The 10 Best Racking Warehouse Systems of 2023 – A racking warehouse system is a storage solution that allows products to be stacked horizontally on many levels. These systems can aid in the management and better utilization of your warehouse space, as well as the organization of freight in order to streamline operations.

Each warehouse has its own set of standards. The ideal racking system should be able to maximize space utilization while minimizing disruption to your activities, particularly the picking process. Consider the following variables to determine which racking system is best for your warehouse:

- Floor Utilization – A racking system’s ability to utilize warehouse floor space.

- Budget – The approximated price per pallet. Consider this when ensuring that the racking system meets all of your requirements.

- Forklift Accessibility – The ability to accommodate forklifts that are used to transport large goods. This takes into account the amount of aisle width that forklifts need to maneuver.

- Storage Utilization – The quantity of space in the racking system that you can use. The amount you’ll require is determined by the volume, size, and weight of your shipment.

- Inventory Management – The warehouse’s preferred order for inventory retrieval.

- Versatility – The ability of racking systems to store a larger variety of items.

Inventory management is critical to simplifying warehouse operations in today’s fast-paced and highly competitive marketplaces. It’s one of the numerous difficulties that warehouse managers confront, but it can be mitigated by choosing the correct warehouse racking system. As a result, in this post, we’ll go over the best racking warehouse systems, as well as the elements to consider when choosing a good racking system and the many varieties.

To find out more about Warehouse Racking, please visit our Warehouse Racking for Sale pages, where you can also request a quote.

How We Selected The 10 Best Racking Warehouse Systems of 2023

We selected the 10 best racking warehouse systems of 2023 by analyzing more than 10 webpages and hundreds of products and reviewers. We also consulted with our experts and drew on our previous experiences.

Here are some of the factors we considered when making our selections:

- The type of warehouse: Different types of warehouses require different types of racking systems. For example, a high-volume warehouse will need a different system than a low-volume warehouse.

- The size of the warehouse: The size of the warehouse will determine the capacity of the racking system needed.

- The weight of the items being stored: The weight of the items being stored will determine the strength of the racking system needed.

- The type of access needed: The type of access needed will determine the type of racking system needed. For example, a warehouse with a lot of forklift traffic will need a different system than a warehouse with a lot of manual picking.

- The budget: The budget will obviously be a factor in determining which racking system is the best fit.

We believe that the 10 racking warehouse systems we have selected are the best on the market for a variety of warehouses. We encourage you to read our reviews and compare the systems to find the best one for your needs.

Best Racking Warehouse Systems Reviews

1. Selective Racking System

Specifications

| Budget | $45 – $65 per pallet |

| Floor Utilization | 40% |

| Storage Utilization | 90 – 95% |

| Inventory Management | First in, First Out (FIFO) |

General Descriptions

Because of its low cost and wide range of sizes and attachments, the selective racking system is the most popular. This racking system is ideal for conventional storage for any application that requires quick access to materials.

Features

- Supports First in First Out (FIFO)

- Clear Aisles of 3 to 3.4m for reach trucks or 3.5 to 4.5m for counter-balanced forklifts.

- Unfettered access to any pallet

- The most common mode of racking

- Storage Utilization: 90%, i.e. for every 100 pallet places available, you can fill 90.

- Allows order picking at lower levels

See Bakery Trays for sale

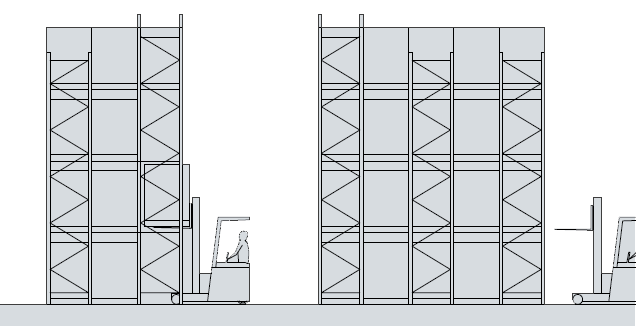

2. Double-Deep Racking System

Specifications

| Budget | $50 – $70 per pallet |

| Floor Utilization | 60% |

| Storage Utilization | 85 – 90% |

| Inventory Management | First In, Last Out (FILO) |

General Descriptions

The double deep racking system is a variation that provides a nice boost in density but necessitates specific equipment (extendable forks) and is more time-consuming to operate. It’s the best of both worlds: selective racking and high-density racking.

