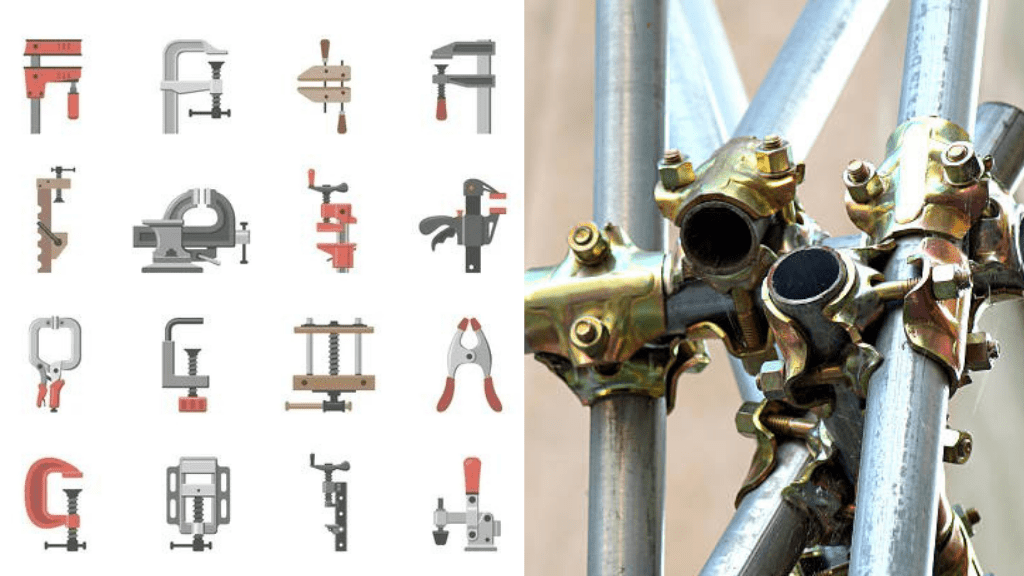

Types of Clamps – A clamp is a tool designed primarily to secure or hold any object firmly in place and stop it from moving or separating by applying pressure inward. When a tool is temporarily employed to place the components during construction or a woodworking operation, the word “clamp” is used. Although there are many different types of clamps on the market, they all serve the same purpose. This article will teach you about the many types of clamps and their applications. Additionally, you’ll learn how to use these clamps.

Linquip is a good place to learn more about clamps. Whatever the circumstance, we can assist you in determining the proper clamps. Linquip offers a wide selection of Clamp Products to make sure you can find one that meets your needs.

All OEM fleets can access a full list of clamps on Linquip’s website. Linquip vendors can assist you with this. Please contact Clamp Experts for more information on how to find a wide range of Service Providers who consistently deliver high-quality products. Linquip platform provides a free quotation request service from available Clamp Suppliers and Companies if you want to know how much a clamp will cost.

What Is a Clamp?

A clamp is a workshop tool that secures objects in position or holds other objects together. They facilitate precise cutting or joining of different materials. These are mostly used in construction, metalworking, and woodworking applications. Although all clamps work in the same way, there are many different types to select from. However, certain claims are specifically made for particular activities because a single clamp-type cannot be utilized for all operations.

A clamp is a helpful tool for securely keeping a workpiece in place while it is being worked on. For example, in woodworking, a clamp is used to fasten a piece of wood to a workbench while carrying out operations like cutting or chasing. A clamp could help keep the workpiece uniform when painting. It is the perfect tool for holding materials like steel, iron, aluminum, and copper, among others, in metalworking applications like welding, grinding, or manufacturing. They help maintain workpieces securely in place on a drill table, which makes them handy for drilling as well.

The workpiece moves during the filing process because pressure is applied to the metal in order to file it. Clamps are used as a result to stop this. When gluing, the clamps can be used to keep objects in position while you wait for the glue to cure.

How Does A Clamp Work?

Objects are tightly held in place with clamps. A clamp’s main function is to give the user a secure grip so they can carry out the necessary task, whether that duty is to clamp an object to a work area or to keep two or more things together.

When a clamp just has one jaw, it is intended to be used with a work surface, such as a workbench, to hold an object firmly. A clamp’s two jaws, on the other hand, will act in conjunction to keep the object in place.

Depending on the mechanism being employed, the jaws are regulated differently on various types of clamps. Some varieties employ a trigger system, in which the jaws are moved by pulling a lever or trigger. In contrast, some models contain a conventional screw that is used to adjust the clamp. The clamp closes around the workpiece when the screw is turned, and pressure is then applied to retain it securely in place.

