Types of Machining Vises – A machine vise can be used as a manual component or as a machining tool. It is a mechanical device made to keep workpieces steady during machining processes. Many conventional production facilities employ machining vises for tasks requiring precise machining and strict tolerances. Manual vises have several advantages, but machining vises are frequently better suited to holding a workpiece still during high-speed machining processes. As a result of the significant vibrations that high-speed machining may produce, machining vises are designed to reduce vibrations and offer superior stability.

On Linquip website, among the many options available to you, you will find all the information you need to know about Electrical Power Connectors, as well as information regarding this marketplace. You can count on Linquip to provide you with as much general and reliable information about this topic, whether you’re a professional or a customer looking for a proper company. We recommend you review a list of all Machining Vises for Sale available in Linquip.

We would be delighted to provide you with more information on how we can help you generate revenue within your industry. Don’t hesitate to contact us if you have any questions! With Linquip’s Solutions for Each Company Level, you will be able to upgrade the capabilities of your organization in order to gain a competitive edge by taking advantage of a wide range of options to enhance your organization’s performance. If you are looking for the simplest or the most sophisticated marketing and advertising package for your business, we can help you ensure that your company gets as many customers as possible to grow its business.

What is a Machining Vise

A vise is described as “any of numerous instruments with two jaws for holding work that shut typically by a screw, lever, or cam” in the Merriam-Webster dictionary. That is fairly general. It is a little more specific on Dictionary.com. “any of numerous tools used to hold an object securely while work is being done on it, often having two jaws that may be pulled together or parted by means of a screw, lever, or anything similar.”

When we refer to a vise in the remaining paragraphs of this text, we mean a tool having a fixed jaw and a moving jaw. Luckily or sadly, there are still many choices available when selecting a vise. These are the vises we were thinking about for our CNC mill. To assist you in choosing the ideal vise for your machine, we’ve also provided the assessment criteria. A different vise may function better in your application.

Types of Machining Vises

There are various types of machining vises. In what follows, the main types are described.

18 Types of Machining Vises include:

- Machinist Vise

- CNC Vise

- Toolmaker Vise

- Pipe Vice

- Flange Machine Vice

- Universal Machine Vice

- Vertical Machine Vice

- Swivel Machine Vice

- Metalworking Vice

- Woodworking Vice

- Heavy-Duty Vice

- Medium Duty Bench Vice

- Chain Vice

- Yoke Vice

- Leg Vice

- Hand Vice

- Combination Hand Vice

- Pin Vice

Machinist Vise

These are the conventional vises that can be seen on a lot of manual milling machines. The vise may be fastened to the mill table using the flanges on its side, which is an easy and practical solution. These vises have the drawback of taking up more space on your mill table than the other choices discussed below. There are two variations of these vises: one with a swivel base and the other with a permanent base. Both of them are great options for a starter vise.

CNC Vise

By providing a more compact design with the same strong holding as a machinist vise, the CNC vise meets the challenges of a machinist vise. Due to its smaller stance, a greater number of vises may be employed at once in less space. Precision grinding is done on several sides of CNC vises so that they may be clamped both horizontally and sideways. Even though it’s a little trickier without the flange to secure them to the table, the vise comes with specialized table clamps that can handle the situation. Lock-down designs are also used in CNC vises.

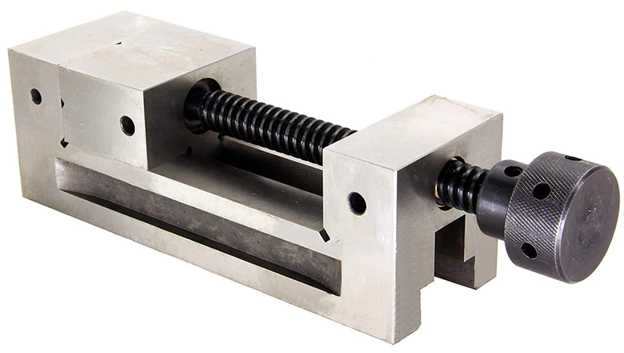

Toolmaker Vise

The toolmaker vises are more difficult to operate but smaller, cheaper, and highly precise. This is because a multistep latch is used to tighten them rather than a long screw. When the work needs to be transferred from one machine to another, toolmaker vises are frequently used. Without damaging the work, you may leave it in a tiny toolmaker and transfer it to other equipment like a drill press, mill, surface grinder, or a bigger machinist vise. The toolmaker vises often do not include accessories like interchangeable jaws or work stops as the machinist, and CNC vises do, yet it prevents the jaws from rising using a lock-down similar design.

