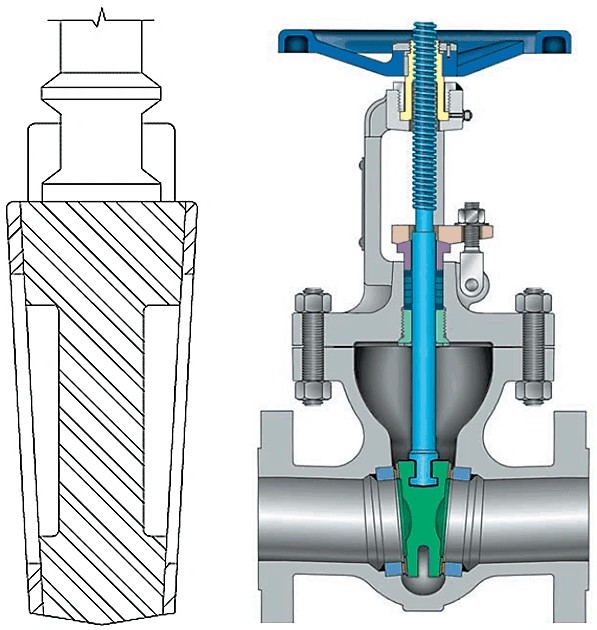

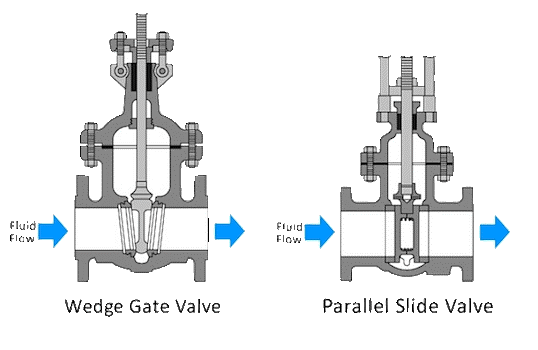

The gate is available in a variety of designs and technologies to ensure that it provides good sealing for a number of applications; however, it can be generally classified as parallel or wedge-shaped. Parallel gates include parallel slide gates, slab gates, and parallel expanding gates. Knife gates are also another type of gate valve whose structure is very similar to wedge valves. In the following, these types are introduced.

Wedge Gates

Wedge type gate valves have a wedge-shaped disc that is seated against two inclined seats. Solid wedges are utilized in applications where there is a high flow or turbulence, such as steam service. Moreover, vibration and chatter are significantly reduced due to the solid structure. In addition to the primary force provided by fluid pressure, the tightening of the stem creates a significant wedging force on the seats, which aids in sealing. Due to reduced rubbing on the seats, the wedge-shaped gate does not stick to the seat in the event of high fluid differential pressure. Hence, it also has a longer lifespan. Split wedge discs are more flexible and can be employed in situations where pipeline strains may cause valve seats to distort.

Parallel Slide Gates

Gate valves can also be found in a parallel configuration, with the gate flat and the seat parallel. Parallel gate valves provide a tight seal by utilizing line pressure. Flat gates are made up of two parts with a spring in the middle. For better sealing, the spring pushes the parts closer to the seats. Parallel gate valves have a safety advantage in higher temperature situations due to their inherent design. In wedge-shaped gate valves, an additional compression force on the seats can cause thermal binding and restricted valve opening due to expansion. Furthermore, because parallel gates have no wedging action, closing torques are reduced, resulting in smaller, less expensive actuators or less manual effort. Parallel gates keep dirt off the seating surfaces since they slide into place.

Slab Gates

Slab gates, known as through-conduit gate valves, are single-piece gates that contain a bore-size hole in the middle. In the open position, the bore is aligned with the two-seat rings. This alignment creates a smooth, turbulence-free flow. This unique design provides for minimal pressure loss on the system and is ideal for transporting crude oil and natural gas liquids. The valve seats are still clean. The disc cavity, on the other hand, can catch foreign particles. As a result, the cavity usually contains a built-in plug for removing the accumulated foreign material during maintenance.

Watch Video about parts of gate valve

Parallel Expanding Gates

Two slab gates are fitted together in expanding gate valves, which offer sealing by a mechanical expansion of the gate. When the slab gate is lifted, the media can flow through both cavities. The outward mechanical expansion for a proper seal is enabled by the upward force on one slab and the stopping of the second slab by a step in the valve body. When the slab gates are closed, the media flow is stopped, and the downward force (stem) on one slab and the upward force (step in valve body) provide for adequate seal.

