A piezoelectric transducer is an instrument that applies the piezoelectric effect to measure variations in strain, temperature, acceleration, pressure, or force by transforming this energy into an electrical load. The electric voltage generated by a piezoelectric transducer can be simply evaluated by the devices of voltage measuring. This voltage is an operation of the pressure or force influenced on it. Physical values such as mechanical force or stress can be measured immediately in this method by employing a piezoelectric transducer.

The electrical charges generated by various types of solid materials are transformed into energy by piezoelectric transducers, a type of electroacoustic transducer. Piezoelectric translates to “electricity produced by pressure.” Piezoelectric Transducers are available from a variety of Suppliers and Companies, as well as various manufacturers and distributors, and there are many Piezoelectric Transducers for Sale on Linquip.

There is a comprehensive list of transducer services on the Linquip website that covers all OEM fleets. Linquip vendors can assist you with this. Please call Piezoelectric Transducer Experts in Linquip to learn more about how to connect with a diverse network of service providers who consistently deliver high-quality products.

What is Piezoelectric Transducer?

A piezoelectric transducer is used as a basis of the origin of the piezoelectric influence. The piezoelectric influence is a complex phenomenon and consists of electronics concepts and many fields of classical physics including elasticity, mechanics, optics, thermodynamics, acoustics, electrostatics, the strength of materials, wave propagation, fluid dynamics, circuit theories, crystallography, etc.

Nowadays, we should measure physical variations such as mechanical pressure applied on metal, temperature ranges modifications, and stress levels in our different situations. We require an instrument that could measure these unfamiliar variations for all these applications in units and calibrations which are known to us. One of these instruments which are most beneficial for us is the Transducer. The transducer is an electrical instrument that can transform any kind of physical quantity to comparable electrical quantities such as electrical current or voltage. The purpose of this post is to explain piezoelectric transducers from various types of the transducer.

The word piezoelectric is obtained from the Greek word piezen, which means to press or squeeze. The piezoelectric influence explains that when mechanical pressure or forces are applied to quartz crystals, generate electrical loads on the surface of quartz crystals. It is identified by Pierre and Jacques Curie. The level of load generated will be influenced by the rate of variation of mechanical force applied to it. i.e. the higher the force, the higher the electrical quantities.

One of the special features of the piezoelectric influence is that it is able to be turned the other way around or reversible. It means that when voltage is applied to Piezoelectric transducer, it changes the dimension along with a particular plane, i.e., quartz crystal setup is located into an electric field, it will modify quartz crystal by an amount influenced by the strength of the electrical effect. If the same setup is set into an electric field and the direction of the field turn, the modification will be inversed.

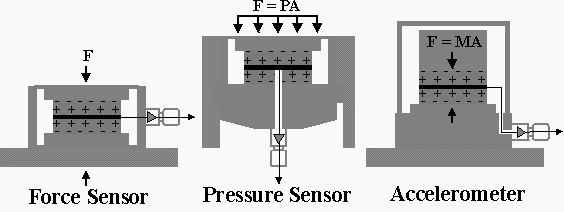

The piezoelectric transducer is too sensitive. Therefore, it operates as a sensor and is utilized in an accelerometer according to its perfect frequency of reaction. The piezoelectric influence is utilized in many applications that contain the generation and identification of sound, electronic frequency production. It operates as an ignition origin for cigarette lighter and employed in force, pressure, microphone, sonar, and displacement measurement.

Piezoelectric Transducers Types

There are different types of them classified by key factors such as piezoelectric crystal material. Some of the limitations that set the nature of the crystal for the application are mentioned as the following:

- The angle at which the wafer is sliced from natural quartz crystal

- Dimension of the plate

- Thickness of the plate

- Method of mounting

Ceramic Piezoelectric Transducers

Based on the capability to generate a ceramic transducer in multiple shapes and sizes, ceramic transducers can be simply modified to a lot of diversities of industrial applications. As a result, they permit for a perfect organization to meet a customer’s particular requirements. Nowadays, the most practical utilization of ceramic piezoelectric transducer manufacturing materials is the compositions of lead zirconate titanate, a solution that dates back to the 1960s. As ceramic transducer application has continued to develop, the utilization of piezo-polymers and composites has obtained acceptance generally.

Rochelle Salt Piezoelectric Transducers

Another material that operates appropriately in transducers is Rochelle salt, which is an artificial synthetic crystal. From many materials that indicate the piezoelectric influence, Rochelle salt generates the highest output of any other material identified thus far.

Nevertheless, it does have its problems, which can reduce its performance in certain applications. These synthetic crystals cannot use in contact with any humidity. They also cannot be utilized at a temperature above 240 degrees Celsius.

