Here you will find everything you need to know about types of pipe wrenches. Pipe wrenches are adjustable tools used to tighten or loosen rounded metal objects such as pipes and rods. There are two jaws on the wrench, the hook jaw on top, and the heel jaw on the bottom. The teeth of both of these jaws are jagged, so when turned, the teeth clinch onto the pipe.

In order to give you a broader understanding of pipe wrenches, Linquip provides a wealth of information. Depending on your intended use, you can find out what Linquip can do for you on our “Tools and Instruments” webpage. Now is the perfect time to learn about pipe wrenches so that you can be more efficient in your work.

Can’t decide which pipe wrench is best for your application? Find the right tool for your job with Linquip’s wide selection of Tools and Instruments Products. Linquip’s online form allows you to obtain quotes from a variety of Tools and Instruments Suppliers and Companies within a short period of time.

What Are the Main Types of Pipe Wrenches?

There are six different types of pipe wrenches, each available in a variety of sizes. Steel or aluminum is the most common material used to make these wrenches. They can be found at most hardware stores. The following types of pipe wrenches are available:

- Straight Pipe Wrench

- End Pipe Wrench

- Offset Pipe Wrench

- Compound Leverage Pipe Wrench

- Strap Pipe Wrench

- Chain Pipe Wrench

Basics

Daniel Stillson designed the first pipe wrench in 1869. The wrench he made was given away to plumbing companies. A pipe wrench has become a staple of the plumber’s toolbox since its invention and is used in almost all types of home repairs.

Two serrated jaws on a pipe wrench dig into the pipe and help it grip. There is a serrated top jaw that adjusts up and down in order to fit pipes of different sizes. Pipe wrenches are unique in that they can only be turned in one direction, so they almost act like ratchets.

Parts

A pipe wrench consists of the following parts:

- Hook Jaw

- Nut

- Body

- Pin

- Heel Jaw

- Spring Assembly

It is possible to attach a separate head assembly to the body of some kinds of pipe wrenches, which are a bit rarer. The pipe wrench, sometimes known as a monkey wrench, is used by plumbers, drillers, and others who work with a threaded pipe.

Types

Generally, straight pipe wrenches are the most widely used type available, and they are suitable for most plumbing projects. These pipes are also two-jaw designs, and their lengths are determined by their handle lengths. Having a longer handle enables more turning power in areas with more space. However, a wrench with a smaller handle is more suitable for confined spaces.

Furthermore, pipe wrenches can be used for a variety of applications, including offset pipe wrenches, compound leverage pipe wrenches, and end pipe wrenches. The two jaws of both offset and end pipe wrenches are oriented in different ways along the handle. Because of this, they can be used in tighter spaces and close to walls. Meanwhile, compound leverage pipe wrenches have locking heads designed to apply more pressure, facilitating the release of seized joints by plumbers.

Below, we will discuss the various types of pipe wrenches in more detail.