Features

- FILO for each slot

- Clear aisle of 3.0 to 3.4m

- Need a forklift truck with extendable reach and camera to assist the operator

- Pallets must be placed on beams at lower levels, and guide rails are employed at higher levels.

- Reach and counterbalanced forklift tricks, as well as order picking devices, can be used to service them.

- Typically, two pallets of the same SKU are placed in each double deep slot.

- Storage utilization: 85-90%

3. Pallet Flow/Live Racking System

Specifications

| Budget | $170 – $185 per pallet |

| Floor Utilization | 70 – 75% |

| Storage Utilization | 85 – 90% |

| Inventory Management | First In, First Out (FIFO) |

General Descriptions

Pallet flow racks are a type of high-density storage system that combines elevated rails with dynamic components like gravity rollers and conveyors. Gravity is used to power these warehouse storage racks. This racking system may increase or even quadruple your warehouse’s storage capacity, and it’s ideal for expiration-date-sensitive products.

Features

- FIFO for each site

- High use of cube

- Clear aisle of 3.0 to 3.4m

- Pallets are put on gravity roll rails and moved by gravitational attraction from entry to exit.

- Separate load in and load out aisles

- One lane per SKU

- utilization: 85-90%

- Full pallets only

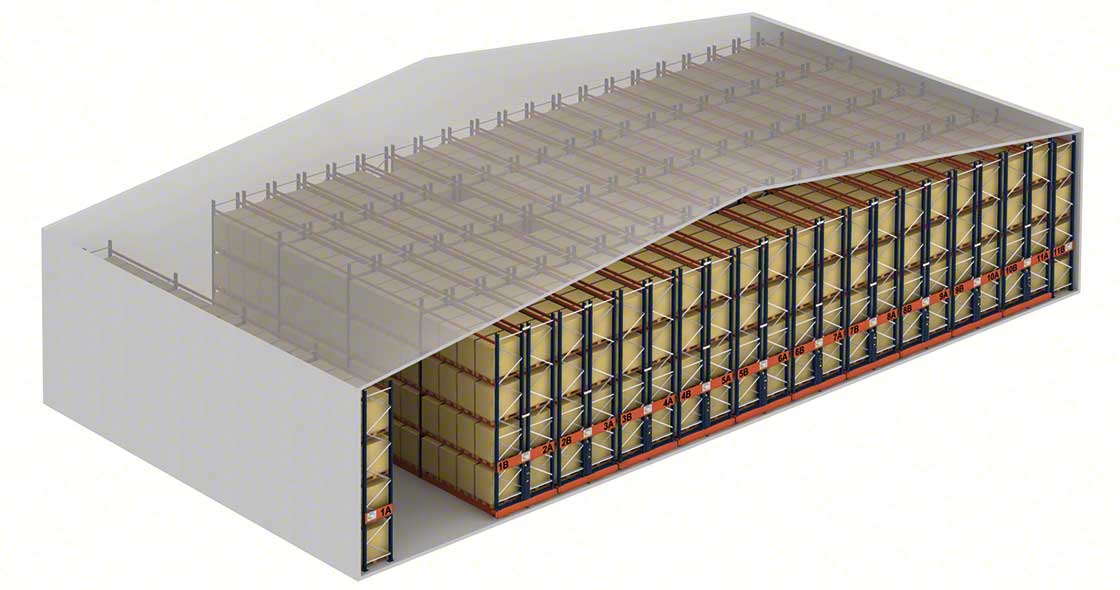

4. Drive-In Racking System

Specifications

| Budget | $160 – $185 per pallet |

| Floor Utilization | 65% |

| Storage Utilization | 60 – 65% |

| Inventory Management | Last In, First Out (LIFO) |

General Descriptions

The drive-in racking system allows you to store products in your warehouse at maximum density. It eliminates aisles in a warehouse and is ideal for storing huge quantities of comparable products in a little amount of space.

Features

- Clear Aisles of 3 to 3.4m for reach trucks or 3.5 to 4.5m for counter-balanced forklifts

- Can be up to 10 or 12 pallets deep and up 6 or 7 pallets high

- FILO for each lane

- To deposit or pick up pallets, the forklift travels down the lane of each racking bay.