If you want to use sensitivity for voltage peak output, synthetic crystals can perform more reliable than natural crystals.

Piezoelectric Transducers based on Operation

A piezoelectric transducer can be classified into sonic, ultrasonic, and mega-sonic transducers based on the working frequency. In all of these classifications, the function and design of transducer change obviously. The sonic transducer operates at an audible frequency level which is less than 20 kHz. Buzzer and unimorph transducer are the main examples of sonic piezoelectric transducers. The ultrasonic transducers normally operate at between 20 to 200 kHz. Finally, the mega sonic transducers operate at the frequency level of MHz.

The principle of a Piezoelectric Transducer

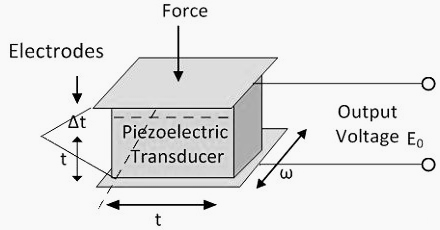

Based on how a piezoelectric material is sliced, three main principles of operation can be introduced for Transducers. They are transverse, longitudinal, and shear.

Transverse effect

When pressure is applied to the main axis ‘y’ then it produces loads and charges along the ‘x’ direction, at an angle of 90° from the line of pressure. The charge is based on the geometrical dimensions of the piezoelectric material.

Longitudinal effect

The amount of load generated is based on the applied force. Unlike the transverse effect, this load is independent of the shape and size of the piezoelectric component.

Shear effect

The load generated is based on the applied forces and they are independent of the size and shape of the element like the Longitudinal effect.

Piezoelectric Transducer Working

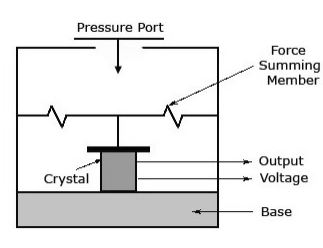

Piezoelectric Transducer working is based on the principle of piezoelectricity. The root of piezoelectric material, usual quartz, is covered with a thin layer of conducting material like silver. But at first, we must explain the role of quartz crystals in Transducers. A piezoelectric transducer contains quartz crystal which is constructed from silicon and oxygen ordered in the crystalline system (SiO2). Typically, the main cell (basic repeating unit) of all crystal is uniform and symmetric but not in piezoelectric quartz crystals. Piezoelectric crystals are electrically unbiased and neutral.

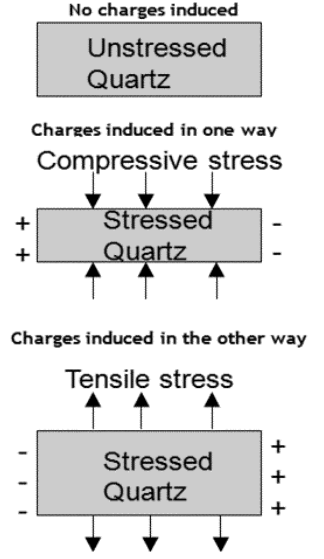

The atoms inside the crystals may not be regularly ordered but their electrical loads are moderate means positive charges neutralize negative ones. The quartz crystal has the specific feature of producing electrical polarity when mechanical force and stress applied to it along a particular surface. Generally, there are two kinds of stress. One is compressive and the other one is tensile.

When there is unstressed quartz, no loads induce on it. In the condition of compressive stress, positive loads are induced on one part and negative loads are induced on the other side. The crystal size becomes longer and thinner according to compressive stress. In the condition of tensile stress, loads are induced in the reverse direction as compared to compressive force and quartz crystal becomes fatter and shorter. If you want to see how this Transducer works more precisely, visit here.

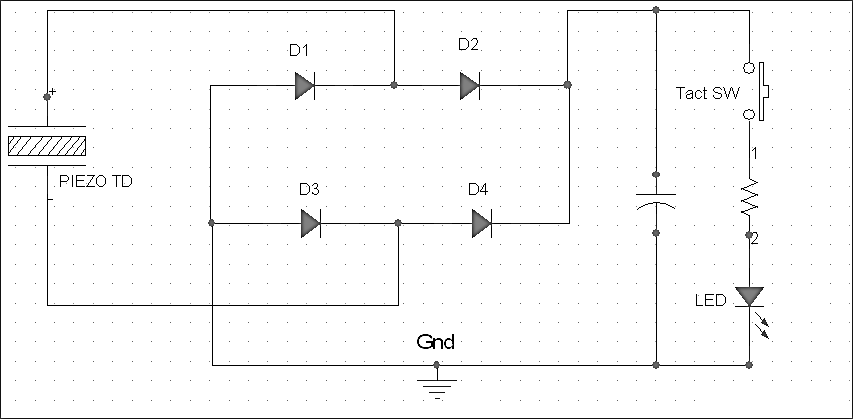

Circuit Diagram of Piezoelectric Transducers

Piezoelectric transducers are contained as an important part of electric and electronic circuits to utilize their electromechanical characteristics in both reverse and direct applications. Thus, it is essential to provide an electric model including the piezoelectric components in electric circuits. This will considerably simplify the analysis of the circuit and the comprehension of its working. The operation of a fundamental transducer can be described by the below figure.

