Types of Insulator Materials- The main purpose of an insulator is to control the unwanted flow of electricity from the powered conductor or conducting components. Electrical insulation plays an important role in every electrical application. With an electrical insulator and its great resistance, basically, no current can flow across it. In this post, we will discuss insulating materials, the features of an appropriate insulating material, different types of insulating materials, air gaps in insulation, the effect of moisture on insulation, and the protection of electrical insulation against moisture.

With Linquip, you have access to a wide range of information about insulators so that you can finish your work more efficiently with a broader perspective. Find out more about Linquip’s offerings proportionate to your application by visiting the website “Electrical Power Transmission.”

If you do not know what to choose from lots of products, you can start with Insulator Products at Linquip. Linquip also allows you to receive quotes from multiple Insulators Suppliers and Companies for free.

We spoke to a representative from Aerial Services who specializes in Aerial installation in London, and he said, “ The insulator is a device that provides the needed insulation between the line conductor and earth. The main types of insulators are the post insulator, post insulator, suspension insulator, and shackle insulator. The purpose of the insulator is to provide support to the overhead line conductors on the poles to stop the current flow towards the earth.”

What Are the Different Types of Insulator Materials?

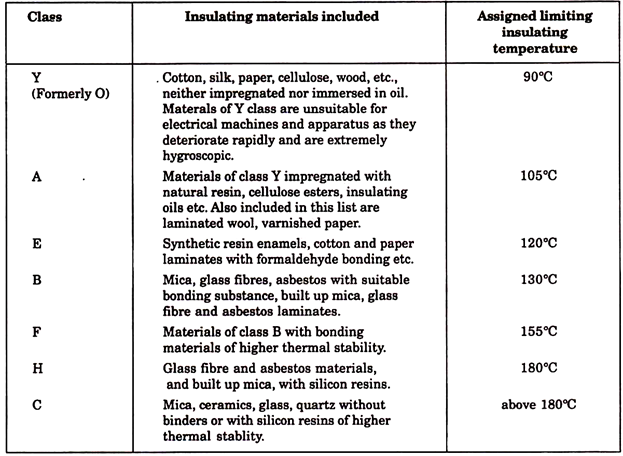

It is possible to classify insulation materials according to their substances and their temperature.

- In terms of their substance state:

- Solid

- Liquid

- Gas

- According to their temperatures:

- Class Y

- Class A

- Class E

- Class B

- Class F

- Class H

- Class G

Introduction to Insulating Materials

Electrical insulating materials are introduced as substances that present a high resistance to the flow of electricity, and for that aspect, they are employed to keep current in its suitable path within the conductor.

A large number of materials and substances can be defined as insulators, many of which have to be used in practice, as no single material or substance can meet all the requirements contained in the numerous and different applications of insulators in electrical engineering. Such requirements need consideration of reliability, physical properties, availability, cost, adaptability to machining functions, etc.

Thus, in some cases, the insulating material, in addition to its performance as an insulator, may have to operate as a rigid mechanical section to the conductor and may be placed out of doors, in which case the insulating qualities should be maintained under all atmospheric conditions, in other application extreme flexibility is needed.

Again, the insulating materials should retain their insulating qualities in electric heaters over a great range of temperatures extending in some applications to 1100°C, and the insulating qualities should be maintained for radio purposes up to very large frequencies.

The insulating materials employed in the conductors are required to be flexible in electrical transformers and machines to have great special electric strength (to decrease thickness to a minimum) and an ability to tolerate unlimited cycles of cooling and heating.

An insulator is used in the overhead line systems on the poles of conductors to control the current flow toward the ground. It plays an important role with its function in the transmission lines. The modeling of an insulator can be performed using various materials like wood, rubber, mica, plastic, etc. The particular substances used in electrical applications are ceramic, glass, steatite, PVC, polymer, etc. But the most usual substance utilized in the insulator is porcelain, and also specific compositions, glass, and steatite materials are also used. This post also discusses an overview of various types of insulator materials and their working principle.

Characteristics of a Good Insulating Material

A good insulating material must possess the following features:

- High dialectic strength

- Great insulating resistance

- Uniform viscosity: it gives uniform thermal and electrical characteristics.

- It should be uniform totally: it keeps the electric wastes as small as possible and electric stresses uniform under great voltage differences.

- Least thermal expansion

- When exposed to arcing must be non-ignitable

- Should be resistance to liquids or oils, acids, gas fumes, and alkalies

- Should have no deteriorating influence on the material, in touch with it

- Low dissipation coefficient (loss tangent)

- High thermal strength

- Large mechanical strength

- Great thermal conductivity

- Low permittivity

- Free from gaseous insulation to control discharges (for gases and solids)

- Should be homogeneous to handle local stress concentration

- Should be resistant to chemical and thermal deterioration

Classification of Different Types of Insulator Materials

Different types of insulator materials can be categorized in the following two ways:

- Classification based on the substances and materials

- Classification based on the temperature

Classification of Different Types of Insulator Materials Based on the Substances

- Solids (Organic and Inorganic)

Wood, Mica, glass, slate, rubber, porcelain, cotton, rayon, terylene, silk, paper, cellulose materials, etc.

