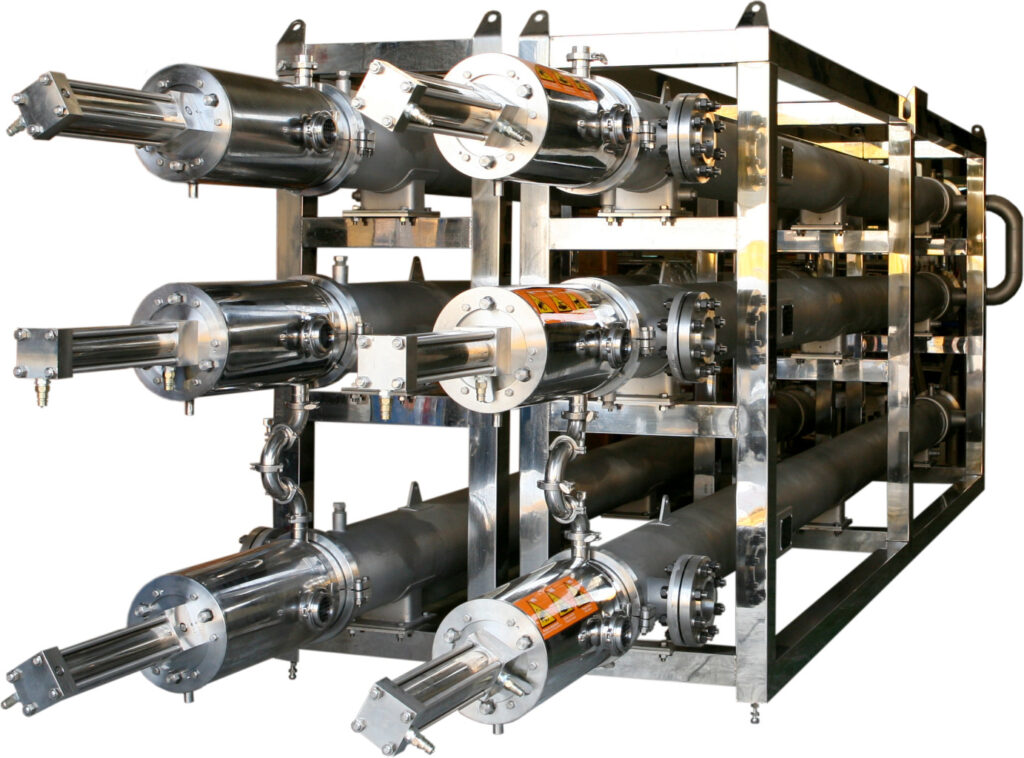

Heat transfer to highly viscous or sticky materials is needed in certain applications. A scraped surface heat exchanger is the best option for providing efficient heat transfer in such applications because the scraping blades prevent the product from accumulating on the internal surfaces. Hence, in this article at Linquip, we aim to explain the scraped surface heat exchanger, its construction, principle, and the uses in different areas.

What is scraped surface heat exchanger made of and where can we see its different uses of?

Scraped surface heat exchanger is made up of a jacketed cylinder with a spinning dasher that holds rows of scraper blades. When the product is being pumped into the cylinder, the heating or cooling medium is being circulated between the cylinder and the jacket. Steam, vapor, or a refrigerant such as ammonia or freon may be used as the medium.

Scraped surface heat exchanger is widely used for heat transfer, crystallization, and other continuous processes in the dairy, chemical, and pharmaceutical industries. It is suitable for viscous, sticky, or particulate-containing materials that need some degree of crystallization. Since these features characterize the vast majority of processed foods, the scraped surface heat exchanger is particularly well suited for pumpable food items. During operation, the substance comes into contact with a heat transfer surface that is quickly and constantly scraped, exposing the surface to untreated product passage. The scraper blades provide simultaneous mixing and agitation in addition to ensuring high and uniform heat exchange.