Quartz crystal covered with silver is utilized as a sensor to produce a voltage when force is applied to it. A load amplifier is employed to measure the generated charge without loss. The resistance used in the circuit is very high. The capacitance of the lead wire that attaches the transducer and piezoelectric sensor influences the calibration. So, the load amplifier is generally located next to the sensor.

As a result, when mechanical force is applied in a transducer, a comparable electric voltage is produced which is amplified utilizing load amplifier and employed for calibration of applied force.

Piezoelectric Transducer Applications

The applications of these transducers are too different. Piezoelectric transducers can be utilized for applications that employ electric power for environmental, industrial, and personal usages.

By utilizing piezoelectric materials, transducers can be employed in a variety of applications, including:

- Air Piezoelectric transducers are regularly utilized in automobile, proximity, and level sensors. They are used in medical diagnostics, infertility treatments, and in ultrasonic imaging for medical applications.

- They are usually employed in residential products like motion and object identifiers, home security alarms, and pest deterrents. Producers apply them to popular electronic instruments such as games, toys, and remote-control units. You can also find them in electric toothbrushes, inkjet printers, and buzzers.

- As piezoelectric materials cannot measure static variations, these are basically employed for measuring plate roughness, in accelerometers, and as a vibration detector. For instance, they are utilized in seismographs to evaluate the vibrations in rockets, or in strain gauges to estimate the vibrations of applied force and stress. They are also utilized for researches on blast waves and high-speed shock waves.

- Piezoelectric transducers are also used by automotive producers to evaluate detonations in engines. They are also employed in automobile seat belts to lock in the reaction to a rapid reduction.

- The sound pressure is transformed into an electric signal in microphones and this signal is eventually increased to generate a louder sound. In electric lighter in kitchens, when the pressure is applied to the piezoelectric transducer, it produces an electric signal which eventually causes the flash to fire up.

- They are also employed in restaurants or airports. In this condition, when a person steps near the door, the door opens automatically using a Piezoelectric transducer. The concept utilized is that when a person is near the door, an electric effect is generated and the door opens automatically.

Advantages and Disadvantages of Piezoelectric Transducers

Piezoelectric transducers have various advantages mentioned as the following:

- These are active transducers. It means that they don’t need external power and force for operation and are self-producing.

- The high-frequency reaction of these piezoelectric transducers makes them a perfect choice for different applications because some parameters in these applications change too quickly.

- They are easy to handle and utilize due to their small dimensions.

Nevertheless, Piezoelectric transducers have some disadvantages as the following.

- Environmental conditions like temperature variations can influence the behavior of the piezoelectric transducers.

- They are not suitable for measurement in static applications. Piezoelectric Transducers can only measure dynamic pressure and are useless to measure static parameters.

- The output voltage of Piezoelectric Transducers is occasionally low in some applications. So, some external amplifiers must attach to their circuit.

- It is very hard to give the desired strength and shape to piezoelectric materials. Therefore, piezoelectric transducers always utilize in the same shape and design in different applications.

By and large, this is all about an outline of a Piezoelectric transducer. A Piezoelectric transducer provides exclusive capabilities that are usually not found in other sensing technologies. They have special advantages (such as amplitude range and wide frequency) and some disadvantages (no static measuring ability) according to the certain application. Finally, it should be said that choosing a particular piezoelectric transducer requires close attention to the performance features.

Download Piezoelectric Transducer PDF

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- How to Wire Up Piezoelectric Sensor? A Comprehensive Guide

- Types of Sensors Detectors/Transducers: An Entire Guide

- Resistive Transducer: Working Principle & Example

- Photoelectric Transducer: Application & Working Principles

- What Is a Pressure Transducer? A Simple Descriptive on the Definition, Working Principle and Considerations

- Important Detailed Information About The Types of Transducers

- Pressure Transducer: Definition, Working Principle, and Types

- Active Transducer : All You Should Know About

- Transducer vs. Sensor: Basic Differences & Advantages of Them

- Temperature Transducer: Definition, Working Principle, and Types

- What are the Main Benefits of an Ultrasonic Transducer?

- All You Need to Know about Transducer