If you have the question “Should I use PVC or CPVC pipe?” be sure to check out this article. In order to effectively decide whether you should use PVC or CPVC pipe, you must understand each material’s traits. Because they perform very similar functions, a few specific questions can help determine the ideal choice for a project.

- When the pipes are exposed to heat, will they be adequately protected?

- How important is the cost of the materials?

- Where will the pipes be placed? What is their size?

A decision about what material is needed, can be made based on the answers to those questions. For example, it is safer to use CPVC if the pipes will be exposed to heat since it is more heat resistant. To learn more about the uses of CPVC and PVC pipes, read this post.

Basics of PVC and CPVC

CPVC and PVC are most likely both used in various projects by contractors and managers. PVC and CPVC have a few distinct differences that are immediately noticeable when you see and handle them. There are, however, even more differences between PVC and CPVC that are critical to determining the correct applications.

Until the advent of PEX, polyvinyl chloride (PVC) and chlorinated polyvinyl chloride (CPVC) had been the most commonly used plastics in plumbing. Homeowners still use CPVC and PVC both abundantly. When choosing pipes and fittings for your new home build or remodel, it is important to consider certain key factors. Builders, contractors, and local officials are excellent resources, but if you know some of the basics, then these discussions will be more productive.

There are many benefits associated with plastic piping, including affordability, a faster and more flexible installation process, and durability. How do you know which plastic pipe is best for your application? What are the best materials for water pipes?

This article provides a comprehensive overview of these two materials. The first thing we need to know is what makes PVC and CPVC different.

PVC

You probably know about PVC pipes. They’re white, flexible plastic pipes commonly used for piping and drainage. PVC pipes have replaced metal pipes as a common material. PVC is the most widely utilized plastic in the world because of its strength, durability, easy installation, and low cost. In liquid handling supplies, such as pipes, fittings, valves, and other products, PVC is typically molded into different shapes.

Natural gas and salt are sometimes used as ingredients in PVC production. These are the benefits of PVC piping:

- It’s eco-friendly;

- It has a long lifespan;

- It is easy to install and maintain;

- It is corrosion-resistant;

- It is cost-effective;

- It is widely accepted by code.

A variety of PVC pipe sizes and dimensions are made by extrusion and are generally offered in 10′ and 20′ lengths. There are both solid wall and cellular core PVC pipe options available. A cellular core is comprised of three layers extruded simultaneously: a solid inner layer, an intermediate cellular core layer, and a solid outer layer. Various ASTM standards are met by PVC pipe for pressure or non-pressure applications.

PVC products and pipework are built to resist oxidation and degradation, making them highly durable. The lifespan of PVC pipes can be as long as 50 years when properly installed. In addition to incorrectly glued joints, tree roots dislodging underground lines or burrowing into the pipe can also cause PVC to fail.

CPVC

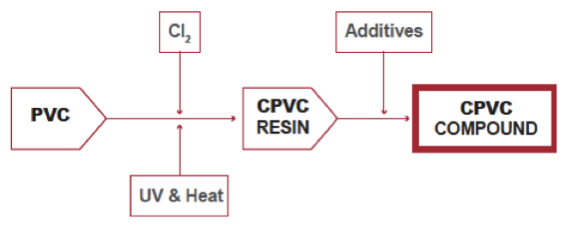

Consider CPVC to be a cousin to PVC. Many factors make them alike, but they are not interchangeable. Both are made up of similar elements, but one separates the two. CPVC is altered by a process known as free radical chlorination, which increases the content of chlorine in the material. CPVC is also a thermoplastic similar to PVC that is used to manufacture a wide range of products.

CPVC can withstand a wide range of temperatures because of its composition. For this reason, many building codes call for the use of CPVC instead of PVC in hot water applications. Due to its composition, CPVC can resist the effects of heavily chlorinated water and is more temperature-tolerant than PVC.

For applications not exceeding 140°F, PVC can be used according to ASTM standards. Over this temperature range, materials can soften, and joints can weaken. The CPVC material can withstand temperatures as high as 200 degrees Fahrenheit.

To kill disease-causing bacteria before the water gets into your home, water companies use chlorine-based disinfection. The methods and levels of disinfection in water systems vary depending on the location and time of year.