- Liquids (Varnishes and Oils)

Linseed oil, spirit, and synthetic varnishes, refined hydrocarbon mineral oils, etc.

- Gases

Carbon dioxide, dry air, nitrogen, argon, etc.

Classification of Different Types of Insulator Materials Based on the Temperature

Important Properties About Types of Insulator Materials

- Resistivity or specific resistance is the feature of a material that determines how strongly the material opposes the flowing of electric current. The resistivity of an appropriate insulator is very large.

- The dielectric strength of a substance is the capability to tolerate electric stresses without cutting off. Dielectric strength is commonly measured in kilovolts per millimeter (kV/mm).

- Relative permittivity or dielectric coefficient is the ratio of the electric flux density generated in the system to that generated in a vacuum.

- The electrical dissipation coefficient (dielectric loss) is the ratio of the energy wasted in the material to the total energy transmitted across it. It is presented by the tangent of the loss angle and, hence, also introduced as tan delta.

Types of Electrical Insulators

Some of the typically used electrical insulating substances are porcelain, mica, paper, Teflon, plastic, rubber, polyvinyl chloride (PVC), ceramic, glass, etc. Different types of insulator materials are used in the following forms:

- Strain insulators

- Pin insulators

- Suspension insulators

- Shackle insulators

The above forms of insulators are normally used in overhead power systems. You can read more about these types of insulator materials by clicking this link.

Besides, some more kinds of insulators and different types of insulator materials are as follows.

Post Insulators

A post insulator is less or more similar to a pin type. It has a comparatively higher number of rain sheds and petticoats. Post type insulators are typically used in substations, but in some applications, they can be employed for overhead lines also. As a result, there are two forms of post insulators: (i) Station post insulators and (ii) Line post insulators.

A line post insulator can be employed for voltages up to 132 kV (pin insulators are utilized for up to 33 kV). In contrast, station insulators are used for low as well as very high voltages in substations. Multiple station post insulators are combined for higher voltage levels.

Glass Insulators

Pin form of glass insulators was earlier employed in the 18th century primarily for use in telephone/telegraph lines. The use of porcelain and ceramic insulators spread in the 19th century. They proved superior protective features than glass and became broadly employed.

To overcome this, glass types with toughened forms were presented, which became common based on their longer lifespan. So, the use of toughened glass types is becoming usual today. Dissimilar to porcelain or non-ceramic types, toughened glass never ages and thus, presents a longer lifespan. So, toughened glass types discs can be employed in suspension insulators.

Polymer Insulators

Polymer insulators contain a fiberglass rod layered by polymer weather sheds. These polymer weather sheds are typically constructed from silicon rubber. A few other substances may also be used for weather sheds, including polytetrafluorethylene (PTFE or Teflon), EPDM, EPM, etc. Polymer insulators are occasionally introduced as silicon rubber insulators or composite insulators. They are approximately 90% lighter than porcelain types and still provide almost equal or better strength.

These insulators have some fiberglass rods and are enclosed with polymer shields. They are low in weight in comparison with the porcelain type while providing better output. These insulators are typically designed with silicon rubber and PTFE.

Long Rod Insulators

A long rod insulator is fundamentally a porcelain rod with an outside weather shield and metal end sections. The main benefit of the long rod model is the removal of metal components between the units, thereby improving the insulator’s strength. Long rod types can be utilized at suspension cases as well as tension locations.

Stay Insulators

The insulator employed in a stay cable (guy wire) is introduced as the stay insulator. It is commonly constructed of porcelain and is modeled so that in case of the insulator cut-off, the stay cable will not fall to the earth. It is also introduced as an egg-form strain insulator.

Air Spaces in Insulation

Once the insulation is modeled, every attempt is made to prevent the existence of air gaps in it. However, it is hard to control air gaps in materials such as impregnated and fabricated insulation, yet these can be handled by gas or oil filling under pressure or vacuum impregnation.

The air spaces exercise harmful influences in the following method:

Ionization happens (the phenomenon being introduced as corona) once solid insulation, including air gaps, is subjected to the voltage.

The consequences of ionization are:

- A great power waste in the insulation

- Thermal instability

- Lowering of the cut-off voltage of the insulation

- There is decomposition, carbonization, and mechanical damage to the insulating material

Thus, when there are air gaps in the system, it must not be overstressed, and the substance should have corona resistance features.

Effect of Moisture on Insulation

When an insulating material is installed in a humid environment, it absorbs a particular amount of moisture. The water vapors are primarily absorbed on the surface, then they spread, tending to decrease the moisture concentration gradient, and eventually, they are desorbed into a lower vapor concentration area.

