The two most common portable compressors are rotary screw air compressors and reciprocating air compressors. The operating costs may be very diverse for the two choices—and not within the way you might think, depending on the way you employ your compressed air, and how the compressor is introduced. Understanding the distinction between the piston and rotary screw compressors and the capabilities of each technology is key to having a better pick. That’s the reason we are here in Linquip putting piston compressor vs screw compressor.

piston compressor vs. screw compressor; an introduction to distinctions

When we compare piston compressor vs screw compressor the biggest distinction between them becomes obvious and it is the way they compress the air. Screw air compressors utilize two fitting helical screws, whereas piston air compressors utilize pistons driven by a crankshaft.

Another distinction is the moving parts as the screw compressor has two moving parts which are not in contact while the piston compressor includes a part of moving parts. The screw compressors work at a lower temperature and coordinated a great cooling framework.

Responding compressors utilize cylinders to compress the air to the line weight you crave. They are basic units, frequently mounted on a little recipient tank, and they more often than not run in start/stop mode on a mechanical weight switch. You’ll certainly tell when they are running since the cylinders make a parcel of clamor. The cooling frameworks of these units are regularly fair blades over which a pulley mounted fan blows a stream of cooling air. The air created by these units is more often than not exceptionally hot and oily—difficult to clean and dry unless a few sorts of assistant cooling and sifting strategy is utilized. On the off chance one looks up the productivity of these units, you will discover that at full-stack they expend more control per unit yield than a screw compressor (as a rule evaluated in kilowatts per 100 cfm, called particular control). But these units are not outlined to run ceaselessly at full-stack, normal loads of over almost 60% of the compressor capacity with overheat and harm the inside components, basically due to the poor cooling methods.

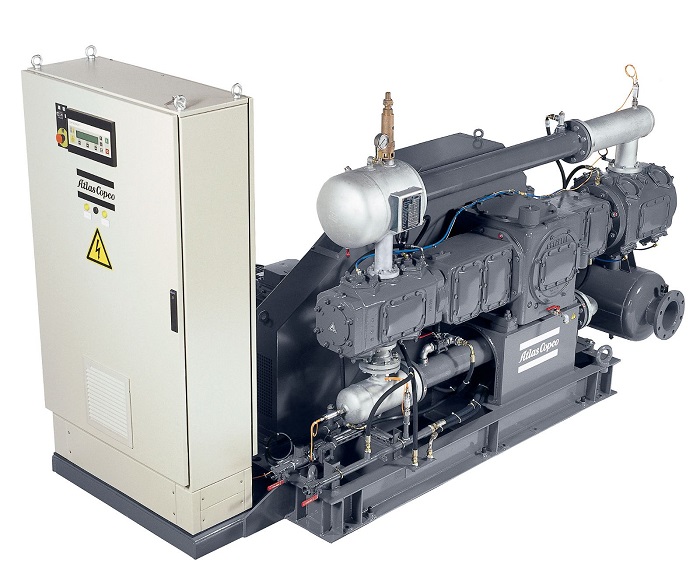

Placing piston compressor vs screw compressor, we find that Screw compressors, on the other hand, are more complex and costly units and can regularly be mounted on the same measured capacity tank. These units most regularly run in a diverse mode, load/unload which implies they run persistently; then again create air at full-stack or run emptied with zero compressed air yield. Screw compressors are much calmer than responding units and have exceptionally great cooling frameworks, compared to car radiators which pass cooling air produced by a fan. These units are planned to run at the full-stack and will deliver much cooler and cleaner air, which can be sent straightforwardly to an air dryer to expel water vapor. These units ordinarily devour less control per unit yield at full-stack than responding units, making them more proficient in that condition.

What Variables Should I Consider?

Before a more detailed technical comparison, let us talk about what should be considered putting piston compressor vs screw compressor to have a better suitable pick: introductory and operating costs, vitality effectiveness, obligation cycle, and benefit interims are vital variables to consider when deciding whether your trade will take advantage most from a cylinder or a rotating screw compressor. Commotion levels are an extra calculation to require into thought.

Beginning Cost vs. Operating Costs. Budgeting for a compressor shouldn’t as it were incorporate how much you pay for your compressor forthright; you, moreover, have to consider how much you’ll pay for your compressor within the long run (i.e. your general working costs). As much as 70-75% of a compressor’s lifetime working costs are gone through vitality utilization, so keep that in mind when selecting a compressor innovation. As you place piston compressor vs screw compressor, you will understand that Pistons have a lower introductory fetched than screws, but screws fetched much less to function over time.