- Drive-in racking resembles the process of block stacking, but there is less damage to pallets and stacking can be higher with the racking.

- Utilization: 50-60%

5. Push Back Racking System

Specifications

| Budget | $275 – $295 per pallet |

| Floor Utilization | 75% |

| Storage Utilization | 75% |

| Inventory Management | Last In, First Out (LIFO) |

General Descriptions

The push-back pallet racking system provides greater pallet storage while also improving selectivity by using separate lanes for each SKU, making them easier to locate, pick, and put away. Push back warehouse storage racks remove the requirement for multiple aisles by allowing for front-loading and unloading.

Features

- Clear aisles of 3 to 3.4m

- It can be three or four pallets deep, but most are simply two.

- Forklift trucks push pallets back from the aisle.

- Pallets are loaded into carts with a reduced friction surface.

- Only used to store complete pallets.

- To avoid pallet damage, forklift drivers must be cautious when loading in and out.

- Utilization: 85-90%

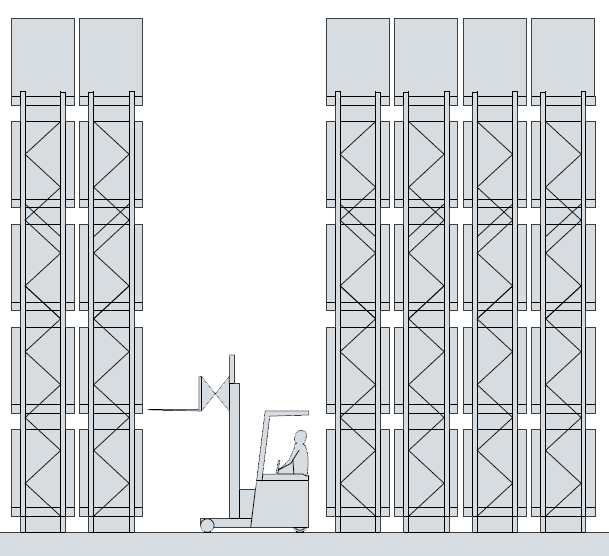

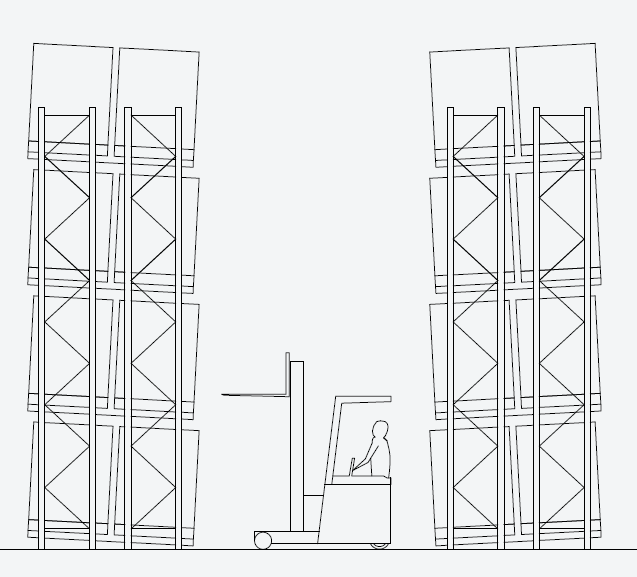

6. Narrow Aisle Racking System

Specifications

| Budget | $50 – $60 per pallet |

| Floor Utilization | 90% |

| Storage Utilization | 95% |

| Inventory Management | First In, First Out (FIFO) |

General Descriptions

Narrow aisle racking is similar to selective racking in that it provides easier access to each pallet. The warehouse storage racks use floor space and roof height to create high-density storage.

Features

- Clear aisle of 1.8 to 2.2m

- Only one machine in an aisle at a time

- Simulates the effects of selective racking.

- At the end of each bay of racking, turret trucks retrieve and place pallets from pick and deposit (P&D) stations.

- Turret trucks need wire or mechanical direction down each aisle’s length.

- Pallets are delivered and picked up by a separate forklift to and from the P&D stations.

- Picking from pallets is possible for order picking machines although not at the same time as turret trucks.