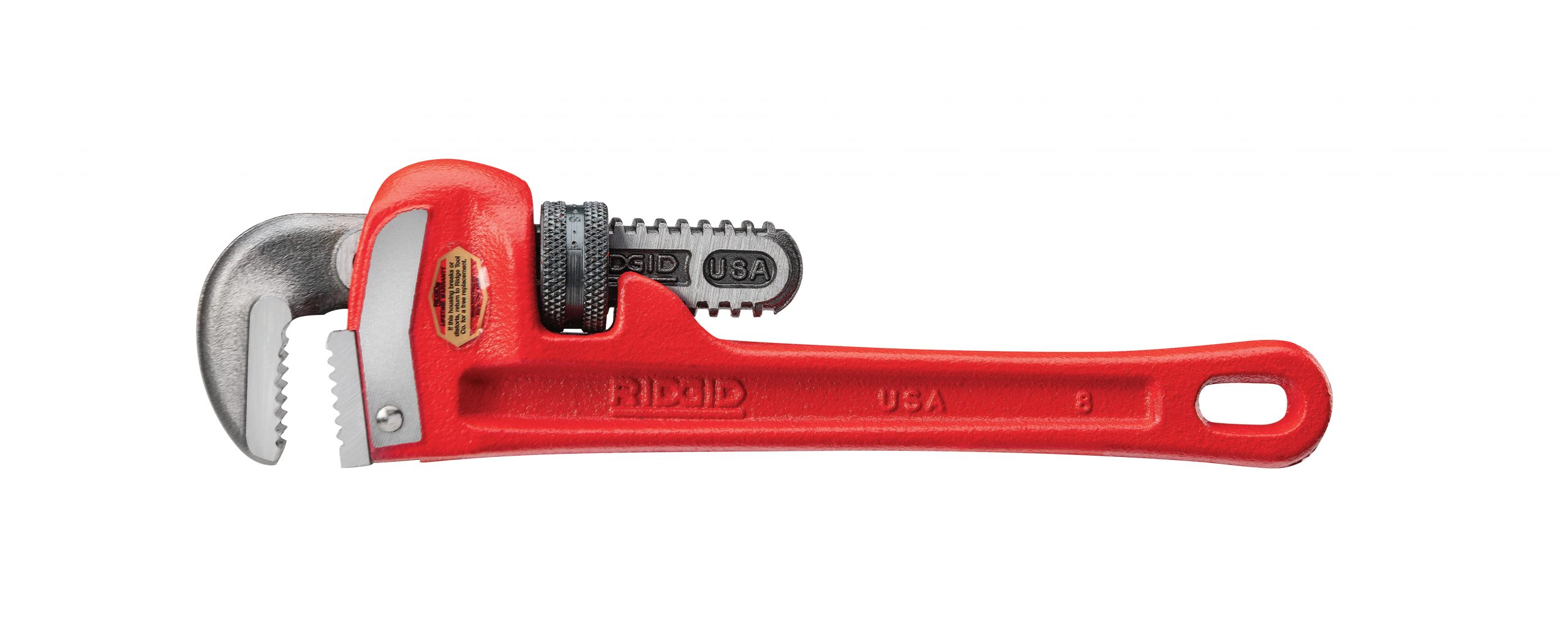

Straight pipe Wrench

Designed by Daniel C. Stillson in 1869, the straight wrench was the first pipe wrench. Straight wrenches are the most popular all-purpose wrenches and are a necessary part of every tool kit. The size of straight wrenches is determined by the length of the handle, which ranges from 9 inches to 60 inches (23 cm to 152 cm).

Straight pipe wrenches are often made from iron and have self-cleaning threads. Parallel to the handle is the head of the wrench. There are many tasks that can be accomplished with this tool. You can choose from a wide range of sizes.

End Pipe Wrench

End pipe wrenches are specifically designed for use on end pipes. It’s intended for end bits within close proximity to walls or in tight spaces. By providing teeth in the jaws allows the wrench to grab onto the pipe and move it more easily. You can easily loosen or tighten end pipes with this wrench since it won’t slip. Thus, this tool is a perfect solution for anything that needs to fit in a limited space.

This wrench’s hook and heel are angled slightly with the handle, allowing it to fit into tight spaces with ease. Working on overhead pipes can also benefit from the end wrench.

Offset Pipe Wrench

Pipe wrenches of this type are designed for pipes at awkward angles or in tight spaces. Typically, this wrench has a closed-end, called a box end. This will allow it to slip over a bolt head vertically. Using the wrench vertically allows you to reach the bolt because you may not be able to reach it from the side. Thus, an offset wrench eliminates the need to worry about the pipe’s sides. Offset wrenches have narrow jaw heads and hook jaws that lie parallel to the handle.

The offset pipe wrench is available in two versions: standard and heavy-duty. You can expect to pay about $50 for this wrench.

Compound Leverage Pipe Wrench

Compound leverage pipe wrenches work best for seized joints because they are more powerful and give you more leverage. Generally, it is used for joints that have become frozen because of build-up, aging, damage, or if they are locked up. This wrench has quite an ingenious design since you exert force to loosen the bolt, but because of its design, the power you provide is amplified so it has more turning force.

