Types of Magnets – A substance or thing that creates a magnetic field is called a magnet. The most noteworthy characteristic of a magnet—a force that pulls on other ferromagnetic elements, such as iron, steel, nickel, cobalt, etc.—as well as the ability to attract or repel other magnets—is caused by this invisible magnetic field.

On the Linquip website, among the many options available to you, you will find all the information you need to know about Magnets, as well as information regarding this marketplace. You can count on Linquip to provide you with as much general and reliable information about this topic, whether you’re a professional or a customer looking for a proper company. We recommend you review a list of all Industrial Magnets Manufacturers available in Linquip.

We would be delighted to provide you with more information on how we can help you generate revenue within your industry. Don’t hesitate to contact us if you have any questions! With Linquip’s Solutions for Each Company Level, you will be able to upgrade the capabilities of your organization in order to gain a competitive edge by taking advantage of a wide range of options to enhance your organization’s performance. If you are looking for the simplest or the most sophisticated marketing and advertising package for your business, we can help you ensure that your company gets as many customers as possible to grow your business.

What is a Magnet?

A substance or thing that creates a magnetic field is called a magnet. The most noteworthy characteristic of a magnet—a force that pulls on other ferromagnetic elements, such as iron, steel, nickel, cobalt, etc.—as well as the ability to attract or repel other magnets—is caused by this invisible magnetic field.

An item constructed of a substance that has been magnetized and produces its own persistent magnetic field is referred to as a permanent magnet. A common example is a refrigerator magnet used to keep notes on the door of the refrigerator. Ferromagnetic materials are those that can be magnetized and are also those that are powerfully drawn to a magnet (or ferrimagnetic). Included in this group are the metals iron, nickel, and cobalt as well as their alloys, a few rare-earth metal alloys, and a few naturally occurring minerals like lodestone. All other substances react weakly to a magnetic field via one of several other forms of magnetism, even though only ferromagnetic (and ferrimagnetic) materials are typically regarded as magnetic.

There are two types of ferromagnetic materials: those that are magnetically “soft,” like annealed iron, which may be magnetized but do not usually tend to do so, and those that are magnetically “hard,” which do. Alnico and ferrite, two “hard” ferromagnetic materials that undergo specific processing in a powerful magnetic field during manufacturing to align their internal microcrystalline structure and make them extremely difficult to demagnetize, are used to make permanent magnets. A particular magnetic field must be provided in order to demagnetize a saturated magnet, and this threshold relies on the material’s coercivity. In contrast to “soft” materials, “hard” materials have a high coercivity. The magnetic moment of a magnet, or alternatively the total magnetic flux it generates, is used to determine the magnet’s overall strength. A material’s magnetization is used to determine the local strength of its magnetic.

A coil of wire used to create an electromagnet functions as a magnet when an electric current flows through it, but loses that function when the current is cut off. The coil is frequently encircled by a core made of a “soft” ferromagnetic material, such mild steel, which significantly boosts the magnetic field the coil produces.

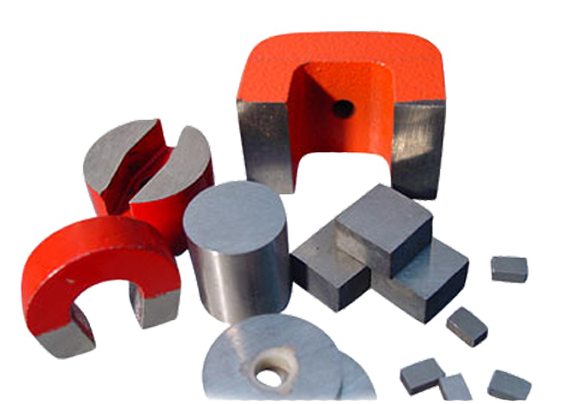

Different Types of Magnets

3 Types of Magnets include:

- Permanent Magnets

- Temporary Magnets

- Electromagnets

Of course, not all magnets are made up of the same materials, thus they may be divided into groups according to their make-up and place of magnetism. Magnets that have already been magnetized are known as permanent magnets. Temporary magnets are materials that function as permanent magnets while a magnetic field is present, but they lose their magnetism when the magnetic field is absent. When an electrical current is conducted via wire coils that have been coiled into magnets, the magnetization occurs. The magnet’s strength may be changed by varying the current’s intensity and direction. The numerous kinds of magnets are broken out below.

Permanent Magnets

Neodymium iron boron (NdFeB), alnico, ceramic or ferrite magnets, and samarium cobalt (SmCo), are the four main types of permanent magnets.

Nickel Iron Boron (NdFeB)

This kind of magnet has a strong coercive force and is made of rare earth magnetic material. Up to 50 MGOe is the highest energy product range they provide. They may often be produced in tiny, compact sizes because of the high product energy level. However, if left uncoated, NdFeB magnets have low mechanical strength, are frequently brittle, and have little corrosion resistance. They may be utilized in several applications if they are given a gold, iron, or nickel plating treatment. They are extremely powerful magnets that are challenging to demagnetize.

Alnico

The first two letters of each of the three primary components—aluminum, nickel, and cobalt—give alnico magnets their name. Despite having high temperature resistance, they are quickly demagnetized and are occasionally replaced in some applications by ceramic and rare earth magnets. They may be made either by sintering or casting, and each method produces magnets with unique properties. Sintering results in improved mechanical characteristics. Casting produces goods with more energy and permits the development of more intricate design aspects for the magnets.

