Types of Hinges and Hinge Materials – Hinges are basic mechanical bearing devices that allow two parts to rotate relative to each other about a fixed axis. The components can move (most often) within a specified arc or with 360° freedom, depending on the type used. Hinges are available in a wide range of sizes and designs. The best hinges for your project are determined by where they will be installed and the finished appearance you want to create.

Visit the Linquip website to learn more about the hinges. Whatever the situation may be, we can assist you in determining the best hinge for your needs. Linquip provides a wide range of Hinge Products to ensure you can find one that meets your requirements.

All OEM fleets may access a comprehensive catalog of hinges on Linquip’s website. Linquip vendors can assist you with this. Please contact Hinge Experts for additional information on where to look for a selection of service suppliers who consistently offer high-quality items. If you want to know how much a hinge will cost, the Linquip platform provides a free quote request service from a variety of Hinge Suppliers and Companies.

The Definition of A Hinge

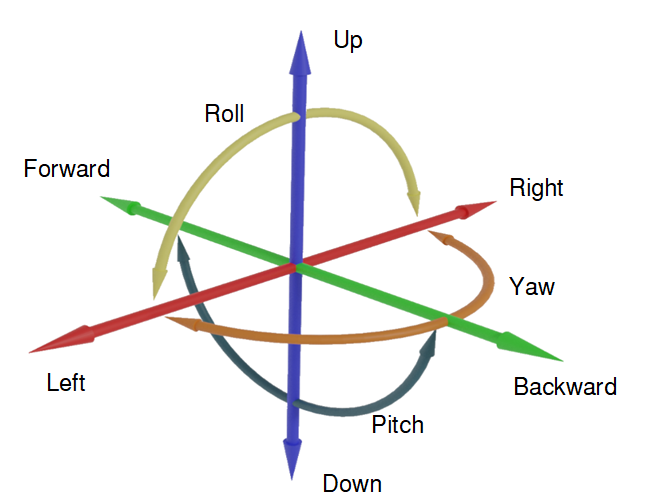

A hinge is a machine component that joins two bodies by permitting angular movement along a fixed axis of rotation but restricting translations and rotations on the other two axes. When a shaft is spinning in a hole, a hinge can be compared to a journal bearing with just one degree of freedom. Hinges can only rotate in one direction, yawing (the most frequent), pitching, or rolling.

Any swinging part can be connected to hinges, a flexible and joined object. Mechanical bearings called hinges are used to link two swinging objects or points to one another and allow them to move independently of one another. The joint can only move at one angle thanks to the restricted movement of hinges, which also limits the other motions of swinging parts.

Doors, containers, furniture, enclosures, jewelry, jewelry, construction, and electronics all often employ hinges. Every application can find a hinge with a design that works. Another option is to create and affordably produce a customized hinge for a certain use.

Different Types of Hinges

17 Types of Hinges include:

- Butt Hinge

- Ball Bearing Hinge

- Butterfly Hinges

- Flag Hinges

- Bullet or Barrel Hinges

- Flush Hinges

- Knife (Pivot) Hinges

- Living Hinges

- Concealed Hinges

- Overlay Hinges

- Offset Hinges

- Institutional Hinges

- Self-closing Hinges

- Spring-loaded Hinges

- Continuous Hinges or Piano Hinges

- Constant Torque Hinges

- Geared Continuous Hinges

For any purpose, there are numerous types of hinges to pick from. Barrels or concealed hinges are both utilized for indoor furniture. Butterfly and strap hinges offer beautiful designs for major entry doors, sheds, or wooden gates. Friction and geared continuous hinges are utilized for industrial electrical enclosures. If none of the available hinge types satisfy your needs, a customized hinge may always be created. The many types of hinges on the market are listed here.

Butt Hinge

The most frequent form of hinge used on doors and windows is a butt hinge, commonly referred to as a mortise hinge. It consists of two leaves joined by a number of knuckles on a shaft or pin. The door is where one leaf is attached, a movable part, while the fixed body is where the second leaf is attached (the door jamb). When the window or door is shut, nothing except the shaft with the pin in it is visible. Both interior and outdoor use of butt hinges is common. They are constructed of steel for use in cabinets indoors, but they are made of stainless steel that resists corrosion for use outside. Butt hinges are no longer than six inches. The term comes from the fact that the hinge is often flush with the wood surface through a mortise. The mortise on this hinge can be full or half. Full mortise refers to the flushing of both leaves to the surfaces of the door and door jamb, whereas half mortise refers to the flushing of only one leaf (usually the moving component).

Ball Bearing Hinge

Normal butt hinges are similar to ball-bearing hinges in appearance. The pivot point differs because hidden bearings are inserted between some or all of the hinge’s knuckles, depending on the hinge’s design. They are more durable and last longer than conventional hinges, which deteriorate more quickly because the knuckles rub against one another. Between the knuckles of the ball-bearing hinge are lubricated bearings. For large entryways or individuals who wear a lot, these robust hinges are ideal.

Butterfly Hinges

The design of butterfly hinges is more visually appealing than that of butt hinges. When adding decorative elements to furniture doors and strength is not a top priority, they are typically employed.

Flag Hinges

The flag hinge is composed of two leaves (male and female), one of which is permanently linked to the pin. The male leaf’s pin is permanently linked to the plate, which is shaped like a flagpole, thus the term flag hinge. The main benefit of using flag hinges is their ease of disassembly. Only gravity holds the male end to the female end. Lift-off hinges are another name for flag hinges.

Bullet or Barrel Hinges

In woodworking projects like small cabinets or jewelry boxes, barrel hinges are frequently used. (Barrel hinges shouldn’t be utilized in installations that are vertical or load-bearing.) When looking at a wood box or cabinet from either side, barrel hinges are completely invisible; they’re an excellent alternative when you don’t want to see a hinge.

Flush Hinges

Flush hinges are designed to allow the leaves to sit flush against each other. This is accomplished by inserting one leaf inside another. This is an advantage over butt hinges because flush hinges do not require a mortise or recess on the surface of the body to which they are attached. These hinges are used in low-load applications.

Knife (Pivot) Hinges

Cabinets include knife hinges. They are also known as pivot hinges, because they have an attachment that resembles the pivot point of a pair of scissors. One hinge leaf is mortised into the end of the cabinet door, and the other into the frame of the cabinet. Once placed, the pivot is all that is visible. Similar to the kitchen doors you see in restaurants, another kind of pivot hinge enables doors to pivot open and closed in both directions. These spring-loaded hinges are larger and heavier than those used in cabinetry.

Living Hinges

Living hinges differ from other types in that they do not rely on knuckles and pins for attachment. It is constructed from the rigid body itself, with a portion cut or thinned to allow for bending. This hinge is commonly found in plastic containers and packaging materials. Because these hinges are made of plastic, they are naturally corrosion resistant. Because of their high fatigue resistance, polypropylene and polyethylene are the best materials for containers with living hinges.

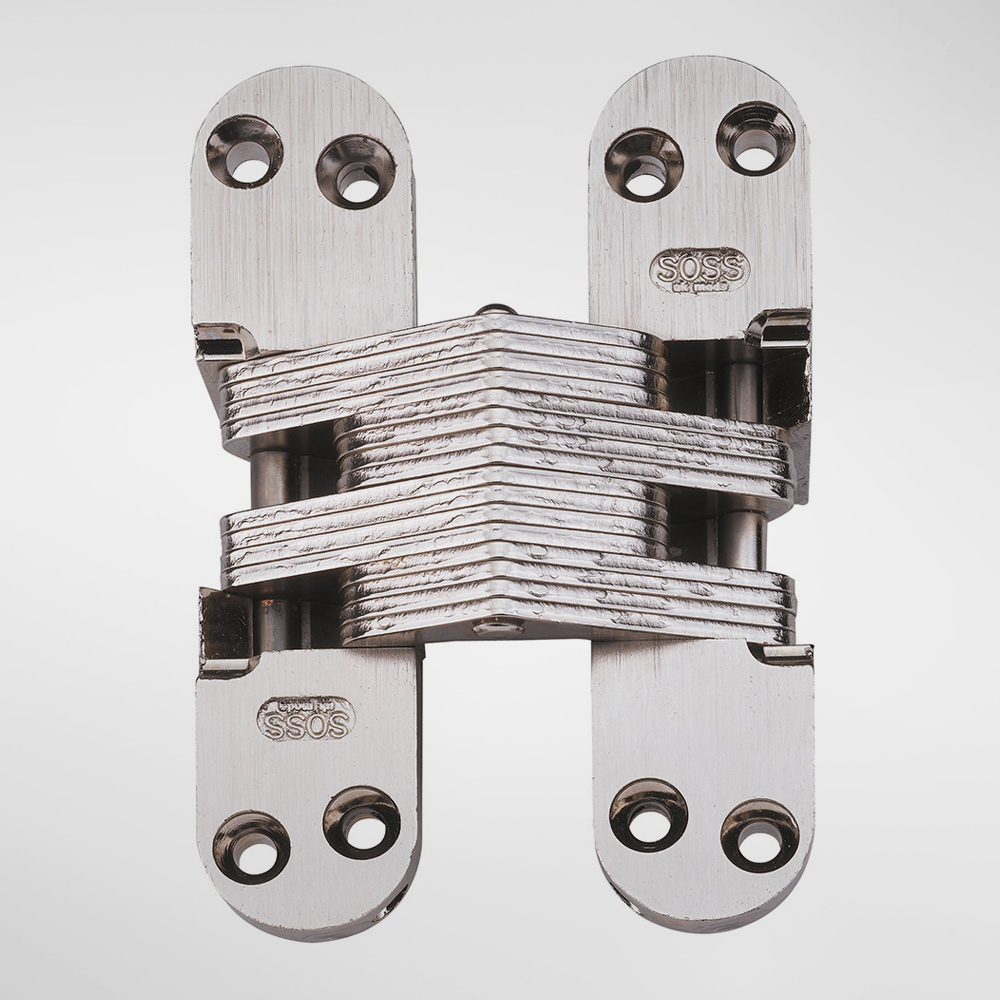

Concealed Hinges

This kind of hinge, like barrel-type hinges, is typically utilized in furniture doors. The hinge cup and the arm are the two components of this hinge. The design and construction of concealed hinges, also known as cup or Euro hinges, are intricate. They are hidden from view, giving the furniture a continuous impression. These hinges may open in a narrow radius and aid with freestyle rotation. Most often, they are utilized in wooden cabinets. It serves a variety of functions because of its three motions in three separate dimensions. Additionally, this kind may be modified after installation, making it useful for buildings with minor flaws. Aside from being adjustable, some designs also include self-closing mechanisms and damping systems.

Overlay Hinges

An overlay hinge, as the name suggests, enables the cabinet door to extend partially or entirely over the frame. When the cabinet door is closed, an overlay hinge can be hidden or semi-hidden, with the hinge visible.

Offset Hinges

A modified butt hinge, an offset hinge is generally used to widen entrances. The design is comparable to that of an institutional hinge. More room is available for passage by opening the door at a 90° angle, which places the door about two inches from the entryway. As opposed to tearing down and building a bigger entryway, this straightforward butt hinge alteration increases access space affordably.

Institutional Hinges

The offset from the pin distinguishes this type of hinge. The leaf is formed in such a way that the offset and overlaying are possible, making it suitable for narrow frames and small clearances. Institutional hinges can be made to have a 270° end play.

Self-closing Hinges

A self-closing hinge is a kind of spring-loaded hinge that utilizes a spring to automatically close doors. The spring exerts a force on the door to close it, while a damper, either mechanical or hydraulic, causes the door’s rotation to slow as it closes.

Spring-loaded Hinges

Spring-loaded hinges are hinges that have a spring to help them open and close the door. The previously mentioned self-closing hinge is one type of this hinge. Another type of hinge is the double action spring hinge. It moves in the same way as a pivot hinge, but with springs attached. The door can swing in both directions, and the springs close it automatically in the center position. Depending on the installation, outdoor spring hinges or indoor spring hinges are required, as weatherproof or waterproof hinges have significant and necessary material differences.

Continuous Hinges or Piano Hinges

Continuous hinges are a type of butt hinge that is built longer and narrower. They have long, narrow leaves that run the length of the door or window to provide extra strength and support. This hinge supports the entire length of the door or lid. It is also known as a piano hinge because it is commonly used to attach piano lids to the body. Continuous hinges can be mortised to the surface to which they are attached. These can be found in a variety of locations, including desk doors, tool boxes, cabinets, and doors.

Constant Torque Hinges

This type of hinge is intended to provide constant resistance when opened or closed. Constant torque hinges are distinguished by their preset torque specifications and cycle lifetime. Torque hinges use friction to hold doors and flaps in any desired position. These hinges are used to adjust the angles of monitors.

Geared Continuous Hinges

A geared continuous hinge varies from a butt hinge in that it moves via gears and a vertical cap rather than knuckles and a pin. This is useful for connecting two heavy objects while allowing one or both to rotate partially. Despite its strength, a significant disadvantage of this type is its limited range of motion.

Hinge Materials

When shopping for hinges, one of the decisions you’ll have to make is which material to use. While the majority of hinges are made of metal, they are available in a variety of metals. Some are harder and stronger than others, while others are better resistant to corrosion. Regardless of the application, you must select hinges made of the appropriate material. The five most common materials used to make hinges are listed below.

1) Cold-Rolled Steel: Cold-rolled steel is used in many hinges. It is an iron alloy that is rolled at room temperature and is also known as cold-formed steel. Cold-rolled steel is not subjected to high temperatures. To preserve its physical properties, it is processed and rolled at room temperature. Cold-rolled steel hinges are strong, durable, and long-lasting, creating them a popular option for a wide range of manufacturing-related applications.

2) Stainless Steel: Stainless steel is perhaps the most popular material used to make hinges. Stainless steel is an iron alloy with trace amounts of carbon. The presence of carbon is primarily what separates stainless steel from other forms of steel. Because of its carbon content, stainless steel hinges provide excellent corrosion and rust resistance.

3) Aluminum: Aluminum hinges are also available. Aluminum is not a metal alloy. It is, in fact, a pure metal. Aluminum, like stainless steel, is inherently corrosion resistant. Aluminum hinges can tolerate wet and humid settings without succumbing to corrosion’s degradative effects. Aluminum hinges, on the other hand, are lightweight and affordable.

4) Brass: Some hinges are constructed of brass, which is not as common as cold-rolled steel or stainless steel. Brass hinges have a high degree of malleability. In other words, they are more easily formed and controlled than other materials. The disadvantage of brass hinges is that they are prone to stress-related cracking. They may break if subjected to significant physical force. Thankfully, not all hinges are subjected to physical stress. Brass hinges may be sufficient for low-stress applications.

5) Bronze: Bronze is a fifth material used to make hinges. Bronze hinges are moderately strong, have great ductility, and offer adequate corrosion resistance. They also have protective features against friction. Bronze hinges are resistant to friction with other metal objects. However, hinges are more expensive than brass hinges.

Download PDF for Types of Hinges and Hinge Materials

There is an option to download the article in PDF format if you find that to be more convenient for you. You can download the file by clicking on the following link.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- 13 Types of Adjustable Wrench: Clear Guide

- 8 Types of O-Ring + Applications (Clear Guide)

- 5 Different Types of Drill Bits for Wood: A Comprehensive Guide

- 33 Types of Pliers & Their Names: A Comprehensive Explanation

- 18 Types of Machining Vises (Clear Guide)

- 28 Types of Clamps: A Complete Guide

- 16 Types of Scaffolding + Components & PDF

- 13 Types of Rivets + Applications & Working Principle

- 7 Types of Solder + Working Principle & PDF

- 9 Types of Pop Rivet + Working Principle (Clear Guide)

- 10 Types of 3D Printing: A Comprehensive Guide

- Types of Electrical Wire + Application (Complete Guide)

- 9 Types of Blind Rivets + Working Principle & Applications

- How Springs Are Made? 5 Fundamental Steps (Clear Guide)

- Types of Drill Bits for Metal: Comprehensive Guide

- All 24 Types of Drill Bits + Video: Clear Guide