Types Of Clamps

There are many sorts of clamps that must be understood as well as their applications. So let’s get started to learn more.

28 Types of Clamps include:

- Hand Clamp

- Material Handling Clamp

- Mechanical Clamp

- Pipe Clamp

- C-Clamp

- Ground Clamp

- F-Clamp

- Quick Action Clamps

- Locking Chain Clamps

- Sheet Metal Clamps

- Kant-Twist Clamp

- Wood Hand Screw Clamps

- Spring Clamps

- Sash Clamps

- Bench Clamps

- Miter Clamps

- Picture Frame Clamps

- Edge Clamps

- Cabinetry Clamps

- Table Clamps

- Web Clamps

- Beam Clamps

- Scissor Clamps

- Vertical Plate Lifting Clamp

- Pneumatic Power Clamps

- Hydraulic Clamps

- Hose Clamps

- Dimide Clamp

Hand Clamp

Hand clamps are hand-operated instruments used to hold or place the work parts during assembly while they are going through any manufacturing process. The primary requirements listed here include the clamp features as well as certain intended uses, such as the clamp type or grip range.

The hand clamps are often available in a very wide range of designs, including bar, draw, parallel, and toggle, and they may be used for a number of tasks, including book binding, picture framing, doormaking, and other manufacturing processes. Laboratory glassware, which is also featured here, is typically used with clamps.

Material Handling Clamp

Material handling clamps are clamping instruments used to hold heavy material that is frequently lifted or moved. Some of the intended uses, such as load capacity and the direction of the clamping action, are among the main parameters of these kinds of tools.

These clamping tool types are typically employed to lift or manipulate heavy weights in construction applications. These particular tools are frequently employed in factories and manufacturing facilities for lifting weights such as rails, girders, pipes, etc.

Mechanical Clamp

Mechanical clamps are used to secure hoses or tubes to the ends of pipe spuds. The material, diameter, and clamp type are among the details of such clamps. These tools, sometimes known as hose clamps, are employed everywhere a flexible fluid connection is required.

For example, within an auto engine’s water pump and the radiator’s intake spud. Depending on the purpose, they can be constructed as single-use or reusable devices and come in a variety of sizes and materials, such as metal or plastic.

Pipe Clamp

Pipe clamps are mechanical devices used to suspend or secure pipes. Such clamps’ parameters include applications such as clamp type and pipe diameter. To suspend several different types of pipes, pipe clamps are frequently employed in plumbing and piping applications. In addition to everything else, these clamps may be used for conduits, guard rails, and exhaust pipes. It is remarkable to learn that these devices come in a number of sizes and shapes, as well as a range of materials, depending on the type of pipe that has to be hung.

Following are some tasks for which the pipe clamp is best suited:

- Woodworking

- Welding

- Metal working

- Found having large opening capacity

C-Clamp

These kinds of clamps are very common and are frequently used for a variety of tasks. The finest feature is that it is unmatched in terms of simplicity and accessibility, therefore the majority of clamp collections begin with a few different sizes of C-Clamps. There are several C-Clamp designs that are available for a variety of task requirements due to the C-Clamp popularity.

- Standard C-Clamps as one of the most popularly known clamp,

- Copper Coated C-Clamps to prevent weld spatter build up,

- Double Anvil C-Clamps for distribution of even load,

- Quick Release C-Clamps for quick action, and

- Deep Reach C-Clamps used for long reach.

These C-clamps are best suited for the following tasks, which are listed below:

- Woodworking

- Metalworking

- Low cost

Ground Clamp

Mechanical devices known as “ground clamps” are employed to ground cables, rods, pipelines, antennas, etc. In addition to this, it is utilized for other more specialized operations like welding and airplane refueling. The intended use and material are included in the specifications of such clamps. Depending on how the ground wire is built, many types of ground clamps are available.

F-Clamp

The f-clamp is a sort of mechanical device that has a large opening capacity. These clamps have a slider bar that makes it possible to simply alter the opening capacity to accommodate a variety of applications. This property of the f-clamp has made it a highly popular clamp, and it is utilized when the opening capacity of a C-Clamp is insufficient.

These F-clamps are best suited for the following tasks, which are listed below:

- Woodworking

- Welding

- Metalworking

- Found having large opening capacity

Quick Action Clamps

One of the most common types of clamps on the market today is the rapid grip or quick action clamp. By pushing the push handle with one hand, these clamps are tightened. These tools resemble f-clamps in that they both have adjustable clamp opening capacities.

These quick-action clamps are best suited for the tasks listed below:

- Speeding the work

- Single Handling

- Woodworking

Locking Chain Clamps

The mechanical locking chain clamps are used to apply a clamp load in confined places, around pipes, or close to any other surface. When the chain is tightened, pressure is applied to the item, which allows it to clamp a variety of forms.

These locking chain clamps are best suited for the tasks listed below:

- Metalworking

- Speeding the work

- One handed

- Varying shapes

Sheet Metal Clamps

Sheet metal clamps are similar to locking clamps in appearance. The main distinction is that they have a sizable surface area at the jaws of the clamp, which is what makes them perfect for gripping sheet metal and comparable materials.

These clamps are perfect for:

- Sheet metal

- Metalworking

- Speeding the work

- One handed

Kant-Twist Clamp

Many machine shops and welders use kant-twist clamps because they transmit load by employing two parallel jaws and by preventing the jaws from wandering. As the clamp is being tightened, the handle is held perpendicular to the load it is supporting, which also keeps the clamp from twisting.

These jobs that these Kant-twist clamps are most suited for are listed below:

- Welding

- Metalworking

- Machining

- Woodworking

Wood Hand Screw Clamps

One of the oldest types of clamps used in woodworking is the wood hand screw clamp, which has jaws that can pivot to clamp at different angles. The best usage for these wood hand screw clamps is in specialized tasks like woodworking.

Spring Clamps

Spring clamps are among the simplest and least expensive mechanical devices. However, these are the ones with the smallest clamp loads and the least amount of opening capacity. This is what makes them the best option for securing a tarp or limiting movement along an axis that isn’t bearing any weight.

These clamps are available in a variety of sizes to accommodate a wide range of jobs. They are formed of metal, and in order to protect users from harm while in use, the handle portion and the tips are often covered with PVC. They may be helpful in jewelry creation, woodworking, and many other crafts. If the PVC coverings at the tips are taken off, a spring clamp can also be used for solder work.

Sash Clamps

Sash clamps are mechanical tools that resemble parallel clamps in a lot of ways. When working on substantial tasks like tabletops, doors, cabinets, or sash windows, this kind of clamp is employed. To ensure a firm hold on the project, typically more than one must be deployed at once. They feature a fixed jaw coupled to a large, flat bar that is quite heavy.

This fixed jaw has a screw that may be turned. They also contain a sliding jaw that may be moved the whole length of the clamp before being locked into place to secure the materials. Large projects may be tightly clamped together with their help while the glue dries. They are a more advanced, lengthier version of the bar clamp.

Bench Clamps

Bench clamps are ones that are used to secure work tables. Through the use of attachment accessories, these types of clamps enable rapid clamping of an assembly and are perfect for use with a wood table.

Some of the tasks listed below involve the use of bench clamps:

- Assembling

- Woodworking

- Welding

Miter Clamps

The term “miter clamp” refers to something which is perfect for joining corners for the assembly. Miter clamps are ideal for the tasks listed below:

- Woodworking

- Assemblies

Picture Frame Clamps

The mechanical picture frame clamps are perfect for mechanically joining rectangular components like picture frames, table supports, window frames, etc. The following tasks are ideal for picture frame clamps:

- Woodworking

- Assemblies

Edge Clamps

The term “edge clamp” refers to a device that can be moved along two axes by means of three different screws. This makes the clamp perfect for gluing an assembly together or for holding down butt-weld components. Edge clamps are perfect for the following tasks:

- Welding

- Woodworking

Cabinetry Clamps

Cabinetry clamps are those ones that have two neighboring cabinets with their face frames flat so that you may screw them together. This is done by applying clamp loads in two axes. Cabinetry clamps are excellent woodworking tools.

Table Clamps

The table clamp may be quickly and easily clamped with one hand when used in conjunction with a welding table for welding assemblies.

Table clamps are ideal for the applications listed below:

- Welding Assemblies

Web Clamps

One of the greatest clamps for difficult forms is the web clamp. The bands that apply load to the assembly are locked using these corners. These clamps are mostly utilized while making furniture out of wood.

Web clamps are ideal for the jobs listed below:

- Woodworking

- Transportation hold downs

Beam Clamps

The mechanical tools known as beam clamps are used to raise steel beams and plates. Lifting is its primary use, which makes it popular.

Scissor Clamps

Scissor clamps are a type of equipment that resembles a lifting clamp. This clamp applies the clamping load by taking advantage of the weight that is being raised. Additionally, the clamp has rough clamping jaws that assist the object being lifted to be better dug into and the grip is improved. Lifting is its primary use, which makes it popular.

Vertical Plate Lifting Clamp

Vertical plate lifting clamps feature revolving teeth that leverage the weight of those being lifted to create an additional load and keep the plate from sliding. The major reason it is popular is for lifting.

Pneumatic Power Clamps

These are pneumatic clamps that firmly and effectively lock together. These kinds of clamps frequently operate automatically and on timers that clamp and unclamp at predetermined intervals. The automobile sector was the first to employ power clamps in an effort to boost production and replace manual clamps.

Today, a variety of applications, such as assembly lines and the manufacturing industry, employ power clamps. They operate automatically and minimize operator intervention, which saves time. They are especially helpful in fields with restricted access or in distant locations where regular clamps cannot reach, such drainage lines.

Hydraulic Clamps

Other than the use of hydraulic power or pressurized liquid to deliver a clamping load, hydraulic clamps are known to be relatively similar to pneumatic clamps.

Hose Clamps

The mechanical tools that are used to secure a hose to a fitting are referred to as hose clamps. These clamps are frequently used on irrigation or car hoses. Hose clamps work best for pipe connections.

Dimide Clamp

The Dimide Clamp is a mechanical tool used for heavy-duty metalworking and welding that combines speed and power through the impact of a wrench. These are the devices that an impact wrench applies to and are made for high torque loads. The dimide clamp is a reliable clamp that is ideal for compressing the parts together by avoiding component slippage, removing the clamp’s bottleneck from a manufacturing line, and doing a number of other things.

In addition, the Dimide clamp may be available with a removable T-handle and a hex head, which makes it possible to use a wide range of drivers, including ratchets, impact wrenches, torque wrenches, breaker bars, and many more. The following are some of the reasons why dimide clamps are favored and utilized:

- High load

- Fast action

- Used for Welding

- Used for Metalworking

- Used for Machining

Download Types of Clamps PDF

There is an option to download the article in PDF format if you find that to be more convenient for you. You can download the file by clicking on the following link.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- 10 Types of Hose Clamps + Design, Applications & Advantages

- 8 Types of O-Ring + Applications (Clear Guide)

- 5 Different Types of Drill Bits for Wood: A Comprehensive Guide

- Types of Drill Bits for Metal: Comprehensive Guide

- 33 Types of Pliers & Their Names: A Comprehensive Explanation

- 18 Types of Machining Vises (Clear Guide)

- The 10 Best Electric Lawnmowers

- Types of Circuit Breaker: A Basic Guide to Know Different Classifications

- 3 Different Types of Hygrometers and Their Applications

- All Types of Pneumatic Fittings: Specifications and Applications

- 7 Types of Capacitors and Their Uses

- Types of Electric Circuits: All Classification with Application

- 5 Types of Proximity Sensors (Application and Advantages)

- The 6 Best Leaf Blowers + Buying Guide & PDF

- The 10 Best Snow Blowers + Buying Guide & PDF

- The 10 Best Electric Pressure/Power Washers

- The 10 Best Torque Wrenches + PDF & Buying Guide

- The 10 Best Circular Saws in the USA

- The 10 Best Hammers

- The 10 Best Mini/Benchtop Milling Machine

- The 8 Best Pressure Washers

- The 8 Best Rust Converter (Review Guide)

- 8 Best Soldering Iron for Electronics & The Like + Buying Guide

- The 7 Best Portable Band Saws + Tips for Choosing

- The 9 Best Cordless Impact Wrenches

- The 10 Best Electric Space Heater + Buying Guide

- The 8 Best Engine Hoists & Accessories + Buying Guide

- Top 10 Irrigation Equipment Suppliers

- Top 10 Railroad Equipment Suppliers in USA & Worldwide

- The 10 Best Steel Toe Boots for Women

- Top Brick Manufacturers in USA & Globally

- Top Water Filter Supplier & Companies

- Top Foam Rubber Suppliers in USA & Worldwide

- Top Crushed Stone Suppliers in USA

- The 4 Best Ceramic Coatings

- All 24 Types of Drill Bits + Video: Clear Guide

- 5 Types of Toggle Clamps with Applications & Characteristics