Thermocouple types are present in various calibrations and combinations of metals. The most usual types are the “Base Metal” thermocouples introduced as Types K, J, T, E, and N. There are also some high-temperature forms defined as Noble Metal thermocouples, including Types S, R, C, and B. We recommend you to see the “What is a Thermocouple” post first to explore more about this worthy instrument.

What is a Thermocouple?

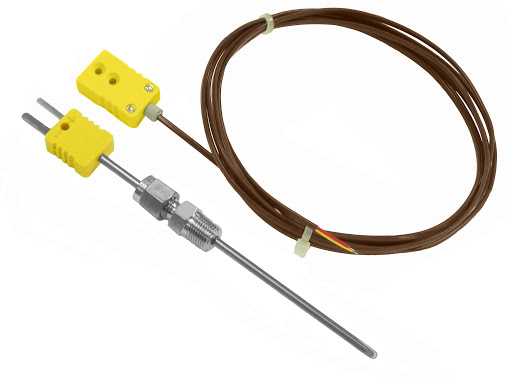

A Thermocouple is a temperature sensor employed for detecting the temperature, and it has two dissimilar wire legs. These metal wire parts are combined at the end of the system to create a junction. Therefore, the temperature can be evaluated in this section. The voltage will be produced when the junction identifies the temperature variation. The produced voltage may also be changed with some temperature calculations.

The applications of thermocouples usually contain particular scientific, OEM, industrial technologies. The industrial ones typically are the generation of power, gas or oil, pharmaceutical, cement, biotech, paper & soft tissues. This device is also utilized in house appliances such as stoves, toasters, and heaters. The advantages of this instrument are great according to its properties like toleration of high-temperature, low-price, and a wide range of types. Visit here to explore more about the fundamental base of thermocouple types.

These functions based on particular calculations from a reference temperature point introduced as the cold or reference junction, and a probe, joined to the main part to be detected. The voltages are applied as reference points due to their relation to the sensing junction because they are produced by combining dissimilar metals. When the machine detects this variation, it estimates the temperature and sends special signs to the measuring section.

Researchers have created some standard calibrations to derive maximum potential from thermocouple types in a set of combinations because different compositions of materials will generate various temperatures, and these different compositions have different strength states and stability.

Different Thermocouple Types & Ranges

There are generally four different thermocouple types, most determined by a capital letter in their name. These are the main body classification, the upper crust type, the rarified kind, and the exotic class. The main body classification consists of usual metals, while the upper crust type provides just platinum compositions. The rarified kind includes Refractory metals, and finally, the exotic class is more particular in nature, usually specific compositions of rare metals utilized for high-tech applications.

Main body thermocouple types are categorized into different types introduced as Type-K, Type-J, Type-E, Type-T, Type-N, Type-R, Type-S, and Type-B. These thermocouple types have their own features. But a thermocouple is covered by particular insulation to prevent it from the surrounding. This safety cover will decrease the corrosion influence significantly.

Rarefied and exotic types have not known alpha codes specialized for them because they are used less frequently. However, some of them have standard temperature ranges.

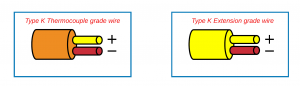

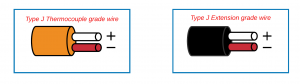

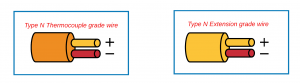

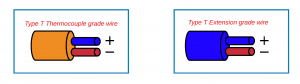

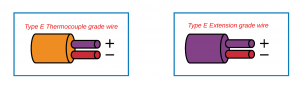

Thermocouples are typically color-coded in addition to their numbering standard. The color codes are various geographically, so it is appropriate to search for the different types based on the region from which the material is constructed.

Standard thermocouple types are listed below.

Thermocouples Types: Based on Base Metal

The base metal thermocouples, known as types E, J, K, T, N, and M, have higher sensibilities than the noble metal. They comprise the most commonly used category of thermocouples and the conductor materials in base metal thermocouples are made of common and inexpensive metals such as nickel, copper, and iron.

K- Type Thermocouple

The k-type is the most common form of temperature sensors and contains a positive (Chromel) and a negative (Alumel) part. This thermocouple is proposed for corrosion or oxidizing environments. But they are not operated well at low temperatures according to the EMF effect from hysteresis. Otherwise, it is too reliable at high-temperatures with high accuracy.

Its composition has Chromel (+) and Alumel (-) legs, and the temperature range varies from 95 to 1260 oC. The accuracy of them is normally +/- 2.2C (or) +/- .75%, the particular error limitation is +/- 1.1C (or) 0.4% and the sensitivity is 28 to 42 µV/°C.

J- Type Thermocouple

This is another frequently utilized thermocouple and includes a positive (Iron) and a negative (Constantan) part. The main applications of this thermocouple are vacuum, reducing, and oxidizing environments.

The temperature range of this thermocouple is from –210 to +1200 °C; however, the life-cycle is lesser at high-temperature in comparison with K-type. It is similar to the K-Type based on cost and reliability. The accuracy of them is typically +/- 2.2oC (or) +/- .75%, the particular error is +/- 1.1C (or) 0.4%, and the sensitivity is 50-60 µV/°C.

N-Type Thermocouple

The N-Type includes a positive (Nicrosil) and a negative (Nisil) part. It has great resistance to degradation according to the variation of temperature and hysteresis. It is typically more expensive than other thermocouple types.

The temperature range of them is between –250 to +1300 °C. Their accuracy is +/- 2.2C (or) +/- .75%, the particular error limitation is +/- 1.1C (or) 0.4% and the sensitivity is 24 to 38 µV/°C.

T- Type Thermocouple

The T-type contains a positive (Copper) and a negative (Constantan) section. Their applications generally include reducing and oxidizing in the vacuum atmospheres. It presents reliable resistance to the decomposition in most atmospheres and high-stability at sub-zero conditions.

Their temperature range is between –200 to 350 °C. The accuracy is approximately +/- 2.2C (or) +/- .75%, the particular error limitation is +/- 1.1C (or) 0.4%, and the sensitivity is between 17 to 58 µV/°C.

E- Type Thermocouple

The E-type has a positive (Chromel) and a negative (Constantan) part, and it is not used for oxidization in particular applications. This form has a maximum EMF per degree but should be prevented from sulfurous atmospheres.

The temperature range of them is between –95 to 900 °C. Their accuracy is normally +/- 1.7C (or) +/- 0.5%, the particular error limitations is +/- 1.1C (or) 0.4%, and the sensitivity is 40 – 80 µV/°C.

M- Type Thermocouple

Type M (82%Ni/18%Mo–99.2%Ni/0.8%Co, by weight) is used in vacuum furnaces for the same reasons as type C (described below). The upper temperature is limited to 1400 °C. It is less commonly used than other types.

Thermocouples Types: Based on Noble Metal

Types B, R, and S thermocouples use platinum or a platinum/rhodium alloy for each conductor. These are among the most stable thermocouples but have lower sensitivity than other types, approximately 10 µV/°C. Type B, R, and S thermocouples are usually used only for high-temperature measurements due to their high cost and low sensitivity. For type R and S thermocouples, HTX platinum wire can be used in place of the pure platinum leg to strengthen the thermocouple and prevent failures from grain growth that can occur in high temperature and harsh conditions.

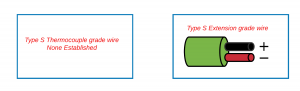

S- Type Thermocouple

The S-type is employed especially in high-temperature applications, including pharmaceutical and biotech industries. Nevertheless, it is used occasionally in low- temperature applications according to its stability and high accuracy.

It has Platinum with 10% Rhodium as positive and pure Platinum as the negative leg. Its temperature range is 980-1450 °C. The accuracy is typically +/- 1.5C (or) +/- .25%, the particular error is +/- 0.6C (or) 0.1%, and the sensitivity is 8 – 12 µV/°C.

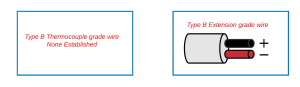

B- Type Thermocouple

The B-Type thermocouples are extremely utilized in high-temperature industries, and the temperature limitation of them is the highest between thermocouple types mentioned above. They have a high state of precision at very high temperatures.

It has Platinum with 30% Rhodium for the positive leg and Platinum with 6% Rhodium for the negative part. The temperature range is from 1370 to 1700 °C. The accuracy is +/- 0.5% (or) +/- .25%, the particular error limitation is +/- 0.25% and its sensitivity is 5 to 10 µV/°C.

R- Type Thermocouple

The R-Type is present for high-temperature applications. It includes a high percentage of Rhodium, close to 50% than the S-Type, which makes it more expensive. This type is similar to the S-Type based on their actions. It is employed in low-temperature systems according to its reliability and high precision.

The temperature range of them is 870 to 1450°C. Its accuracy is +/- 1.5C (or) +/- .25%, the particular error is +/- 0.6C or 0.1%, and the sensitivity of them is 8 – 14 µV/°C.

Thermocouples Types: Based on refractory Metal

These thermocouples are well suited for measuring extremely high temperatures. Typical uses are hydrogen and inert atmospheres, as well as vacuum furnaces. They are not used in oxidizing environments at high temperatures because of embrittlement. A typical range is 0 to 2315 °C, which can be extended to 2760 °C in an inert atmosphere and 3000 °C for brief measurements.

C- Type Thermocouple (W5)

Type C Thermocouples are made from Tungsten Rhenium alloys and designed for extremely high temperatures up to 4,200 F (2315 C). The thermocouple materials must be utilized in hydrogen, inert, or vacuum atmosphere to prevent failure from oxidation. Maximum Temperature Range is influenced by bare wire diameters, protective sheaths, and to a small degree, the attached connectors or extension wire leads.

These thermocouples are widely used in semiconductor processing and equipment, military and defense testing, research, high-temperature materials manufacturing, aerospace, power generation, and others.

G- Type Thermocouple (W)

The Type G combination was the earliest combination developed in the tungsten-rhenium thermocouple system. It suffers, however, from the brittle behavior of the pure tungsten positive leg. For this reason, the positive leg is generally shipped in the as-drawn condition. This results in an emf shift when the thermocouple is exposed to elevated temperatures (generally > 2000°F) in use. The primary advantage of the G combination is the higher Seebeck coefficient obtained at temperatures > 900°F. Modern instrumentation minimizes the importance of this advantage.

These thermocouples are widely used in heat treat ovens and hipping ovens.

D- Type Thermocouple (W3)

Type D thermocouple has Tungsten with 3% Rheniumfor the positive leg and Tungsten with 25% Rhenium for the negative part. Its maximum temperature is 4,200°F (2,320°C). These thermocouples are widely used in semiconductors, solar, and aerospace applications.

Other Types of Thermocouple

The other types of thermocouples are described below.

Chromel–gold/iron-alloy Thermocouples

In these thermocouples (chromel–gold/iron alloy), the negative wire is gold with a small fraction (0.03–0.15 atom percent) of iron. The impure gold wire gives the thermocouple a high sensitivity at low temperatures (compared to other thermocouples at that temperature), whereas the chromel wire maintains the sensitivity near room temperature. It can be used for cryogenic applications (1.2–300 K and even up to 600 K). Both the sensitivity and the temperature range depending on the iron concentration. The sensitivity is typically around 15 µV/K at low temperatures, and the lowest usable temperature varies between 1.2 and 4.2 K.

Type P (noble-metal alloy) or “Platinel II” Thermocouples

Type P (55%Pd/31%Pt/14%Au–65%Au/35%Pd, by weight) thermocouples give a thermoelectric voltage that mimics the type K over the range 500 °C to 1400 °C, however, they are constructed purely of noble metals and so shows enhanced corrosion resistance. This combination is also known as Platinel II.

Platinum/molybdenum-alloy Thermocouples

Thermocouples of platinum/molybdenum-alloy (95%Pt/5%Mo–99.9%Pt/0.1%Mo, by weight) are sometimes used in nuclear reactors, since they show a low drift from nuclear transmutation induced by neutron irradiation, compared to the platinum/rhodium-alloy types.

Iridium/rhodium alloy Thermocouples

The use of two wires of iridium/rhodium alloys can provide a thermocouple that can be used up to about 2000 °C in inert atmospheres.

Pure noble-metal Thermocouples Au–Pt, Pt–Pd

Thermocouples made from two different, high-purity noble metals can show high accuracy even when uncalibrated, as well as low levels of drift. Two combinations in use are gold–platinum and platinum–palladium. Their main limitations are the low melting points of the metals involved (1064 °C for gold and 1555 °C for palladium). These thermocouples tend to be more accurate than type S. Their economy and simplicity are even regarded as competitive alternatives to the platinum resistance thermometers that are normally used as standard thermometers.

HTIR-TC (High-Temperature, Irradiation Resistant) Thermocouples

HTIR-TC offers a breakthrough in measuring high-temperature processes. Its characteristics are: durable and reliable at high temperatures, up to at least 1700°C; resistant to irradiation; moderately priced; available in a variety of configurations – adaptable to each application; easily installed. Originally developed for use in nuclear test reactors, HTIR-TC may enhance the safety of operations in future reactors. This thermocouple was developed by researchers at the Idaho National Laboratory (INL).

Difference in Thermocouple Types

Each configuration of thermocouple types has a different temperature level, although the maximum temperature modifies with the size of the wire employed in the thermocouple. The maximum state is also restricted by this size, while the thermocouple construction determines the temperature range. So, it can be concluded that a very small device may not obtain the full temperature range.

The thermocouple cable or wire is employed to make the thermocouple probes in order to detect the temperature applying the point of Cold Junction Compensation (CJC) method.

Various thermocouple types like J or K type use dissimilar mixtures of materials in their wire. At the CJC method, the millivolt value presented by the thermocouple shows the variation in temperature sensing introduced as the reference point.

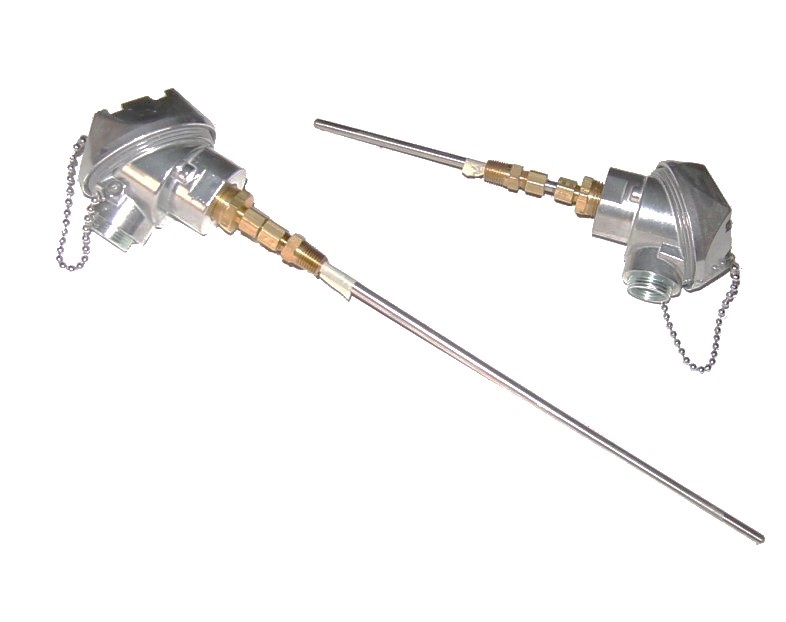

Thermocouple Probes vs. Thermocouple Wire

It is essential to know that a temperature sensor can only measure its own temperature. As discussed before, the choice of a probe sensor vs. a wire style device is an important matter of how appropriate to get the thermocouple system to the procedure of temperature we are trying to sense.

For instance, we can propose detecting the temperature of a liquid in an enclosed or partially enclosed source. Utilizing a wire transducer may be appropriate if the liquid does not harm the conductor substances. But if the liquid is corrosive and high-temperature or high-pressure, then a probe system with a thermowell will be a better choice.

How are Insulated Thermocouple Wires Identified?

The insulation of the thermocouple wire has color coding for identification. Popular datasheets explain that the negative part in the insulated wire is red. The positive leg has the color of the thermocouple extension grade wire. The outer cover of the thermocouple wire is normally brown. It is usual to have a color-coding marker in the white material for high-temperature devices.

What is the Difference between Standard and Special Limits of Error (SLE) Wire?

Standard vs. SLE (special limits of error) wire operates with the precision of the wire. SLE wire is similar to the standard wire with the additional property of having a little better stability. The accuracy of thermocouple types modifies with the device substance. For instance, a type T thermocouple that contained copper wire in the positive part and constantan (or copper-nickel composition) in the negative leg is the best choice with high accuracy for the lower temperature applications.

What is the Difference between Thermocouple Grade and Extension Grade Wire?

Thermocouple grade is a wire that is utilized to show the sensing reference or the probe section of the thermocouple. On the other hand, the extension wire is only used to send the thermocouple sign from a probe to the detector instrument. The extension wire usually has a lower temperature range in which the wire can be utilized. It may send a sign at a higher temperature than received from the system, but the wire physically is not exposed to high temperatures.

What is the Maximum Length of Thermocouple Wire?

Various factors can influence the length of a thermocouple. As a total guideline, under 30 meters with 20 AWG (American Wire Gauge) or thicker wire in the section without electromagnetic effect is appropriate. The other main features in specifying thermocouple length are total resistance and preventing electrical noise of the system. The resistance modifies depend upon the type and the wire size because various thermocouple wires are constructed from different substances.

The amount of resistance loop is influenced by the amplifier system attached to the circuit. Loop resistance is also specified by calculating the length by the resistance per double feet dimension as introduced as “Resistance Vs. Wire Diameter” for thermocouple types and configurations. It should be said that the probe size must be added to the calculation of the wire length.

The second important feature in operating a thermocouple wire is to prevent it from any electromagnetic systems. Thermocouple wire produces a low voltage output and should not be applied close to the power systems, motors, etc. A metal shield wire is usually used to reduce the noise value.

Thermocouple Wire vs. Extension Cable of Thermocouple Types

It is important to notice that the signal does not directly come from the junction when using a thermocouple, but it is produced from the thermocouple conductors and the junction of the end of the wires. As discussed before, the precision of the signal may be influenced by the thermocouple substances and the temperature variation.

Thermocouple wire is accessible in Standard ranges and particular limitations defined in ANSI/ASTM E230 standard. For example, when you have a thermocouple probe constructed of specific precision Type T (±0.5C or 0.4%) wire that tolerates the high-temperature variation, you need to connect it to an extension cable. Nonetheless, the total precision of your overall sensing will continue to have some limits of error due to the lengths of the conductor.

But remember one key factor, Extension Grade wire is only evaluated and ensured to 200oC; any use in higher temperatures cannot be certified to meet particular limitations unless the wire is calibrated again and the practical tolerance utilized in the total measurement precision.

Choosing Thermocouple Types

At first, it is important to recall that both precision and limitation are based on such factors as device alloys, the measured temperature, the construction method, the substance of the surface, the state of the materials (solid, liquid, or gas), and the size of either the wire or the sheath.

How do We Choose between Different Types?

Choosing the best kind of thermocouple is an issue of relating the device to your sensing requirements. Here are some factors to take into consideration:

Temperature Range

The various thermocouple types have different temperature levels. For instance, Type T with its Copper part has a max temperature near 370oC.

Conductor Size

The size and shape of the thermocouple wires require to be noticed when long cycle-detecting is applied. For example, T-type thermocouples are utilized up to 370 oC, if the main system consists of #14AWG wires (or 0.064” Diameter). Nevertheless, when the device includes 30AWG wires, the temperature range reduces to 150oC.

Accuracy

T-type thermocouples have the best accuracy of all the base metal thermocouple types. This is followed by E-Type and, respectively, types J, K, and N for standard limitations of error according to ANSI/ASTM E230.

Some other essential factors are the sheath composition in probe devices, insulation substance in surface sensors, and sensor geometry.

Why are Type K Thermocouples So Popular?

Type K thermocouples are so popular according to their broad temperature level and durability. The conductor metals employed in them are more chemically static than Type J (Iron) and Type T (copper). While the output signal of type K is approximately lower than T, J, and E types, it is greater than its major competitor (Type N) and has been used more than them.

Application of Thermocouples Types

Application of thermocouple types consists of sensing steel during machining. K, B, S, and R types are more suitable for this operation according to their high-temperature limits. This helps the constructer understand when the particular substance is melted to a special temperature. Heating devices also run appropriately with the thermocouples. Thermocouple types can detect temperatures and run the gas shut off instruments in petroleum industries.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

How to put back on the probe backbon small frig model number is RS08DR