A strain insulator is an electrical insulator designed to be used in mechanical tension (strain) to withstand a suspended electrical wire or cable pull. Strain insulators are used in overhead electrical wirings for supporting overhead power lines and radio antennas. A strain insulator is inserted between a pair of lengths of wire to isolate them from each other electrically while keeping a mechanical connection. Also, they are used where a wire joins a pole or tower to transmit the pull of the wire to the support with electrical insulation. Engineers used Strain insulators first in telegraph wire systems in the middle of the 19th century.

What Are Strain Insulators?

A standard strain insulator is a piece of glass, fiberglass, or porcelain which are shaped to adjust two cables or the supporting hardware on the support structure and a cable shoe. The supporting structure can be a hook eye or eyelet on a steel pole/tower. The insulator’s shape maximizes the space between the cables while maximizing the insulator’s load-bearing transfer capacity. for example, for guy-wires, radio antennas, overhead power lines, and most of the other loads, the strain insulator usually bears physical tension.

In some situations, while the line voltage needs more insulation than a single insulator can provide, we can use strain insulators in series. The series is able to support the same strain as single insulators, but a series presents much higher effective insulation in the system. Series are a set of insulators that are connected to each other by using special hardware.

In terms of the insufficiency of one string for the strain, we use two heavy steel plates to bundle several insulator strings mechanically effectively. One plate is on the wire end, and the other one is positioned at the support structure. These fixings are almost globally used on long spans, the same as a power line crosses a lake, river, canyon, or other regions needing a longer rather than nominal span.

Typically, strain insulators are used outdoors in overhead wiring. In these environments, they are exposed to rain, pollution, and urban settings. As a practical matter, the insulator’s shape becomes critically crucial because if we have a wetted path from one cable to the other, it leads to a low-resistance electrical path. Strain insulators designed for horizontal mounting (known as “dead ends.”) have flanges to shed water, while strain insulators expected for vertical support (known as “suspension insulators”) are usually bell-shaped.

Types of Strain Insulators

Some types of strain insulators we use in common applications are listed below:

- Egg Type: Egg type strain insulator has low-voltage applications and is used in utility-pole guy cables to restrict any voltage on the guy caused by an electrical defect on the pole from reaching the lower parts accessible to the citizens.

- For 66 kV, 230 kV, and 115 kV AC lines, High-voltage strain insulators. The number of insulator skirts changes based on the voltage value and atmospheric conditions.

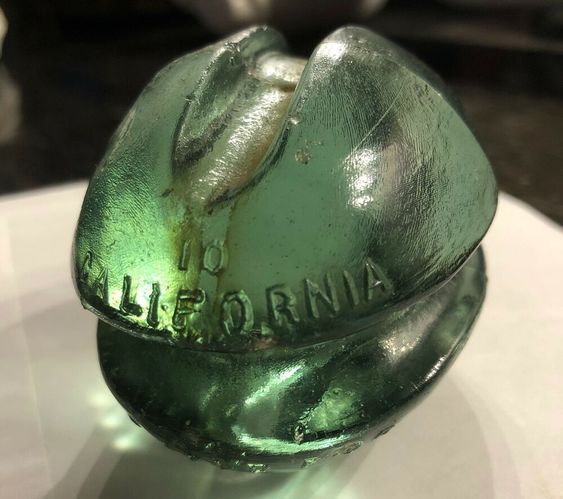

- For radio antennas, we use a pyrex-glass strain insulator.

What are Electrical Insulators?

As an ordinarily thought, electrical insulators are a non-conducting material, but in fact, a better description for them is a poor conductor or a matter of high resistance to the electric current flow. We can compare different insulating and conducting elements with each other by means of materials electric constant known as resistivity. You can also see a semiconductor.

We use electrical insulators for holding conductors in position, separating them from surrounding structures and from one another. An electrical insulator makes a barrier between exciting parts of an electric circuit and limits the current to wires’ flow or other conducting paths as desired. The insulation of electrical circuits is an essential demand for all electrical and electronic apparatus’s successful operation. Several types of materials are used as electrical insulators, and the collection is made fundamentally based on the particular requirements of each purpose.

The copper conductors employed in the electrical wiring of industrial plants and homes are insulated from the building and each other by plastics or rubber. Overhead power lines are maintained on porcelain insulators that do not be affected by outdoor exposure. For large electric generators and motors that run at high temperatures and high voltages, engineers usually insulated them using mica.

In some cases, solid insulation is used in conjunction with gaseous or liquid insulation. For example, in high-voltage transformers, solid insulation has mechanical rigidity, but oil or other liquid materials contribute to remove heat from the equipment and system and increase insulation strength. Insulating materials like silicon nitride can be employed in thicknesses as small as microns and in the microscopic structures’ integrated circuits.

Application of Insulators

For high-voltage electric power transmission, overhead conductors are uncovered, and the surrounding air is insulated wires. Conductors for lower voltages in distribution lines have some insulation but are regularly bare same as the high-voltage. Insulating supports, name insulators, are necessary at the points where utility poles or transmission towers support them. Also, insulators are required where the wire connects to buildings or electrical devices, such as circuit breakers or transformers, to insulate the wire from the position. Hollow insulators with a conductor in them are known as bushings.

Materials

For high-voltage power transmission, insulators are made from porcelain, glass, or composite polymer materials. Porcelain insulators are constructed from clay, alumina or quartz and feldspar, and are coated with a smooth glaze to shed water. Porcelain insulators made from rich alumina are employed where we need high mechanical strength, and it is a criterion. The dielectric strength of porcelain is about 4–10 kV/mm. On the other hand, glass has higher dielectric strength, but it has condensation. Also, the thick unusual shapes required for insulators are challenging to cast without internal strains. Some insulator companies stopped producing glass insulators in the 1960s and switched to ceramic material insulators.

Lately, some electric services have begun changing to polymer composite materials for some kinds of insulators. These are usually comprised of a fiber reinforced plastic made central rod and outer weather shed made of Ethylene Propylene Diene Monomer Rubber (EPDM) or silicone rubber. Composite insulators are less expensive, lighter in mass, and have excellent hydrophobic properties. The combination of discussed materials makes insulators ideal for service in polluted regions. However, these insulators do not have the long-term proven service life of porcelain and glass yet.

Design

The electrical failure of an insulator because of excessive voltage can happen in one of two following ways:

- A Puncture Arcis a malfunction and conduction of the insulator’s material, inducing an electric arc through the inside of the insulator. Typically, the heat produced by the arc damages the insulator irreparably. The voltage across the insulator (when installed in its usual manner) is the Puncture Voltage that makes a puncture arc.

- A Flashover Arc is a failure and conduction of the air nearby or along the insulator’s surface, making an arc along the surface of the insulator. Usually, insulators are designed to resist flashover without damage. The voltage causes a flashover arc, known as Flashover voltage.

Most of the high voltage insulators are produced with less flashover voltage than puncture voltage, so to avoid damage, flashover happens before puncturing.

Pollution, Dirt, salt, and especially water on the surface of a high voltage insulator may lead to a conductive path across it, creating leakage currents and flashovers. When the insulator is wet, The chance of flashover voltage can be decreased by more than 50%. High voltage insulators for outdoor usages are formed in unique shapes to maximize the leakage path’s length along the surface from one end to the other, name as the creepage length, to minimize the leakage currents.

For accomplishing this purpose, the surface is molded into a series of grooves or concentric disc shapes. They usually have one or more sheds, downward viewing cup-shaped surfaces that work as umbrellas to guarantee that the part of the surface leakage path beneath the ‘cup’ stays dry in rainy weather. The smallest creepage distance is about 20–25 mm/kV but must be improved in airborne sea-salt or high pollution areas.

Types of Insulators

These are the common types of insulators: strain insulator, pin insulator, post insulator, suspension insulator, shackle insulator, bushing, line post insulator, station post insulator, and cut-out.

Pin Insulator

As the name implies, the pin type insulator is positioned on a pin on the pole’s cross-arm, and there is a groove on the upper end of the insulators. The conductor is placed in this groove and is fixed to the insulator with annealed wire with the same matter as the conductor. Pin type insulators are used to transmit and distribute communications and electric power for voltages up to 33 kV. Insulators produced to operate at voltages between 33 kV and 69 kV are usually very big, and employing them has become uneconomical in the past years.

Post Type Insulator

These types of insulators were devised in the late 1930s and are more compact than conventional pin-type insulators and have immediately replaced many pin-type insulators on systems up to 69 kV, and we can use them for operation at up to 115 kV in some configurations.

Suspension Insulator

For voltages of more than 33 kV, it is usual to use suspension-type insulators. A suspension insulator consists of a number of porcelain or glass discs connected by metal links in series and the form of a string. At the bottom end of the string, we have the suspended conductor. At the same time, the top end is fastened to the cross-arm of the tower. Depending on the voltage, the number of disc units can vary.

Strain Insulator

We need a tower, dead-end, or anchor pole where angles off in another direction or a straight section of line ends. These poles must resist the horizontal (lateral) tension of the long straight segment of wire. For withstanding this lateral load, strain insulators are utilized. For less than 11 kV, shackle insulators can be employed in low voltage lines as strain insulators. However, in high voltage transmission lines, suspension (strings of cap-and-pin) insulators are used and in a horizontal direction attached to the cross-arm. In some systems, such as long river spans, the tension load in lines is extraordinarily high, and we should use two or more strings in parallel.

Shackle Insulator

In the earlier days, engineers used shackle insulators instead of strain insulators. But in recent years, they are generally used for low voltage distribution lines. We can use these insulators either in a vertical position or in a horizontal position. They can be fixed to the pole with a bolt or to the cross arm directly.

Bushing

Allows one or several conductors to pass through a partition, same as a tank or a wall, and insulates the conductors from them.

Insulation of Antennas

Engineers usually build a broadcasting radio antenna as a mast radiator, and that means the whole mast structure is energized with high voltage, which must be insulated from the ground. We use steatite mountings, while they have to resist not only the weight of the mast construction and dynamic forces but also the voltage of the mast radiator to the ground, which can reach up to 400 kV at some antennas. Also, lightning arresters and arcing horns are necessary because the strike of lightning to the mast is usual.

Guy wires carrying antenna masts typically have inserted strain insulators in the cable run for keeping the antenna’s high voltages safe from short-circuiting to the ground or creating a dangerous shock. Frequently guy cables have many insulators placed for breaking up the cable into sections to prevent undesired electrical resonances in the guy. The employed insulators are usually made of ceramic and cylindrical or egg-shaped. The advantage of this construction is the ceramic material under compression instead of tension, which can resist a more significant load. If the insulators tear, the cable is still linked to the end.

These insulators are equipped with overvoltage protection equipment. Static charges on guys have to be analyzed, due to the dimensions of the guy insulations. Static charges can be much higher for high masts compared to the voltage caused by the transmitter. As a result, it requires dividing guys by insulators into multiple segments on the highest masts.

We use particular twin lead-type feedlines to attach antennas to radio equipment, and they must often be kept at a distance from metal structures. For this purpose, we use insulated supports called standoff insulators.