Different Types of centrifugal pumps used in industries can be classified according to various criteria, including design code, impeller types and numbers, applications, and so on. In this article, we will describe the classification methods of these pumps.

Centrifugal pumps are classified as a subclass of dynamic axisymmetric turbomachines. Centrifugal pumps are used to convert the rotational kinetic energy to hydrodynamic energy to move the fluid. The rotational energy usually comes from an electric motor or an engine.

Centrifugal Pumps are classified using a variety of ways, including application, design code, impeller kinds and numbers, and so on. The types of centrifugal pumps available are a crucial consideration while utilizing this product. Several suppliers and companies, as well as various Manufacturers and Distributors, provide various types of centrifugal pumps, and there are several Types of Centrifugal Pumps For Sale on Linquip.

There is a comprehensive list of centrifugal pumps services on the Linquip website that covers all factory operations. Linquip vendors can assist you with this. Please contact Centrifugal Pumps Experts in Linquip to learn more about how to connect with a diverse group of service providers who consistently deliver high-quality products.

The fluid enters the impeller along or near the axis of the pumps. The impeller accelerates the fluid. Then, it flows radially toward a diffuser or volute casing through which it leaves the pump.

Centrifugal pumps are used in all facilities such as oil production systems, refineries, petrochemical plants, and power plants. Also, they can be used to supply water in agriculture, food processing, and residential buildings. Therefore, a proper selection among different types of centrifugal pumps is significant according to the application.

Centrifugal pumps can be applied to transfer liquids over long distances through cross-country pipelines. Another application is to provide the desired pressure, such as in a boiler feedwater pump.

⇒ View a List of Centrifugal Pumps for Sale and Their Suppliers ⇐

Basics of Centrifugal Pumps

A Centrifugal pump is a rotary machine that transforms kinetic energy into the pressure head of the fluid. External power from an electric motor or diesel generator turns the pump impeller. Then, under the influence of centrifugal force, the fluid entering the impeller reaches its tip and leaves the volute casing.

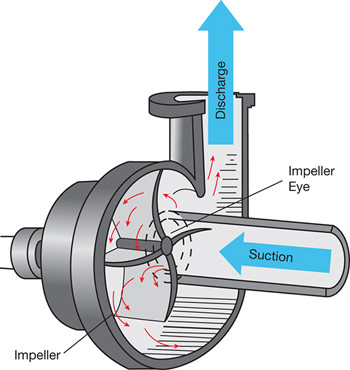

In the following figure, a cross-sectional view of a centrifugal pump depicts the flow path from the inlet to the outlet.

Working Principle of Centrifugal Pumps

The following steps are taken to complete an energy conversion by a centrifugal pump:

- Fluid enters the pump suction.

- It enters the rotating impeller eye. Impeller gets its energy from a motor, engine, or turbine.

- The impeller pushes fluid outward by centrifugal force. During this process, the fluid reaches velocity and pressure.

- Fluid enters inside the volute (sometimes with a diffuser), reducing its velocity and increasing the pressure. It also delivers fluid into the discharge nozzle.

Impeller and volute are the main components that are responsible for energy conversion. Impeller gives the energy to the fluid, and the volute helps to provide the same hydraulic head.

The following equation shows how the efficiency of a centrifugal pump can be calculated:

\eta =\rho gHQ/P_{m}

In this equation, Pm is the mechanical input power to the pump (measured in W). ρ, g, Q, and H are fluid density (kg/m3), gravity acceleration (m/s2), flow rate (kg/m3), and head added to the fluid flow (m), respectively.

The added head to the fluid is a sum of the static lift and any losses due to friction, valves, or pipe bends. Power is usually stated as kilowatts or horsepower. The pump efficiency may be expressed for the pump or as a combined efficiency for both the pump and motor.

Parameters Influencing the Centrifugal Pump Performance

There are points that should be considered in choosing a centrifugal pump for better performance and away from defects and problems.

Suction Pressure

If the fluid pressure on the suction side is less than required, it may cause cavitation. Cavitation severely affects pump performance and can permanently degrade the impeller.

Suction Flow

The constant flow is required at the suction; otherwise, it will not work at the design point. If the flow decreases at suction, discharge flow reduces consequently. If there is no flow during suction, it severely damages pump components. This pump cannot operate in dry conditions. Thus, if it is depleted after the last use, you must fill the pump before you start it.

