The industrial and manufacturing industry has seen growth for many years and is one of the largest industries across the globe. Valued at $7 trillion in 2023, with a slight decline of 3% due to COVID-19 and other factors, there are still no signs of this booming part of the economy ever going away. Originating as one of the most important parts of human civilization and the reason behind job prosperity everywhere, manufacturing has seen momentous changes as of late. Making a generation shift from both personal and machine-based assembly lines, it has now stepped into the world of “smart factories” — which are factories and industrial units that incorporate certain robotics, augmented reality (AR), machine learning (ML), data analytics, and many other cutting-edge technologies.

This is shaping the future of manufacturing, business, and industrial companies everywhere — and we are going to investigate the industrial processes and how they are being revolutionized by technology.

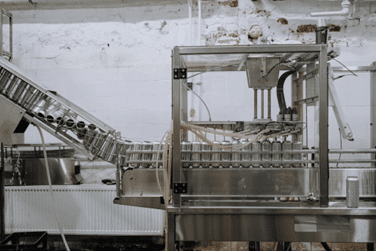

Industrial Automation

The automation in the world of equipment and warehouses has been around for a lot longer than you would imagine. If you think back to the Industrial Revolution, you will know that it’s where the beginning of all mechanical production methods came from, and these continue to shape this sector today. Originally powered by water and steam engines, this was the first evolution in technology that we have seen businesses incorporate. It’s a long way from the “industrial revolution” we’re looking at today.

We can all think back to the time of the Industrial Revolution and consider that the stepping stone into the AI world we’re in today — manufacturing only kicked off by the time of the Mass Production era. It was brought about by Henry Ford, who revolutionized manufacturing as we know it; he was responsible for all the automated repetitive tasks. Those included jobs that were known as less desirable, which welcomed mechanical systems that increased the efficiency and output of all warehouse workers. Businesses then began to thrive, and more workman efficiency was created because of the newfound automation in this industry.

Computerized Automation

By the mid-20th century, computerized automation was a phrase people were starting to repeat – but it took quite a while to grow. Let’s compare it to the appearance and expansion of the National Football League (NFL), which admittedly was born a bit earlier, in the 1920s – but which took quite a while to find its feet and start gathering attention, recognition, and prestige. The NFL stayed regional and niche for a while, being a very minor league, and the same was true of computerized automation; Christopher Strachey’s checkers-playing program was almost a gimmick for some time, and it wasn’t until the 1960s that the potential of AI started to gain recognition. However, both the NFL business and AI-adopting businesses began to thrive and grow, and as automation sped up tasks, we saw the manufacturing and industrial sectors take off at the speed of light.

During this process, computer technology was formed, which enabled sophisticated automation more closely linked to what’s available today. This also brought about the implementation of programmable logic controllers, also known as PLCs, for the control and monitoring of the overall process in manufacturing. The PLCs are responsible for automating a specific process in a factory, business, or other industrial space — so they could now automate processes, machine functions, and product lines.

This particularly came in handy with the heavy industry and equipment spaces, as workers in general struggle with heavy products and lifting — so tech and AI are crucial for the longevity of a workman’s career. And while places like the NFL may not be using PLCs, today we are seeing them adopt automation and AI technology for game planning and strategic decisions, so we can see just how far this tech has come and how versatile it is.

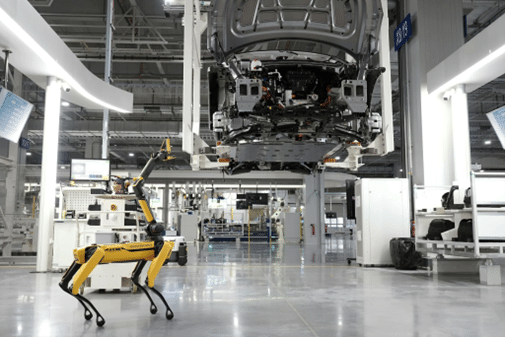

Robotics

By the time of the late 20th century, and in particular by the late 1960s, there were already rollouts of industrial robots. They began to gain traction, and their practical applications in manufacturing environments led to streamlined production and better business practices. Robots of this kind were used in the integration of production tasks, such as welding, assembling, painting, and many other heavy-duty tasks. Overall, this was the first mark in history to make a difference in the output of quality and forge a future that excited the population in the world of technology.

Digital revolution and industry 4.0

The creation of Industry 4.0 and the digital revolution started to boom in the early 2010s. Not too far away from today’s business uses, it still feels pretty historical when you compare the trends we see now. First incorporated in Germany, where they were (and still are) the leaders of all highly advanced manufacturing tech, the integration of digital technologies into the manufacturing process led to the creation of more smart factories. Smart factories themselves were nothing new, but they helped shape Industry 4.0, which paved the way for transformative change.

They didn’t just grow because of smart technology; there were also advances such as IoT, sensors, and data analytics — which created a new era of intelligent automation.

Current trends

Now, we know that all of those manufacturing advances may have sounded very ahead of the times — but it’s 2024, and we’re witnessing some of the biggest automated growths we have ever seen.

Not solely put into place to assist workers with their roles, AI is now here to create predictive maintenance processes, real-time optimization, and automated systems — which cut out the chances of human error. This has created sustainable growth for businesses across the globe, as there are limits on how many hours an employee might work, and further limits on availability, skills, etc. With artificial intelligence and machine learning, you can teach your company’s internal processes to the robot — and cut out all these limits, and the prospects of errors from an employee.

There are also many wider applications for AI; we’ve already talked about how it is helping many sports teams and bodies like the NFL improve their game, plan ahead, and take the optimum approach to every season. In essence, we’re now asking – what can’t it do?!

Overall, industrial automation has grown into an industry that is never going to be outdated; it keeps evolving. It’s fast, ahead of the times, and always looking at routes to turn productivity into profitability — which is the end goal for businesses everywhere.