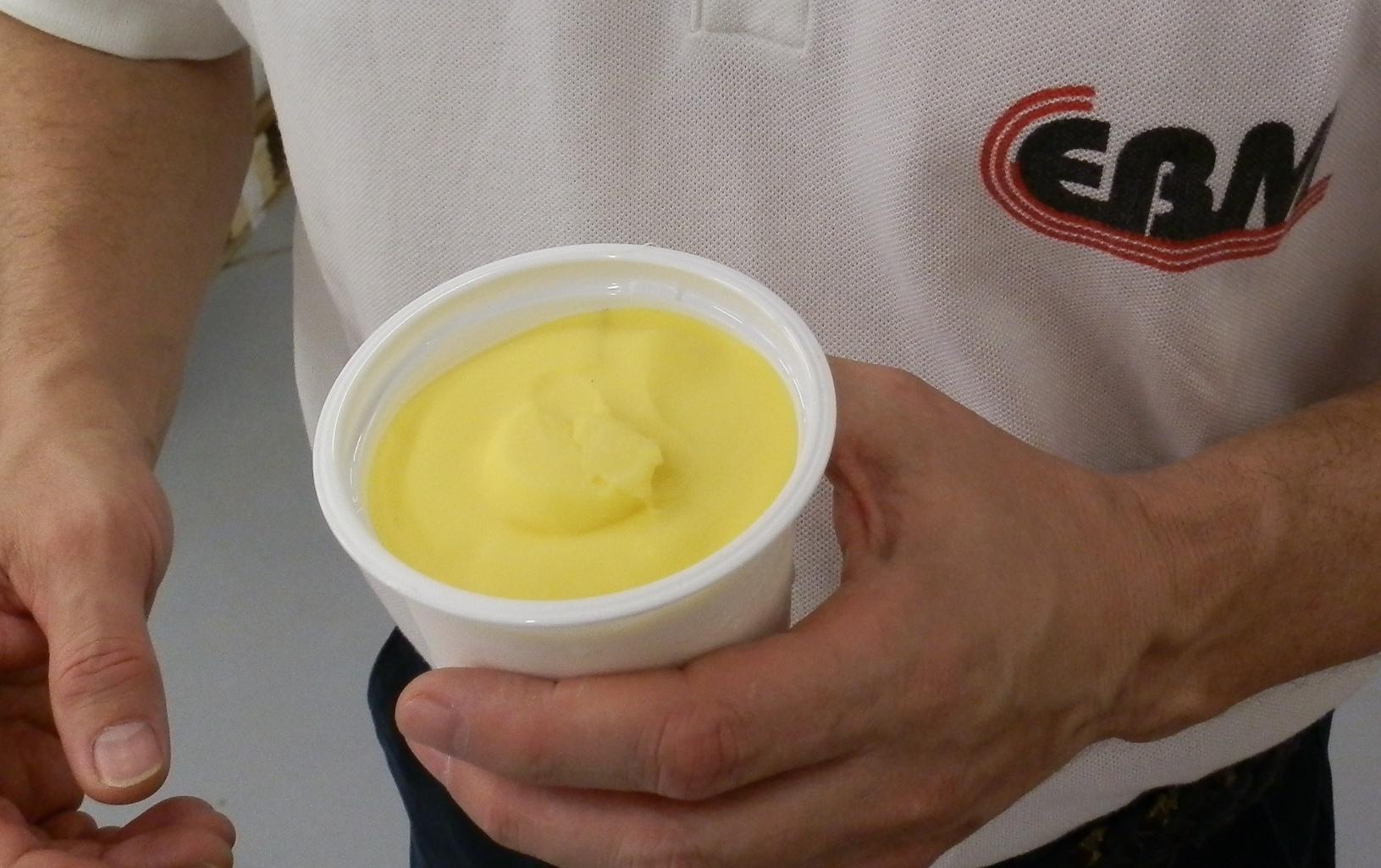

Only a scraped surface heat exchanger allows for heat exchange in sticky and viscous foods such as strong salad dressings, margarine, chocolate, peanut butter, fondant, ice cream, and shortenings. Since the boundary layer is constantly replaced by new material, high heat transfer coefficients are obtained. Because the residence time in the heat exchanger is typically only a few seconds, so higher temperature gradients can be used to transfer heat with few undesired side effects, minimize the risk of adverse reactions. Shanghai Ftherm® Machinery Co., Ltd. has a wide range of scraped surface heat exchangers and specifications, with a single heat exchange area ranging from 0.08 square meters to 7.0 square meters, which can be used to produce medium-low viscosity to high-viscosity products, whether you need to heat or cool the product, crystallization, pasteurization, retort, sterilization, gelation, concentration, freezing, evaporation and other continuous production processes. Furthermore, the substance is only in contact with the heating surface for a few seconds, and high-temperature gradients can be used without the risk of adverse reactions.

scraped surface heat exchanger construction

Spring-loaded spinning blades rub the surface and essentially drain liquid from it in the scraped surface heat exchanger. Alternatively, the rotational forces cause the blades to rotate towards the heat transfer surface. When liquid materials are removed, any fouling material accumulated on the surface is also eliminated, meaning the contamination of the process solvent is kept to a minimum. This can be critical when flavor and texture are essential product attributes.

