Here’s Linquip’s guide to the Best Mini/Benchtop Milling Machine in 2024. Adding a milling machine to your home shop will enhance your store countless times. After reading this article, you will have the chance to make the best choice.

There is plenty of information about milling machines available at Linquip, so don’t worry. The best mini-milling machine on the market is introduced to you by Linquip as a means of helping you do your job better. We have a page called “What Is Milling Machine?” where you can find out what Linquip can offer you based on your intended use.

Have you considered purchasing a mini/benchtop milling machine? You can search through Linquip’s extensive selection of Milling Machine Products for free in order to find the right product you are looking for. Linquip platform can help you if you need to know the price of a milling machine and other related equipment. We make the process of requesting free quotes from Milling Machine Suppliers and Companies quick and easy. It will not take long for you to receive them.

The use of milling machines was once the exclusive domain of large factories and garages. Nowadays, however, milling machines have become much more widely used due to technological advances. To create desired designs or textures, milling machines machine out a variety of materials, including wood and metal. As this technology has been put into entrepreneurs’ hands more and more frequently in the last few decades, the world of milling has enjoyed a kind of renaissance.

In response to this increase in overall demand, milling machine buyers now have a variety of choices and competing companies to choose from. In this post, we have compiled a list of the most cost-effective and best-quality milling machines available today in order to meet these needs. Our objective is to outline the strengths and weaknesses of each milling machine, as well as provide the criteria for ranking and evaluating each one.

List of 12 Best Mini/Benchtop Milling Machines in 2024

According to the factors that we will mention in this article, Here is the List of 12 Best Mini/Benchtop Milling Machines in 2024:

- Grizzly G8689 Mini Milling Machine Buy Now

- JET 350017/JMD-15 Milling/Drilling Machine Buy Now

- PROXXON MICRO Mill MF 70, 37110 Buy Now

- OTMT OT2213 X2 Variable Speed Mini Milling Machine Buy Now

- WEN 33013 4.5A Compact Benchtop Milling Machine Buy Now

- LittleMachineShop HiTorque Mini Mill Buy Now

- SUNWIN Metal Mini Milling Machine Buy Now

- SHOP FOX M1110 Mill and Drill Buy Now

- Klutch Mini Milling Machine Buy Now

- Grizzly G0781 3/4 hp Mill/Drill Buy Now

- Sherline 5400-Deluxe – Sherline Deluxe 5400 Series Mill Buy Now

- Taig Tools Micro Mill – Taig 2019CR-ER Micro Mill Buy Now

How We Selected The Best Mini/Benchtop Milling Machine in 2024

When selecting the best mini or benchtop milling machines, our approach was thorough and multifaceted to ensure we provided reliable and practical recommendations for a variety of users, from hobbyists to small-scale professionals.

- Technical Specifications Review: We started by examining the core technical specifications of each machine, such as horsepower, spindle speed (RPM), and overall machine size and weight. This allowed us to assess the capability of each machine in handling different materials and the types of projects they are best suited for. We also looked at the voltage requirements to ensure the machines could be easily accommodated in typical workshop settings.

- Performance and Precision: Key to any milling machine is its performance and precision. We delved into how well each machine maintains accuracy and consistency during operation. This involved looking at user reviews, expert opinions, and any available case studies. Machines with high precision and reliable performance scored higher in our evaluation.

- Ease of Use and Versatility: We considered how user-friendly each machine is, especially for beginners or those who might not have extensive experience with milling machines. Adjustability, control interface, and the ease of setup and maintenance were crucial factors. Additionally, we looked at the versatility of each machine – how well it adapts to different materials and the range of tasks it can perform, including the availability of compatible accessories and upgrades.

- Durability and Brand Reputation: The build quality and durability of each machine were assessed, as a milling machine is a significant investment. We favored machines built to last and that require minimal maintenance. Brand reputation and customer support were also important factors, as they indicate the manufacturer’s confidence in their product and their commitment to customer satisfaction.