Pipe Vice

When doing plumbing work, the pipe vice is utilized to restrain the tubing while cutting or threading the pipes. It is created to endure vice pipes that are 200 mm in diameter or as little as 3 mm. It may either be mounted to a workbench or utilized with a portable tripod support. The lightweight, simple-to-transport mobile tripod stand is typically used for jobs that need to be completed outside the workplace. Longer pipes can be created by combining two or more.

Flange Machine Vice

The heavy-duty machine vice is another name for the flange machine vice. This kind of machine vice is utilized for securing the kinds of projects that frequently shock the operator while being machined. A square end with a box-style handle fastened to it is built on one of the spindle’s ends and is used to turn the spindle.

Universal Machine Vice

This machine vice is very practical and often used. The benefit of this machine vice is that work may be done in a variety of orientations, including horizontally, vertically, and angularly. It is mostly used for producing tools.

Vertical Machine Vice

Vertical machine vices are the following kind of vice. All other vices are distinct from this one. Jobs in this vice are held vertically, as the name would imply. In place of jaws, this vice has flanges. It is incredibly simple to use.

Swivel Machine Vice

The swivel machine vice is similar to a flange machine vice in terms of construction and structure, but it has a different type of base that allows the vice to be rotated at any angle. It has the advantage that straight or angular machining may be done without removing the task from the vice.

Metalworking Vice

These vices are often known as machinist vices or engineers’ vices. It keeps the metal component in position. The channel bar of a metalworking vice is made of steel, although the vice is mostly constructed of cast iron. The cast is chosen because it is sturdy, robust, and reasonably priced. Typically, a metalworking vice is used for processes like cutting and filing.

This metalworking vice’s jaws are frequently detachable within the unit so that they may be changed. The jaws of the metalworking vise are coated with a soft material, such as aluminum, wood, copper, or plastic, for delicate work. The goal of doing this is to safeguard the content. Typically, a metalworking vice is fastened to a workbench with the front of the jaws extending just over the front edge. Behind the vice bodies of the metalworking, vices may be a small anvil.

Woodworking Vice

The woodworking shop uses this kind of vice. Jaws are used in the building of such vices. In order to hold the workpiece firmly, one jaw grasps it while the other moves against it. The jaw may be operated firmly thanks to a screw mechanism. Wood, plastic, and metal are usually used to make woodworking vices. Depending on the precise task, it must be completed.

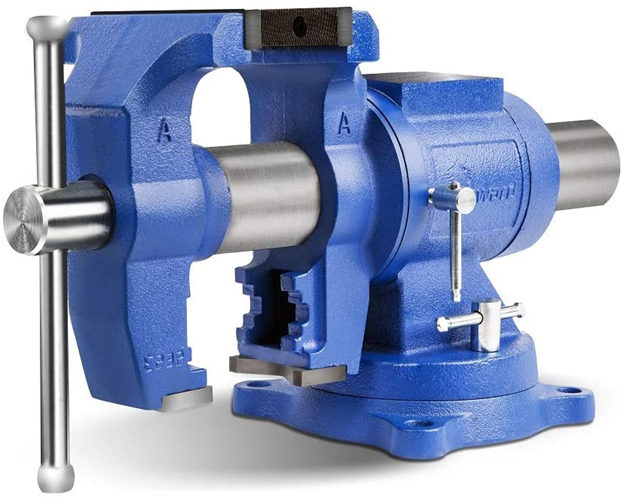

Heavy-Duty Vice

The heavy-duty bench vice is mostly built of iron so that it can withstand heavy uses. Separated steel jaws, an ACME-threaded main screw, and a precise sliding bar are the components of a heavy-duty vice. There are sturdy bench vices on the fixed platform.

Medium Duty Bench Vice

The heavy-duty bench vice, which was previously addressed, is closely connected to the medium-duty bench vice. Additionally, it is composed of iron and offers the option of changing its steel upper jaws. Some of these jaws also include an integrated anvil and 360-degree swivel.

