Introduction

Welcome to the amazing world of semiconductor manufacturing! A grain of sand becomes the brains of our digital devices thanks to semiconductor technology. We learn about the laborious processes that turn sand into silicon wafers, the building blocks of our electronics. This process is a marvel of science and engineering, from heating sand to a liquid to imprinting circuits smaller than a grain. Discover this complex process and how tiny chips power our devices.

Understanding Semiconductors and Silicon Wafer

Solid, high-stack semiconductors create a complex structure akin to a skyscraper. The foundation is the first part of building construction. A silicon wafer serves as the semiconductor’s base in a similar manner. Silicon that is taken out of sand is used to make most wafers. However, have you ever wondered how these minuscule sand grains could form into a wafer? The steps involved are as follows:

- Sand is heated to the point of melting into a liquid of high purity, at which point it crystallizes to solidify.

- An ingot is the term for the silicon rod that results. Thinly sliced wafers form a disc from these nuggets.

- Sliced wafers have a rough and imperfect surface. Thus, the wafer’s surface is polished using polishing machines. The rationale is that surface flaws may adversely impact an electronic circuit’s accuracy.

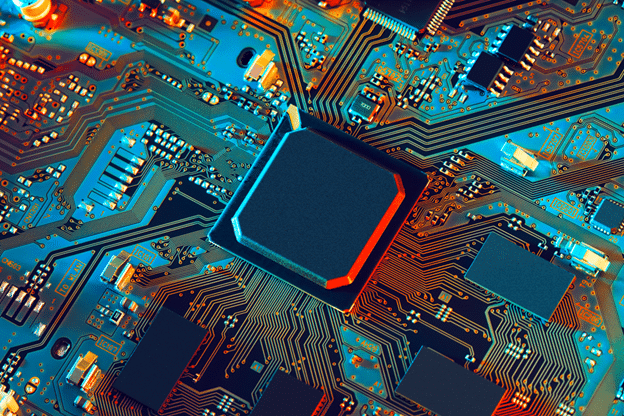

- Silicene wafers have a grid pattern on their surface, as shown in this photo.

This type of wafer is the primary semiconductor material. An increase in wafer diameter results in a corresponding increase in chip production capacity.

Deposition

It all starts with a silicon wafer. Wafers are cut from a 99.99% pure silicon salami-shaped bar called an “ingot” and polished to an extremely smooth surface. Before the first layer can be printed on the wafer, thin films of materials that conduct electricity, separate electricity, or conduct electricity, and a semiconductor are put on it. This depends on the type of structure that is being made. We call this crucial stage “deposition.”

Imprinting The Integrated Circuit

A semiconductor, diode, resistor, and capacitor are all connected in a way that makes the circuit seamless. Each of these parts processes and stores electric signals in a different way. This is made by applying a complicated pattern using photomasks that, through a process known as photolithography, capture its reduced size. A photomask is made when the circuit design is produced using computer-aided design software and then replicated using an electron beam onto a glass substrate composed of ultra-pure quartz.

Lithography

Because lithography limits the size of transistors on a chip, it is an essential step in the chip-making process. This step involves inserting the chip wafer into a lithography machine, which is us, and exposing it to either extreme ultraviolet (EUV) or deep ultraviolet (DUV) light. The wavelength of this light ranges from 365 nm for simpler chip designs to 13.5 nm for the production of the tiniest details possible, including those that are thousands of times smaller than a sand grain.

The Etching Process

In semiconductor fabrication, the etching process selectively removes unnecessary components from the wafer surface using a liquid or gas etchant until the desired circuit patterns remain. The more popular method is dry etching, also known as plasma etching, despite being more expensive and complex due to its higher yield. We must first create a plasma state. After being released from this plasma state, a radical atom turns volatile and retreats from the wafer surface, removing any surface material that had not been coated and shielded by the photoresist beforehand.

The Thin-Film Process

Materials stacked densely at the atomic or molecular level in a film so thin that highly sophisticated technology is required for even deposition is necessary for a semiconductor chip to have the desired electrical properties.

Packaging

From design to production, the process of producing a silicon wafer with functional chips involves thousands of steps and can exceed three months. With a diamond saw, the wafer is cut into individual chips in order to remove the chips. Sliced from a 300-mm wafer, which is the most commonly utilized size in semiconductor production, these so-called ‘dies’ have different sizes for different chips. While some wafers have thousands of chips on them, others only have a few dozen.

Conclusion

We have now successfully traversed the intricate and fascinating route of semiconductor fabrication. Every stage of the process, from the first sand melting to the last silicon wafer slicing into individual chips, is an amazing feat of ingenuity and precision. The voyage demonstrates the astounding amount of work and technological advancement required to produce the small but potent chips that power our contemporary world. How these tiny fragments, formed from regular sand, became the brains of our digital age is a monument to human ingenuity. This process not only powers the technology of today but also clears the path for its advancement.