- Cost-Effectiveness: Finally, we considered the cost of each machine in relation to its features and capabilities. While some high-end models offer advanced features, we also recognized the importance of value for money, especially for hobbyists or small businesses. Machines that offer a good balance of quality, performance, and price were highlighted as they represent a sensible investment for most users.

Basics of Mini/Benchtop Milling Machine

A benchtop milling machine is a miniature version of the large industrial milling machines you will find in large factories. Consequently, they are perfect for DIY projects requiring precision and strength without needing a full-sized machine.

These smaller machines, however, are usually less powerful because of their size. There are some that are grossly underpowered, while there are others that are suitable for most DIY projects. To achieve success, you must purchase an excellent benchtop milling machine.

In spite of the fact that these machines are often not the most economical, they offer great capabilities that cannot be matched by simpler, cheaper tools. In the end, a mini milling machine can prove invaluable for freelance technicians, interior designers, DIY enthusiasts, or even artists, and if you employ it correctly, you might even save time and money in the process.

You know what a milling machine is worth if you are in the manufacturing industry. Often found in assembly lines and tool and die shops, these machines perform a variety of tasks. A milling machine is necessary for nearly every industry, from automobiles to science labs. In comparison to a standard 3D printer, they are capable of producing parts with greater precision.

The versatility of these tools is often used to shape items and remove metal and other materials to make flat surfaces. In addition to this, they can also create irregular surfaces, drill, bore, produce slots, and produce flutes in drills.

When operating a milling machine, safety precautions should be taken just as they are when using any other device. As far as your well-being is concerned, it is advisable that you wear safety glasses and hearing protection.

Milling machines consist of stationary cutting tools and movable tables that are controlled either manually or automatically. To produce the desired results, a workpiece is secured to a table that moves around a rotating blade.

The mini mill machine is similar to a full-sized milling machine. However, it is smaller, sitting on a workbench or table and making or modifying components from wood, metal, and composite materials. While large milling machines can have a horizontal or vertical orientation, mini milling machines are typically vertically oriented, with the shaft axis also vertical.

Mini/Benchtop Milling Machine Buying Guide

The creation of the list of top benchtop milling machines required going through a significant number of milling machines that are practically available to sole proprietors as well as small businesses and organizations. Creating criteria from which they could be judged helped us determine which ones remain. There are some straightforward criteria – for example, the cost and the capabilities. You should also consider the mini milling machine’s personal or practical value to your needs.

When choosing the best mini mill machine, consider factors such as:

- Size

- Ability to adjust the table position

- Clamps that hold materials in place

- Speed range

- Motor power and horsepower

- Depth to which the spindle can reach

- Torque

- Table-to-head distance.

Also available are options such as inbuilt lighting, powered assisted tables, and coolant pumps. There is generally a direct relationship between the more extras you want and the higher your bill.

This buyer’s guide can help you sort through the tons of options out there and help you choose the right one.

Motor Power

Power is the key to a machine’s ability to work well and work with a wider variety of materials. Ideally, you want the most power possible. There is, however, a cost associated with more power. This is why selecting a machine depends on how much power you need. Buying a more powerful machine that you do not need is a waste of money.

You might be able to get by with a 3/4 HP motor if you do light projects. A 1 HP motor is recommended for regular use. Your budget and the jobs you plan to do will determine how much you can afford. A machine with a lower power rating does not necessarily mean that it is of poor quality.

Range of Motion

There should be a lot of movement on your machine’s x- and y-axis. By doing this, you can make holes at precisely the right size and at the correct location. If your device does not have a wide range of motion, you may not be able to accomplish specific tasks. When the machine is incapable of putting the hole where you want it to be, your project will be hard to complete.

Durability

Your machine’s durability is essential. The last thing you want is for it to break soon after you use it. The expensive nature of these machines should ensure that they last for many years. You should look for high-quality materials such as cast iron and treated aluminum. Cast iron makes machines stronger, so the more cast iron a machine has, the stronger it will be.

Besides the external components, you should also consider the internal ones. Because it is harder to see what is inside the machine, it can be more challenging. For this reason, your best bet will be to read reviews, such as ours.

Design

The blades and other cutting tools work in different directions on the material, so you can choose either a vertical or horizontal machine.

Features

A number of features are required on a good machine, including digital readouts, cast-iron construction, three- or four-axis motions, high-speed spindles, tilting heads, and heavy-duty horsepower.

Tooling and Accessories

When buying a mill, you want to make sure that the tools and accessories are readily available on the local market. The selection of tools and accessories should be based on thorough research.

Precision

Choosing a CNC mill that uses computer numerical programming will give you the highest degree of precision. They are worth the extra cost even though they are more expensive.

Capabilities

More or less, this depends on the machine’s size, power, whether it’s a horizontal or vertical mill, and whether it’s retrofittable (and how easy that is). All of these factors combined allow one to expect a machine to perform a variety of tasks. For the most part, a higher rating is assigned to a product with more excellent capabilities.

Price

The machines needed to be evaluated based on cost-to-benefit ratios in order to actually compare them. As an example, a machine that can perform 60% of the same task for only 10% of the price was considered to be of better overall value.

Best Mini/Benchtop Milling Machine Reviews

We have compiled this list of the best mini milling machines based on our extensive evaluations of products in different price ranges. To make a well-informed choice, make sure to read our buying guide and check out our best models.

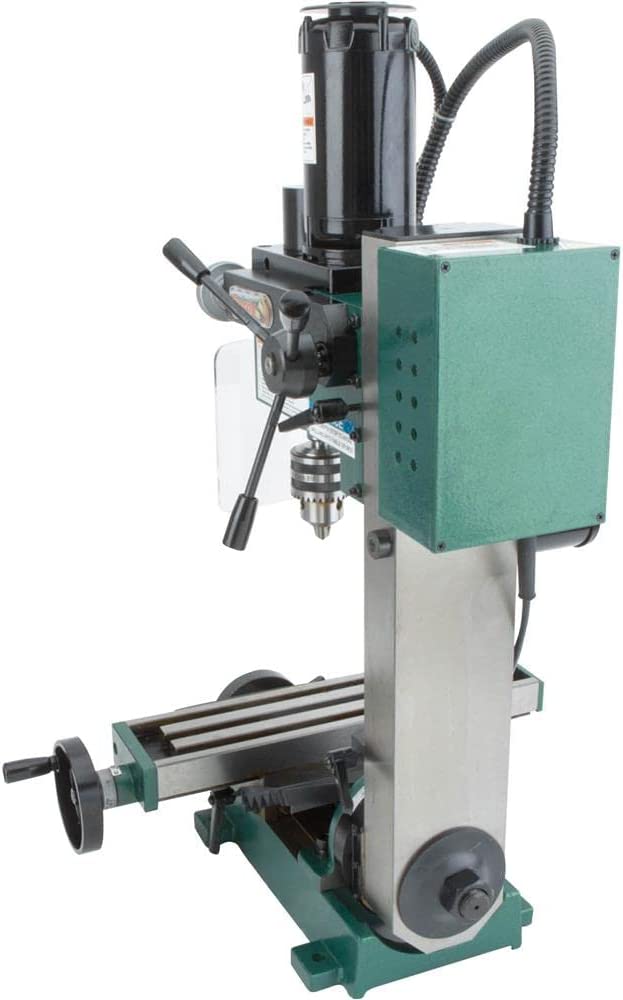

1. Grizzly G8689 Mini Milling Machine

Specifications

| Item Weight | 149 pounds |

| Item Dimensions | 19 x 20.5 x 30 inches |

| Horsepower | 3/4 |

| Table travel | 7-5/16-inch longitudinal and 4-inch cross |

| Head travel | 7-1/2-inches |

Grizzly G8689 Mini Milling Machine is an excellent choice if you want to mill small parts and tools. With its 3/4 horsepower motor, the machine can drill 1 inch, mill 1 inch, and face 1 inch with a wide range of advanced features. This small mill sets up quickly and securely on your bench, making it easy to control the cuts precisely. Additionally, its variable speed control and gear drives will guarantee you will have no trouble milling.

The machine features a safety shut-off switch to ensure your safety while milling. Furthermore, you will be able to set the device for precise cuts through the adjustable depth stop control. If you need to work on small parts and tools, you also get a fine feed head control. Easy-to-set-up knobs and controls simplify the setup process. Features, such as adjustable dovetail ways and zero-setting dials, ensure that you get accurate cuts with the best setup.

Despite being a mini milling machine, you can use it for creating small engine heads for motorcycles. In most cases, however, it is used for small items, such as gunsmithing parts and tools. Thanks to its heavy-duty cutting tools, it is capable of milling hardened steels.

2. JET 350017/JMD-15 Milling/Drilling Machine

Specifications

| Item Weight | 440 Pounds |

| Item Dimensions | 42.75 x 28 x 29 inches |

| Horsepower | 1 |

| Table travel | 14 inches longitudinal and 1-1/2 inches cross |

| RPM | 110 – 2,850 |

The device’s lightweight construction makes it easy for people with a small workshop to move it around. In addition to offering simple belt-driven drilling, it has the capabilities of a milling machine’s table for precision cutting. One-piece cast iron columns provide the support needed to make the mill strong and effective.

JET 350017/JMD-15, like all other machines, is tested to ensure it delivers consistent quality and meets high standards. The company has more than 750 service centers in the U.S., so you can be assured that experienced technicians will provide you with parts and services. This machine’s 1 HP motor can create pieces from hardened steel and other tough materials. Depending on the materials you are working with and the precision you require for the finished product, you can adjust the speed of the machine from 110 RPM up to 2,580 RPM.

For any type of work, the model has a positive quick-stop knob, which gives the user complete control. Furthermore, you will have easy-to-read depth gauges and belt covers and a belt adjustment feature to allow you to make the necessary customizations.

3. PROXXON MICRO Mill MF 70, 37110

Specifications

| Item Weight | 18.21 pounds |

| Item Dimensions | 16.93 x 11.02 x 9.45 inches |

| Horsepower | 1/8 (Maximum) |

| Table travel | 2 ¾ inches vertical |

| RPM | 5,000 – 20,000 RPM |

In case you have a limited budget, the Proxxon 37110 MICRO Mill is what you should get. This is the best benchtop milling machine available today at this price point. It’s smaller than other options, making it better for small workshops like the ones your average homeowner might have. It produces little vibration and is reasonably quiet. In particular, if you’re concerned about waking up your neighbors, these features make this machine a good choice for homeowners.

Thanks to its lightweight and slim design, it is easier to fit into tight spaces. It functions as well as other compact options without compromising on performance. Still, it is quite precise and works quite well. In addition to the cast iron base, the vertical column and compound table are made of aluminum. In all likelihood, it will last a long time. With its handwheels, this machine can be adjusted very accurately, which makes it ideal for use in precision-related situations.

If you want to use this milling machine in jewelry, optics, electronics, or model construction, you should consider it.

The axes on this machine aren’t extremely precise, which is one of its significant problems. There is a tendency for them to move slightly away from zero when you adjust them. There shouldn’t be any problem with this for most people. It may, however, be extremely frustrating for some people, especially if they’re performing precision tasks.

4. OTMT OT2213 X2 Variable Speed Mini Milling Machine

Specifications

| Item Weight | 140 pounds |

| Item Dimensions | 22.04 x 19.68 x 29.13 inches |

| Horsepower | 1/2 |

| Voltage | 110 Volts |

| RPM | 0 – 2,500 RPM |

As you can see, the OTMT Variable Speed OT2213 Benchtop Mill offers the best value for money because there are cheaper models available, but they don’t offer the same quality as this one.

There is really no reason to regret spending a little extra on this model, as it is well worth consideration. In the opinion of the users, the machine worked perfectly. This machine was compared to some larger models, and they found it to be more affordable and the best value.

The X and Y axes showed some slippage, which was one of the disadvantages. If we had concentrated solely on milling, everything would have been fine. This is an affordable benchtop mill, so you have to deal with it. The price of perfection will be much higher if you want it.

5. WEN 33013 4.5A Compact Benchtop Milling Machine

Specifications

| Item Weight | 130.1 pounds |

| Item Dimensions | 23.25 x 22 x 29.5 inches |

| Horsepower | 1/2 |

| Motor | 4.5 Amp |

| RPM | 100 – 2,500 RPM |

A 13-inch swing tool is used on this single-phase milling machine. The tool can be used to create flat surfaces, angled edges, straight holes, contours, pockets, and slots, as well as other projects, so it can be used for a variety of DIY and crafting jobs.

With a capacity of 5/8-inch end mills, 1/2-inch drillings, and 1 1/8-inch faces, the WEN can accommodate a wide range of cutters, bits, and mills. Left or right movement is possible with the bevel head. Depending on the speed, the low speed can go from 100 – 1,100 RPM, and the high speed can range between 100 and 2,500 RPM. On the X-axis, you can move the item 11 13/16 inches; on the Y-axis, 5 1/8 inches, and on the Z-axis, it can move 7 inches. You will find tooled ruler markings for your convenience in order to maintain complete accuracy.

For stability, the base has bolt holes for anchoring the machine to a table. It weighs 130.1 pounds, which is a heavy enough weight to minimize vibrations. Hobbyists will find this milling machine very useful as it can do a variety of cutting, including aluminum, acrylic, and soft metals.

6. LittleMachineShop HiTorque Mini Mill

Specifications

| Item Weight | 124 pounds |

| Item Dimensions | 19.7 x 23.2 x 36.3 inches |

| Horsepower | 0.67 |

| Wattage | 500 |

| RPM | 2,500 RPM |

This machine is significantly lighter than others. A smaller base and a lighter weight make it a more attractive option than many others listed here. Therefore, smaller workshops may be able to accommodate it better. Homeowners with small workspaces may find this reliable.

LittleMachineShop’s HiTorque Mini Mill is fantastic, but it has a few shortcomings. The product description mentions things such as “most torque in class.” However, it is difficult to determine how much torque the machine has. The information isn’t easily accessible anywhere. The product description contains small inconsistencies like this, which raises suspicions about the overall quality of the device.

Also, this machine has a bad spindle lock design. This causes the parts to become deformed and practically unusable because it is much tighter than it should be. There is also a very poor level of customer service.

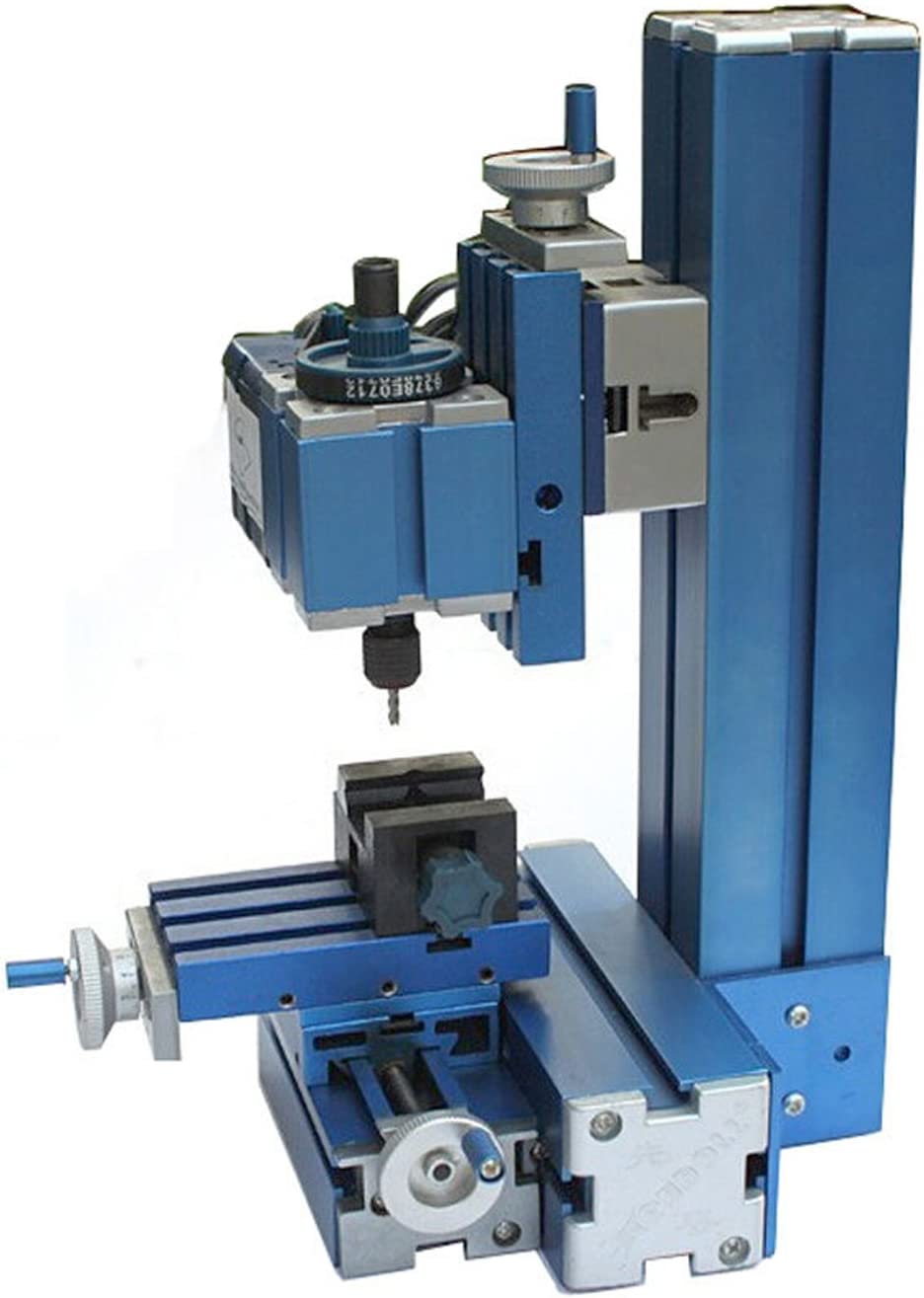

7. SUNWIN Metal Mini Milling Machine

Specifications

| Item Weight | 6.2 pounds |

| Item Dimensions | 9.8 x 9.8 x 5.9 inches |

| slide travel | 1.37 to 1.77 inches |

| RPM | 20,000 RPM |

Small metalworking and woodworking tasks can be handled easily with this mini milling cutter, which is perfect for hobbyists, especially students. Metal is used for all major components, including the spindle, tailstock, slider, pedestal, connection piece, motor blades, and gears. It is composed of carbon steel, aluminum, and acrylonitrile butadiene styrene (ABS), a material commonly used in CNC machining that has varying properties and melting temperatures depending on the ratio of each of the three ingredients.

With a weight of 6.2 pounds, this milling machine is not too heavy to carry around or store when you want to change locations. The dimensions of the unit are 9.8 inches by 9.8 inches by 5.9 inches. A 1.1-inch vice clamp is used with clamping dimensions between one and six millimeters.

When you use the correct tooling, feed, and speed, the unit can mill small pieces of steel. Resin, general steel, aluminum, and brass are soft materials that are best suited to high-speed steel (HSS). A cemented carbide or carbide tool will be needed for titanium and high-carbon steel. Purchasing additional tools is not necessary with the mill since it comes fully assembled out of the box.

8. SHOP FOX M1110 Mill and Drill

Specifications

| Item Weight | 413 pounds |

| Item Dimensions | 39.6 x 31.5 x 31 inches |

| Voltage | 15 Volts |

| Horsepower | 3/4 |

| RPM | 0 – 2,000 RPM |

Another mid-range mill is the SHOP FOX M1110. Despite the fact that it costs a little more than our top choice, it’s not as expensive as certain other options on the market. You can mill more precisely with its 12 different lathe speeds. It has only 3/4 horsepower, which is less powerful than some other options. Although it is not suitable for all DIY projects, it should still work for most.

Compared to other options currently available, this machine appears to be significantly less durable. You’ll probably need to purchase another one in the near future because it doesn’t seem to last very long at all. Due to the high price, you will probably end up spending quite a bit in the long run. The purchase of two moderately-priced machines is quite expensive, as you might expect.

The paint that comes with this mill is not high-quality at all, so you will have to re-paint it soon after purchase. Furthermore, you will need to keep everything clean and lubricated regularly.

9. Klutch Mini Milling Machine

Specifications

| Item Weight | 143 pounds |

| Item Dimensions | 20 ½ x 20 1/6 x 29 15/16 inches |

| Voltage | 110 Volts |

| Horsepower | ½ |

| RPM | 100 – 2,500 RPM |

In general, this mini milling machine can be used for light work, such as by hobbyists. As one of the best machines for jewelry, electronics, and optical projects, it is specially designed to handle slow feed rates, light feeds, and high tolerances. There is no vibration at all in the base because it is fully made of cast iron.

It is satisfying to know that the machine is extracts, transforms, and loads (ETL) listed, which means that it has been tested by Intertek and is certified as meeting national standards. You can use ETL to copy data originating from one or more sources and transfer it to a system that presents it differently than it appears in the source. As a result, different types of data input can be combined. You can keep track of multiple projects that require milling a variety of materials using ETL. It will also present you with the most suitable option for each project.

Worktable dimensions are 3 5/8 x 15 3/8. Drilling capacity is 1/2 inches, face milling capacity is 1 3/16 inches, and end milling capacity is 5/8 inches. Adding to the benefits of this milling machine is that many upgrades are available. It is very helpful as you become familiar with its functionality and want to enhance it.

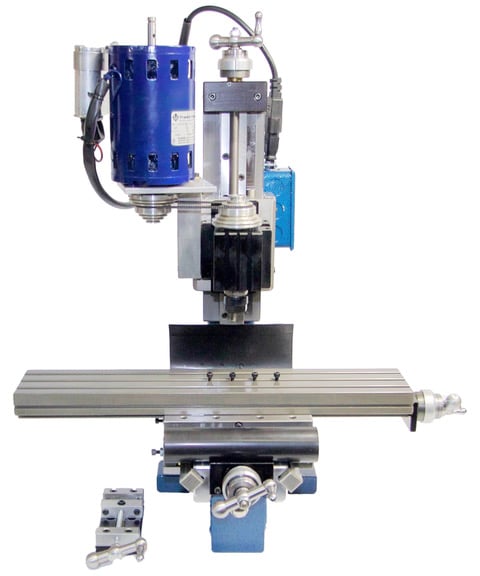

10. Grizzly G0781 3/4 hp Mill/Drill

Specifications

| Item Weight | 167 pounds |

| Item Dimensions | 25 x 22 x 28 inches |

| Voltage | 110 Volts |

| Horsepower | 1 |

| RPM | 2,000 RPM |

This mini milling machine from Grizzly shares many features with larger milling machines. You can use it in your workshop to work on tough metal with its 1-hp motor. It can be used to make small tools and parts, but it can also work on complex parts, such as small engines, if the settings are correct. As the unit comes with a stand, you don’t need to mount it on a table. This will be a great addition to your machine collection, whether you are just starting out or already established.

The motor has a horsepower capacity of 1 HP and is single phase. It has a 15-inch swing. There is 11-inch head travel as well as 2-inch spindle travel. The longitudinal travel is 18-7/8 inches, and the inch cross travel is 6-7/8 inches.

Featuring options such as a clear guard on a spindle, fine feed head control, and a two-speed gearbox, it offers great control to users. With the proper settings and 90-degree head tilt, you will be able to work on intricate shapes effortlessly.

11. Sherline 5400-Deluxe – Sherline Deluxe 5400 Series Mill

Specifications

| Item Weight | 36 pounds (Approx.) |

| Item Dimensions | 33 x 17 x 14 inches (Approx.) |

| Voltage | 90V DC |

| Horsepower | 0.34 HP |

| RPM | Variable, up to 2800 RPM |

The Sherline Deluxe 5400 Series Mill represents a top choice for hobbyists, educators, and small shop owners. Known for its precision and versatility, this compact milling machine is ideal for a variety of small-scale machining tasks. The 5400 series features a solid 10-inch base, which improves stability and reduces vibration during operation, enhancing the precision of milling tasks.

Notably, the Sherline 5400 is equipped with adjustable zero handwheels and a high-torque 90V DC motor with variable speed control. This allows for precise control over milling operations, accommodating a wide range of materials and milling techniques. The machine’s versatility is further enhanced by its compatibility with a wide range of Sherline accessories, allowing users to expand its capabilities as needed.

12. Taig Tools Micro Mill-Taig 2019CR-ER Micro Mill

Specifications

| Item Weight | 65 pounds (Approx.) |

| Item Dimensions | 18.5 x 17.5 x 16.25 inches (Approx.) |

| Voltage | 110V (Standard US Outlet) |

| Horsepower | 0.25 HP |

| RPM | Up to 10,000 RPM (Variable) |

The Taig 2019CR-ER Micro Mill is a compact and versatile machine, highly regarded in the world of small-scale, precision machining. It’s particularly favored by hobbyists, educators, and small business owners for its exceptional precision and adaptability. The 2019CR-ER model is part of Taig’s reputable lineup of micro mills, recognized for their solid construction and precise milling capabilities.

This machine stands out due to its robust build quality and precision lead screws, which provide exceptional accuracy in milling operations. The Taig 2019CR-ER is well-suited for a variety of tasks, ranging from intricate hobbyist projects to more demanding small business applications. It’s a manually operated mill that can be upgraded with motorized components, making it a flexible choice for a range of users.

Download The 12 Best Mini/Benchtop Milling Machines in 2024 PDF

You can download this article as a PDF so that you can access it whenever you like.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More In Linquip

- The 10 Best Mini/Benchtop Milling Machine

- The 10 Best Glues for Metal + Tips for Choosing

- 10 Best CNC Machines & Routers for WoodWorking

- 10 Types of CNC Machine + Applications & PDF

- 13 Parts of CNC Machine + Function & PDF: A Clear Guide

- What Is CNC Machining & How Does It Work? (A Comprehensive Guide)

- Why are Precision Machined Parts Important in the Manufacturing Industry?

- How Does a Packaging Machine Work?

- How to Keep an Industrial Bottle Capping Machine Running Smoothly

- The 9 Best Commercial Patio Heaters + Buying Guide

- The 10 Best Drywall Anchors + Buying Guide

- The 10 Best Box Cutter/Utility Knife Options

- The 8 Best Pliers + Buying Guide

- 11 Types of Drilling Machines and Their Usages

- 5 Types of Grinding Machines + Applications & Characteristic