Ferrite or Ceramic

Ceramic or ferrite permanent magnets may be simply and cheaply manufactured by sintering or pressing sintered iron oxide with barium or strontium carbonate. However, these magnets must be ground using a diamond wheel since they are frequently fragile. They are among the magnets that are most frequently utilized; they are powerful and difficult to demagnetize.

Cobalt Samarium (SmCo)

SmCo magnets are extremely powerful and challenging to demagnetize, just as NdFeB magnets. They can endure temperatures of up to 300 degrees Celsius and are also very temperature and oxidation resistant. Based on the energy range of their products, SmCo magnets may be split into two separate groups. The energy product range for the first series (Sm1Co5) is 15–22 MGOe. The range of the second series (Sm2Co17) is between 22 and 30 MGOe. They may, however, be costly and of poor mechanical strength.

Temporary Magnets

Since they are essentially any substance that responds to a magnetic field by behaving like a permanent magnet, temporary magnets can come in a variety of chemical and physical forms. Paper clips and other soft iron objects frequently act as transient magnets.

Electromagnets

A wire is wound into several loops and wrapped around a magnetic core to create an electromagnet, or solenoid. Electromagnets are magnetized by passing an electrical current through a solenoid, which produces a magnetic field. The field is strongest inside the coil, and it varies in strength according to the quantity of loops and the current’s intensity.

The strength of an electromagnet can also be influenced by the material used to make the core of the coil, or the core of the solenoid. The magnetic field won’t be very strong if a wire is wrapped around a piece of wood or another non-magnetic substance. The magnet’s power will significantly rise if the core is made of ferromagnetic material, such as iron. What makes an electromagnet a transient magnet, then? Because the magnetic field vanishes when the battery’s power is cut off, the current also stops.

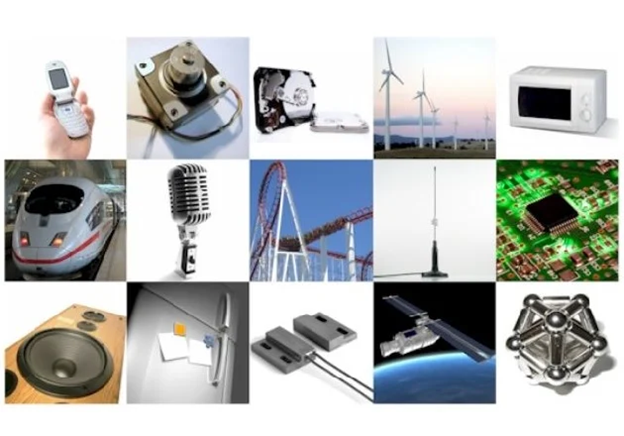

Applications of Magnets

Here are the some of the most prevalent applications of magnets:

- Magnetic recording medium: A reel of magnetic tape is included in each VHS tape. On the magnetic coating of the tape, the data that make up the video and sound are encoded. Magnetic tape is also used in common audio cassettes. Floppy disks and hard disks in computers both store data on a thin magnetic layer.

- Credit, debit, and automatic teller machine cards: Cards for automated teller machines, credit cards, and debit cards all feature magnetic stripes on one side. This strip encrypts the data needed to get in touch with a person’s financial institution and access their account (s).

- Historically huge computer displays, as well as older televisions (not flat-screen): Electromagnets are used to direct electrons to cathode ray tube-equipped TV and computer screens.

- Speakers and microphones: To transform electrical energy (the signal) into mechanical energy, most speakers use a permanent magnet and a current-carrying coil (movement that creates the sound). The coil conveys the signal as changing current that interacts with the field of the permanent magnet and is wound around a bobbin connected to the speaker cone. A magnetic force is sensed by the voice coil, which in turn moves the cone and pressurizes nearby air to produce sound. The same idea is used by dynamic microphones, but in reverse. A coil of wire and a membrane or diaphragm make up a microphone. A unique magnet with a certain form contains the coil. The membrane and coil both vibrate in response to sound. A voltage is induced across the coil as it travels through the magnetic field. This voltage causes a current to flow across the wire that produces the original sound.

- Electric guitars: Magnetic pickups are used in electric guitars to convert the vibration of the strings into an amplified electric current. Because the magnet directly senses the vibrations and a diaphragm is not used, this differs from the concept behind the speaker and dynamic microphone. The revolving tonewheels used in the Hammond organ instead of strings operated on a similar concept.

Download Types of Magnets PDF

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- 8 Types of O-Ring + Applications (Clear Guide)

- 18 Types of Machining Vises (Clear Guide)

- 28 Types of Clamps: A Complete Guide

- 16 Types of Scaffolding + Components & PDF

- 13 Types of Rivets + Applications & Working Principle

- 7 Types of Solder + Working Principle & PDF

- 9 Types of Pop Rivet + Working Principle (Clear Guide)

- 4 Types of Solid Rivets + Working Principle

- The 10 Best Drywall Anchors in 2022 + Buying Guide

- The 10 Best Box Cutter/Utility Knife Options in 2022

- What Is Flush Rivet And How Does It Work? (A Comprehensive Guide)

- The 8 Best Soldering Irons in 2022 + Buying Guide

- The 9 Best Commercial Patio Heaters in 2022 + Buying Guide

- The 10 Best Glues for Metal in 2022 + Tips for Choosing

- What Is The Difference Between A Blind Rivet And A Pop Rivet?

- What Are Blind Rivets and How Does It Work? (Comprehensive Guide)

- What Are Solid Rivets And How Do They Work? (Clear Guide)

- 33 Types of Pliers & Their Names: A Comprehensive Explanation