The number of scraper blades is four, although any number of blades can be used; however, as the number of blades increases and so does the capital cost. Furthermore, a large number of blades are not needed because the internal time between successive scrapes is comparatively short, i.e. the residence time of liquid particles on the surface is limited. The number of blades is an empirically determined balance between capital cost, reasonable rotational speed, and liquid viscosity. Maintenance costs can be comparatively high due to the revolving pieces.

The principle of the scraped surface heat exchanger.

Scraped surface heat exchangers may be filled with liquid or have a peripheral stream of liquid enter the exchanger. The former may be mounted vertically or horizontally, but the latter is usually mounted vertically so that the liquid flows downwards due to gravity. This is the desired arrangement when evaporation is taking place, such as in a concentrating operation, with the vapor being removed under vacuum from the top of the evaporator assembly. The residence time in the equipment can be very short, which is advantageous for handling heat-sensitive liquids. In addition to the benefits stated, the equipment is ideal for multipurpose applications and that evaporation to dryness is possible where a solid product is needed.

scraped surface heat exchanger in the food industry

Scraped surface heat exchanger is a double pipe component with a coolant in the annulus that runs countercurrent to the process fluid flow. Briefly mentioned at first, now let’s learn more about scraped surface heat exchanger in food industry. Scraped surface heat exchanger used in the food and chemical industries can vary greatly in terms of construction materials and application. It has been used for decades to replace inefficient batching operations with more uniform, controllable, and continuous processing.

Cheese sauce, desserts, caramel, deboned beef, pet food, and fruit products are examples of typical applications. Food Grade Scraped Surface Heat Exchangers are commonly used in the food industry. These Scraped Surface Heat Exchangers are typically constructed of stainless steel and polished internally so that they can be washed and primed for other items to be handled without leaving any residue of either the materials of production or the process fluids that were previously processed by the Scraped Surface Heat Exchangers.

Typical applications for a scraped surface heat exchanger in food industry include: Ketchup, mayonnaise, hummus, peanut butter, puddings, salad dressings, bread dough, gelatine, baby formula, skin lotions, and shampoos are examples of “viscous goods”. Egg products, fruit purées, cream cheeses, and fishmeal are examples of “heat-sensitive products”.

Products that crystallize and change process include coffee/tea extracts, icings and frostings, sugar concentrates, margarine, shortening, spreads, gelatine broth, lard, fondant, and beer and wine. Meats, eggs, pet foods, jams and preserves, and rice puddings are examples of “particulate products”. Caramel, cheese sauces, powdered cheese, gums, gelatine, perfume, and toothpaste are examples of “sticky goods”.

Final Words

In this blog post we learned that scraped surface heat exchangers are used to heating liquid foods with large solid particles. These heat exchangers rub the inside surface of the heating chamber with blades continuously. Scraping prevents intensely viscous foods from being burnt on the heating floor, so this is one of the advantages of scraped surface heat exchanger. Leave us comments and ask your questions by registering at Linquip to gain more information regarding scraped surface heat exchanger and its applications, and any other items.

Hi, We are a peanut butter manufacturer. We require a scraped surface heat exchanger. Do you have a South African Distributor?

Thanks for visiting our website. You can visit our Industrial Equipment page, where you can find various heat exchangers based on your application and demand. You can also visit our expert page and take advice from hundreds of professionals on your issue.

I’m interested in youre scrape surface heat exchanger can you send me a process flow for eggs and contact person with phone number.Thank you ,Robert Brodhagen. robertbrodhagen@yahoo.com

I want the designing of Scraped Surface Heat exchanger as I want to use it for milk product like Cheese, cheese spreads and shrikhand which are quite viscous in nature. How the scraper blades works inside heating tube and how procts comes out after heating raw product. Please provide me some video or some demonstration of your product. Warm regards

Thanks for visiting our website. You can visit our Industrial Equipment page, where you can find various Heat Exchangers based on your application and demand. You can also visit our expert page and take advice from hundreds of professionals on your issue.