- Utilization: 90%

7. Steel King SK3000® Structural Rack

Specifications

| Frame Bracing | Braces are 1.5” x 1.5” |

| Beams | Manufactured with high-strength steel |

| Connections | 2” adjustability for better space utilization |

General Descriptions

Because it is made of strong C-channel structural steel, Steel King’s SK3000 pallet racking by Prologis Essentials delivers increased overall strength and stiffness. The SK3000 is a high-performing material handling rack and the greatest value in structural pallet racks today, with a longer service life, fewer maintenance costs, and greater safety. The SK3000 Structural Rack is a modular system that can be configured to accommodate a range of applications and quickly extends as per your needs.

Upright frame columns come in three sizes: 3′′, 4′′, and 5′′. The use of structural channel steel allows for increased resistance to forklift impact damage while also boosting load bearing capacity and seismic resilience. The whole horizontal and diagonal bracing uses structural angle. High-strength steel beams are one-piece, seamless, and continuously welded with a complete vertical weld. Bolted beams may be adjusted in 2′′ vertical increments with ease.

A thick 7 gauge wrap-around connector plate is used for column-to-beam connections, which helps square the rack for a tighter connection. When compared to single bolt systems, using two bolts per beam gives 57 percent higher strength. Your system’s shear strength is improved with Grade 5 hardware. The bolted connectors are built to RMI specifications.

The strength of SK3000 can be seen from top to bottom. Standard footpads are welded to each column and are comprised of 7 gauge steel plates, effectively distributing floor stresses. There’s also a footpad that’s more durable. Powder coating is not only more attractive, but it is also more resistant to impact damage, chemicals, chips, and scratches than liquid coating.

8. Cantilever Racking

Specifications

| Load capacity | Can support loads up to 10,000 pounds per arm |

| Depth | Is available in depths of 4 feet to 12 feet |

| Height | Is available in heights of 10 feet to 40 feet |

| Arm lengths | Are available in increments of 2 feet |

General Descriptions

Cantilever racking is a type of racking system that is designed to store long, bulky items. It is made up of a series of vertical columns that support a series of horizontal arms. The arms extend out from the columns to support the load. Cantilever racking is a good choice for storing items such as pipes, beams, lumber, and furniture.

Cantilever racking is a good choice for storing long, bulky items. It is a high-capacity, easy-access, and durable racking system. However, it can be expensive and require specialized equipment.

Features

- Open front design: The open front design of cantilever racking allows for easy access to the stored material.

- High-quality materials: Cantilever racking is made from high-quality materials and is designed to withstand heavy loads.

- Customizable: Cantilever racking can be customized to meet the specific needs of your business.

9. Mobile Racking

Specifications

| Load capacity | Can support loads up to 10,000 pounds per carriage |

| Depth | Is available in depths of 4 feet to 12 feet |

| Height | Is available in heights of 10 feet to 40 feet |

| Number of carriages | The number of carriages in a mobile racking system can vary depending on the size of the warehouse and the amount of material to be stored. |

General Descriptions

Mobile racking is a type of racking system that is designed to maximize warehouse space. It is made up of a series of mobile carriages that are mounted on rails. The carriages can be moved independently of each other to create access to the stored material. Mobile racking is a good choice for warehouses with limited space and high turnover rates.

Mobile racking is a good choice for warehouses with limited space and high turnover rates. It is a high-density, easy-access, and durable racking system. However, it can be expensive and require specialized equipment.

Features

- Mobile carriages: The mobile carriages are what make mobile racking unique. They allow for easy access to the stored material without having to move the entire racking system.

- Rails: The rails provide a stable platform for the mobile carriages to move on.

- Brakes: The brakes prevent the mobile carriages from moving when they are not supposed to.

- Safety features: Mobile racking systems come with a variety of safety features to prevent accidents. These features include guards, warning lights, and alarms.

10. Versatile Racking

Specifications

| Load capacity | Versatile racking can support loads up to 10,000 pounds per beam. |

| Depth | Versatile racking is available in depths of 4 feet to 12 feet. |

| Height | Versatile racking is available in heights of 10 feet to 40 feet. |

| Number of bays | Versatile racking is available in heights of 10 feet to 40 feet. |

General Descriptions

Versatile racking is a type of racking system that is designed to be customized to meet the specific needs of a business. It is made up of a variety of components that can be combined to create a racking system that is perfect for the specific application. Versatile racking is a good choice for businesses that need a flexible and scalable racking system.

