Motors and generators are the indispensable parts of the electrical system that we use either in industries such as power stations, or for domestic applications. The requirement for electrical systems producing high energy and consuming less power, the invention of new models of these electrical devices is seen. One of the many kinds of motors that has come to our aid in recent decades is Synchronous motor.

In this article of Linquip we intend to introduce this motor, its working principle, main components, and talk about its different types. We know that many of you are about to buy one so, we will talk about different applications this motor fulfills. Read on to have your questions on this topic answered.

In the beginning, we prepared for you a simple definition of synchronous motors which helps you to enter further sections. Let’s begin!

What Is a Synchronous Motor?

A synchronous motor is an AC motor in which the rotation of the shaft is the same pace as the frequency of the applied current. In other words, the way a synchronous motor works is the same as an AC motor does but with the difference that the total number of rotations made by the shaft in synchronous kind is equal to the integer multiple of the frequency of the applied current.

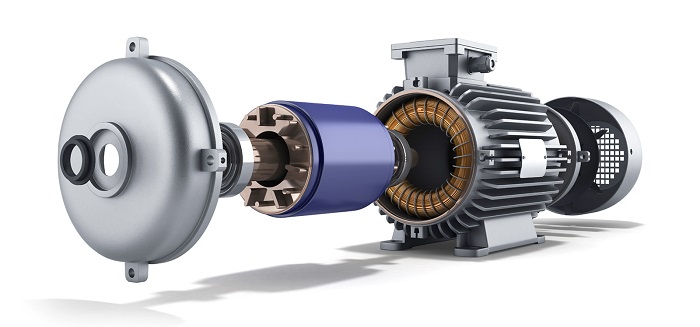

The synchronous motor doesn’t depend on induction current for its working. In this kind of motor, and unlike the induction motors, there are multiphase AC electromagnets on the stator that produce a rotating magnetic field. In synchronous, the rotor consists of a permanent magnet that is synced with the rotating magnetic field and rotates in synchronous to the frequency of current applied to it.

In the following two sections, you will be acquainted with the design of this kind of motor and learn how it exactly works. Please read on.

Shunt DC Motors: An Easy-to-Understand Explanation of Working Principle and Components

How Is a Synchronous Motor Designed?

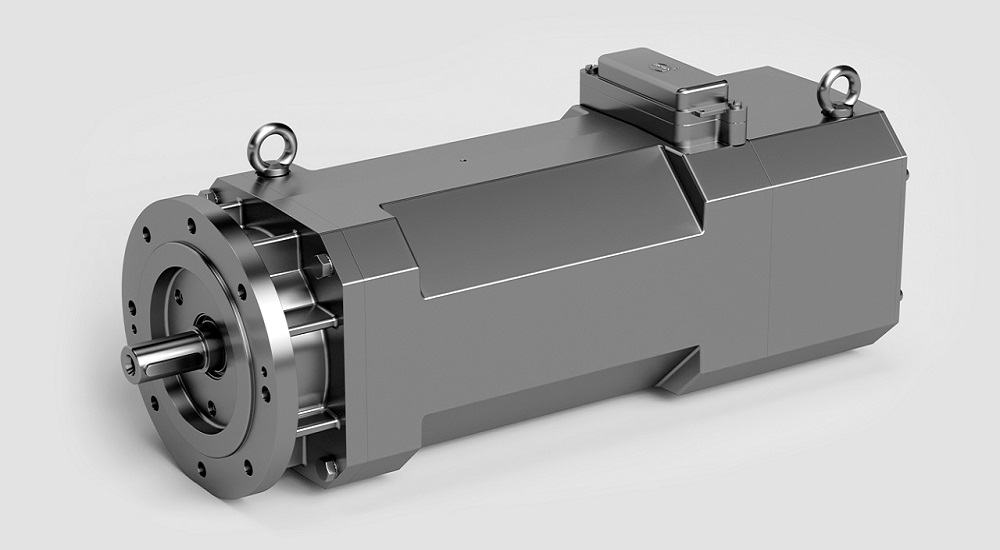

Like many other motors, the stator and the rotor are two main components of the synchronous motor. The stator frame of a synchronous motor has a wrapper plate that key bars and circumferential ribs are attached to. To support the machine, footings or frame mounts are used and slip rings and brushes are used to excite field windings with DC.

A synchronous motor uses cylindrical and round rotors for 6 pole applications. When a larger quantity of poles is required, salient pole rotors are the best choice to be used. The construction of a synchronous motor has the same construction as a synchronous alternator does.

The Construction of Synchronous Motor: All the Necessary Details You want to Read About

How Does a Synchronous Motor Work?

The interaction between the magnetic field of the stator and the magnetic field of the rotor. Three phase power feeds The stator of the motor that contains three phase windings. So, the stator winding makes a rotating magnetic field that is of a 3 phase. As we mentioned before, direct current supply is a source for the rotor.

The rotating magnetic field that the stator winding produces is where the rotor enters into and rotates in synchronization. Now it is more clear for you that the speed of the motor depends on the frequency of the supplied current. Actually, the Speed of the synchronous motor is controlled by the frequency of the applied current.

As a summary of what has been said so far, the three phase stator winding of a synchronous motor carries three phase current and makes three phase rotating magnetic flux. On the other hand, the rotor also carries DC supply and produces a constant flux. If we consider that we have a 50 Hz power frequency, from the above relation we can see that the 3 phase rotating flux rotates about 3000 revolutions in only one minute or 50 revolutions in just 1 second.

In some cases, it happens that the rotor and stator poles are of the same polarity (N-N or S-S). It causes a repulsive force on the rotor. This polarity will be N-S very soon and it causes an attractive force. But because of the inertia of the rotor, it is unable to rotate in any direction due to that attractive or repulsive force, and the rotor remains in standstill condition. It is why a synchronous motor is not self-starting.

So far, you get familiar with the overall function of the synchronous motors. Now that you know what is the purpose of this construction and how it works, let’s see how many types it has and how they differ from each other.

Brushed DC Motor: A Comprehensive Explanation of Working Principle, Parts, and Types

Different Types of a synchronous motor

based on the method of magnetization of the rotor, there are two types of synchronous motors which are:

-

Non-excited Motor

-

DC Current Excited Motor

-

Non-excited Motor

- In this type of motors, the rotor is magnetized by the external stator magnetic field and the rotor has a constant magnetic field. In this type, to make the rotor, high retentive steel such as cobalt steel is used. This causes three other classifications as a permanent magnet, reluctance, and hysteresis motors.

- For the design of Permanent magnet synchronous motors, a permanent magnet is used along with steel. They have a constant magnetic field in the rotor, so induction winding cannot be used for starting. Being used as gearless elevator motors.

- The rotor of the reluctance motor is made up of steel casting with poles of projecting tooted. The rotor poles are less than the stator poles in order to minimize the torque ripples.

- Hysteresis motors are self-starting motors. in this type of synchronous motors, the rotor is a smooth cylinder made-up of hard cobalt steel. This type of motor is expensive and is usually used where there is a need for precise constant speed.

What is a Hysteresis Motor: Ultimate Guide

-

DC Current Excited Motor

When the rotor of a synchronous motor is excited using the direct current supplied directly through slip rings, it is called DC current excited motor.

The Main Features of Synchronous Motors

- The first feature of the synchronous motors is that the speed is independent of the load. It means that the speed of the motor is not affected by the variation of the load.

- The second main feature is they are not self-starting and they need a prime mover to rotate the motor at their synchronous speed.

- And the last main characteristic is that a synchronous motor works for both leading and lagging power factor.

Where Is a Synchrounous Motor Used?

Synchronous motors are usually used where there is a need for precise and constant speed. Low power applications of these motors include positioning machines. This kind of electric motors is also applied in robot actuators. Some other applications make use of synchronous motors such as ball mills, clocks, and record player turntables. Besides, these motors are also used as servomotors and timing machines.

Conclusion

In this article, we tried to show you what exactly a Synchronous motor does. To make it clear for you, we analyzed the working principle of synchronous motors and elaborated on how they work. We explained the parts it consists of. After that, we delved into different and main types. then, we reached the different characteristics and features. At last, we told you about its applications and where it is used more commonly.

If you have any experience of using different types of synchronous, we will be very glad to have your opinions in the comments. By the way, if you have any questions about this topic and if you still have ambiguities about this device in your mind, you can sign up on our website and wait for our experts in Linquip to answer your questions. Hope you enjoyed reading this article.

Why are so many links failing in the “Read more on Linquip” boxes? Clicking on them results in a “404 Page not found” error!

Thanks for visiting our website, Brian! We first apologize for any inconvenience experience you had with this article. Your valuable comment will be considered for the next update of the post.

Interesting Blog!

Thank you so much for visiting our website. We are looking forward to hearing more from you.