Vitality Effectiveness. On the off chance that both a cylinder and a screw were running the same sum of hours, the screw compressor will be much more proficient and have lower working costs than the cylinder over the lifetime of the compressor. When selecting an innovation, inquire yourself: Is the starting or lifetime fetched more imperative to you and your trade?

Obligation Cycle. Since cylinder compressors are restricted in their obligation cycles, they’re perfect for applications with no obligation cycle prerequisites and no everyday running hours. Screw compressors, be that as it may, have long obligation cycles. In reality, different types of screw compressors are designed to run 100%, all day, each day!

Benefit Interims. Having a piston compressor vs screw compressor we reach the point that there are more moving parts in a cylinder compressor than in a screw, which comes about in expanded machine wear and tears. Screw compressors don’t have as much wear; consequently, they have decreased upkeep needs. But be beyond any doubt that it’s vital to keep any sort of compressor on a steady support plan! This will offer assistance guarantee machine productivity and ideal framework execution.

Noise Levels. Cylinder compressors are uproarious – particularly in comparison to screw innovation. In the event that you’re seeking out a lower-noise machine or a no commotion level is required, you’ll need to consider a screw compressor.

piston compressor vs screw compressor; mathematical sight

For a 10-cfm stack, a 100 cfm 25 hp (21.3 kW at full stack) screw compressor devours 21.3 kW for 10% of the time (2.1 kW) and 7.4 kW for 90% of the time (6.7 kW). This implies the entire normal control utilization is 8.8 kW to create 10 cfm, a particular control of 88 kW per 100 cfm.

A comparative measured 25 hp responding compressor that, say, can create as it were 90 cfm at 21 kW, runs 11% of the time to nourish the same stack (2.3 kW) but expends no control when it isn’t creating air. This works to add up to normal control of 2.3 kW or a particular control of 23 kW per 100 cfm—almost 4 times more vitality effective!

Now let’s leave piston compressor vs screw compressor and have a more technical look to compare these two kinds of compressors:

|

Screw Air Compressors |

Reciprocating (Piston Type) Air Compressors |

|

As there’s as it were one-cylinder sort inlet valve Carbonation is less thus shutdown for cleaning the valves isn’t required. |

This has around 8 or more valves in add up to & subsequently will require visit cleaning due to tall Carbonation. |

|

Space required is exceptionally less coming about in a compact machine. Presently nearly all brands are giving machines with inbuilt discuss dryers or discuss dryers mounted on the same flat discuss recipient/tank in this manner making the machines indeed more compact. |

The space required is more. None of the brands are advertising discuss dryer mounted on the same discuss recipient/tank. |

|

In a screw compressor the screws (air-end) pivot in one heading in this manner causing less clamor, warm,th and vibration. Moreover, Screw Compressor is slip mounted subsequently establishment isn’t required. No extra has taken toll on the establishment. |

These compressors require establishment as well as grouting for huge machines due to tall unequal powers & tall vibration. Here the cylinders rise and drop (vertical machine) or move back and forward within the barrel in this manner causing as well much vibration. Thus, it includes extra establishment fetched. |

|

Moo Oil Substance in outlet air as these machines have a 3 organize oil partition framework. Oil Substance is, as a rule, less than 3 ppm (particles per million). |

No oil division framework in this manner oil substance in outlet air is moderately much higher compared to screw compressors. This oil substance increments when cylinder rings and oil rings wear out permitting oil to move up to the compression side. |

| The most extreme weight that a few brands give with this innovation is 14 Bar (g). In case more is required at that point as it were alternatively accessible is Responding Cylinder Sort Air Compressors. |

The greatest weight that a few brands give with this innovation is 200 Bar (g). There are Tall Weight Compressors from 35 to 70 Bar (g) and after that, there are breathing discuss compressors that utilize this innovation to allow tall weight for profound ocean jumpers at around 200 Bar (g). |

Revolving screw compressors give numerous focal points over their responding compressor counterparts. Estimate, air conveyance, obligation cycle, and life span are all variables that solidly arrive in favor of a rotating screw compressor. We are here on Linquip to discuss all aspects of technical issues, so write for us about your experiences with these compressors in the comments anyway if this article on piston compressor vs screw compressors didn’t meet your needs, you can sign up on our website and our experts will be responding your questions.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Piston Compressors: The Most Comprehensive Guide to Know Piston Compressor

- Everything You Need To Know About Different Types Of Compressors

- What are Hydrovane Compressors?

- How an Air Conditioners Compressor Work?

- 3-phase air compressor: what is it and how to wire it

- The Essential Guide to the 4 Types of Air Compressors

- Difference Between Air Compressor and Air Pump