Speed Control of Induction Motor- An induction motor is a constant speed motor, which in a practical definition means that variation in the speed of the motor is approximately little relative to the total loading level. While the speed of a DC shunt system can be modified too simply with appropriate efficiency, the speed drop of induction motors can cause considerable loss of efficiency and reduces power factor. As induction motors are broadly employed in various applications, the speed control of an induction motor is an important consideration. So, different methods of speed control are discussed below in this post.

On the Linquip website, you can find a wealth of information about induction motors, and you are sure to find everything you will ever need to know about them. We have a team of experts who are specialized in motors and are ready to assist you with any questions that you might have regarding the speed control of induction motors. If you would like to continue reading, we strongly recommend you read Linquip’s article entitled “What is Motor?” first.

You now have the chance to become a Linquip Expert and gain access to all the benefits that Linquip can offer you in this regard. Do you have an interest in contributing to the Linquip website as a guest author? Your content can be submitted as a Guest Post on the Linquip platform if you wish.

Introduction to Speed Control of Induction Motor

Several types of motors are being utilized for general aims in our environment from house-hold devices to machine systems in industrial applications. Now, the electric motor is an indispensable and vital source of energy in many industries. The performance and function needed for these motors are too wide.

If you consider the speed control issue of the motors available in the market, stepper and servo systems monitor their speed with a pulse step, whereas the brushless DC and the induction motors determine the speed with an additional resistor or DC supply of voltage. For instance, a three-phase induction system is fundamentally a fixed speed motor. So, it is relatively hard to monitor its speed. However, the speed control of induction motor is operated to solve the reduction in efficiency issues and improve the electrical power coefficient.

This post presents the speed control principle, the structure, and the characteristics of the different methods that can determine the speed relatively simply by employing the particular circuits. Visit here to explore fundamentally about the speed control of induction motor. The speed of induction motor can be investigated from aspects: Rotor and Stator Side.

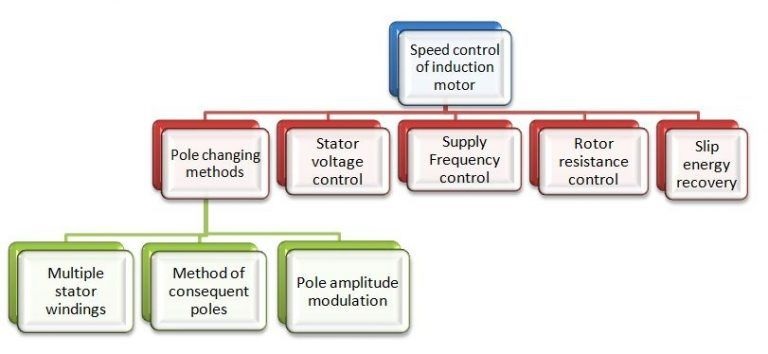

The speed control of an induction motor based on the stator aspect can be categorized as:

- V / f monitoring or frequency controller

- Variation of the values of stator poles.

- Monitoring the supply voltage.

- Adding variable rheostat in the stator system

The speed control of an induction system according to the rotor side are classified as:

- Using additional resistance on rotor section

- Cascade controlling way

- Injecting particular slip frequency emf to the rotor section

Speed Control of Induction Motor from Stator Side

By Changing the Applied Voltage

According to the torque formula of induction motor,

T=\frac { { K }_{ 1 }s{ E }_{ 2 }^{ 2 }{ R }_{ 2 } }{ \sqrt { ({ R }_{ 2 }^{ 2 }+{ (s{ X }_{ 2 }) }^{ 2 }) } } =\frac { 3 }{ 2\pi { N }_{ s } } \frac { s{ E }_{ 2 }^{ 2 }{ R }_{ 2 } }{ \sqrt { ({ R }_{ 2 }^{ 2 }+{ (s{ X }_{ 2 }) }^{ 2 }) } }

Rotor resistance R2 is fixed and if the slip value (s) is quite small, the term (sX2)2 is also small that it can be removed. So, T can be related to sE22 where E2 is the emf induced in rotor and E2 ∝ V.

Therefore, T can be evaluated based on (sV2), which means, if the required voltage is reduced, the final torque drops. Hence, the slip rises to supply the same load torque with a reduction in voltage, and as a result, the speed reduces. This method is too simple and effective but rarely employed because large variation in voltage output is needed for relatively few changes in velocity.

In other words, a large variation in final voltage will cause a large modification in flux density and will disturb the magnetic states of the system.

By Changing the Applied Frequency

The synchronous velocity of the moving magnetic field in an induction motor can be calculated by

{ N }_{ s }=\frac { 120f }{ P } (RPM)

where f is the frequency of the system and P is the number of poles in the stator. The synchronous velocity varies with the change in the frequency of the system.

The real speed of an induction motor is given as the next equation:

N={ N }_{ s }(1-s)

While this method is not commonly employed, it may be utilized where the motor is supported by an external generator (so that frequency can be simply changed by the speed variation of the main mover). The motor current at a lower frequency may increase according to the value of reactance. And if the frequency is improved beyond the standard value, the maximum torque reduces while the velocity rises.

In an induction motor, emf is presented by induction like a transformer which is given by

E\quad or\quad V\quad =\quad 4.44\phi KTf\quad or\quad \phi =\frac { V }{ 4.44KTf }

In this equation, K is the winding coefficient, f is frequency, and T is the number of rotations per phase. Now if we modify the frequency, synchronous velocity also varies but with a reduction in frequency flux and this flux variation causes the saturated condition in rotor and stator cores. Therefore, it is vital to keep the flux constant and this is only feasible if we modify the voltage. So, the ratio of V/f should be kept constant. This is the V/ f method. We should supply changeable voltage and frequency to control the speed of the induction motor by the V/f method by employing the inverter and converter set.

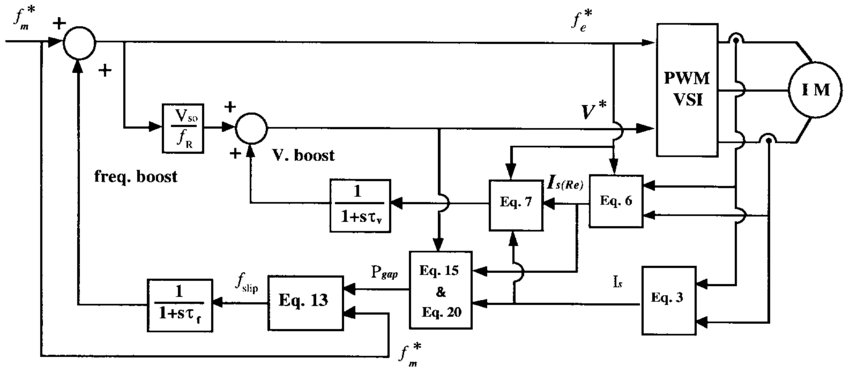

Constant V/F Control of Induction Motor

This is the most common solution for the speed control of induction motor. Like the above method, if the system frequency is decreased keeping the rated source voltage, the flux of air gap will be saturated. This will cause an additional current in the stator and distortion of the flux. Thus, the stator voltage must be decreased with the frequency to keep the flux constant.

The magnitude flux of the stator is related to the stator voltage and the system frequency. So, if the rate of voltage and frequency is maintained constant, the flux also remains fixed. The developed torque is relatively kept constant by keeping V/F fixed. This solution presents greater run-time efficiency. So, several types of speed drives apply constant V/F mode (or variable frequency based on variable voltage method) for the speed control of induction motor. Along with a broad level of speed controlling, this solution also provides the soft-start ability.

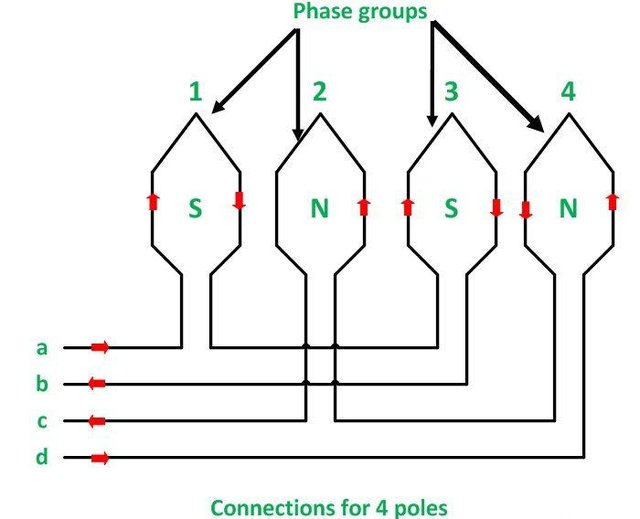

Changing the Number of Stator Poles

The stator poles can be modified and revised by two methods including Multiple system winding (MSW) and Pole Amplitude Modulation (PAM).

Multiple Stator Winding Method

We supply two divided windings in this method of speed control of induction motor in the stator. These two particular windings are electrically separated from each other and are covered for two various numbers of poles. Applying a switching configuration on one winding can provide the possibility of speed control. This solution has some disadvantages including the lack of smooth speed control. In addition, this way is too costly and less effective due to using two different windings.

Finally, this method can only be employed for a squirrel cage type of motors. It can be seen that running speed can be modified by the stator poles variation from the above formula of synchronous velocity. So, this method is commonly utilized for squirrel cage type of induction motors, since the rotor of this type revises itself for any number of poles. Variation in stator poles is obtained by two or more special stator windings insulated for a various number of poles in the same sections.

For instance, a system is provided with two 3-phase windings, one for 6 poles and the other for 8 poles to supply a frequency of 60 Hz

- i) synchronous velocity by 6 pole windings can be calculated, Ns = 120*60/6 = 1200 RPM

- ii) synchronous velocity by 8 pole windings can be calculated, Ns = 120*60/8 = 900 RPM

Pole Amplitude Modulation Method (PAM)

The primary sinusoidal mmf wave is alternated with another particular mmf wave including the different number of poles in this method of speed control of induction motor.

Suppose f1(θ) is the main mmf wave of induction motor whose velocity is to be determined, f2(θ) is the modulation mmf wave, P1 is the number of poles of a system whose speed is to be monitored, and P2 is the number of poles of a secondary wave.

{ f }_{ 1 }(\theta )={ F }_{ 1 }sin\frac { { P }_{ 1 }\theta }{ 2 }

{ f }_{ 2 }(\theta )={ F }_{ 2 }sin\frac { { P }_{ 2 }\theta }{ 2 }

So, we can obtain the modulation resultant mmf wave as:

{ F }_{ r }(\theta )={ F }_{ 1 }{ F }_{ 2 }sin\frac { { P }_{ 1 }\theta }{ 2 } sin\frac { { P }_{ 2 }\theta }{ 2 }

By applying the sinusoidal formula, we will finally achieve the resultant mmf wave as:

{ F }_{ r }(\theta )={ F }_{ 1 }{ F }_{ 2 }\frac { cos\frac { ({ P }_{ 1 }-{ P }_{ 2 })\theta }{ 2 } -cos\frac { ({ P }_{ 1 }+{ P }_{ 2 })\theta }{ 2 } }{ 2 }

It means that the resultant mmf wave will include two various number of poles, i.e;

{ P }_{ 11 }={ P }_{ 1 }-{ P }_{ 2 }\quad and\quad { P }_{ 12 }={ P }_{ 1 }+{ P }_{ 2 }

Therefore, by the number of poles variation, we can simply modify the velocity and adjust the speed control of induction motor.

Speed Control of Induction Motor from Rotor Side

Rotor Rheostat Control

This method is very similar to control the DC shunt motor by employing an armature rheostat.

However, this solution is just feasible for slip ring type of induction motors and requires an external resistance in the rotor which is not possible for other motors.

Cascade Operation

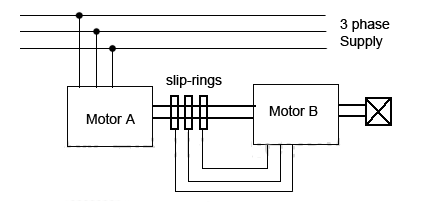

Two motors are used in this method for speed control of induction motor. Both motors are set on the same shaft so that both operate at the same velocity. One motor is supported by a 3-phase source and the other motor is supplied by the induced emf from the first motor with slip-rings. The configuration of them is presented in the following diagram.

If motor A is supposed as the basic motor and motor B is provided as the auxiliary system, we can define other parameters as the following:

Ns1: the frequency of system A, Ns2: the frequency of motor B, P1: number of stator poles of system A, P2: number of stator poles of system B, N: velocity of the system and equal for both motors, and f: frequency of the supply source.

Now, we can define the slip of motor A as:

{ S }_{ 1 }=\frac { { N }_{ S1 }-N }{ { N }_{ S1 } }

If the frequency of the rotor produced emf in system A is introduced as f1 = S1f, the auxiliary section of motor B is supported with the emf produced in rotor, therefore we can calculate the speed of secondary system as:

{ N }_{ S2 }=\frac { 120{ f }_{ 1 } }{ { P }_{ 2 } } =\frac { 120{ S }_{ f1 } }{ { P }_{ 2 } }

now we can put the value of S1 as the following and obtain the final equation

{ S }_{ 1 }=\frac { { N }_{ S1 }-{ N } }{ { N }_{ S1 } }

So;

{ N }_{ S2 }=\frac { 120f({ N }_{ S1 }-N) }{ { P }_{ 2 }{ N }_{ S1 } }

When the load is zero, the velocity of the auxiliary section of the rotor is equal to the synchronous speed and N = Ns2. So, from the last equations, it can be achieved that

{ N }=\frac { 120f }{ { { P }_{ 1 }+P }_{ 2 } }

With this solution, four particular speeds can be provided as the following:

- a) when just the system A operates, corresponding velocity = Ns1 = 120f / P1

- b) when just system B runs, corresponding velocity = Ns2 = 120f / P2

- c) When commutative cascading method is applied, speed of the system = N = 120f / (P1 + P2)

- d) When differential cascading method is employed, speed of the system = N = 120f (P1 – P2)

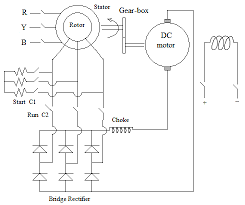

By Injecting EMF In Rotor Circuit

Speed control of induction motor is done in this method by injecting a particular voltage in the rotor diagram. The injected voltage (emf) needs to have an equal frequency with the slip frequency. However, there is no limitation for the phase of that emf. If the injected emf has the opposite phase with the rotor, the resistance of the system will be improved. Otherwise, if the injected voltage has the same phase as the rotor, the resistance will reduce. As a result, by the phase variation of injected voltage, speed control of induction motor can be applied properly.

The main benefit of this solution is a broad state of speed control can be obtained. This particular emf can be entered into the system by different steps like the Kramer system, Scherbius system, etc.

Which Drive Is Not Used to Control the Speed of An Induction Motor?

The moisture control technique is not used for a three-phase induction motor drive.

Download Speed Control of Induction Motor PDF

The PDF version of this article is available for individual download, making it easy to keep on your computer. Simply click on the link below to start downloading.

Read More In Linquip

- Working Principle of Induction Motor: 2022 Full Guide

- Efficiency of Induction Motor: Calculation & Equation

- What is Capacitor Start Induction Motor: A Complete Guide

- What Are Shaded Pole Induction Motors? 2022 Ultimate Guide

- What Is Split Phase Induction Motors? 2022 Ultimate Guide

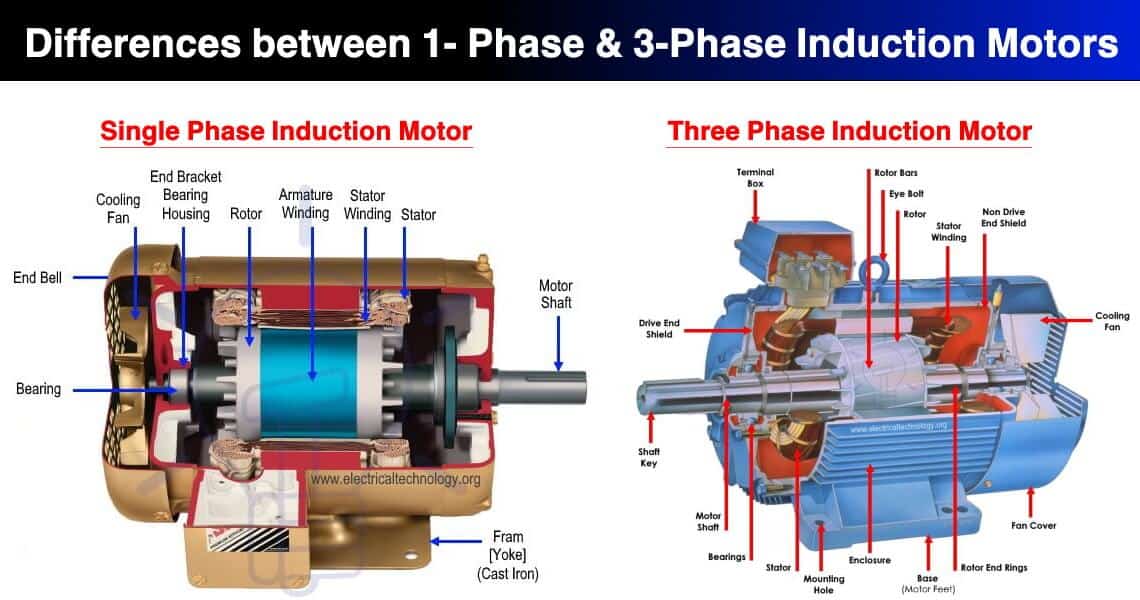

- Difference Between Single Phase and Three Phase Induction Motor: All you need to know

- Single-Phase Induction Motor : All You Need to Know About It

- Types of Induction Motor: A Concise and Useful Guild

Very Useful information pertaining induction motor. Can you send on LT motor with heavy duty .

You can find different types of Motors on Linquip.com

this page is very emportant studys about electricity !

Thank you for your comment Alex.