Types Of Industrial Sewing Machine – Typically, large quantities of clothing are manufactured using industrial sewing machines. A power-driven industrial sewing machine moves at a high rate of speed. Industrial sewing machines come in many different varieties. There are various unique sewing machines made for creating particular seams and stitch types.

The many types of sewing machines are mentioned on this page so that you may have a thorough understanding of them. With an illustration, the application of these devices is also described. Beginners would benefit from having an easier time visualizing how the machine might be used to create ordinary goods.

On the Linquip website, among the many options available to you, you will find all the information you need to know about the Industrial Sewing Machines, as well as information regarding this marketplace. You can count on Linquip to provide you with as much general and reliable information about this topic, whether you’re a professional or a customer looking for a proper company. We recommend you review a list of all Industrial Sewing Machine Products available in Linquip. You can also be encouraged to visit Industrial Sewing Machine for Sale and find the most suitable device based on your applications and demands.

What Are Industrial Sewing Machines?

Contrary to household sewing machines, which you’re probably more familiar with, industrial sewing machines have been constructed and designed with extreme care, precision, and durability for continuous use with high performance and reliability in the serial production of sewn goods, such as clothing, home textiles, industrial textiles, etc.

As a result, there are many different types of sewing machines to accommodate a wide range of sewn objects and stitching procedures. Industrial sewing machines may not appear very familiar to you, yet they are essential tools for your everyday life and have a positive impact on society.

Advantages Of Industrial Sewing Machines

Industrial sewing machines are made to operate more quickly so that greater productivity, particularly for mass manufacturing, may be achieved. Modern technologies are included in high-quality industrial sewing machines to ensure reliable manufacturing of better-quality clothing. Putting together different technologies that save time and don’t require a lot of skill and that automate and standardize manual tasks would improve quality and productivity even more.

Precision Manufacturing, Machining, And Quality Control Systems

High-end industrial sewing machines use precisely processed parts, a skilled production process, and a cutting-edge quality control system. Some commercial overlocking devices have a stitch rate of more than 8,000 per minute. Each component must absolutely grab sewing threads in order to provide flawless seaming at such a high pace. Key components of those machines are made to pass each other with practically no clearance every 7/1000 seconds in order to achieve that. These essential components’ quality is specified and controlled at the micrometer level. High-precision components, expert production, and a quality control system allow for high-speed operation for increased productivity.

Achieve Increased Productivity And Quality

For better-quality clothing, high-end industrial sewing machines come with a variety of technology. Take Yamato’s Fast and Dry technology, for instance. To maintain the quality of clothing goods, it is crucial to avoid oil stains on sewing machines. Nevertheless, because of interactions with textiles, a number of sliding components, such as needle bars and looper mechanisms, must be exposed.

Yamato created the first sewing machine in history to run at an ultra-high speed using microlubrication technology thanks to cutting-edge coating technology, unique sealing technology, and a lubricating section design. With the use of micro-lubrication technology, lubricating fluids are contained inside the machinery, resulting in high-quality textile goods that are free of oil leaks.

Ideal Stitch Quality

Depending on the kind of clothing, different stitch qualities are needed. For instance, exceptionally stretchy seaming is necessary for compression clothing with high elasticity. Yamato’s patented Active Thread Control technology, often known as -8 technology, actively regulates thread supply quantities and timing to provide desired seam characteristics. It may provide historically significant elastic and soft seams that are excellent for lightweight, soft, flexible microfiber clothing.

Active Thread Control produces excellent seams across a wide range of fabrics.It supports a wide range of seams, including tight seams as well as soft and stretchy seams. With less strain placed on each thread, Yamato Active Thread Control creates the perfect thread balancing control to create any desired seam.

Devices For Deskilling And Labor-Saving Tasks To Increase Quality And Productivity

To increase quality and efficiency, industrial sewing machines can be fitted with a variety of labor-saving and deskilling technologies. Consider the back-tacking technique used on premium T-shirts. Yamato’s automated back-tacker detects fabric edges and, in a fraction of a second, activates ten actuators to regulate threads in the air before burying them behind the seam to improve the comfort of T-shirts. To increase productivity, backtacking may help to eliminate the need for bar-tacking.