Versatile racking is a good choice for businesses that need a flexible and scalable racking system. It is a customizable, flexible, scalable, durable, and efficient racking system. However, it can be expensive and require specialized expertise to install.

Features

- Customizable: Versatile racking can be customized to meet the specific needs of a business.

- Flexible: Versatile racking can be easily adjusted to accommodate changes in the business.

- Scalable: Versatile racking can be easily expanded to accommodate growth.

- Durable: Versatile racking is made from high-quality materials and is designed to withstand heavy use.

- Efficient: Versatile racking can help to improve efficiency by providing easy access to stored material.

FAQs about Racking Warehouse Systems

Why Should We Use a Warehouse Racking System?

For one thing, using a racking system is far less expensive than doubling the size of an existing warehouse. Adding a racking system to your warehouse can double or even triple the number of goods you can handle, and adding forklifts to a simple warehousing operation usually results in a significant increase in efficiency.

Businesses nowadays are more concerned with the bottom line than ever before, and a warehouse without even the most basic racking system is nearly always inefficient. Forklifts are generally present in warehouses that deal with large commodities, making the transfer to a racking system much easier.

What Safety Concerns Are We Looking At?

You’ll need to take extra special precautions to avoid damage because your raw materials will be stored dozens of feet above the warehouse floor. Pay strict attention to any slack racking system components, especially after installation, because even the smallest mistake could result in materials falling.

Also, make sure to adhere to each manufacturer’s rigorous load limitations. While your racking system may appear to be capable of handling more, it is not safe and could result in goods being damaged or workers being injured. Rack audits should be conducted regularly to maintain product integrity.

What is a Concentrated Point Load?

The weight of a concentrated static load is not equally distributed throughout the deck’s surface. A point load is a static load that is concentrated at certain locations on the deck. For example, a container with feet or bars that hold the weight, which is concentrated in a few different regions of the container, could be used.

How Often Should We Have My Racks Inspected?

MHI (Material Handling Institute) recommends having your racks evaluated at least once a year. Additionally, if a forklift or other warehouse equipment damages your racking system, we recommend having your racks inspected replacing the damaged item. In your warehouse, safety should be a top priority.

Why Do My Racks Need to be Anchored?

Racking must be attached to the floor, according to the Rack Manufacturers’ Institute. This is true for all racking frames at all times. Contact the manufacturer if you’re not sure what size anchor bolts to use. If you’re in a seismic zone, you may need more than a conventional ½” anchor bolt to meet the requirements.

You may only require one anchor bolt per column, or you may need to utilize all four holes in the base, depending on the racks and your position. Your manufacturer should be well-versed in the regulations and can ensure that your racks are properly grounded to comply with local regulations. Anchors maintain the racks in place, ensuring pallet racking reliability and durability while also ensuring warehouse safety.

Conclusion

Due to the huge range of racking systems available on the market, choosing the best racking warehouse systems can be a difficult undertaking. Considering the elements described above is the best method to prevent becoming overwhelmed with this activity. The ideal warehouse racking system will help you make the most of your space while also streamlining your warehouse processes.

Call today to speak with one of our Material Handling Service Providers on Linquip if you are ready to automate inventory management or are searching for a solution to boost efficiency, or if you have another question about pallet racking or any other warehouse equipment or services.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Best LED Lighting for Warehouse & Gurage

- Warehouse Equipment Products

- Best Led Fixtures for Warehouse and Garage

- A Clear Guide to Top Warehouse Lighting Manufacturers and Suppliers

- Warehouse Racking Manufacturers & Suppliers: Clear Guide

- Best Warehouse Lighting: 7-Top Ranked Models

- Power Solutions for the Crypto Mining Industry

- Warehouse Lighting Fundamentals: Ultimate Guide

- Prologis Essential Company Page on Linquip

- List of All Prologis Essential Service

- Prologis Essentials General Services

- Prologis Essentials Installation

- Prologis Essentials HVAC Maintenance

- Structural Pallet Racking for Sale by Prologis Essentials

- Warehouse Lighting Products by Prologis Essentials

- High bay LED lighting Products by Prologis Essentials

- Warehouse Solar Products by Prologis Essentials