In an insulating substance, moisture diffusion, as a fundamental rule, occurs when the electrical instrument is inoperative. Once the current is carried by the electrical line, the moisture spreads from the insulating material (i.e. substance dries up).

All solid dielectrics, based on the absorption of moisture in the highly humid surrounding, can be categorized as the following:

- Hygroscopic and wettable substances

- Non-hygroscopic and wettable substances

- Non-hygroscopic and non-wettable substances

The air having high moisture is a resource of issues in electrical insulation and can even cause a breakdown in electrical systems.

The influence of humidity on insulating substances brings about the following variations:

- Changes in electrical features

- Chemical variations

- Physical and mechanical changes

Changes in Electrical Features

- The humidity absorbed by insulating substances causes a reduction in the volume resistivity (particularly surface resistivity), an increase in the dissipation constant, and a particular increase in dielectric factor, a reduction in dielectric strength based on the change in field distribution within the insulating substance.

- Conducting bridges may appear within the surface of the insulating substance under electric tension current and high humidity.

- In some cases, the thin layers created of the moisture on the insulating substance dry up while the equipment is operating. Such locations get a carbonized spot, and such spots may combine with time and build up a particular bridge; thus a short circuit may result.

Chemical Variations

- High humidity always causes hydrolysis

- High humidity favors the fungi growth in some insulating substances, which in turn reduces organic insulating materials.

Physical and Mechanical Changes

- Some materials like polymers, plastics, and substances filled with cellulose filters expand in the presence of high moisture.

- The mechanical strength of the insulating substance is dropped in the presence of humidity.

Protection of Insulation against Moisture

The insulation can be protected against moisture by some particular solutions, including:

Impregnation of Winding

The windings of all low-voltage instruments are saturated with baking varnishes (sometimes compounds are also employed). Impregnating compounds and varnishes increase the moisture resistance of windings. Impregnation treatment tightens the windings, improves their thermal conductivity, increases their mechanical and electrical strength, and improves heat resistance.

Making Insulation Hydrophobic (Waterproof)

The insulating materials configurations are occasionally rendered hydrophobic to support them against moisture. This form of treatment is particularly efficient for polymers, including hydroxyls and cellulose-base insulating substances.

Compared to old broadly employed methods using bitumens, asphalts, waxes, water-proofing employing some hydrophobic silicon materials free of carboxyls and hydroxyls is finding ever-increasing favor. Paper, cotton compositions are rendered hydrophobic using a methyl triethoxisilane in absolute alcohol or methyl butoxidiamine silane in carbon tetra-chloride.

Hermetic Sealing

Hermetic sealing (using special compounds) is typically employed to protect insulation against humidity and help in supporting adequate insulation features of components and protect them against mechanical issues. This method is widely influenced by impregnation, coating, and potting in compounds.

The sealing methods in use are injection, molding, dipping, encapsulation, etc. The compounds most typically utilized in sealing the insulation of low-voltage systems are butyl methacrylate, polyester-styrene, polyurethane, styrene, and silicon base compounds.

The insulating substance or component to be sealed should be thoroughly dried out. Asphalt, wax, or bitumens were employed in old sealing treatments.

Properties of Insulators

The features of an insulator are mechanical, and dielectric strength is great, insulation resistance is large to control the leakage current. Different types of insulator materials should be free from impurities, cracks, and nonporous.

Applications of Insulators

The applications of insulators are many. Some of them are as follows:

- They are employed in circuits and electric boards to improve safety techniques.

- Special insulators protect the substance from heat and electricity.

- Rubbers and plastic are used to create daily products.

FAQs about Types of Insulator Materials

- What is an example of a material that is considered to be an electrical insulator?

Rubber, plastic, wood, and glass are good electrical insulators. Therefore, they are used for covering materials that carry electricity. Electricity is protected by the plastic covering around wires. Electrical systems use insulating materials such as porcelain, glass, steatite, polymer, ceramic, and PVC.

Download PDF for Insulator Material Types

You can download the PDF version of this article using the link below so that you can use it whenever you need.

linquip.com-8 Main Types of Insulator Materials 2023 Ultimate Guide

Watch Video for Electrical Insulation Materials

This video provides an overview of materials used for electrical insulation.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

-

- A Brief Look at Types of Multimeters

- A Quick Look at Types of Proximity Sensors

- A Good Look at Types of Thermostats

- A Quick Look at Types of Spectrophotometers

- Difference between Conductors and Insulators: Practical Guide

- Shackle Insulator: Applications and Working Principles

- What is Disc Insulator? Types & Applications

- What is Post Insulator? Types & Applications

- Detailed Information About Suspension Insulators

- Detailed Information About Strain Insulators

- What is a Stay Insulator?

- 4 Main Types of Insulator Used in Overhead Lines

- Pin Insulator: a Simple Overview of The Working, Pros And Cons