Types of Fire Hydrant Systems – A fire hydrant is a visible connection point for firemen to tap into a water supply that is installed in predetermined areas. Fire hydrants with connections to a water service network must be installed in all buildings, parking lots, roadsides, mines, and industrial zones, among other places. They’re made to supply firefighters with the water they need to attack and extinguish a fire quickly. Underground fire hydrants were used until the 18th century. Above-ground pillar-type fire hydrants became popular and widely employed from the 19th century onwards. A fire hydrant is just a pipe with a valve that allows water to flow from a water main to extinguish a fire.

A well-designed and well-laid out Hydrant System constitutes the backbone of the entire firefighting system, being one of the oldest but still most effective and widespread firefighting solutions. It is made up of heavy-duty above-ground and subsurface pipework as well as accessories. Every critical location has external and fire escape hydrant valves. A fire hydrant is a conduit that permits water to flow from the water main into a fire hydrant under the direction of a valve.

The Fire Hydrant Protection System is designed to battle large-scale fires in all risk classes. It’s built to keep working even if a section of the impacted structure falls. On Linquip, we’ll go over the many types of fire hydrant systems on this topic.

⇒ View a Comprehensive List of Fire Hydrants for Sale and Their Suppliers ⇐

What is a Fire Hydrant System?

Fire hydrants are required to keep your municipality functioning smoothly. Fire hydrants are used by firemen to put out fire. Fire hydrants allow them to swiftly tap into water utility’s pressurized water supply. To start the water flowing, the firemen remove a nozzle or two, attach hoses to the nozzles, and turn the valve. They can immediately determine how much pressure they have available depending on the hydra’s body color and nozzle type, allowing them to avert disaster and property damage.

But which type of fire hydrant should you use? The piece that remains above ground is recognizable to most people, but fire hydrants extend many feet below the earth as well. There are two varieties of barrel hydrants, wet and dry, as well as standpipes, for the most part. Depending on the environment, they have a variable structure and mechanism. Wet barrel hydrants are significantly more frequent in the south, where they are less likely to freeze during a hard winter, but dry barrel hydrants are more popular in areas where freezing is a concern.

Fire Hydrant Working

Many sites have different types of fire hydrant systems with a variety of valves and connecting points. Firefighters find fire hydrants, attach their hoses, and then pump a massive amount of pressurized water to extinguish the fire. The hydrant’s valve cover is removed using a specific pentagonal wrench. The firefighters then open the valve to allow the water to flow after attaching the hoses.

They normally have a nut or bolt to turn on to start the flow and a connecting point to connect a fire hose to. Every fire hydrant is nothing more than a connection to the main water line. A riser pipe links the hydrant valve to the ground underneath it. Normal hydrants, on the other hand, do not affect the water pressure or flow. They act as valves, allowing firemen to use the existing pressure in the water lines. While all of this may appear to be straightforward, the underlying mechanics of a fire hydrant are more complicated and vary by area.

Main Types of Fire Hydrants

The two types of fire hydrant systems are dry barrel and wet barrel. The wet barrel fire hydrant provides a steady flow of water, whereas the dry barrel fire hydrant requires a valve release to allow water to enter. It is intended to allow immediate access to water in the case of a fire. Fire Brigade Connections are independent systems that function similarly to building-specific fire hydrants, providing fire protection that is easily accessible to firefighters. Hydrant System guidelines and approval are available from NFPA, NBC, IS, TAC, FM, and local fire authorities, among other national and international organizations.

Wet Barrel Hydrants

Wet hydrants are commonly utilized in areas where freezing is not an issue. The water in the main supplies the hydrant close to the surface in these sorts of fire hydrant systems. As a result, it is sensitive to freezing in cold temperatures.

Wet barrel hydrants are an industry-standard in places where freezing is not a concern, with possible operational lifespans of over 100 years when properly maintained. Because all of the mechanical components are above ground, this is the case. This indicates that the water in the main feeding the hydrant runs near to the surface, exposing it to freezing. The more fundamental process is important for their survival, but it also contributes to their tendency to freeze in cold temperatures.

Dry Barrel Hydrants

The water is stored underground in a dry hydrant system. In frigid places, the Earth’s temperature is frequently greater than the cold surrounding temperature. As a result, this design can avoid the danger of freezing. When firefighters need to utilize the dry hydrant system, they open a valve on top of the hydrant and insert their hose into it. The drain valve within the hydrant opens as a result of this. This permits water to enter, which the firemen may use to extinguish the fire.

Slide-gate, compression, and toggle mechanisms are the three types of dry barrel hydrants. The hydrant’s water valve is located far below ground in the hydrant’s base in dry barrel hydrants. No water remains in the hydrant’s system after it has been utilized since the whole water system is below the frost level. The hydrant’s danger of freezing and frost damage is greatly reduced as a result of this. Checking if there is any water in the hydrant’s base is part of the hydrant’s maintenance cycle, which is normally done with a plumb line. If moisture appears, it might indicate that the hydrant’s drain valve is malfunctioning, leaving it vulnerable to freezing.

Difference between a Dry barrel Hydrant and a Wet barrel Hydrant

The following are the primary distinctions between a wet hydrant and a dry hydrant:

Wet Hydrant or Wet Barrel Hydrant has the following features:

- When water freezing isn’t a concern, wet hydrants are employed.

- The water in this design is above ground.

- Wet Hydrant is less expensive and easier to build.

- Because of the ease of access, wet barrel hydrants are easier to maintain.

Dry Hydrant or Dry Barrel Hydrant includes the following characteristics:

- In frigid climates where the temperature often falls below the freezing point of water, dry barrel hydrants are employed.

- To avoid freezing, the water in the dry barrel design is maintained below ground.

- Dry barrel hydrants, on the other hand, are more expensive and harder to build.

- The upkeep is rather difficult.

Choosing the Right Types of Fire Hydrant Systems

The Colors

All fire hydrants are color-coded following NFPA regulations. These hues represent the predicted flow of the procedure. The top crowns of fire hydrants are usually painted. The following table lists the most prevalent colors in order of flow.

Fire hydrants come in a variety of hues, some of which have meaning and others that don’t. The hydrant’s body color is mostly a subject of personal preference; however, it is frequently red or safety green to make them more visible from a distance. During an emergency, this aids firemen in swiftly locating the hydrant. Some localities will utilize a color scheme to indicate the amount of available water pressure at each hydrant.

The meaning of the colors on a fire hydrant’s nozzle caps is something that emergency responders and utility personnel are typically familiar with. In general, the color red is reserved for specific tasks such as firefighting. White denotes that the hydrant is on the water utility’s service, but not necessarily on the water main, whereas yellow indicates that the hydrant is on the water main with high pressure. Violet is most commonly associated with non-potable water that meets international standards, such as untreated water from a lake or pond.

Standards & Codes of Fire Hydrants

The following norms and standards are used as design recommendations for fire hydrant systems:

- NFPA 25

- NFPA 1

- AWWA

- NFPA 291

- BS EN 14384

- 21.3M

- DIN 3222

- BS 750

- AS 2419

- DIN EN 14339

- FP-009

- IS 13039

- IS 3844

Standpipes

Standpipes are a useful tool for firefighters, even though they work differently than traditional hydrants. Standpipes are a viable alternative to sprinkler systems because they allow firefighters to distribute water to a specific section of a building. They are typically located in a fixed interior location in a large structure. This permits those who are unable to evacuate the building to self-extinguish a fire. Standpipes are therefore an important tool for firefighters, particularly in big structures where a huge number of hoses would be required to extinguish the fire.

Selecting the appropriate fire hydrant for your water utility necessitates long-term planning and consideration. You may be considerably more confident in your choice if you engage with a reputable hydrant provider like Team EJP, who can guide you through the procedure. Take the time to consider all of your alternatives so you can select the best solution for your water utility that will provide reliable service for many years. Get in touch with Linquip right away!

Operational Information of Types of Fire Hydrant System

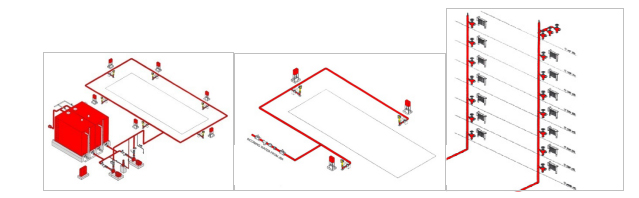

A fire hydrant installation is a system of pipework that is linked directly to the water supply main to give water to every hydrant outlet and is meant to provide water for firefighting. Water is dumped into a fire engine, where it is pumped and sprayed on the flames. Hydrant pumps should be installed when the water supply is unreliable or insufficient to pressurize the fire mains. The following is an example of a typical hydrant installation that is fed directly from the water main and pressured by fire pumps:

The Electric Driven Pump, Jockey Pump, and Stand-by Diesel Driven Pump make up the Fire Pump Station. Pressure switch contacts control the pump’s functioning, which is based on the hydrant network’s header pressure. The jockey pump and main pump’s delivery are linked to a shared delivery header.

Water pressure is maintained in the Fire Hydrant Line at all times. If there is a tiny pressure drop in the system and the pressure approaches the Jockey pump’s preset pressure setting, the Jockey pump will automatically start to adjust for the pressure difference. If one or more hydrant valves are opened to battle a fire, the Jockey pump will not be able to compensate for the water loss, leading to a further decline in pressure. When the lowering pressure approaches the main pump’s preset pressure, the main pump will immediately start. In the event of a power outage, a diesel engine-driven backup pump will be activated.

To draw water from the water main, a firefighter connects a fire hose to the fire hydrant and opens a valve. The majority of fire hydrants are intended to flow no less than 250 gallons (950 liters) of water per minute.

Summary

The primary function of different types of fire hydrant systems is to provide water for fire suppression. They can, however, be used for a variety of secondary applications, such as:

- Line Flushing: Fire hydrants can be used to flush main distribution system lines because of their high flow capacity and ease of usage.

- Testing System: Fire hydrants can be used to assess the distribution system’s hydraulic capability.

- Other Common uses: Fire hydrants are also commonly used for commercial construction work, sewage cleaning, roadway building, and street cleaning, among other things.

Visit this in-depth video or contact Linquip Experienced Companies to learn more about firefighting systems, their application, operation, and different types of fire hydrant systems.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- Fire Hydrant: Working Principles, Function & Diagram

- A Cheat Sheet For The Types of Pump Couplings

- Types of Piston Pumps

- Different Types of Pumps: Ultimate Guide in 2022

- Types of Centrifugal Pumps: All Classification & Working Principles

- Different Types of Hydraulic Pumps: a Complete Guide

- 5 Types of Vacuum Pump and Applications + PDF

- 3 Types of Positive Displacement Pump + Name & PDF

- 9 Different Types of Rotary Pumps + PDF

- 5 Types of Concrete Pumps + PDF

- 6 Type of Sump Pump and Which Are Better to Buy?

- Types of Pump Casings (In Centrifugal Pumps & Others) + Pros & Cons

- 3 Types of Well Pumps + Applications

- 3 Types of Oil Pumps + Working Principle & PDF

- 6 Main Types of Dynamic Pumps: Examples + PDF

- 5 Main Types of Fuel Pump & How They Works?

- 3 Types of Vane Pumps: Working Principles & Application

- Types of Water Pumps and Their Principles

- Types of Submersible Pumps: All Classification With Details

- Types of Centrifugal Pumps: All Classification & Working Principles

- 10 Parts of Hydraulic Pump + PDF & Function

- Working Principles of Hydraulic Pump (With Videos)

- Hydraulic Pump Working Principles: Ultimate Guide

- What is Hydraulic Pump: Learn The Basics, Boost Your Knowledge

- The 5 Best Air Source Heat pump in 2022 (Clear Guide)

- 7 Best RV Water Pump In 2022 (Clear Guide & Review)

- The 10 Best Electric Air Pump in 2022 (Clear Guide)

- 9 Different Types of Rotary Pumps + PDF