Isolation valves in block valves in process systems, power plants, and high-temperature valves in refineries all benefit from this seal.

Knife Gates

In the case of plastic solids and high-viscosity slurries like paper pulp, a knife gate valve is employed to cut through the material and stop the flow. A knife gate valve has a tapered knife-like edge on its lower surface and is usually not wedge-shaped. Because they pass the seat rings every time they open and close, these valves are self-cleaning.

Seat

The gate valve is equipped with two seats that carry out and ensure the seal with the gate. Gate valve seats are either integrated with the valve body or in the form of a seat ring. Seat rings are threaded into position or pressed into position and sealed welded to the valve body in the seat ring construction. For greater temperature service, the latter type of construction is preferred. Integral seats are made of the same material as the valve body, whereas pressed-in or threaded-in seats allow for more variation.

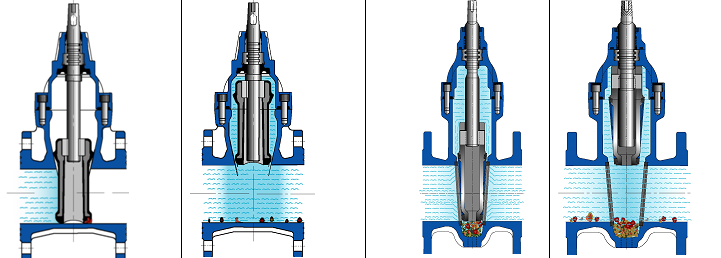

Metal or resilient seats are available for wedge gate valves. A wedge moves towards a groove in the bottom of the gate valve body in metal seated gate valves, trapping particulates contained in the fluid. As a result, resilient seated gate valves are favored in water distribution systems because they enable a tighter shut-off. In resilient seated gate valves, a wedge, often composed of ductile iron, is enclosed in resilient material (elastomer) and therefore forms a tight seal. The seating takes place between the rim of the wedge and the valve body. There is no need for a groove at the bottom of the valve for this. Resistant seated gate valves can thereby seal around tiny solids transported by the water flow.