PVC vs. CPVC

People immediately notice the additional letter that separates PVC from CPVC. When retrofitting or building a house, you can’t use PVC or CPVC interchangeably. Once you realize what the “extra C” means, the main difference between PVC and CPVC becomes clear, as well as why they are used differently.

Differences in Chemical Composition

PVC and CPVC differ primarily by their compositions.

PVC Pipes

The name PVC implies that it is a plastic composed of carbon and chlorine. As a result, it is a highly durable and flexible material that does not rust or rot and has good resistance to bacteria. For these reasons, it seems like an ideal material for transporting water.

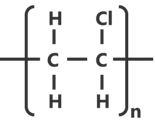

PVC is a flexible man-made plastic, usually used to make pipes and fittings for the plumbing industry. It has stabilizers to prevent degradation and oxidation. The chemical composition of PVC is two carbon atoms binding together with three hydrogen atoms and with one chlorine atom, which are all bonded by single bonds. Molecular units (monomers) are further linked with molecules of the same structure to form chains (polymers), from which PVC products like pipes are made.

CPVC Pipes

CPVC is a thermoplastic made from polyvinyl chloride resin that has been further chlorinated. Its chemical composition consists of two carbon atoms bound together, two hydrogen atoms, and two chlorine atoms bound to these two carbons. Polymer chains of CPVC are formed by attaching this molecule to others. The long service life of CPVC is due to its superior resistance to degradation. The first CPVC piping systems were installed in 1959, and they are still in use today without any problems.

The main difference between CPVC and PVC is that CPVC has more chlorine (due to an additional chemical reaction during the manufacturing process). There can be a 20% increase, but it depends on the manufacturer. Water moving through the pipe is unaffected by the additional chlorine. This difference cannot be seen from the outside because it exists on a molecular level.

Differences in Sizes and Colors

CPVC and PVC look remarkably similar on the outside. Both forms of pipe are strong, rigid, and available in the same sizes of pipe and fittings. There is only one noticeable difference in color. The color of PVC is generally white, while the color of CPVC is cream.

PVC Pipes

A PVC pipe’s usual color is white or dark gray, with the pipe’s technical description listed on the side. Among PVC products, rigid PVC (also known as uPVC, products commonly used in construction and piping) and flexible PVC (plasticized PVC, commonly known as PVC, insulation used on electrical cables) are available. Neither form of PVC is dangerous when handled and does not leach chemicals when used as it was meant to be. The sizing of PVC pipes is based on the IPS (Iron Pipe Size) system.

CPVC Pipes

It is known that all CPVC pipes are sized in two ways; in nominal pipe size (NPS), which refers to the diameter of the interior hole, and in copper tube size (CTS), which refers to the outside diameter of the tube. NPS pipes are generally gray, and CTS pipes are yellow. Specifications are often printed on the sides of each type of pipe.

Differences in Temperature Tolerance

Using PVC and CPVC for water applications has one significant weakness.

PVC Pipes

The PVC material can only withstand temperatures up to 140 degrees F. If the temperature rises above 140 degrees, the PVC will melt. In order to give you an idea, the maximum temperature of a hot water heater is usually between 120 and 140 F. Therefore, PVC is probably not a good choice for indoor plumbing.

CPVC Pipes

In this situation, CPVC is the better choice. The temperature limit for CPVC is 200 F, which is a 60-degree increase in temperature. This material is still not the most temperature-tolerant in plumbing, but it is far superior to PVC.

The 200°F maximum operating temperature for CPVC is based on the extent and likelihood of material damage. Temperature thresholds for CPVC are as follows, with general approximations and rounding off:

- Softening begins at 240°F (Vicat Softening Temperature);

- Turns viscous at 350°F;

- Material Carbonizes at 425°F;

- Flash ignition temperature is 730°F.

Differences in Pipe Strength

The addition of chlorine to CPVC increases its heat tolerance, but it also alters its strength. PVC and CPVC are both strong, but CPVC is harder, which means it is more likely to break. In contrast to PVC, CPVC is more brittle and prone to warping and cracking. It is, however, more flexible. The CPVC tube should be supported every three feet if it is long.