Chain Vice

A chain is used to secure the pipe in a chain vice. The clamping effectively maintains the pipe’s v-shape. To fit well with uneven pipes or other items, this chain is constructed of steel with high tensile strength. Because the length of the chain is what restricts the vice’s working range, the chain vice has a tendency to have a wider working range and a big capacity.

The large clamping area of the chain defines the pipe’s whole circumference. One of the major drawbacks of the chain vice is that it takes much longer than other vice kinds to secure a pipe in place with one because the chain needs to be threaded between the tool’s jaws carefully and properly in order to clamp the pipe firmly in place.

Yoke Vice

The yoke vice, also known as the hinged vice or the adjustable jaw vice, clamps the pipe in place using a screw. The vise securely holds the lengths of the pipe thanks to a moving top jaw and a fixed lower jaw with a V-shape. These jaws have serrations to provide a secure grasp on the item.

Leg Vice

The blacksmith shop typically employs the leg vice. Blacksmithing tasks like forging, bending, and other processes are completed while a hot job is fixed in it. It is hung on the workbench in this fashion.

There is only one leg, and it is immediately set on wood. A hinge connects the two jaws—the fixed jaw and the moveable jaw—to one another. With the assistance of a sturdy spring leaf placed between these two jaws, the moveable jaw handle readily opens when it is rotated. There is a spindle that is installed on the top side of both jaws, where square threads are cut.

When the handle is turned, a nut box is inserted to allow the moveable jaw to open in the outside direction. The hard iron that makes up its entire body. Because of this, when we hit it with a hammer, it blows without causing any harm.

Hand Vice

This vice has a long leg like the leg vice and opens similarly to that vice. Only smaller-sized jobs are permissible in this vice.

It cannot be fixed to a workstation and is held in hand, as the name indicates. A wing nut, which is a point on the spindle positioned between the two jaws, is used in place of a handle (fixed one and the movable one ). Because the spring load is fixed, it opens without difficulty.

Combination Hand Vice

The combined hand vice may be used as a hand vice as well as a tiny bench vice. It may be used as a hand vice in practice. It comes with a base clamp as well. It may also be mounted to the bench with the aid of this clamp. It serves as a little bench vice in this way.

Its unique selling point is that, like a swivel vice, it can be fitted at any desired angle by releasing its wing nut. And in this, the steel forging technique is used to create the combination hand vice. The spindle’s threads on the right and left sides are severed. As a result, it is easy for both jaws to open or close simultaneously.

Pin Vice

The pin vice functions similarly to a small drill chuck. Similar to a chuck in a pin vice, there are three jaws. The upper portion is long and slender, and it has six or eight panes. A hole in the vice’s body is used to store cables or pins. The pin vice can be forced open and shut by hand. It can be used by watchmakers or instrument manufacturers to retain a screw, a pin, etc.

Download Types of Machining Vises PDF

You can download the PDF format of this post from here.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- 33 Types of Pliers & Their Names: A Comprehensive Explanation

- 8 Types of O-Ring + Applications (Clear Guide)

- The 10 Best Circular Saws in the USA

- The 10 Best Hammers

- The 10 Best Mini/Benchtop Milling Machine

- The 8 Best Pressure Washers

- The 8 Best Rust Converter (Review Guide)

- 8 Best Soldering Iron for Electronics & The Like + Buying Guide

- The 10 Best Fertilizer Spreader

- The 7 Best Portable Band Saws + Tips for Choosing

- The 9 Best Cordless Impact Wrenches

- The 10 Best Electric Space Heater + Buying Guide

- The 8 Best Engine Hoists & Accessories + Buying Guide

- Top 10 Irrigation Equipment Suppliers

- Top 10 Railroad Equipment Suppliers in USA & Worldwide

- The 10 Best Steel Toe Boots for Women

- Top Brick Manufacturers in USA & Globally

- Top Water Filter Supplier & Companies

- Top Foam Rubber Suppliers in USA & Worldwide

- Top Crushed Stone Suppliers in USA

- The 4 Best Ceramic Coatings

- The 10 Best Torque Wrenches + PDF & Buying Guide

- 11 Types of Drilling Machines and Their Usages

- 5 Types of Grinding Machines + Applications & Characteristic