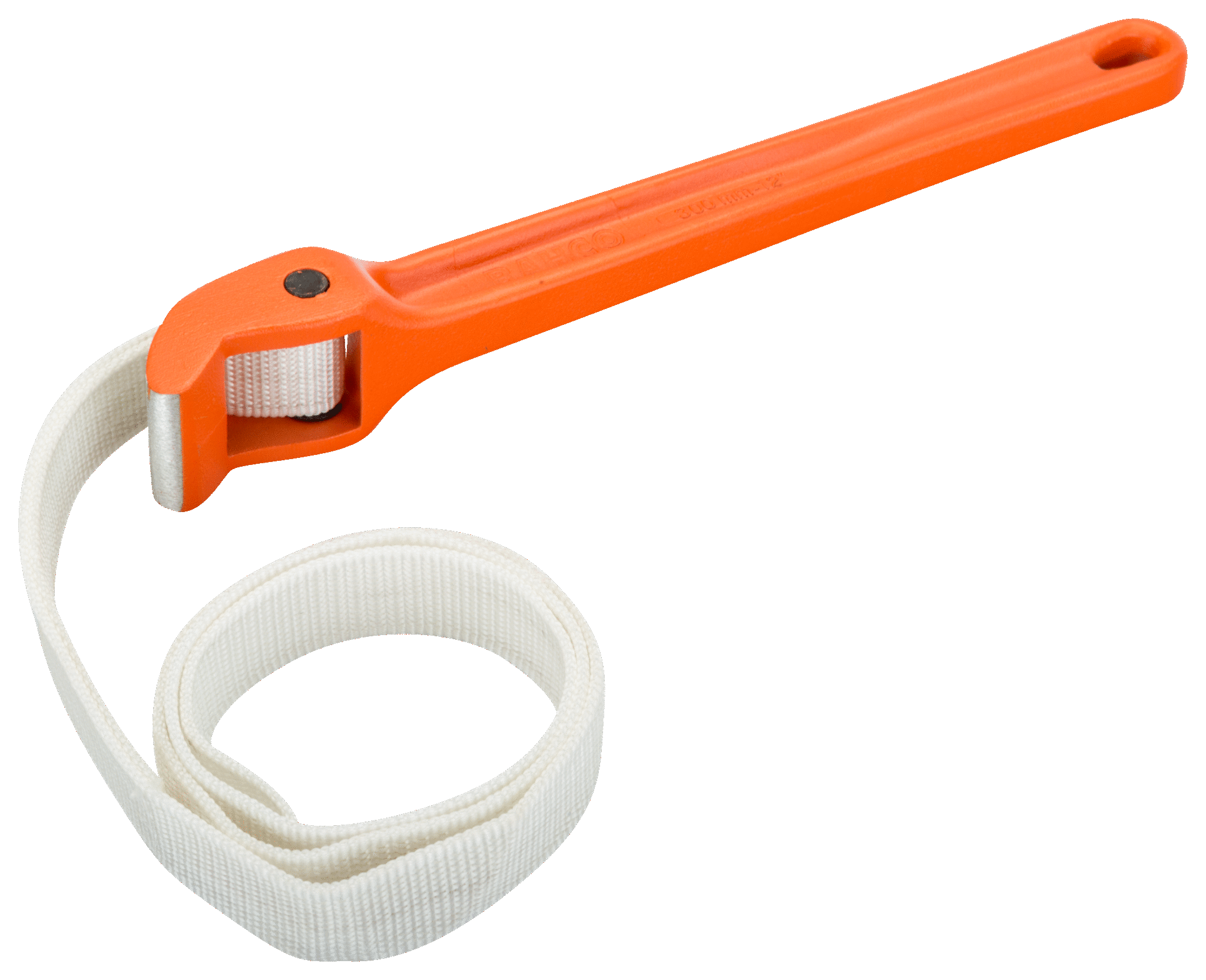

Strap Pipe Wrench

Strap wrenches do not have a traditional wrench head. Instead, they have rigid handles with straps that you can attach to pipes. Straps are pulled in tension around the pipe in order to grip it. The handle of many strap pipe wrenches makes it easier to hold them firmly. The traditional use of this type of pipe is when it has an odd shape. There is a frictional interaction between the strap and the pipe that enables this pipe wrench to work differently from traditional pipe wrenches.

In addition, it can be self-tightening. There are many kinds of straps: rubber, chain, leather, polymer, and even metal.

Chain Pipe Wrench

If you have to work with pipes that are very tight, it may be necessary to use a chain pipe wrench. The construction of this product is unique. The hook jaw is replaced with a chain, which is why it’s known as a chain pipe wrench. The chain should be placed around the pipe and tightened until it provides a good grip. The weight of this type is an advantage over other types of wrenches.

Pipe Wrench Use

The first step is to select the correct wrench for the pipe you are going to adjust. As soon as the jaws are tight, slowly lower the hook jaw using the nut. Make sure to give the pipe a bit of space between it and the rear of the wrench mouth. The top jaw and bottom jaw of the wrench should be the only parts that touch the pipe. A pipe touching the backside of the wrench can reduce gripping power. Upon attaching the wrench to the pipe, engage the clinching action by turning the wrench in the correct direction.