Fluid Density

High-Density fluids do not work with centrifugal pumps. The higher the density, The more work must be done by the pump to push the fluid. This creates less than ideal conditions for performance and maintenance due to the increased need for power and maintenance.

Fluid Viscosity

Centrifugal pumps are suitable choices for clean and low-viscosity fluids. Generally, fluids with a viscosity of less than 500 Centistoke are the right choices. You can design a pump to transfer more viscous fluids, but that requires more power and is more inefficient.

Fluid Vapor Pressure

Very low vapor pressure may cause cavitation. If you work with such fluids, make sure you always have sufficient pressure in your system.

Types of Centrifugal Pumps

There are various methods to classify centrifugal pumps, including application, design code, impeller types and numbers, and so in. In this section, the most common ways to categorize centrifugal pumps are explained. It should be noted that a pump may be placed in two or more groups at the same time.

Classification of Centrifugal Pumps Based on the Flow Type

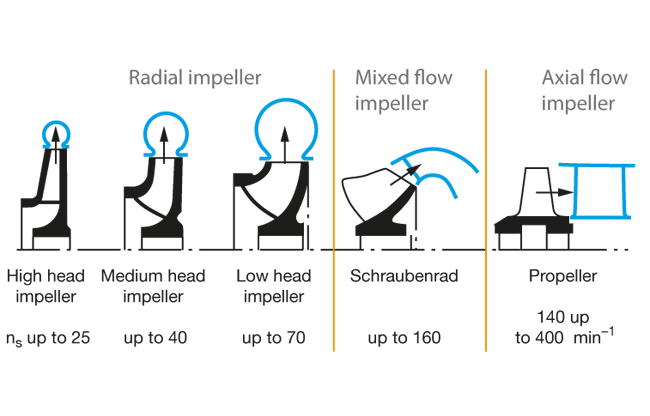

Accordingly, radial, Axial, and Mixed flow are three types of centrifugal pumps. The figure below shows the flow path through these types of pumps as well as their specific speed ranges.

The specific speed of a pump is expressed by the following equation:

N_{s}=\frac{nQ^{\frac{1}{2}}}{H^{\frac{3}{4}}}

In this equation, n is the pump speed (in rpm). Also, Q and H are flow rate (kg/m3) and head (m) at the best efficiency point.

Radial Pumps

In radial pumps, the fluid comes out of the impeller after 90 degrees of rotation relative to the suction. The most common centrifugal pumps are in this category. Fluid enters the horizontal suction flange and exits through a vertical outflow flange. So, the discharge is perpendicular to the shaft of the pump. This design is applied when there is a flow limitation and you want to raise discharge pressure. Therefore, radial design is high pressure and low flow rate pump. Most pumps utilized in the oil and gas industries fall into this category.

Axial Pumps

In an axial flow pump, the fluid moves parallel to the shaft. This procedure resembles the working of a propellant. The most significant application of this pump is when there is a large flow rate and very little pressure head. For example, they are common in dewatering pumps and water circulation pumps.

Mixed Pumps

As the name implies, in a mixed flow pump, the fluid flows mixing both radial and axial properties. So, that is a tradeoff between axial and radial pumps. Mixed pumps operate at high flow rates with a decent increase in the head.

Classification of Centrifugal Pumps Based on Number of Stages

Two or more impellers can be utilized in the pump, depending on the requirements and on-site operating conditions.

Single Stage Pumps

This pump has only one impeller and the highest increase in pressure head is 125 meters. The simple structure, stable operation, high speed, lightweight, small volume, high efficiency, large flow capacity, and easy maintenance are essential advantages of single-stage pumps. Single-stage centrifugal pumps can be classified into horizontal pumps, vertical pumps, single-suction pumps, and double-suction pumps.

The single impeller is designed to be useful for a large flow rate and relatively lower pressure head.

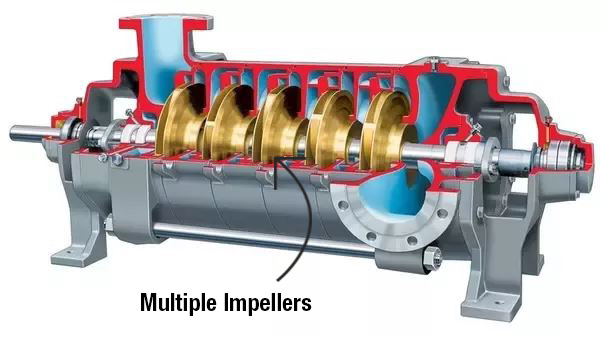

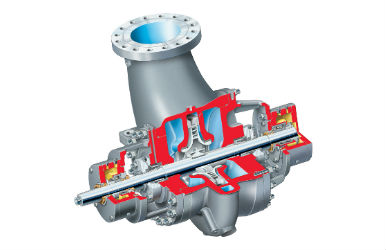

Multistage Pumps

The fluid pressure at the outlet of the pump can be very large. Therefore, if a very high head at discharge is needed, the multistage pump is used. In this design, impellers are connected in series to increase the fluid pressure at each stage.

Classification of Centrifugal Pumps Based on Design Codes

Regarding the use of code for pump types, the following two cases are usually used.

API 610

This design is mostly used in oil and gas, petrochemical, and related process industries.

ISO 5199 / ISO 2858 / DIN 24256

DIN 24256 is now integrated with ISO 2858. These standards are utilized for all pump design types.

Classification of Centrifugal Pumps Based on Types of Volute

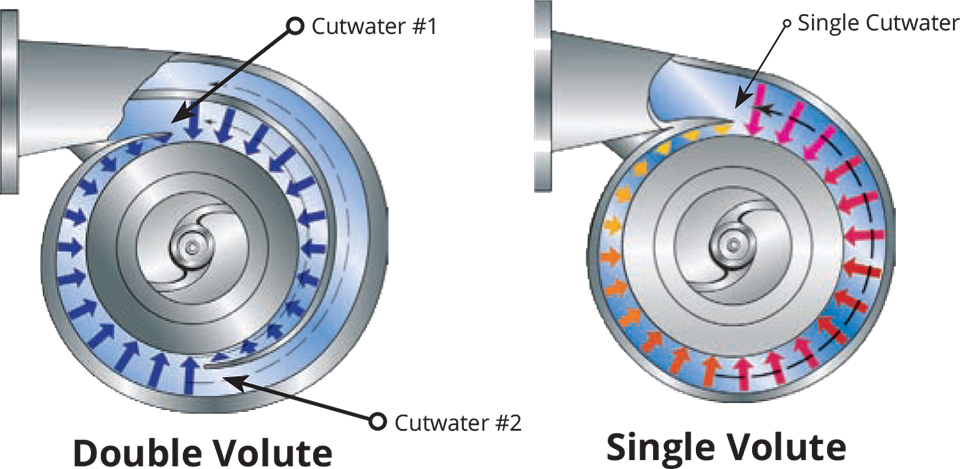

Pumps are divided into two categories, single-volute or double-volute, depending on their casing type.

Single Volute

In a single volute casing, the flow is discharged from the impeller into one volute, which winds completely around the impeller. This casing has one cut-water that delivers the fluid flow towards the outlet of the pump. Most of the pumps in the refinery are of single volute types.

Double Volute

A double volute casing has two cut-waters positioned 180 degrees apart. Double volute has a benefit over the single. It minimizes the defection of the shaft when the pump works outside the BEP best efficiency point (BEP).

Classification of Centrifugal Pumps Based on Number of Suctions

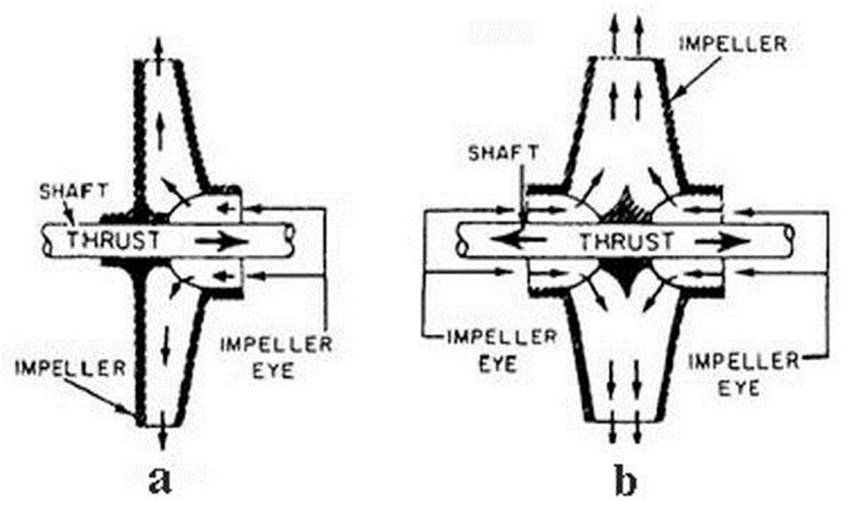

Most centrifugal pumps are single-suction designed; however, sometimes it is necessary to have double-suction designs.

Single Suction

In a single-suction centrifugal pump, the fluid flows into the inlet, and the entire liquid immediately flows into the impeller eye (the inlet of the impeller). The centrifugal force then produces pressure as the water leaves the impeller.

Double Suction

Single-suction will not suffice when the flow rate is too high. In this case, double suction centrifugal pumps are used. The impeller of this pump is engineered so that fluid enters from both sides in comparison with the single side in a normal case.

However, the name “double suction” must not confuse you. Even in the double suction design, there is only a single suction and discharge flange. The difference is in the design of the impeller and casing.

Classification of Centrifugal Pumps Based on Casing Designs

Radially and axially split pump casings are two different designs discussed below:

Radial Split

If a centrifugal pump casing has a vertical connection to the shaft (perpendicular to the shaft and parallel to the impeller), this is a radially split casing.

Axial Split

An axially split casing of a centrifugal pump has a design in which the casing is split along the centerline of the shaft. The casing is divided into two halves that are separated horizontally, parallel to the shaft axis.

To better understand the above explanations, you can watch this video about the radial split casing and this one about the axial split casing.

Classification of Centrifugal Pumps Based on Shaft Orientation

Accordingly, centrifugal pumps have either vertical or horizontal shaft positions.

Vertical Shaft

In a vertical pump, the shaft is in a vertical orientation, and the pump is usually placed in the sump. These pumps are used in limited spaces. For example, pump in borewell and sump collection are of this type.

Horizontal Shaft

Horizontal pumps are more commonly used because they are easy to maintain. In this type, the shaft is positioned horizontally.

Classification of Centrifugal Pumps Based on Impeller Position

Accordingly, centrifugal pumps are classified into overhung impeller pumps and between bearing pumps.

Overhung Impeller Pump

In an overhung impeller pump, the impeller is installed on the end of a shaft, which overhangs its bearings. In this pump, the impeller is suspended through a single bearing. This configuration facilitates both vertical and horizontal installation of the pump.

Between Bearing Pump

In between bearing type of centrifugal pump, the impeller is placed on the shaft, and the shaft is suspended at both ends between two bearings. Horizontal multistage pumps are provided in this design.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Download Types of Centrifugal Pumps PDF

Read More on Linquip

- A Cheat Sheet For The Types of Pump Couplings

- What Is a Multistage Centrifugal Pump Used for

- Parts of Centrifugal Pumps

- Different Types of Hydraulic Pumps: a Complete Guide

- Different Types of Pumps: Ultimate Guide

- Working Principle of a Centrifugal Pump

- Types of Screw Pumps: How Each Type Gives Benefits?

- Centrifugal Pump: Working Principles, Function & Diagram

- Types of vane pumps: review the types, select the best

- Types of Fire Hydrant Systems

- Types of Piston Pumps

- Types of Dynamic Pumps

- Types of Fuel Pump

- Parts of Water Pump

- 5 Types of Vacuum Pump and Applications + PDF

- 7 Parts of Gear Pump and Function + Diagram & Applications

- 10 Parts of Reciprocating Pumps + Function, Application and Working

- 3 Types of Well Pumps + Applications

- 3 Types of Oil Pumps + Working Principle & PDF

- 5 Types of Concrete Pumps + PDF

- 6 Type of Sump Pump and Which Are Better to Buy?

- 20 Parts of Submersible Pump + PDF

- 3 Types of Positive Displacement Pump + Name & PDF

- 10 Parts of Hydraulic Pump + PDF & Function

- 7 Parts of Screw Pump: Advantages and Disadvantages

- 8 main Parts of Piston Pump and Function + Work & PDF

- 9 Different Types of Rotary Pumps + PDF

- 12 Types of Water Pressure Pumps with Applications & Characteristics

Enjoyed reading the article above , really explains everything in detail.

Thanks for visiting our website and leaving your comment! We hope to hear from you again in our other posts.