Industrial equipment is a solution to all needs and problems a company or organization has. There are many requirements these equipment and machines need to fulfill and yet slip rings are a tiny part of these devices that play an important role.

And if you’ve ever come across a slip ring and didn’t know what it was, you’re in the right place. In this article, you’ll find out everything about slip rings, industrial equipment, and the connection between the two.

You’ll also find real life examples and how slip rings solve an important requirement, so keep on reading!

What is a Slip Ring and What is its Function

Slip Ring is a small device that was initially designed and produced to eliminate wire winding problems in devices that feature a rotary part to it.

Therefore, it’s a small device that’s often overlooked, but is very important at bridging the gap between a stationary and a rotary part of a device or a machine.

However, this isn’t its only function. Thanks to a simple yet very wise and versatile design, slip rings can also transmit electrical signals, power, data, and even other mediums such as fluid.

On top of that, they’re also used to add resistance to generators, limit the total spinning speed of devices such as wind turbine’s blades, and more.

With so many different types and even available custom solutions, slip rings can fit many different needs and provide a couple of different functions at once.

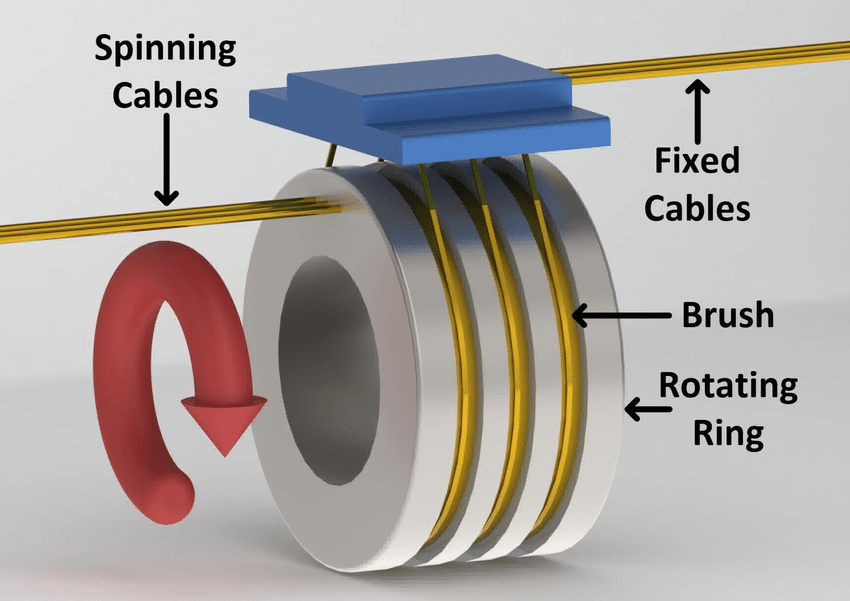

Two of the main components of slip rings include the outer casing which is a ring and the inner part which is called a brush or a wiper. As the rotary contact is made, the brush within the ring slides, creating a stable contact while eliminating wires from the moving joints of the machine.

Real Life Examples of Slip Ring Use

With so many different types and availability of slip rings, a wise and versatile design, slip rings are used in many different industries and they’re featured in so many different devices, machines and hardware.

Slip rings are often used in the food and beverage industry, in wind turbines, for aerospace, factory automation, robotics, radars, medical imaging equipment, monitoring equipment, and many others.

There are even slip rings that can transmit ethernet or fiber optic signals, which are used to transmit data between the electrical device and another remote device. You can even find wireless power slip rings that can transmit signals at unlimited RPM or brushless slip rings that have a super long lifespan.

All of these types work well for certain types of devices, machines, and equipment, but with such wide use, you can find slip rings in almost any device today.

Slip rings are an invention decades old, but they’re still the primary choice for use in equipment and devices that have both a rotary and a stationary part of a device because of their versatility, reliability, and ability to eliminate wiring problems around the joints.

Slip Ring Types

There are many different slip ring types and some of the most common types you can come across are the following:

- Pancake ring

- Mercury contact ring

- Ethernet or Fiber optic slip rings

- Through hole ring

- Miniature slip ring

These are the most common slip ring types, however, there are plenty of variations of existing types to match the needs of certain industries or equipment types.

On top of that, there are also various slip ring innovations that now include a wireless slip ring type or a brushless slip ring type that can last much longer than the regular slip ring that features brushes and yet is considered the future of a slip ring.

With 6 main slip ring types, its variations only differ mostly in size so slip rings can fit even in the smallest devices or hardware, but also in the larger machinery and equipment where there’s barely any space around the joints.

Another difference between the types is the medium it can transmit. While almost all slip ring types transmit electrical signal and power, there are slip ring types that can transmit ethernet signal, fluid, coolant, water, or even gas.

Moflon specializes in producing some of the most common slip rings as a manufacturing leader in the industry with over 30 years of experience, and apart from standard slip rings that can transmit electrical signal, power, analogue signals, and digital data, they also provide custom solutions to customers who need a custom slip rings built to fit their projects.

Benefits and Advantages of Slip Rings

The biggest benefit of slip rings is the ability to eliminate wire winding problems in the machines and equipment where there are both a rotary and stationary part to it.

While slip ring eliminates wires from joints, it not only removes a hazard and possible downtime of the machine due to wiring problems, but it also provides a superb contact between stationary and a rotary part through the ring.

Therefore, slip rings are used to simplify the operation and eliminate error which all leads to an improvement in the mechanical performance.

Slip rings are built in such a way that they can last long as long as they’re well maintained and they come in many different types, shapes, and sizes so they can fit many devices and equipment across many industries.

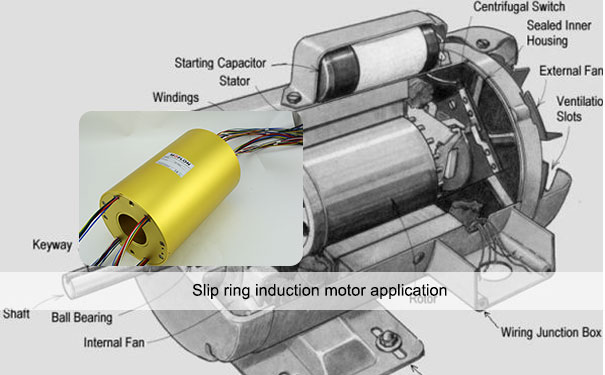

With such a simple yet wise build, slip rings have a smooth acceleration even under heavy load, they have a high overloading capacity, and they can even be used to adjust the speeds of an induction motor by adding resistance to the motor.

Therefore, slip rings are a great starter for machinery that needs a slow start and yet stable power connection throughout the use.

Conclusion

Slip rings are a couple of decades old devices and yet they’re one of the most versatile and stable solutions to not only one, but a couple of different requirements and problems.

With the newest versions of slip rings, they’re here to stay for long as the best solution to eliminate wires from the joints, eliminate wire winding, and improve the versatility and mechanical performance of the equipment.

Therefore, slip rings can be found in so many different high-end industrial equipment, as well as commercial or even consumer equipment in so many industries.