Stem

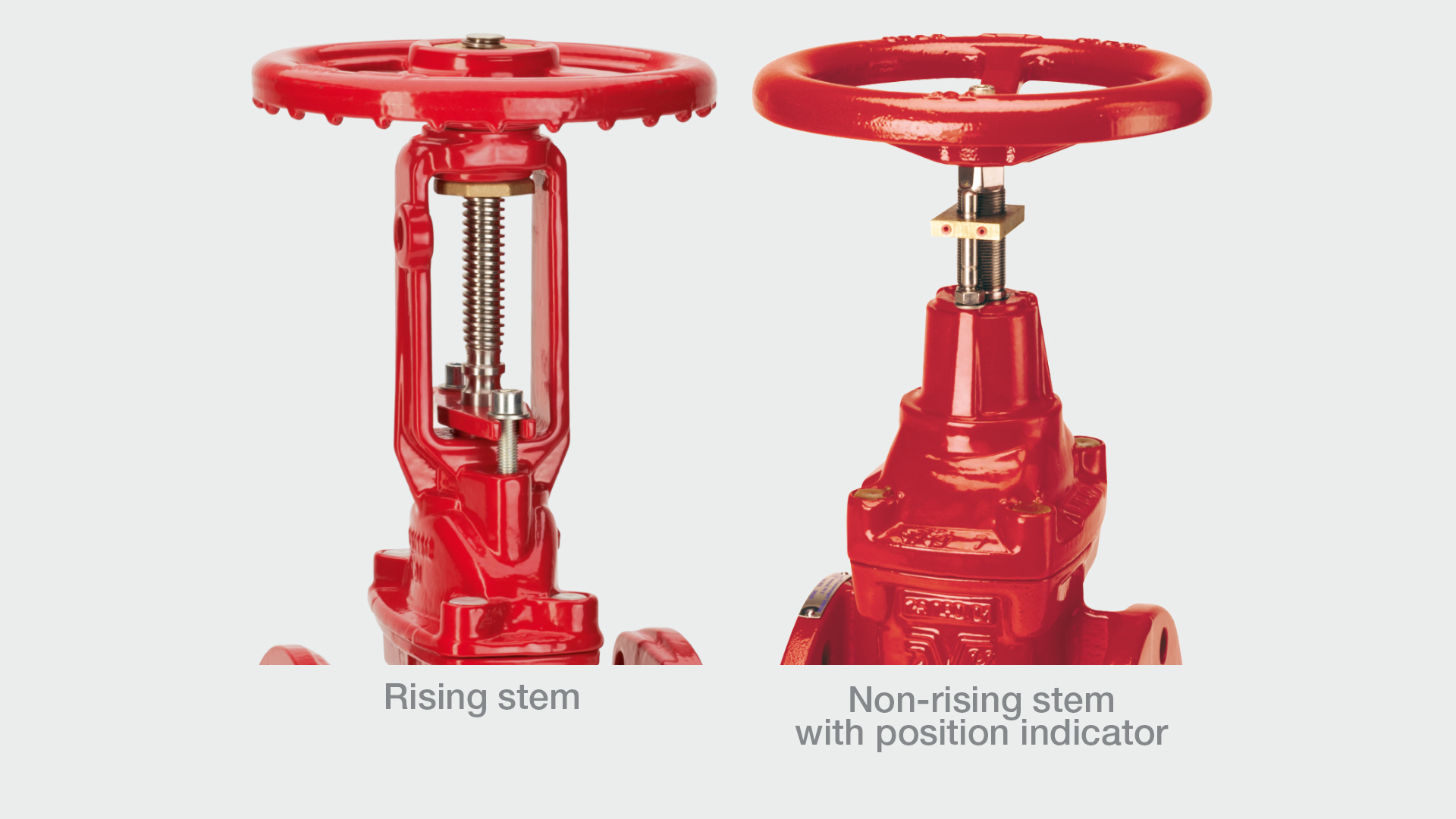

The gate is lifted and lowered by spinning a threaded stem. The stem is rotated by a manual wheel or actuator. The stem is classified into two groups, depending on the design:

- Rising stem

- Non-rising stem

Outside Screw and yoke (OS&Y), also known as rising stems, are fixed to the gate. The threads are so on the actuation side. As the gate is elevated or lowered, the stem goes up and down with it. As a result, they contain built-in visual indicators of the valve’s state and are simple to lubricate. They can’t be used with bevel gears or actuators because they have moving components. Hence, rising gate valves are appropriate for manual actuation. In contrast, a non-rising stem is attached to the actuator and threaded into the gate. An indicator is usually threaded onto the stem to display whether the valve is open or closed. For applications with limited vertical space as well as in underground installations, non-rising gate valves are prevalent.

Bonnets

The internal parts of a gate valve are protected by a bonnet. It is bolted or screwed into place on the valve body, forming a leak-proof seal. As a result, it can be removed for repairs or maintenance. Gate valves can have bolt, screw-in, union, or pressure seal bonnets, depending on the application.

Bolted Bonnets

Larger valves and higher-pressure applications require bolted bonnets for sealing. The bonnet and valve body are flanged and bolted together in this design.

Screw-in Bonnets

Screw-in bonnets are the simplest to make. They are commonly found in small valves and create a long-lasting leak-proof seal.

Union Bonnets

A union nut keeps union bonnets in place. The union nut rests on the lower edge of the bonnet and screws into the threads of the valve body. This design prevents the leak-proof seal produced by the nut from deteriorating due to repeated bonnet removal. Consequently, union bonnets are frequently used in applications that necessitate routine inspection, repair or cleaning.

Pressure Seal Bonnets

A pressure seal bonnet is another form of bonnet used in gate valves. This design is used for valves that will be subjected to high pressures, often in excess of 2250 psi (15 MPa). The pressure seal bonnet is distinguished by the fact that it ends in a downward-facing cup that fits inside the valve body. The sides of the cup are pushed outward when the internal pressure in the valve rises, enhancing the body-bonnet seal.

Advantages and Disadvantages of Gate Valves

The benefits of the gate valves can be stated as follows:

- Good shutoff features

- The body construction is simple, and the production process is more efficient

- The length of the structure is rather short

- The torque needed to close and open the door is minimal

- Gate valves are bidirectional and hence they can be utilized in two directions

- Low resistance to flow;

- Pressure loss through the valve is minimal

The following disadvantages can also be considered for them

- They cannot be opened or closed quickly

- Gate valves aren’t designed to control the flow

- Gate valves often have two sealing surfaces, which makes processing, grinding, and maintenance more challenging

- The abrasion and friction of the sealing surface increase while opening and shutting. Furthermore, it is possible to develop abrasions when the temperature is high

- In open conditions, they are sensitive to vibration

You can also find a lot of manufacturers that provide gate valves in Linquip.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip