Choosing the right transformer is crucial for ensuring reliable and efficient power distribution. Dry-type transformers, known for their safety and low maintenance requirements, have become the preferred choice for many industrial, commercial and infrastructure applications. From custom-built solutions by ELSCO to innovative designs by global giants like Siemens and Toshiba, here are the features and benefits that make these options the best in their class.

What Is a Dry-Type Transformer?

A dry-type transformer is an electrical device that transfers electrical energy between circuits through electromagnetic induction without using liquid for cooling or insulation. Instead, it relies on air gas and solid insulation materials like epoxy resin or silicone rubber. This design makes them safer, better for the environment and easier to maintain than oil-filled models.

They’re commonly used indoors and outdoors where reliability, fire safety and reduced environmental impact are crucial. You’ll find them in commercial buildings, industrial facilities, renewable energy installations and infrastructure projects.

Types of Dry-Type Transformers

Dry-type transformers are categorized based on different factors such as their construction, insulation materials and applications. Here are the most common types:

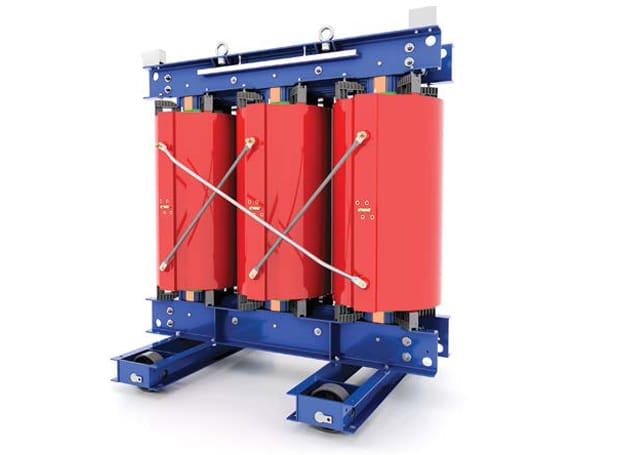

Cast Resin Transformers

Cast resin transformers feature windings encapsulated in epoxy resin, forming a solid block. This construction provides high mechanical strength and excellent moisture, dust and chemical resistance.

Many industries favor these medium-voltage dry-type transformers for their low partial discharge levels and reliability in harsh environments. Cast resin transformers are used in indoor and outdoor settings, including industrial plants, tunnels and renewable energy installations where durability and environmental resilience are crucial.

VPI (Vacuum Pressure Impregnated) Transformers

VPI transformers have vacuum-impregnated windings with epoxy resin, ensuring thorough insulation and bonding. This method enhances thermal conductivity and dielectric properties while offering resistance to moisture ingress. VPI transformers are generally medium-voltage dry-type transformers commonly chosen for their reliability and long service life in industrial applications, infrastructure projects and renewable energy installations.

Encapsulated Transformers

Encapsulated transformers are completely sealed in epoxy resin or silicone rubber, providing robust protection against moisture, dust and mechanical damage. They offer high dielectric strength and thermal stability, making them suitable for harsh environments and outdoor installations. These transformers are ideal where protection against corrosive substances or airborne contaminants is necessary, ensuring reliable operation over extended periods.

Self-Cooled Transformers

Self-cooled transformers use natural convection for cooling without additional mechanisms like fans. They feature a simpler design, lower maintenance requirements and quieter operation than forced air-cooled transformers. They’re suitable for applications with lower power ratings where noise and additional energy consumption from cooling fans are undesirable.

Forced Air-Cooled Transformers

Forced air-cooled transformers incorporate fans or blowers to force air over the windings, enhancing cooling performance. This design allows for higher power ratings and better thermal management, maintaining optimal operating temperatures even under varying ambient conditions. They’re commonly used in applications requiring higher power densities, continuous operation at full load and where stringent thermal management is essential.

Open-Wound Transformers

Open-wound transformers, also known as open coil transformers, feature windings that aren’t encapsulated or enclosed in resin or epoxy. Instead, they are wound around the core and left exposed. This design allows for natural air circulation, aiding in cooling. Open-wound transformers are typically used where easy access to windings for maintenance and repair is important.

However, they’re more susceptible to environmental contaminants and mechanical damage than encapsulated types. They’re commonly found in applications such as small industrial equipment, lighting circuits and specialized electrical systems where accessibility and ease of service are prioritized over protection from external factors.

Cast Coil Transformers

Cast coil transformers feature windings cast in epoxy resin with high thermal endurance, ensuring exceptional mechanical strength and thermal stability. They offer superior resistance to environmental stresses, minimizing the risk of cracking or delamination over time.

Cast oil transformers are preferred for demanding environments such as industrial facilities, mining operations and marine applications where reliability, safety and long-term performance are critical considerations.

Who Manufactures the Best Dry-Type Transformers?

When it comes to high-quality dry-type transformers, several manufacturers stand out for their innovation and reliability. These companies offer a range of products designed to meet the diverse needs of various industries and applications. Here are some of the best dry-type transformer manufacturers:

ELSCO Transformers

ELSCO Transformers (Electrical Service Company) is widely regarded as a leading dry-type transformer manufacturer for its high quality. ELSCO engineers transformers known for their strong construction and superior performance. They meet stringent industry standards, as well as Energy Star and Department of Energy ratings. The company offers a range of custom-built solutions tailored to meet specific customer needs and provides emergency replacements for dry-type transformers.

Siemens

Siemens is a global leader in electrical engineering and electronics that provides a comprehensive range of dry-type transformers. Siemens transformers are known for their innovative designs and high efficiency, making them suitable for demanding industrial and commercial applications.

Schneider Electric

Schneider Electric offers a diverse range of dry-type transformers known for their reliability and energy efficiency. Its products are designed to meet global standards and are used in various applications, from industrial plants to commercial buildings to infrastructure projects.

Toshiba

Toshiba is a well-respected dry-type transformer manufacturer, offering products that combine advanced technology with reliability and efficiency. Toshiba transformers are used in the industrial, commercial and power generation sectors.

Factors to Consider When Choosing a Dry-Type Transformer

Selecting the right dry-type transformer involves evaluating several critical factors to ensure it meets your application’s specified requirements. Understanding these requirements helps you make an informed decision that guarantees optimal performance, efficiency, safety and longevity. Here are the key considerations to keep in mind.

Power and Voltage Rating

Evaluate the voltage levels — primary and secondary — and power rating (kVA) required for the application. This ensures the transformer can handle the expected electrical load without overloading.

Cooling Requirements

Consider the cooling method (natural or forced air-cooled) based on the environment and power rating. Forced air-cooled transformers are suitable for higher power ratings and environments where efficient heat dissipation is necessary.

Environmental Conditions

Evaluate the operating environment, including temperature, humidity and exposure to dust, chemicals or corrosive substances. Choose a transformer with appropriate insulation and protection, such as encapsulated or cast resin types, for harsh conditions.

Installation Location

Assess whether the transformer will be installed indoors or outdoors. Outdoor installations require transformers with robust protection against weather conditions, such as cast resin or encapsulated.

Load Type

Understand the nature of the load, whether it’s continuous, fluctuating or subject to surges. Transformers should be selected to handle the load profile without compromising performance or life span.

Regulations and Standards

Ensure the transformer complies with relevant industry standards and regulations, such as NEMA, ANSI and IEEE. Compliance guarantees safety, reliability and performance.

Maintenance and Accessibility

Factor in the ease of maintenance and accessibility for inspection and repairs. Some transformers, like open-wound types, offer easier access to windings but may require more frequent upkeep. Lower voltage transformers also generally require more frequent maintenance than their medium and higher voltage counterparts.

Noise Levels

Consider the noise the transformer generates, especially if installed in sound-sensitive areas. Choose low-noise designs if necessary.

Efficiency and Losses

Consider the transformer’s efficiency and losses, like core and copper waste. High-efficiency transformers reduce energy consumption and operational costs over time.

Reliability and Life Span

Evaluate the transformer’s expected life span and reliability. High-quality insulation and construction materials contribute to longer service life and reduced downtime.

Budget and Cost

Balance the initial purchase cost with long-term operational expenses, including maintenance, energy losses and potential downtime. Sometimes, a higher upfront investment in a more efficient or robust transformer can save you money over time.

Manufacturer Reputation and Support

Consider the manufacturer’s reputation and the availability of technical support and service. Reliable companies provide better-quality products and after-sales support.

Selecting the Right Transformer for Your Needs

Selecting the right dry-type transformer is essential for optimal performance and efficiency in power distribution systems. Leading manufacturers offer a range of high-quality options suitable for diverse applications. Understanding the unique features and advantages of each brand and type lets businesses and engineers can make informed decisions that ensure long-term reliability.