Top steam turbine manufacturers in India– Steam turbines are used to power generators and to produce electricity, as well as to provide propulsion for ships, planes, and missiles, and may be found all over the world. They transfer heat energy in the form of evaporated water into motion by applying pressure to spinning blades. The steam turbine has been developed to the millimeter, and it is one of the most challenging products to design and manufacture. Only a few places in the world manufacture large steam turbines. We’ve prepared a list of the best steam turbine manufacturers in India in this post.

On Linquip website, among the many options available, you will be able to find all the information you need regarding steam turbines and their related products, as well as other details about the steam turbine industry. Linquip is committed to providing you with as much general and dependable information about steam turbines as possible, whether you are a professional in the steam turbine industry or a customer searching for steam turbines. There is a list of Steam Turbine Manufacturers available on Linquip.

Do you want to find out how we may be able to generate more revenue for your business by providing you with a marketing package? If so, then reach out to us today! As Linquip’s Solutions are tailored for companies at all levels, you will have a number of options to choose from that will allow you to upgrade the capabilities of your business in order to gain a competitive edge. In short, we can help you set up any type of marketing and advertising package you desire, from the most basic to the most complex, so that your business attracts as many customers as possible. What questions do you have about the price of steam turbine devices and equipment? Are you interested in finding more details about this topic? Through Linquip, you can submit a request to a variety of Steam Turbine Suppliers and Companies and receive free quotes from each.

The Fundamentals of Steam Turbines

What Is a Steam Turbine?

A Steam Turbine is a constant volume machine that extracts thermal energy from pressured steam and converts it to mechanical work. Because it provides rotational motion, the turbine is particularly suited to powering electrical generators. Steam turbine generators at central power plants such as solar thermal electric, nuclear, and coal power plants produce more than 88 percent of the energy in the US, according to the US Department of Energy.

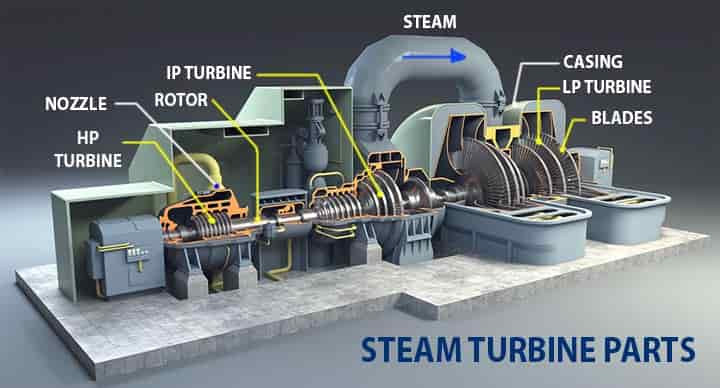

The fact that a steam turbine is powered by steam gives it its name. As steam passes through the turbine’s spinning blades, it expands and cools, releasing the majority of the energy it contains. Because of the steam, the blades are constantly rotating. As a result, the blades convert the vast majority of the steam’s potential energy into kinetic energy. The turbine is then used to power a generator, which produces electricity. The most basic components of a steam turbine are the blades and rotors. A group of blades is referred to as a “stage.” They have steam inlets and outputs as well, typically a set of nozzles.

Operational and Design Principles

The entropy of the steam entering the turbine equals the entropy of the steam departing it, making an ideal steam turbine an isentropic process. In contrast, no steam turbine is totally isentropic, with typical isentropic efficiencies ranging from 20% to 90% depending on the turbine’s use. The interior of a turbine is made up of several sets of blades or buckets. One set of stationary blades is connected to the casing, while another set of moving blades is attached to the shaft. The sets are coupled with certain minimum clearances, with the size and layout of the sets changing at each stage to maximize steam expansion.

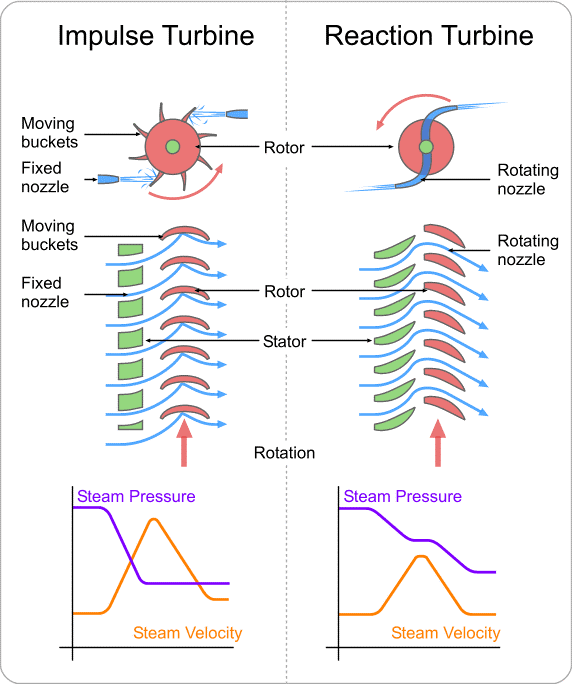

The thermal efficiency of a steam turbine is affected by its size, load, gap losses, and friction losses. They can achieve peak efficiency of roughly 50% in a 1,200 MW (1,600,000 hp) turbine; smaller turbines have lesser efficiency. To improve turbine efficiency, steam is expanded and put to work in a series of processes. The amount of energy taken from these stages determines whether they are categorized as impulse or reaction turbines. Most steam turbines use a combination of reaction and impulse designs, with each stage operating as either one or the other, but the overall turbines use both. Lower pressure stages are usually reaction types, while higher pressure stages are usually impulsed types.

Impulse Type of Steam Turbine

Fixed nozzles direct the steam flow into high-speed jets of an impulse turbine. The bucket-shaped rotor blades transfer the kinetic energy of these jets into shaft rotation as the steam jet changes direction. The pressure drop is restricted to the stationary blades, resulting in a net increase in steam velocity over the stage. As the steam flows through the nozzle, the pressure drops from the inlet pressure to the output pressure (atmospheric pressure or, more usually, the condenser vacuum). Because of the high ratio of steam expansion, steam leaves the nozzle at a high velocity. As it leaves the nozzle, the steam leaving the rotating blades has a large fraction of its maximal velocity.

Reaction Type of Steam Turbine

Reaction turbine rotor blades form convergent nozzles when they are aligned. In this sort of turbine, the reaction force, created when the steam accelerates through the nozzles formed by the rotor, is utilized. The stator’s fixed vanes direct steam onto the rotor. It emerges from the stator as a jet that completely fills the rotor’s diameter. In comparison to the blades, the steam then reverses direction and builds up speed. A pressure drop develops across both the stator and the rotor as steam accelerates through the stator and decelerates through the rotor, with no net change in steam velocity across the stage but a reduction in both pressure and temperature, representing the work generated in the rotor drive.

Different Types of Steam Turbines

A steam turbine is a large turbo machine that generates mechanical energy from thermal energy. All steam turbines can be classified into several categories based on the number of general flow, cylinders, heat source, working principle, and flow direction. They can also be classified according to exhaust conditions, casting or shaft design, and drive type. However, there are two sorts of steam turbines: impulse and response, as previously indicated. Condensing, non-condensing, automated extraction, mixed pressure, and regenerative extraction are the five fundamental types of steam turbines based on exhaust circumstances.

A) Types Based On Principle of Operation:

- Reaction turbine

- Impulse turbine

B) Types Based On the Number of Cylinders:

- Single Cylinder Turbine

- Multi-Cylinder Turbines

C) Types Based On Means of Heat Supply

- Single Pressure Turbine

- Reheat Turbines

- Dual Pressure Turbine

D) Types Based On the Direction of Steam Flow

- Axial Flow Turbine

- Radial Flow Turbine

- Tangential Flow Turbine

E) Types Based On Exhaust Condition

- Condensing Turbine

- Non Condensing Turbine

Maintenance of Steam Turbine

After giving time for the rotor to establish a straight plane (no bowing), the turning gear is disengaged and steam is introduced to the turbine, first to the astern blades, then to the forward blades, slowly rotating the turbine at 10–15 RPM (0.17–0.25 Hz) to gradually warm the turbine. Warm-up times for large steam turbines can take up to ten hours.

Due to the high rotation velocities, rotor imbalance might cause vibration, which could result in a blade breaking away from the rotor and passing through the casing. To avoid this risk, great work is put into balancing the turbine. High-quality steam, either superheated (dry) or saturated with a high dryness fraction, is also used to power turbines. This shields the blades from being bombarded with condensed water, which causes impingement and deterioration quickly (moisture carry over). The thrust bearings on the turbine shaft may be damaged by liquid water entering the blades. To prevent this, condensate drains are installed in the steam pipework leading to the turbine, as well as controls and baffles in the boilers to ensure high-quality steam.

Top Steam Turbine Manufacturer in India in 2023

The table below includes the top Steam Turbine Manufacturers in India, along with their annual sales. The following sections provide further details about each company’s headquarters, including the number of employees and descriptions of corporate operations.

Table 1: Top Steam Turbine Manufacturer in India in 2023

| Company | Headquarters | No. of Employees | Annual Sales |

|---|---|---|---|

| Bharat Heavy Electricals Limited (BHEL) | Delhi, India | 1000+ | $250 Mil. and over |

| Siemens India | Worli, Mumbai | 1000+ | $250 Mil. and over |

| Triveni Turbines | Bengaluru, Karnataka | 500-999 | $50 - 99.9 Mil |

| Arani Power Systems | Madinaguda, Telangana | 50-99 | $10 - 24.9 Mil |

| Chola Turbo Machinery | Bengaluru, Karnataka | 100-199 | $10 - 24.9 Mil |

| Kessels Engineering Works Pvt Limited. | Rajendra Place, New Delhi, Delhi | 100-199 | $10 - 24.9 Mil |

| NS Trebo Pvt. Ltd | Industrial Area, Ghaziabad | NA | $10 - 24.9 Mil |

| NCON Turbine | Bengaluru, Karnataka | 50-99 | $10 - 24.9 Mil |

| TurboTech Precision Engineering Pvt. Ltd | Bengaluru Rural, Karnataka | 10-49 | $1 - 9 Mil |

| IB Turbo | Worli, Mumbai, Maharashtra | 10-49 | $1 - 9 Mil |

Top Steam Turbine Manufacturer in India in 2023 Summaries

Bharat Heavy Electricals Limited (BHEL)

Bharat Heavy Electricals Limited, BHEL, is a state-owned engineering company located in New Delhi, India. It is owned by the Ministry of Heavy Industries of the Indian government and is known as the largest power generation equipment company, was established in 1956. This company designs, manufactures, engineers, constructs, tests, commissions, and services a broad range of products, systems, and services for the major sectors of the economy, including industry, power, transmission, transportation, renewable energy, oil, gas, and defense.

It has a network of 16 production units, 2 repair units, 4 regional offices, 8 service centers, 8 foreign offices, 15 regional centers, 7 joint ventures, and infrastructure that allows it to complete over 150 projects at locations across India and internationally. To satisfy the increased demand for power generation equipment, the company has constructed a capability to achieve 20,000 MW of power equipment per year.

BHEL maintained its market leadership position in the Power Sector in 2015–16, with a 74 percent market share. In 2015–16, BHEL achieved its highest ever commissioning/synchronization of 15059 MW of power plants in domestic and international markets, representing a 59 percent increase over the previous year. BHEL has surpassed 170 GW of the installed base of power generating equipment with the all-time high commissioning of 15000 MW in a single year FY2015-16. For over 40 years, it has also been exporting its power and industry segment products and services. The global references of BHEL can be found in 76 countries on all six continents. BHEL produced power plants have a total installed capacity of over 9,000 MW in 21 countries, including Malaysia, Oman, Iraq, the United Arab Emirates, Bhutan, Egypt, and New Zealand. Turnkey projects and after-sales services are among its main exports.

Siemens India

Siemens Limited is a technology corporation that specializes in the industry, infrastructure, digital transformation, transportation, and electrical power transmission and generation. It is Siemens AG’s flagship listed company in India. The corporate structure of the organization is well-suited to satisfying industry demands for increased efficiency, quality, flexibility, and speed. The company is well positioned to assist the country in achieving long-term success thanks to its diverse portfolio, market-oriented organizational structure, global technology leadership, and strong local competency. Siemens’ long-term connection to India dates back to 1867 when firm founder Werner von Siemens personally supervised the construction of the first telegraph line connecting London and Calcutta. Siemens now has a large manufacturing footprint across the country, as well as a nationwide sales and service network, as well as different Centers of Competence and R&D centers.

Siemens provides a comprehensive variety of electrical engineering and electronics products and services. Buildings-related products, drives, industrial plant-related products, automation, energy-related products, lighting, medical products, and transportation and logistics-related products are among the company’s offerings.

Triveni Turbines

The Triveni Group of Companies is a focused, rapidly expanding conglomerate with diverse interests in Engineering, Co-Generation, Clean Water Solutions, Distillery, and Sugar. Triveni’s precision engineering capabilities has been at the forefront for more than five decades. The company is an industry leader in engineering, providing cutting-edge solutions for Turbo-Generator islands and industrial GearBoxes. The Triveni Group has built India’s first cogeneration plant. Triveni has been providing reliable, efficient steam turbine solutions for over five decades. Triveni Turbine Ltd. is a significant manufacturer of industrial steam turbines in India, with a market share of more than 60%. Triveni has installed over 5,000 steam turbines in over 70 countries, including Europe, Africa, Central, and Latin America, Southeast Asia, and SAARC countries, across 20 sectors.

Biomass IPP, District Heating, Municipal Solid Waste IPP, Palm Oil, Paper, Sugar, Naval, Textiles, Metals, Cement, Carbon Black, Solvent Extraction, Chemicals, Pharmaceutical, Petrochemicals, Fertilizers, Oil & Gas Municipal Solid Waste based Independent Power Plants (IPPs), and Captive Power Plants are just a few of the industries Triveni serves (CPPs). Every client connection is cherished at Triveni, and long-term partnerships are prioritized. Manufacturing and supplying industry-specific, custom-made steam turbines are the company’s main capabilities. Triveni Turbines focuses on offering the best service in the market with a well-managed 24×7 “Complete Customer Care network’. Triveni is a pioneer in the steam turbine market thanks to its unique flair and strategic approach.

Arani Power Systems

Arani Power Systems is a manufacturer of steam turbines ranging in size from 5 to 45 MW. From Hyderabad, India’s steam turbine technology hub, full-fledged research and development engineering, manufacturing, no-load run test, quality assurance, supply chain management, marketing and sales, erection and commissioning after sales and service groups operate. Arani Power provides Steam Turbine-Generator (TG) Packages following thorough system engineering integration. To establish the mechanical soundness and dynamical vibrational behavior of the turbine and rotor-bearing System as a whole, fully completed turbines are tested at full speed and no load using steam. The manufacturing facility has its own steam boiler and accompanying infrastructure, as well as a large test-pit and control room.

ARANI uses the most advanced and best technology in developing steam turbines that match worldwide standards, as it evolves to satisfy ever-increasing demand. This company creates and delivers customized goods that are cost-effective and meet international requirements. Arani Power Systems features a cutting-edge production facility, as well as a mechanical run test facility. Arani Power Systems has well-established R&D and Engineering divisions, as well as efficient supply chain management. Arani also has a good after sales and Renovation & Modernization department with sound Troubleshooting capabilities for Erection & Commissioning of delivered Steam Turbines or STG Sets and to fulfill customer’s expectations.

Chola Turbo Machinery

Chola Turbo Machinery International Pvt Ltd (CTMI), based in Hoskote, 25 kilometers from Bangalore, has rolled out a great number of turbines up to 30 MW across a range of industries, including Biomass and Municipal Solid Waste based Independent power plants (ipps), Captive power plants (cpps), and Co-generation plants in industries such as Sugar, Paper, Textiles, Fertilizers, and Steel.

CTMI is backed by a team of devoted technocrats that are continually evaluating quality and testing standards while working on design and development projects. Their steam turbine packages are the result of extensive research and development as well as dynamic engineering. The packages, which have a base design and scope, can be utilized for power generation and mechanical drives, with outputs ranging from 7.5 kW to 30 MW. CTMI employs bespoke software for its equipment design in addition to the many software (for 3D modeling and design) already accessible on the market.

Kessels Engineering Works Pvt Limited.

Since its inception in 1987, Kessels has been a dominant force and has established a leading position in the market for producing and providing industry-specific, tailor-made Steam Turbines to meet the needs of customers. Over the years, the company has achieved great success in designing, manufacturing, and installing steam turbines in a variety of industries, including sugar, steel, paper, chemical, and nuclear power, with a single installed capacity of 30000 KW.

Kessel’s commitment to utilizing cutting-edge technology in the construction and design of its steam turbines adds value to the customer’s entire energy solution. Using advanced assembly lines and employing highly trained and motivated personnel, they have been successful in meeting these standards for over 500 customers with a combined installed capacity of over 1500MW across India and many other countries across the world, including Fiji, Vietnam, Pakistan, Nepal, Argentina, Korea, Trinidad & Tobago, Oman, Uganda, Bangladesh, Peru, and the United Arab Emirates.

NS Trebo Pvt. Ltd

NS Terbo Pvt. Ltd. is an ISO 9001-2000 certified firm that specializes in the design, engineering, and manufacture of high-speed rotating machinery such as steam and gas turbines, turbo generators, and crucial spare parts, as well as high-speed reduction gear boxes.

N.S. Terbo Pvt. Ltd. provides a variety of services:

- Developing, engineering, and manufacturing steam turbines up to 15 MW to meet the specific needs of various industries, such as independent, captive, and co-generation power plants.

- Steam Boilers

- Power Plant EPC

- Up to 15 MW Biomass Power Plant on a Boot/Turn Key Basis

- Steam Turbine and Power Plant Overhauling, Refurbishment, and Rehabilitation

- Repair Services for Steam Turbines

- Engineering of Turbine Components

- Erection & Commissioning Services

NSTPL uses cutting-edge technology in the design and production of steam turbines. These are put through a series of quality checks to guarantee that the final product is faultless. The API 611 and API 612 standards are met by our product line. NSTPL additionally provides clients with turbine-related services and essential information on product application and adaptation.

NCON Turbine

NCON Turbo Tech, a prominent manufacturer, exporter, and supplier of steam turbines with capacities ranging from 5 kW to 5000 kW, was founded in 1990. For over 30 years, the company has been manufacturing world-class Steam Turbines and Spare Parts that give energy savings to companies all over the world, true to its name (“NCON” stands for eNergy CONservation). Textiles, chemicals, paper, pharmaceuticals, rice, sugar, distilleries, food processing, and a variety of other industries are all well-suited to their turbines. Our product line is designed to work with saturated steam, low pressure, ultra-low pressure, high pressure, and superheated steam.

TurboTech Precision Engineering Pvt. Ltd

TurboTech is a leading manufacturer of turbomachinery and mechanical engineering in India. Today, TurboTech can look back on a record of 25 years, starting with an in-house prototype development of the first ever indigenous Gas turbine models of 50 KW and 500 KW in the city of Bengaluru, India, in 1989. Today, TurboTech has created a line of steam turbines specifically designed for the process industry. TurboTech aims to add value to its business areas of turbomachinery and power engineering by providing end-to-end solutions, from engineering to delivering power to the end user. The guiding principles provide a framework for producing breakthrough technologies in the pursuit of safety, reliability, value for money, innovation, and sustainability in the company’s ongoing product development.

TurboTech manufactures a variety of steam turbines, gas turbines, and turbomachinery for essential applications in the process, oil and gas, and aerospace industries. TurboTech has suitably adaptable and inexpensive Steam turbine solutions for industrial and Power Generation from the smallest requirement of a few Kilowatts to as large as 5.5 MW. They are versatile, economical to install and operate, and astonishingly mild in the environment. TurboTech also provides additional services to STG Island, such as AMC, O&M, BOOT, and Equipment Rentals.

IB Turbo

In India, IB Turbo has continually delivered efficient and reliable steam turbines, supplying 4200 MW of net electricity generating equipment to over 650 turbines in over 25 nations. In India, IB Turbo has established a strong reputation as a reliable and respected name in the field of mini power plants. Most international technical standards and local meteorological conditions are met by IB Turbo engineers. At all of its locations, IB Turbo maintains a strong Quality Management System.

Download Top Steam Turbine Manufacturers in India PDF

There is the option to download this article in the form of a PDF file if you would prefer to read the article in that format. Clicking on the link provided below will take you to the download page.

Conclusion

This article has compiled data and business descriptions for some of the most well-known steam turbine manufacturers in India, as well as a quick primer on steam turbine fundamentals. Visit the Linquip website to learn more about these firms and to find suppliers of more industrial and commercial equipment.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Provider

Read More In Linquip

- How Does a Steam Turbine Work? A Simple Descriptive Guide

- Types of Steam Turbine: An easy-to-understand and practical Classification

- Steam Turbine Parts: A Comprehensive and understandable Introduction to All Components

- Steam Turbine Efficiency: Complete Explanation

- Top 15 Gas Turbine Manufacturers In India

- Top Wind Turbine Manufacturers in USA (Comprehensive Guide)

- Top Wind Turbine Manufacturers In India (Comprehensive Guide)

Thankyou for the valuable information. May your blogs progress.

Thanks for visiting our website and leaving your comment, Kalyan! We hope to hear from you again in our other posts.