Differences in Cost

CVPC pipes are more expensive due to the addition of chlorine during the manufacturing process. However, not by a lot, Both PVC and CPVC are much more affordable than metal or PEX. A PVC or CPVC’s exact price and quality will vary depending on the manufacturer. The resistance to heat of CPVC will always be higher than that of PVC, but it won’t always function properly when heated above 200 degrees Fahrenheit. Before installing the pipe, check for specifics.

Because CPVC is an expensive material, it is typically used for hot water applications, whereas PVC is utilized for cold water applications, such as irrigation and drainage. Whenever you’re deciding between PVC and CPVC, take the following factors into consideration: temperature and cost.

Differences in Adhesives and Bonding Agents

Certain types of adhesives, such as primers, cement, or bonding agents, may be needed to connect pipes and fittings, depending on the materials and particulars of the job or project. CPVC and PVC adhesives are made for specific types of piping, so they cannot be interchanged with other types.

Which One Should I Choose: PVC or CPVC?

You can safely use CPVC where PVC is used. PVC and CPVC are both approved for transporting potable water, such as bathing, drinking, and cooking, but only plumbing with ANSI / NSF 61 certification should be used. CPVC and PVC are both chemically resistant and largely resistant to degradation from acids, alkalis, and most organic chemicals. However, for both materials, it is imperative to use UV stabilizers or install them underground to prevent degradation from the sun.

CPVC and PVC pipes in plumbing applications are quieter, less expensive, and easier to install than copper and iron pipes. These thermoplastic pipes are insulated by their inherent properties, so they make condensation on the pipes less likely to form, and they maintain the temperature of cold and hot water more effectively than copper pipes.

These pipes come in the same lengths and have the same end shapes. They are innately fire retardant due to their chemical composition, which contains a halogen, the element chlorine. As a result of these stable properties, CPVC and PVC have long, useful performance lives. Many homeowners have used PVC and CPVC plumbing products for decades. Based on historical information as well as independent research studies, it is believed that PVC and CPVC can last 50 years or more under the right conditions and correct installation.

Often, a material can be identified by the color of the pipe or, if it is not, by reading the manufacturer’s markings on the side.

In most cases, PVC and CPVC cannot be used interchangeably. If you’re trying to decide whether to use PVC or CPVC pipes, make sure to consider both their abilities and limitations. Cold-water applications and pressure or non-pressure systems are best suited to PVC, whereas hot-water applications, fire sprinkler systems, and water supplies are better suited to CPVC.

This section discusses the specific applications of both PVC and CPVC pipes.

PVC Pipes

You should weigh the pros and cons of PVC pipes when choosing the materials for your construction projects. In many situations, PVC is the more affordable and more suitable option. Here are a few instances where PVC pipes can be useful:

Indoor Plumbing

The fact that PVC pipe is very resistant to corrosive gases and chemicals makes it a great choice for transporting drinking water. In addition, it has insulation properties, so that outside temperatures won’t affect the temperature of the water.

In many cases, PVC can be used not only for drainage or cleanouts but for plumbing as well. It is, however, better to use CPVC when temperatures are limited.

Cold-Water Applications

Transporting cold water is one of the best uses for PVC. Water will stay cold and clean thanks to its great insulation.

Restrictions on Outdoor Applications

PVC is commonly employed in drainage systems and other underground purposes. Installed correctly, PVC can last for a long time. However, it is not weather-resistant. It can be damaged by direct sunlight and freezing temperatures when outside.

Pressure Systems and Non-pressure Systems

In a pressure system, changes in sea-level distribution are involved. To ensure your PVC or CPVC meets local requirements, it’s important to check local requirements. In most cases, PVC is the best material for both pressure systems and non-pressure systems. Water supply lines, irrigation lines, drinking water lines, and swimming pools, and fountains are some common applications of PVC in pressure systems. PVC can be used for non-pressure systems such as sanitary drainage, sewer lines, and roof drains.

