Different types of gear coupling are critical since they all make gear coupling but in different machines. A gear coupling is designed to convey high torques and has a seat with a kind of gender coupling. There are several types of gear coupling available depending on the application. You will read about what gear couplings really are. You will also find different types of gear coupling. Follow us in Linquip.

What are Gear couplings?

To answer this question, we must first define what coupling is. A coupling, at the simplest, is a power transmitter. Couplings serve as connecting components between any two shafts. The type of complexity of connectivity, the power to be transferred, and the field of operation all play a significant role in the coupling type collection. Gear couplings fall into the heading of flexible couplings and can relay extremely high torques. You can also find more types of a gear coupling.

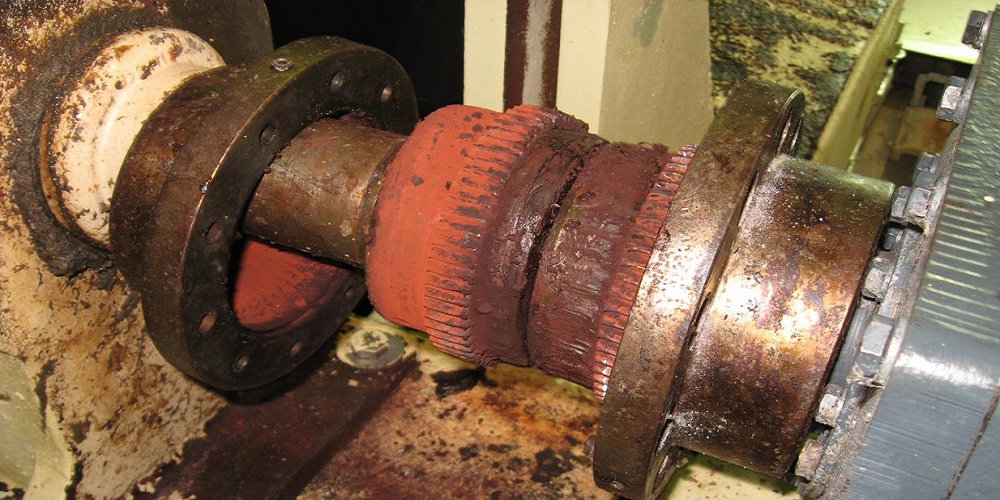

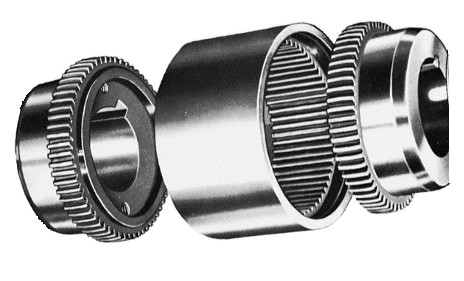

Gear couplings, often known as gear couplings, are a form of coupling that is often used in high-torque, high-power applications. Gear couplings can normally tolerate more torque than universal joints, whereas universal joints produce less vibration. A gear coupling is made up of two hubs with external and internal teeth and a one- or two-piece sleeve.

Gear couplings have a general misalignment capability of 0.01-0.02 inches in parallel and 2 degrees in angular. They are sometimes used in pairs of spacer shafts to bridge the gap between driving and driven machinery. They are usually lubricant-required, but some are designed for lighter-duty use of lubricant-free nylons or other polymers for the center sleeve.

Types of gear coupling

There are various types of gear couplings utilized in various kinds of machines, such as:

Full Gear Couplings

The double engagement forged steel coupling is the regular series 100 complete gear coupling and is used in the majority of industrial applications. It has a large end float capability and can compensate for both parallel (offset) shaft misalignment and angular misalignment.

Half Gear Half Rigid Couplings

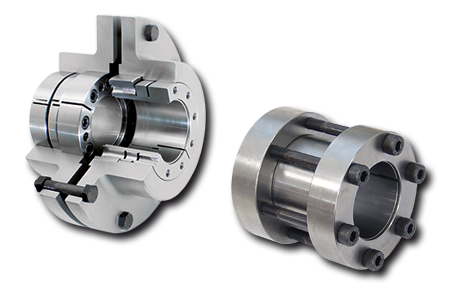

The Series 100 Half Gear Coupling is made up of a flexible and rigid half. The open half is a regular Series 100 half coupling with an outer sleeve and an inner hub, while the rigid half has a flanged hub.

Rigid Couplings

A type of coupling used to connect shafts that are aligned. Among types of gear coupling, the rigid coupling is the simplest kind. Rigid couplings are used where exact shaft alignment is required; shaft misalignment can affect the coupling’s performance as well as its existence.

Floating shaft assemblies

This makes for long-distance shaft connections. For example, if you have an engine that needs to power a fan 15 feet away but there is no place to install connecting shaft supports, a floating shaft assembly is a good solution.

Slide couplings

These are used where any axial movement is needed and thermal shaft expansion must also be considered.

Shear pin couplings

Next to the above types of gear coupling, shear pin couplings are suitable for applications that often overrun or get clogged. When the pin inside the coupling breaks, the equipment stops working. This avoids damage by shutting down the machine as loads get dangerously high.

Disconnect couplings

These are similar to shear pin couplings in that they can easily disconnect depending on the case. Disconnect couplings are suitable for both medium- and high-speed applications.

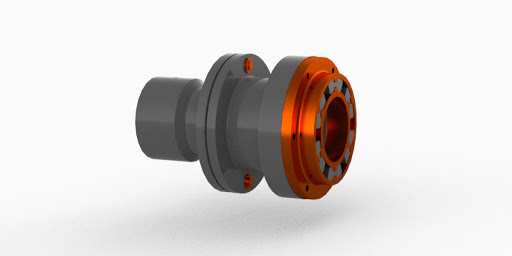

Flanged gear couplings

Flanged gear couplings are made up of short sleeves surrounded by a perpendicular flange. For each pole, one sleeve is placed such that the two flanges match up face to face. The flanges are held together by a series of screws or bolts.

Continuous sleeve gear couplings

To wrap up the different types of gear coupling, we mention continuous sleeve gear couplings that have shaft ends that are joined together and abutted against each other before being enclosed in a sleeve. These sleeves are usually made of copper, but they may also be made of nylon.

In this article, we learned that gear coupling is a mechanical mechanism that transmits torque between two non-collinear axes. Couplings are usually made up of two flexible joints that are attached to each shaft. This joint is often linked by a third axis known as a spindle. The majority of joints are made up of a pair of internal or external gears. To allow angular displacement between the two gears, the gear side and outer ring are crowned.

We also discovered different types of gear coupling. This is all about some types of a gear coupling. If you have any queries regarding this article, ask by commenting. Also, if you like this article, don’t forget to share it on social networks. Subscribe to Linquip for more about types of a gear coupling. Thanks for reading it.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- What Is a jaw Coupling? With the Focus on the Working Principle, Size & Dimension

- The Practical Guide To Types of Coupling in 2021

- What is Grid Coupling? Essential Details You Need To Know

- A Cheat Sheet For The Types of Pump Couplings

- Advanced Guide: Types of Rigid Couplings

- The Quick Guide To The Types of PVC Couplings

- Types of Shaft Couplings: A Simple Guide to The Types

- What is Disc Coupling: A Complete Guide

- The Complete Library of Types of Flexible Coupling

- What Is a Fluid Coupling? Diagram + Parts

- Flange Coupling Adaptor: Working Principle and Applications

- What Is a Sleeve Coupling? Everything You Need to Know

We are so grateful for your kind words. Thanks for sharing your review with us and the community. Please sign up on Linquip with any further comments or suggestions you wish to share. Again, thank you for taking the time to review our article!

Thanks for the information. A mechanical gear coupling is needed to transfer torque between two shafts. You have mentioned all the gear coupling types with proper images. Keep it up.

We appreciate you stopping by our site and expressing your thoughts. It is our sincere desire to continue receiving feedback from you in future articles.