Various Types of Industrial Sewing Machine

12 Types of Industrial Sewing Machine include:

- Single Needle Lock Stitch Machine

- Double Needle Lock Stitch Machine

- Overlock/Serger Machine

- Flatlock/Cover Stitch Machine

- Single Needle Chain Stitch Machine

- Feed Of The Arm Machine

- Blind Stitch Machine

- Button Attaching Machine

- Buttonhole Machine

- Bartack Sewing Machine

- Longarm Quilting Sewing Machine

- Computer-Controlled Cycle Machine

Industrial sewing machines are employed in industries because they are designed to produce goods for mass consumption. This comprises sectors like sewing-dependent businesses like clothing, footwear, home furnishings, and others. These machines are designed to sew a broad range of materials, including muslin, canvas, leather, and plastic, making them incredibly flexible. Unlike home machines, these are constructed of sturdy materials, such as metal, and can operate for extended periods of time without the motor overheating or requiring any maintenance.

They are quicker, more precise, and more efficient than their domestic counterparts since they are mechanical with little or no computerized elements. There are many various sorts of industrial machines, and the majority of them are simply intended to perform their basic job, which increases their endurance. The machines are expensive, but only because of their high-quality construction, long lifespan, and low maintenance requirements. As a result, this used equipment has a high resale value and frequently aids in the growth of several small businesses.

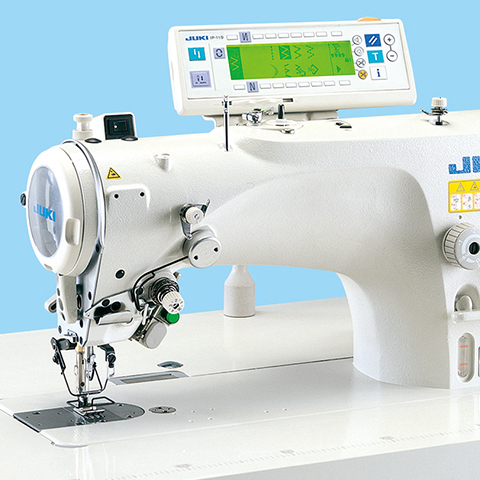

Single Needle Lock Stitch Machine

These are the most prevalent sewing machines that are readily available and may be found in all sewing-related businesses as well as tailor shops all over the world. With the 301 stitch type and frequently with the addition of a zig-zag stitch, it stitches mostly in a straight line (304 stitch type). Any accessible type of cloth, even heavier textiles like canvas or denim, can be used for this. There are several sorts of attachments available, including pressure feet, needle types, feed dogs, and UBT. One thread is needed for the needle, while the other is needed for the bobbin. With SNLS machines, tasks like seaming, hemming, and attaching are ideal. To be compatible with emerging IoT solutions, these devices are now being modified with electronics.

Double Needle Lock Stitch Machine

The operation is the same as before, but this time there are two needles, so there is a two-needle thread, bobbin thread, tensioner, take-up, thread guide, spool pin, and needle holder instead of one. The stitch is employed in various seaming processes on shirts, jeans, overcoats, and other similar garments and runs parallel to one another.

Overlock/Serger Machine

The overlock machines are used to stitch two pieces of fabric together, as well as strong seams, neatly completed hems, and fabric edges. These machines come in two varieties, one for simple overlocking and the other with an overlock stitch and a chain stitch safety stitch. They have a cutter that trims the fabric edge as it is fed, resulting in a neat finished edge.Overlock machines, in contrast to lockstitch machines, feed loopers from several thread cones rather than the bobbin. It has a speed that can reach up to 9000 rpm, which is far faster than any other sewing machine, although domestic overlock machines are much slower to make them more user-friendly and adaptable. These machines, which have a two-to-five thread option, are used for hemming, seaming, and completing knit edges for sportswear, intimate apparel, fleece textiles, etc.

Flatlock/Cover Stitch Machine

These machines are specifically designed for cover stitch stitching.This works by interlacing the looper threads at the seam’s base with the needle threads. On the top side of the seam between the two needle threads, another thread is woven into the top spreader. Several forms of stitch formation may be accomplished by varying the number of threads, such as the two-needle bottom cover stitch, the two-needle cover stitch with cover thread, and the two-needle four-thread cover stitch, among others. With this machine, 400 and 600 stitch classes are possible. These machines may be used for binding, flat seaming, hemming knit clothing, adding elastic, attaching pocket facing to jeans, and many other sewing tasks thanks to their extensive stitching capabilities.