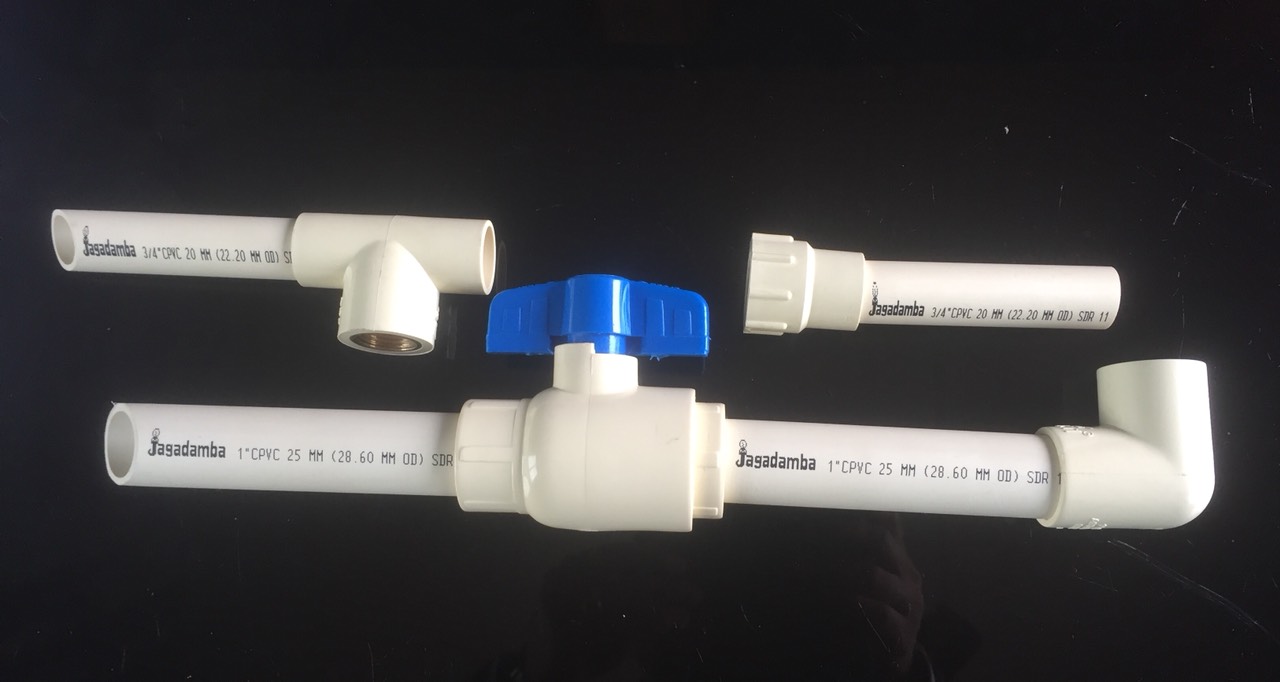

CPVC Pipes

The use of CPVC is also often possible when PVC is used. Due to the material differences, however, CPVC is only suitable for certain applications. Here are some examples:

Hot-Water Applications

For applications involving hot water, CPVC is a much better choice than PVC because it can withstand temperatures up to 200 F.

Applications Pertaining to Water Supply

PVC and CPVC are clearly the best water transport materials because of their chemical composition and low costs. In addition to transporting drinking water, CPVC is also commonly used for drainage.

CPVC is technically comparable with PVC, however, it is mainly used within the home for indoor water distribution systems (the pipes that transport water to fixtures). If your home has corrosive soil or water, CPVC is the perfect material.

Fire Sprinkler Systems

While it might seem that CPVC would melt in a fire, it actually has a classification of the best possible fire protection. The material is non-flammable, does not produce smoke, and does not produce burning droplets. For this reason, CPVC is an ideal material for fire sprinkler systems.

Not suitable for freezing conditions

Both PVC and CPVC are capable of withstanding maximum and minimum water temperatures. In spite of both types of pipes keeping water cold, freezing temperatures can damage them. Therefore, CPVC piping cannot be installed in a location that may be exposed to temperatures below 32°F.

Is It Possible to Use PVC and CPVC Together?

Despite the fact that all NPS size pipes and fittings will fit together, mixing and matching materials is not recommended. This can compromise the pressure and temperature rating of the pipeline. We always recommend that pressurized pipe systems be built from matching materials and schedules.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip