A steam condenser is a closed vessel-type heat exchanger applied to convert low-pressure exhaust steam from the turbine to water. A steam condenser is a mechanical device employed to condense exhaust steam of the turbine into the water. It conducts this process with the help of cooling water that circulates inside it from the cooling tower. The pressure within a steam condenser is held below the atmospheric pressure to enhance efficiency. It is commonly used to lower the backpressure of the exhaust at the turbine end.

Functions of the Steam Condenser

The steam condenser takes exhaust steam from one end and contacts cooling water circulating within it from the cooling tower on the other. In power plants, the Steam Condenser Is an Essential Product of Industrial Tools. Steam Condensers are available from a variety of suppliers and companies, as well as Manufacturers and Distributors, and there are many Steam Condensers for Sale on Linquip.

Linquip’s website has a complete selection of Steam Condenser services that will meet all of your needs. Linquip vendors can assist you with this. Please contact Steam Condenser Experts in Linquip to learn more about how to connect with a diverse group of service providers who consistently deliver high-quality products.

The purpose of using a steam condenser is:

- helping keep the pressure low (below atmospheric pressure) at the steam turbine end to get maximum possible energy and reduce the specific steam consumption of a power plant.

- supplying pure feed water to and from the hot well. The water is again pumped to the boiler using a boiler feed pump.

- raising the heat transfer rate by removing other non-condensable gases from the exiting steam.

Why Is Steam Condensed?

The water molecules within the bottle begin to condense or change from vapor to liquid water when there is no heat present. When matter transforms from a gas to a liquid, the molecules take up significantly less area and exert far less pressure.

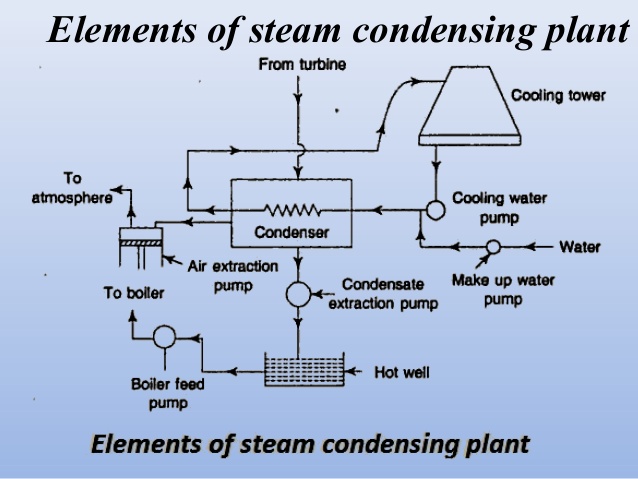

Steam Condenser Parts

The components required to operate a steam condenser are as follows.

Condenser

It is used to condense the steam. The steam with low pressure delivers its heat to the coolant (here water from the cooling tower), and it converts into the water through the condensation process.

Condensate Extraction Pump

A Condensate Extraction Pump (CEP) is a pump installed between the condenser and the hot well to transfer the condensate from the condenser to the hot well.

Hot Well

It is a pit between the condenser and the boiler. It takes the condensate by condensate pump from the condenser. The feed water is carried from the hot well to the boiler.

Boiler Feed Pump

It is a pump located between the hot well and boiler to deliver the feed water from the hot well to the boiler. This is accomplished by increasing the condensate pressure above boiler pressure.

Air Extraction Pump

It is a pump utilized to extract or remove the air from the steam condenser.

Cooling Tower

It is a tower containing cold water, and this water is provided to circulate inside the condenser to cool the steam.

Cooling Water Pump

It is a pump installed between the condenser and the cooling tower. It circulates the coolant within the condenser.

Steam Condenser Working Principle

In this section, we will give a basic description of how a steam condenser works.

A flow of cooling water is continuously circulating from the condenser inside a steam condenser to the cooling tower and the cooling tower to the condenser. When low-pressure exhaust steam leaves the turbine and passes through the condenser, it loses the heat and condenses into water. The circulating cooling water performs the extraction of the heat from the steam.

Two types of devices are installed on the condenser: the condensate extraction pump and the air extraction pump. Therefore, when the steam condenses into water, it re-circulates again to the steam generator with the help of a condensate extraction pump. Using the air extraction pump, a vacuum (the pressure below the atmospheric pressure) is created inside the condenser so that cooling water can circulate easily and also the condensate flow can be stabilized.

Due to the low pressure inside the condenser, the air enters the system so that the condenser is filled with a mixture of water, air, and steam.

Vacuum Efficiency

The vacuum efficiency describes the degree of completeness in obtaining the required vacuum in the condenser. It can be expressed by the following relation:

Vacuum\ efficiency=\frac{Actual\ vacuum}{Ideal\ vacuum}=\frac{Actual\ vacuum\ recorded\ by\ gauge}{Barometric\ pressure-Absored\ pressure\ by\ steam}

Condenser Efficiency

The ideal condenser only dissipates the latent heat so that the condensate temperature is equal to the saturation temperature (boiling point of water) corresponding to the condenser pressure. Latent heat is referred to the heat needed to turn a solid into a liquid or vapor without temperature change.

Ideally, the maximum temperature of the outlet cooling water is the condensate temperature but is less than the actual. So, the efficiency of the condenser is expressed as the ratio of the actual increase in cooling water temperature to the maximum increase in temperature:

Condenser\ efficiency=\frac{t_2-t_1}{t_3-t_1}

where, t1 and t2 are the cooling water inlet and outlet temperatures, respectively. Also, t3 is the saturation temperature corresponding to the pressure of the condenser.

Steam Condenser Types

In this section, we will explain the classification of the steam condenser and the operation basics of each type. The condenser can be generally classified into two categories: Direct Contact-type Steam Condenser, and Surface Condenser. In what follows, we will describe each type in detail.

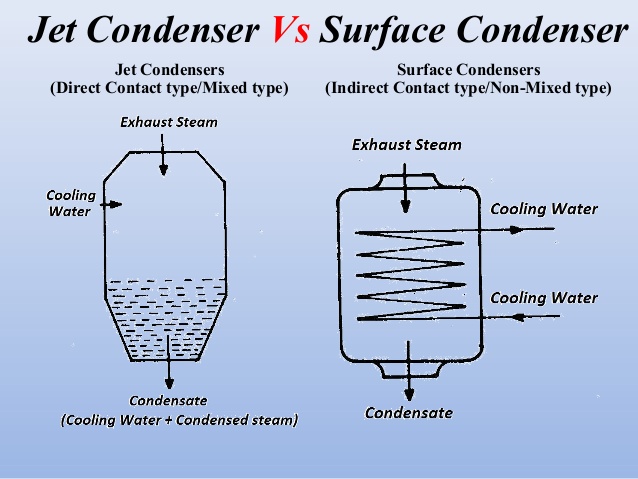

Direct Contact-type Steam Condenser

In this type, the steam (condensate) and the cooling water are mixed and become a single stream. In general, it is available in the market at a low cost. Moreover, the design of the direct contact type of condenser is very simple. However, in some cases, the mixture of cooling water and condensate is not allowed, and this type of condenser cannot be used.

Jet Condenser

Since it is a direct contact type condenser, the cooling water, and the condensate are mixed together and come out. As the steam is mixed with the cooling water, it is not possible to recirculate the cooling water to the boiler until it crosses through a water treatment plant. Because the condensate contains salt, it cannot be utilized as feed water to the boiler. The application of this type of condenser is where enough amount of good quality water exists.

Jet condenser sometimes loses some of the condensate and needs much power to pump during the condensation process. The condensing capability of the jet condenser is much higher than other types.

The jet condenser can be classified into four types:

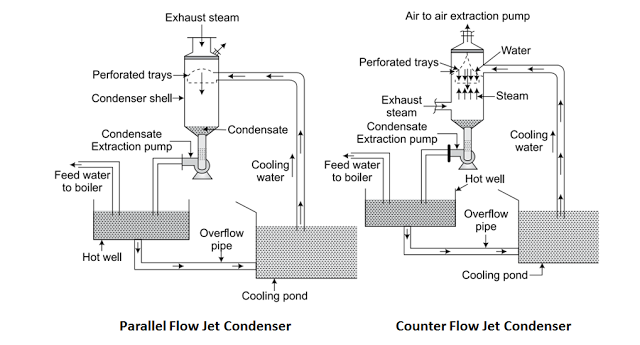

Parallel Flow Condenser

The direction of the steam flow and the cooling water flow direction is the same in a parallel flow jet condenser. Both flows come from the top of the condenser and, after mixing, come out from the bottom of the condenser.

As the steam and cooling water mix, the steam condenses. The condensate, cooling water, and air travel downwards and are removed by the air extraction pump and condensate extraction pump. The condensate pump carries the condensate to the hot well, and then the excess water flows through the overflow pipe into the cooling water tank or pond.

Counter Flow Condenser

This is exactly the opposite of a parallel flow jet condenser, where cooling water comes from the top side of the condenser, and exhaust steam enters the condenser from the bottom of the condenser. Therefore, the cooling water direction is downwards, and contrarily, the direction of exhaust steam is upwards.

In counter flow jet condensers (or low-level jet condensers), the air pump is installed at the top. The air pump makes a vacuum to draw the water from the cooling tower. The cooling water enters the condenser. It falls on the perforated conical plate to turn into a large number of jets. The falling jet of cooling water gets stuck in the trays, from where it exits in the second series of jets, and meets with the exhaust steam coming in from the bottom.

As the steam mixes with water, it condenses. The condensate and cooling water go down to the condensate pump through a vertical pipe. Finally, the pump conveys it to the hot well.

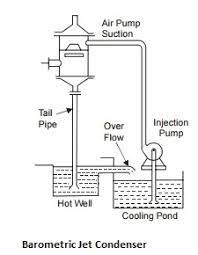

Barometric Jet Condenser

In the barometric condenser (or high-level jet condensers), the shell is installed on top of the hot well at the height of 10.36 meters. To achieve this, the discharge segment of the condenser is fitted with a long vertical tube which is called a tailpipe. No condensate extraction pump exists in this type of condenser. The current is entirely flowing with the help of gravity. However, there is a cooling water injection pump to deliver the cooling water from above the condenser. The barometric condenser is used with a vertical discharge pipe at a high level.

The steam enters from the bottom and travels upwards, facing the cooling water moving downwards. Other operations of this type of condenser is similar to counter flow condenser. The vacuum is made at the top of the shell of the condenser. The cooling water moves to the top of the condenser using a vacuum and injector pump. The condensate and cooling water come down through a long vertical discharge pipe into the hot well. Finally, the surplus hot water moves to the cooling tank or cooling pond through an overflow pipe.

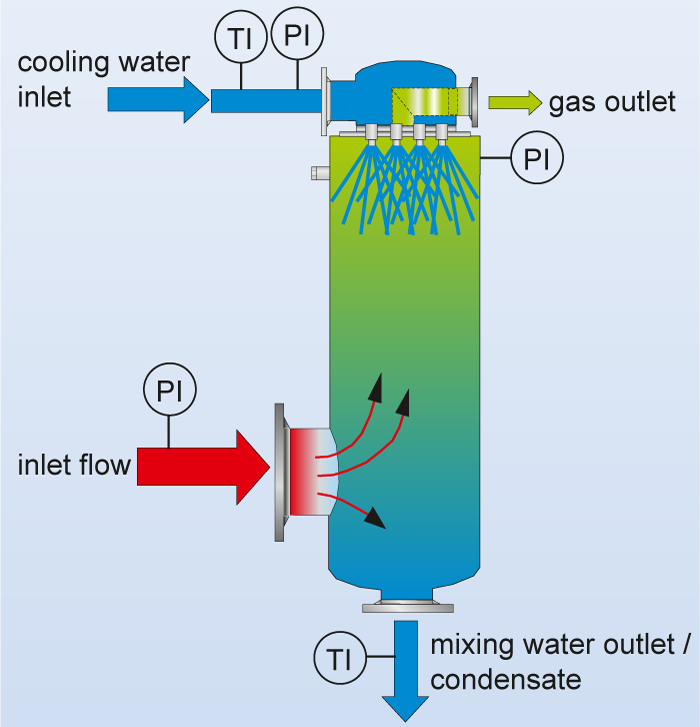

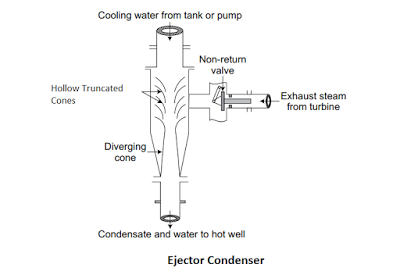

Ejector Condenser

In the Ejector condenser, the cooling water is injected from above. This condenser is equipped with a no-return valve through which exhaust steam enters the condenser. This condenser also has multiple convergent nozzles that help reduce the pressure inside the condenser. So, due to low pressure, the exhaust steam is drawn into the condenser through the no-return valve and mixed with the condensate and the cooling water.

Finally, there is again a divergent nozzle that converts the kinetic energy into the pressure energy and increases the pressure at the condenser exhaust to help extract the condensate from the condenser. The cooling water and the condensate are then drained into the hot well.

Surface Condenser

In general, surface condensers are used in the power plant. This condenser is also known as the shell and tube type condenser. No contact exists between the cooling water and exhaust steam. Therefore, the extracted condensate can be reused without any water treatment in the boiler. For this reason, the entire condensate can be applied as boiler feed water. It is also called a non-mixing type condenser.

The surface condenser includes a horizontal cylindrical vessel from cast iron and is packed with tubes through which cooling water flows. The perforated plates cut the condenser ends. The tubes are placed inside these plates in such a way as to prevent any water leakage into the center of the condenser space.

The water tubes pass horizontally through this space. In the surface condenser, the cooling water comes into the boiler through the lower half of the tubes in one direction. It returns in the other direction through the upper half. There are two water pass types; a single pass where water flows in one direction and a double pass or two passes in which water circulates in the condenser tubes in both directions.

At the top of the condenser, the exhaust steam enters and flows downwards because of the suction of the air extraction pump. When the steam flows in contact with the tubes containing cooling water, the steam condenses, where the heat transfer is conducted by conduction and convection processes. At the bottom, there is a condensate extraction pump that helps extract the condensed water from the condenser.

The surface condenser is applied in ships because it can transfer only a limited amount of water to the boiler. It is also broadly used for land installations in cases where there is a shortage of good quality water.

The surface condensers are classified based on the condensate flow direction, the arrangement of the tubes, and the installation of the extraction pump, as follows:

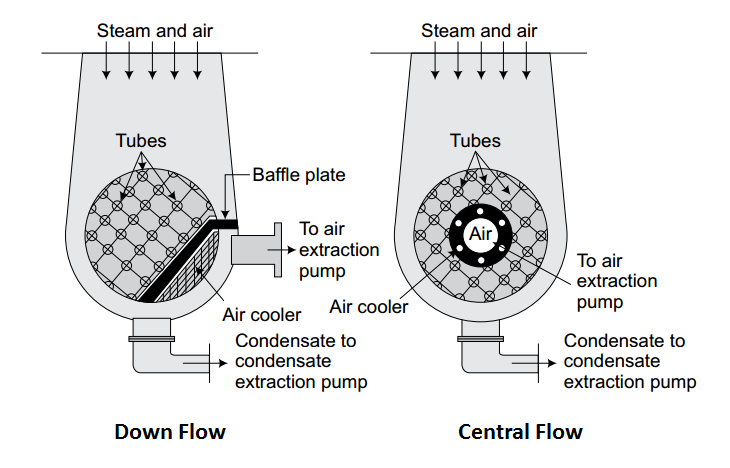

Down Flow Surface Condensers

In this type of surface condensers, the steam enters at the top portion of the condenser. It moves downwards over the tubes because of the gravity and air extraction pumps. The condensate is gathered at the bottom and then pumped by a condensate extraction pump. The tube of the dry air extraction pump exists near the bottom and is covered by baffle plates to prevent the condensate from entering.

When the steam travels downwards, it comes in contact with several cooling tubes, loses the heat, and gets condensed. In the down flow condenser, the steam flows perpendicular to the direction of cooling water flow. This is why this type of condenser is also called a cross-surface condenser.

Central Flow Surface Condensers

In the central flow surface condenser, the steam enters from the top of the condenser and flows downwards. In this condenser, the suction pipe of the air extraction pump is located in the center of the tube nest. Due to this placement, the exhaust steam moves radially inward across the tubes to the suction pipe. The radial motion of the steam ensures better heat transfer as the contact area with the tubes increases. The condensate is collected at the condenser bottom and pumped to the hot well.

It can be said that the central flow condenser is the modified form of the down flow condenser.

Regenerative Surface Condensers

In this condenser, the condensate is heated using the regenerative procedure. In this method, the condensate passes through the exhaust steam coming into the condenser from the turbine or engine. So, its temperature increases, and it can be used as the feed water to the boiler. It enhances the efficiency of the steam generation plant remarkably.

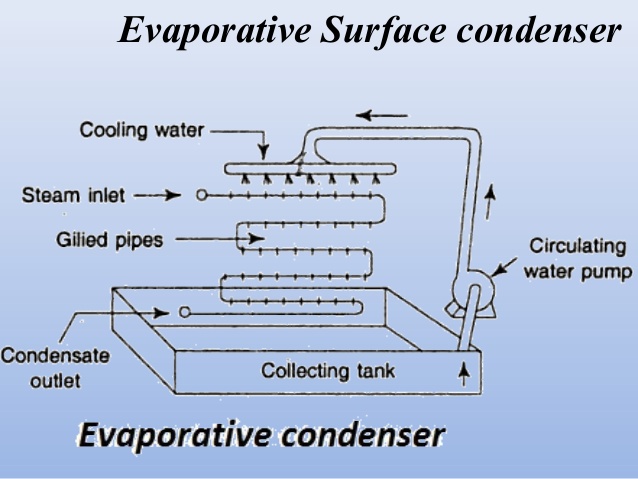

Evaporative Surface Condenser

In evaporative surface condensers, the steam enters the condenser from the top part in a series of tubes on which a cold water film falls. At the top of the condenser, a couple of nozzles are installed to spray cooling water. At the same time, the air flow is created to circulate over the water film. As the air circulates over the film of water, some of the cooling water evaporates.

As a result of this fast evaporation, the steam circulating within the series of tubes condenses. The remaining cooling water is collected at a raised temperature and reused. By adding the required amount of cold water, it is brought to the initial temperature.

Comparison between types of steam condensers

As mentioned above, direct contact-type and surface condensers have fundamental differences that are described here.

- In direct contact condensers, despite surface condensers, the cooling water and exhaust steam are mixed.

- For higher capacity plants, the use of surface condensers is more suitable than direct contact condensers.

- Condensing operation using a direct contact condenser is cheaper and easier.

- Condensate cannot be reused in direct contact condensers, but in surface condensers, it can be reused.

- The volume of water circulating in the direct contact condenser is less than that of the surface condenser.

- Unlike surface condensers, the maintenance costs of direct contact condensers are low.

- More power is required for air and water pumping in direct contact condensers.

Steam Condenser Applications

One of the applications of condensers (e.g., surface condensers) is in the thermal power plant to condensate the steam coming out from the turbine. Steam condensers are also applied in some food processing industries.

Steam Condenser Advantages

Given that there are different types of steam condensers, we will explain their advantages separately.

Direct Contact-type Steam Condenser

- The design of these condensers is simple.

- The construction of these condensers is cheap.

Surface Steam Condenser

- No mixing occurs in surface condensers. Therefore, pure condensate can be obtained, which can be reused in the boiler.

- Vacuum efficiency is greatly improved.

- The amount of cooling water needed for heat exchange purposes is almost low.

Steam Condenser Disadvantages

As advantages, the disadvantages of steam condensers can be listed by their types.

Direct Contact-type Steam Condenser

- Since the cooling water and the condensate come out in one stream, it is necessary to reuse the condensate with water treatment.

- In a direct contact-type condenser (e.g., jet condenser), vacuum efficiency is low.

Surface Steam Condenser

- Due to the complicated design, the initial cost is high.

- Due to the larger size of surface condensers, more floor space is required.

- The maintenance and repair of this type of condenser are relatively expensive.

Effects of Air Leakage

Another problem with condensers is air leakage. The sources of air leakage are:

- Leakage through packing and joints

- Dissolved air in feed water

- Air penetration along with sprayed water (in the jet condenser)

It has some adverse effects on the performance of condensers:

- Thermal efficiency drop.

- The need for cooling water increase.

- Heat transfer rate decrease (Due to poor thermal conductivity)

- The possibility of corrosion increase.

Download Steam Condenser PDF

Read More In Linquip

- Water Tube Boiler: What You Need to Know

- How Steam Boiler System Works?

- 5 Best Steam Boilers Worth Buying

- What is u-tube heat exchanger? An undeniable advantageous system

- The Complete Guide To Air Source Heat Pumps Disadvantages

- 16 Parts of Heat Pump and Functions (Clear Guide)

- Heat Exchanger Parts: Description of Configuration

- Parts of Boiler and Their Function in the Boilers

- What Is a Condenser; Parts, Functions and types