Single Needle Chain Stitch Machine

In contrast to lockstitch, which employed many threads to stitch into the cloth, this machine is used to generate chain stitch. This makes the stitch far more stretchy, which is why stretch materials employ it. Both a zig-zag stitch and a straight stitch may be created by the machine. This may be used for ornamental stitching or bindings in addition to sewing seams. This machine comes in a variety of variations with numerous single and double needle configurations. The Kansai Machine is a multiple needle chain stitch machine used for smocking and pintucking tasks.

Feed Of The Arm Machine

Lapped seams are intended to be sewn on this machine. The inseam, the yoke’s attachment to the back, and the front and back rise are the three areas where it is most frequently employed in jeans. Furthermore, shirts and other light to medium-weight fabrics can be utilized with it.

Blind Stitch Machine

The invisible stitch produced by this machine is used to hem shorts, skirts, and trousers. For commercial manufacturing, it took the place of conventional hand-blind stitching.

Button Attaching Machine

With the help of this machine, buttons are sewn on with a lock stitch. By only altering the button clamp and spacing mechanism, the machine may be programmed to modify its configuration according to buttons with two holes, four holes, or shanks. Some machines have automatic button-feeding systems that do the operator’s button-placing task for them.

Buttonhole Machine

Using a lock stitch or chain stitch, this machine is used to make tidy buttonholes. Because of its security and robustness, lock stitching is the more popular of the two, although chain stitching provides a more attractive finish but has less durability. The machine has a knife attached to cut through the buttonhole and may be programmed to create several styles of buttonhole.

Bartack Sewing Machine

This unique device is only to be used with bar tacks. In order to strengthen particular sections of clothing and accessories, such as the rear pocket on trousers, the bottom of flies, the belt loops, etc., bar tack is frequently employed.

Longarm Quilting Sewing Machine

This machine is designed specifically for quilting and has large arms to provide space for material handling. For simple quilting, these machines come in mechanical and computerized varieties.

Computer-Controlled Cycle Machine

These machines are used to sew labels, logos, ornamental stitches, and other items. They have been pre-programmed to move in a specific pattern on their own. The cloth is placed on a template, and the sewing machine then recognizes the positioning and begins. They are especially useful for removing the human factor from small, complex tasks and delivering consistently perfect stitching.

FAQs about Types Of Industrial Sewing Machine

- How many types of industrial sewing machines are there?

Lock stitch sewing machines and chain stitch sewing machines are the two main types of industrial sewing machines. Lock stitch machines work mostly with woven textiles to create stitches by pulling a bobbin thread and a needle thread against one another.

- What is the difference between a commercial and an industrial sewing machine?

Industrial machines are built to handle heavier loads and run for longer periods of time than residential machines. They can also handle more demanding jobs. An industrial model would be better suited if you are serious about your sewing tasks and will need to use your sewing machine frequently.

- Is it worth buying an industrial sewing machine?

Simple: if you use your machine frequently, an industrial sewing machine is definitely what you need. Don’t allow intimidation to rule your life. Many settings on many more recent industrial sewing machines are also suitable for novices.

Conclusion

You may acquire all the details you want about the industrial sewing machines and details about this market on the Linquip website, one of the numerous possibilities available to you. Whether you’re a professional or a client seeking for a reputable business, you can rely on Linquip to give you as much basic and trustworthy information on this subject. We advise you to look through the whole range of industrial sewing machine Experts and take advice from our professionals. If you need any services required for your product, you can count on Linquip and visit industrial sewing machine Services.

Download PDF for Types of Industrial Sewing Machine

You can download the PDF format of this post from the link provided here.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More On Linquip

- The 6 Best Industrial Sewing Machine

- 12 Types of Electric Saws: Clear Guide

- Different 15 Types of Hand Saws: Clear Guide

- Different Types of Bolt Heads + Benefit of Bolts and Nuts

- Different 5 Types of Fasteners: A Practical Guide

- Types of Drill Bits for Metal: Comprehensive Guide

- Different Types of Socket Wrench: Clear Guide

- 42 Types of Wrenches + Guide for Choosing a Wrench

- Different Types of Socket Wrench: Clear Guide

- 13 Types of Adjustable Wrench: Clear Guide

- All 24 Types of Drill Bits + Video: Clear Guide

- 3 Types of Crimping Tools + Name & Their Uses

- 33 Types of Pliers & Their Names: A Comprehensive Explanation

- 53 Differents Tools for Construction Workers

- 11 Types of Drilling Machines and Their Usages

- 5 Types of Grinding Machines + Applications & Characteristic