Due to their jagged shape, these teeth do tend to leave teeth marks along the surface of the metal pipe. This is why you should not use these wrenches on decorative pipes like showerhead stems that will be visible. A leather or cloth strap can be attached tightly to the pipe under the area where you will be using the wrench to avoid scarring decorative pipes.

Soft metals are primarily used with pipe wrenches. They can actually damage fittings if used on harder metals. It is recommended that pipe wrenches be avoided when used with common nuts and bolts since they will cause damage to the fittings quickly.

Considerations for Choosing the Best Pipe Wrenches

A few factors to consider when choosing a pipe wrench are the size as well as the design of the jaws and handles.

Size

Before purchasing any pipe wrench, make sure to check your pipes’ sizes. It may be best to buy a set that includes a selection of the most common sizes since there is no one-size-fits-all for the pipes.

Jaw Design

As the jaws of a pipe wrench hold the pipe in place, they are by and large its most important feature. One-handed tightening of pipes is made possible by spring-loaded jaws. Among the variations can be found forged hook jaw and heel jaw wrenches that are suitable for professional use, as well as set jaw wrenches. Furthermore, the teeth in a jaw play a role in how well it grips smooth surfaces, which means that the sharper the teeth are, the better they are able to grasp the surface.

Handle Design

The handles of pipe wrenches are usually made of steel, aluminum, or cast iron. Handles made of aluminum are much lighter than those made of cast iron. For those with arthritis or mobility issues, rubber grips or cushioned grips can be especially useful. It is even possible to find some that feature ergonomic handles to reduce user fatigue which is especially useful after long periods of use.

Conclusion

Our goal in this post was to introduce you to one of the most important parts of every tool kit, pipe wrenches. Each of the six basic pipe wrench types was explained comprehensively. We discussed the most important considerations in choosing the right pipe wrench for your application. In this post, there is also a brief description of how pipe wrenches are used. Feel free to contact Linquip’s Tools and Instrument Experts with any questions you may have about the best pipe wrench for your needs. You can also find Tools and Instrument Service Providers on Linquip if you need any special service for your tool.

Download PDF for Types of Pipe Wrenches

You can download the PDF format of this post from the link provided here.

Buy Equipment or Ask for a Service

By using Linquip RFQ Service, you can expect to receive quotations from various suppliers across multiple industries and regions.

Click Here to Request a Quotation From Suppliers and Service Providers

Read More on Linquip

- 13 Types of Adjustable Wrench: Clear Guide

- 8 Types of Torque Wrenches + Characteristic & Usage

- Different Types of Socket Wrench: Clear Guide

- 15 Types of Wrench Sets and Their Features

- 42 Types of Wrenches + Guide for Choosing a Wrench

- Different Types Of Screw Heads: A Practical Guide

- How to Use a Torque Wrench? (Working Principle & Types)

- How to Use a Socket Wrench? A Complete Guide

- 12 Types of Pipe Benders and Their Characteristics

- 27 Types of Screwdrivers + Names (Comprehensive Guide)

- Different 5 Types of Drill Bits for Wood: a comprehensive guide

- 22 Types of Water Hoses and Their Characteristics and Usages

- Types of Drill Bits for Metal: Comprehensive Guide

- 3 Types of Crimping Tools + Name & Their Uses

- 17 Types of Hinges and Hinge Materials: A Complete Guide

- 9 Types of Blind Rivets + Working Principle & Applications

- Types of Electrical Wire + Application (Complete Guide)

- 17 Types of Ratcheting Wrenches + Their Characteristics & Usages

- 10 Types of 3D Printing: A Comprehensive Guide

- 3 Types of Magnets + Name & Applications

- 4 Types of Solid Rivets + Working Principle

- 9 Types of Pop Rivet + Working Principle (Clear Guide)

- 7 Types of Solder + Working Principle & PDF

- 27 Types of Plumbing Tools + Table of Characteristic & Usage

- 13 Types of Rivets + Applications & Working Principle

- 16 Types of Scaffolding + Components & PDF

- 28 Types of Clamps: A Complete Guide

- 18 Types of Machining Vises (Clear Guide)

- 8 Types of O-Ring + Applications (Clear Guide)

- 11 Types of Industrial Chains + Their Features and Applications

- 8 Types of Scissors + Table of Characteristics and Usage

- 11 Types of Hand Tools And Their Usage

- 8 Types of Abrasives + Benefits & Usage