Welcome to Linquip Blog. Today and in this article, we are going to deal with Servo Motor Types. The information in this article gives a significant collection of data you need to know about different types, and privileges of Servo Motors. A servo motor is one of the widely used variable speed drives in industrial production and process automation and building technology worldwide.

Our team gathered all of the necessary information on this topic to eliminate the need for reading diverse content on other websites. Stay with us until the end to find the answer to your question on this topic. We have a long journey ahead of us, so take a deep breath, sit back, and keep reading this article until the end.

An Introduction to Servo Motors

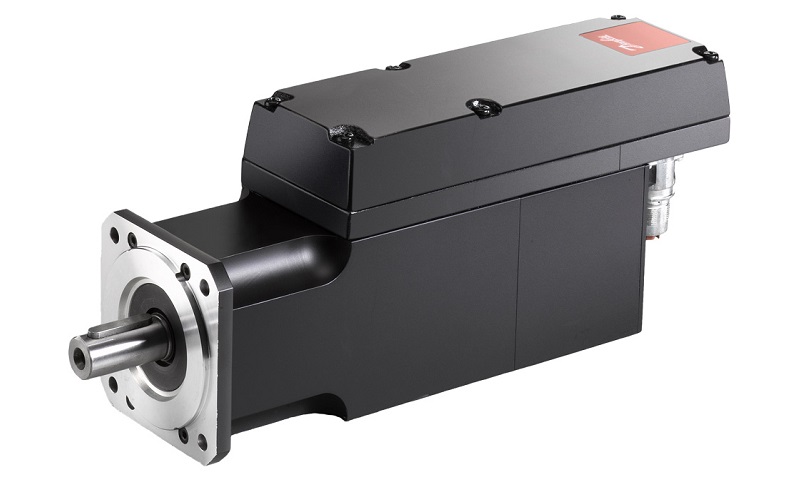

A servo motor is a rotational or translational motor to which power is supplied by a servo amplifier and serves to apply torque or force to a mechanical system, such as an actuator or brake. Servo motors allow for precise control in terms of angular position, acceleration, and velocity. This type of motor is associated with a closed-loop control system. A closed-loop control system considers the current output and alters it to the desired condition. The control action in these systems is based on the output of the motor. It uses a positive feedback system to control the motion and final position of the shaft.

There are two types of current flow in these motors – AC and DC. AC servo motors can handle higher current surges and are thus more commonly found in heavy industrial machinery. ISL’s DC Servo Motors are best suited for smaller applications and have excellent control-ability and feedback. In a servo motor speed is determined by the frequency of the applied voltage and the number of magnetic poles.

Servo motors offer versatility in the manufacturing environment. Common applications include Collaborative robotics, Conveyor belts, Automatic door openers, CNC turning, and Automation systems. In the last section of this article, we will mention some of the most important applications of different types of servo motors.

A Full Explanation on Types of Servo Motors

As it was told before, the servo motor is most commonly used for high technology devices in industrial application like automation technology. It is a self-contained electrical device, that rotate parts of a machine with high efficiency and great precision. Now that we are familiar with the construction and the usages of servo motors, it is time to know the different types of it.

Generally, there are 5 different types of Servo Motors which are commonly used in various industries. In this section, we are going to get familiar with these five types with a full explanation.

1) DC Servo Motor

The motor which is used as a DC servo motor generally have a separate DC source in the field of winding & armature winding. The control can be archived either by controlling the armature current or field current. Field control includes some particular advantages over armature control. In the same way, armature control includes some advantages over field control. Based on the applications the control should be applied to the DC servo motor. DC servo motor provides very accurate and also fast response to start or stop command signals due to the low armature inductive reactance. DC servo motors are used in similar equipments and computerized numerically controlled machines.

2) AC Servo Motor

AC servo motor is an AC motor that includes encoder is used with controllers for giving closed loop control and feedback. This motor can be placed to high accuracy and also controlled precisely as compulsory for the applications. Frequently these motors have higher designs of tolerance or better bearings and some simple designs also use higher voltages in order to accomplish greater torque. Applications of an AC motor mainly involve in automation, robotics, CNC machinery, and other applications a high level of precision and needful versatility.

3) Positional Rotation Servo Motor

Positional rotation servo motor is the most common type of servo motor. The shaft’s o/p rotates in about 180o. It includes physical stops located in the gear mechanism to stop turning outside these limits to guard the rotation sensor. These common servos involve in radio-controlled water, radio-controlled cars, aircraft, robots, toys and many other applications.

4) Continuous Rotation Servo Motor

Continuous rotation servo motor is quite related to the common positional rotation servo motor, but it can go in any direction indefinitely. The control signal, rather than set the static position of the servo, is understood as the speed and direction of rotation. The range of potential commands sources the servo to rotate clockwise or anticlockwise as preferred, at changing speed, depending on the command signal. This type of motor is used in a radar dish if you are riding one on a robot or you can use one as a drive motor on a mobile robot.

5) Linear Servo Motor

Linear servo motor is also similar to the positional rotation servo motor discussed above, but with an extra set of gears to alter the o/p from circular to back-and-forth. These servo motors are not simple to find, but sometimes you can find them at hobby stores where they are used as actuators in higher model airplanes.

Applications of Servo Motors

It is true that this article is about different types of servo motors, but it might be a good idea to get acquainted with some of the applications of different types of servo motors. The servo motor is small and efficient, but serious to use in some applications like precise position control. This motor is controlled by a pulse width modulator signal. The applications of servo motors mainly involve in computers, robotics, toys, CD/DVD players, etc.

The following are some of the most important applications of Servo Motors:

- The servo motor is used in robotics to activate movements, giving the arm to its precise angle.

- The Servo motor is used to start, move and stop conveyor belts carrying the product along with many stages. For instance, product labeling, bottling and packaging

- The servo motor is built into the camera to correct a lens of the camera to improve out of focus images.

- The servo motor is used in robotic vehicle to control the robot wheels, producing plenty torque to move, start and stop the vehicle and control its speed.

- The servo motor is used in solar tracking system to correct the angle of the panel so that each solar panel stays to face the sun

The Servo motor is used in metal forming and cutting machines to provide specific motion control for milling machines - The Servo motor is used in Textiles to control spinning and weaving machines, knitting machines, and looms

- The Servo motor is used in automatic door openers to control the door in public places like supermarkets, hospitals, and theatres

Conclusion

The present article was an attempt to deal with Servo Motor Types and deliver all the essential information about how these different types work and where they are used. A servo motor is a rotational or translational motor to which power is supplied by a servo amplifier and serves to apply torque or force to a mechanical system, such as an actuator or brake. Servo motors allow for precise control in terms of angular position, acceleration, and velocity.

If you have any experience of using different types of Servo Motors, we will be very glad to have your opinions about their performance in the comments on our website Linquip. Moreover, if you have any questions about this topic, you can sign up on our website and wait for our experts to answer your questions. Hope you enjoyed reading this article.

Great .

Brief and nice explanation. Thank you.

Question? I am wanting to flip a table from laying flat and flipping it over 180 degrees. It would have approxamtaly 200 pounds plus on it. What would be the idea servo motor to handle this type of project? would an AC servo work best and can it be programed to let the weight down easy on the down side?

Thanks for visiting our website, Bruce! You can visit our Industrial Equipment page, where you can find various pumps based on your application and demand. You can also visit our expert page and take advice from hundreds of professionals on your issue.